Silicon carbon composite material and preparation method thereof, lithium ion battery containing same

A silicon-carbon composite material, composite material technology, applied in nanotechnology for materials and surface science, battery electrodes, secondary batteries, etc. The effect of lithium storage capacity characteristics, easy control of oxidation degree, specific capacity and cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

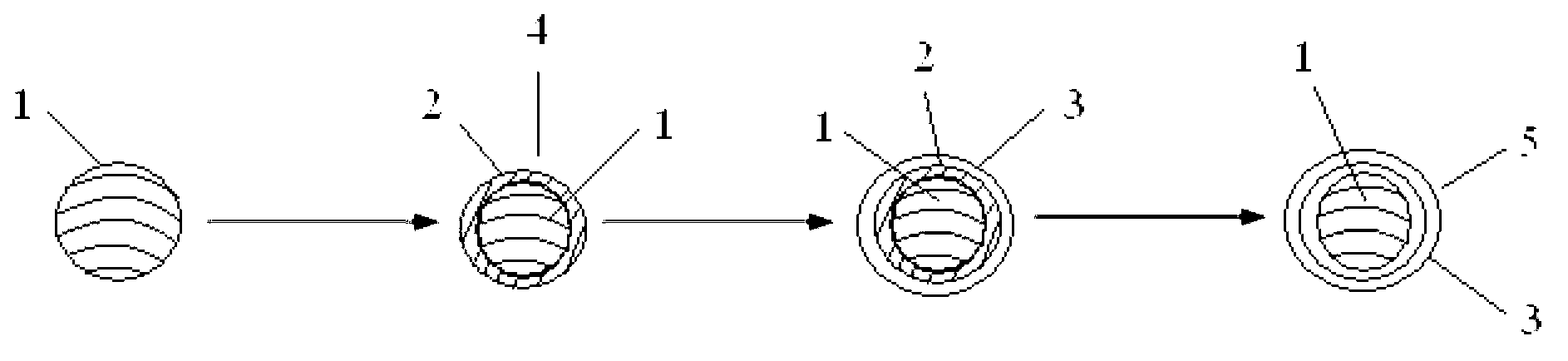

[0030] This embodiment provides a method for preparing a silicon-carbon composite material, comprising the following steps:

[0031] (1) Weigh a certain amount of silicon powder with a particle size of 5 μm, heat it up to 480°C at a rate of 7°C / min in an air atmosphere in a muffle furnace, and burn it for 1.2 hours to obtain a composite of silica-coated silicon. Material 4.

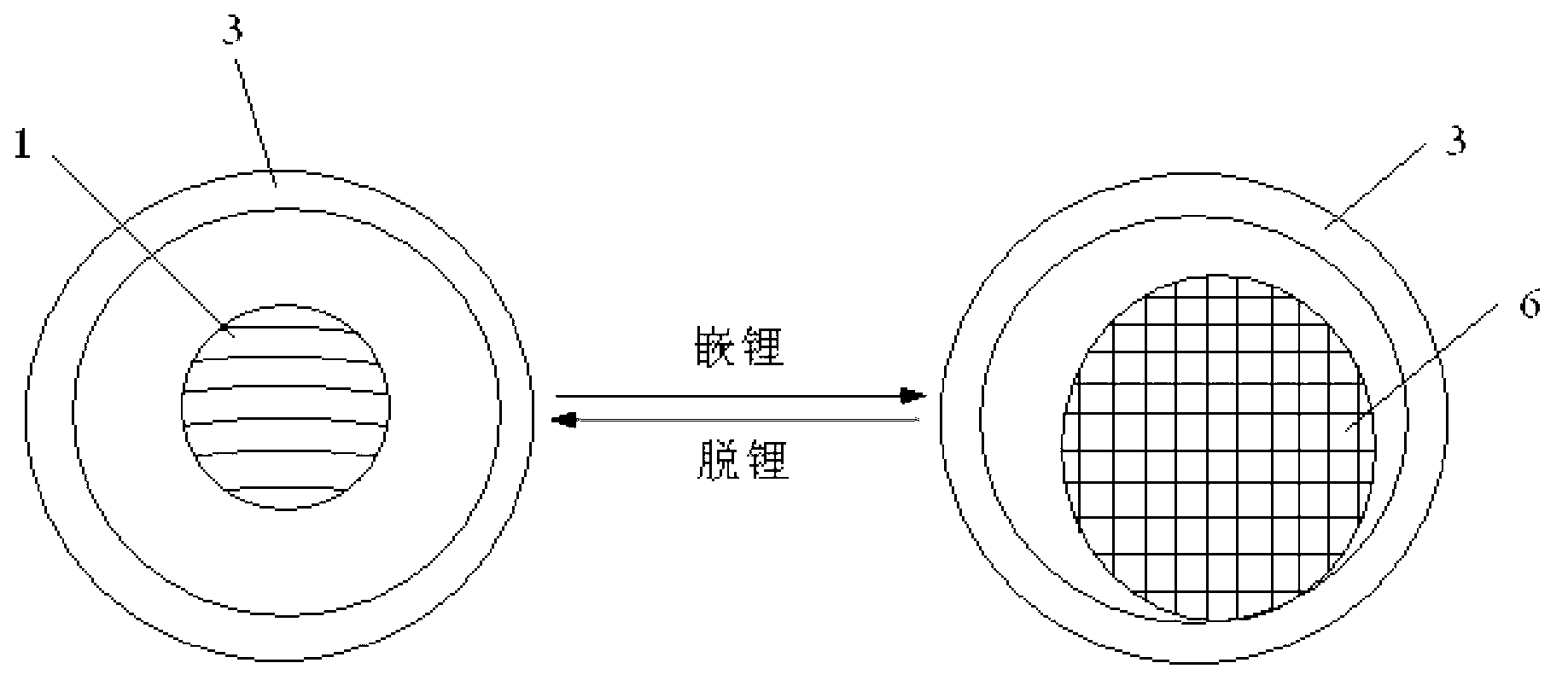

[0032] (2) Put the silica-coated silicon composite material 4 in the center of the tube furnace, evacuate the tube furnace until the pressure in the furnace is less than or equal to 0.01 atmosphere, and then raise the temperature to 500 °C at a rate of 7 °C / min At this time, a mixed gas of argon and acetylene (wherein the volume ratio of argon and acetylene is 9:1) was introduced, and then the temperature of the furnace was increased by 50°C and kept for 100 minutes. The carbon layer 3 coated on the silicon dioxide-coated silicon composite material 4 by the chemical vapor deposition method is uniform, an...

Embodiment 2

[0040] This embodiment provides a method for preparing a silicon-carbon composite material, comprising the following steps:

[0041] (1) Weigh 1,000 grams of silicon powder with a particle size of 5 μm, heat it up to 500°C at a rate of 7°C / min in an air atmosphere in a muffle furnace, and burn it for 1.5 hours to obtain a composite of silica-coated silicon. Material.

[0042] (2) Mix the silica-coated silicon composite material with 80 grams of phenolic resin by ball milling, and burn at 700° C. for 3 hours under an inert atmosphere.

[0043] (3) Corroding the silicon dioxide with an excess of hydrofluoric acid with a concentration of 7wt%, to obtain a carbon content of 9wt% in the silicon-carbon composite material.

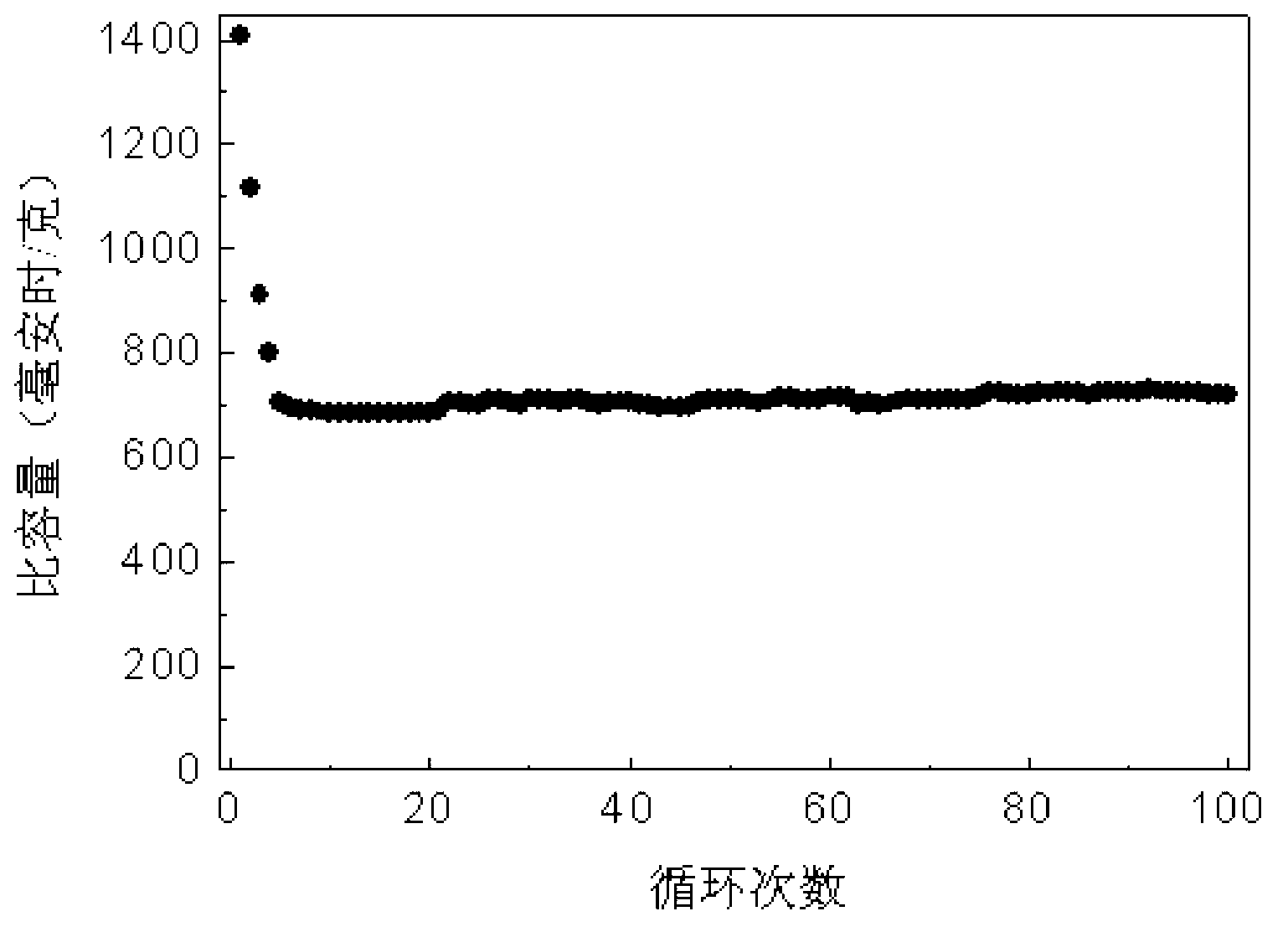

[0044] The manufacturing method of the CR2025 button battery is as in Example 1. The battery manufactured according to the method of this embodiment has a specific discharge capacity of 1232mAh / g for the first time, and remains at 833mAh / g after 105 cycles.

Embodiment 3

[0046] This embodiment provides a method for preparing a silicon-carbon composite material, comprising the following steps:

[0047] (1) Weigh a certain amount of silicon powder with a particle size of 30nm, heat it up to 550°C at a rate of 8°C / min in an air atmosphere in a muffle furnace, and burn it for 2 hours to obtain a composite of silica-coated silicon. Material.

[0048] (2) Put the silicon dioxide-coated silicon composite material in the center of the tube furnace, evacuate the tube furnace until the pressure in the furnace is less than or equal to 0.01 atmosphere, and at this time, pass the mixed gas of argon and acetylene (wherein , the volume ratio of argon and acetylene is 9:1), and then the temperature is raised to 700°C at a rate of 8°C / min and kept for 50 minutes.

[0049] (3) Corroding the silicon dioxide with excess hydrofluoric acid with a concentration of 8wt%, to obtain a carbon content of 7wt% in the silicon-carbon composite material.

[0050] The manuf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com