A kind of high compacted silicon carbon composite negative electrode material and its preparation and application

A silicon-carbon composite material and silicon-carbon composite technology, which are applied in the preparation/purification of carbon, silicon compounds, silicon oxide, etc., can solve the problem of difficult to control oxygen content, weak interface bonding, low compaction density of silicon-carbon composite materials, etc. problems, to maintain structural integrity, improve electrochemical performance, improve cycle stability and first-time efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

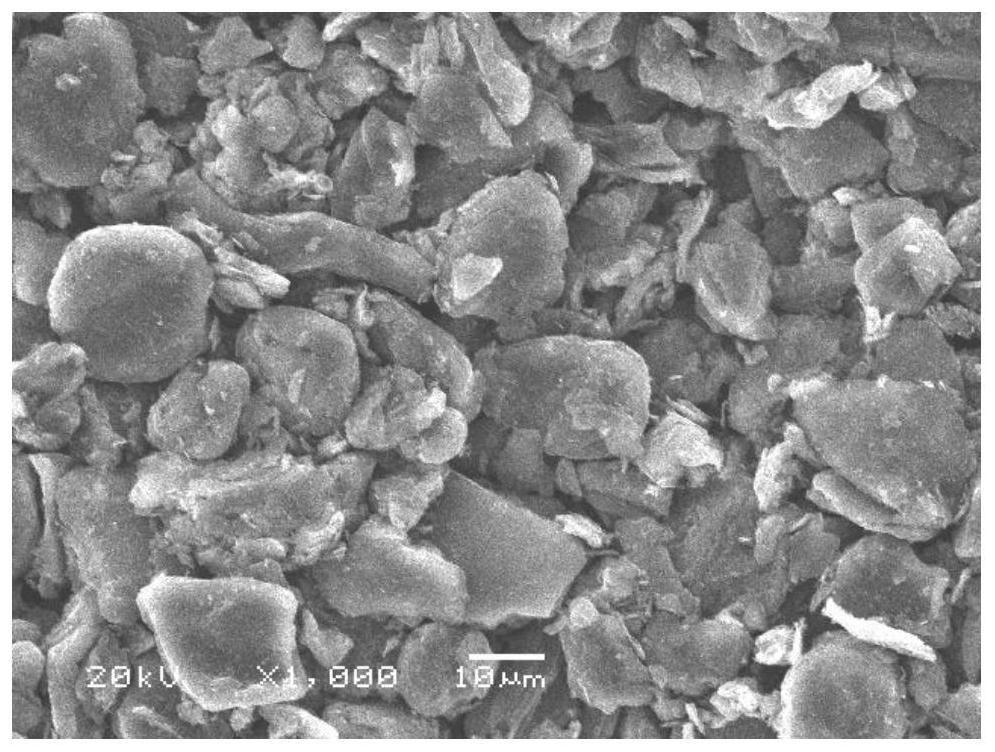

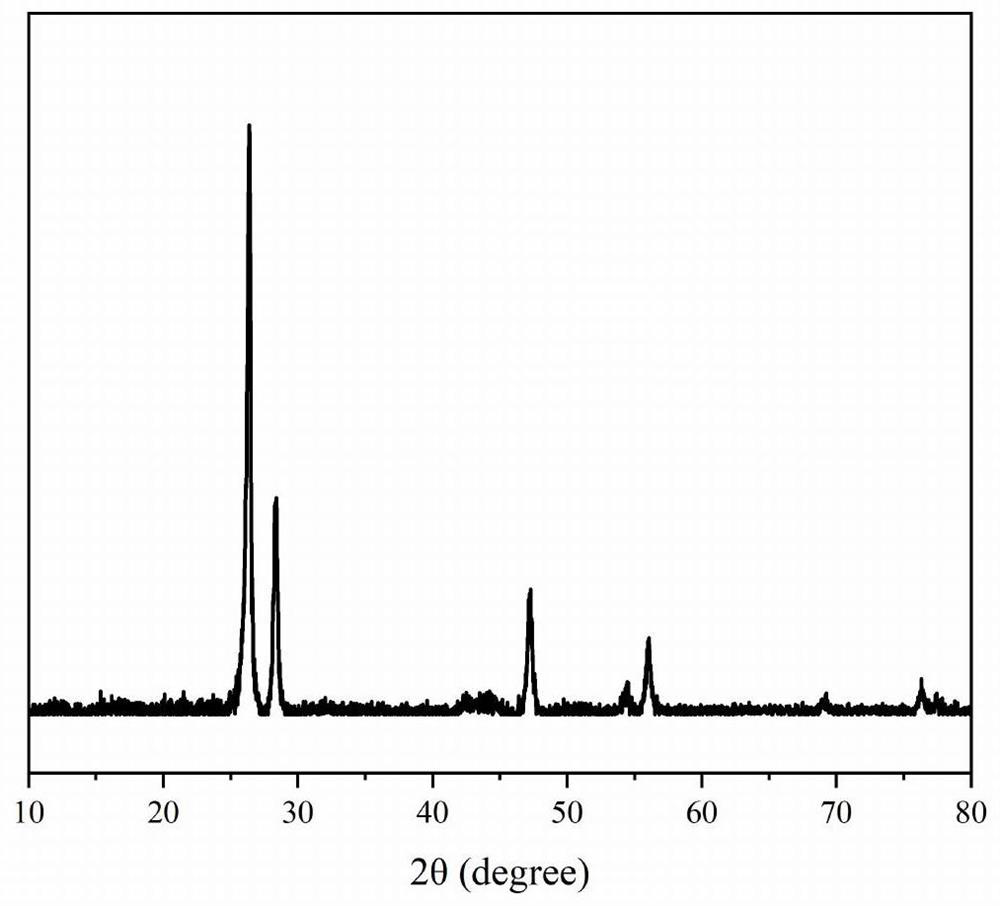

[0095] Using SiO coarse powder with an average particle size of 0.5 mm as raw material, after crushing and crushing, SiO fine powder with an average particle size of 1 μm is obtained; chemical vapor deposition method is used, acetylene is used as raw material gas, argon is used as carrier gas, and the deposition temperature is at 650°C, holding time 1h, gas flow rate of acetylene 120ml / min, argon 40ml / min, coating a thin carbon layer on the surface of SiO fine powder to obtain silicon monoxide particles (SiO@C) wrapped in a thin layer of carbon; SiO @C particles, metallic Mg, non-metallic B powder, mixed salt (LiCl:NaCl molar ratio 7:3, eutectic point 570°C) were mixed and granulated by extrusion granulation according to the mass ratio of 1:0.2:0.05:1 pellets to obtain a composite precursor; put the composite precursor into a sintering boat and place it in a muffle furnace for sintering reaction under an argon atmosphere, and heat up to 700°C at a speed of 5°C / min, react for 6 ...

Embodiment 2

[0100] Mix the low-oxygen porous silicon prepared in Example 1, artificial graphite powder with a particle size of 6 μm, pitch with a particle size of 3 μm, and toluene in a mass ratio of 1:0.5:0.08:4 and mix them uniformly in a high-speed disperser, then Spray granulation was performed to obtain a silicon-carbon precursor; the silicon-carbon precursor was placed in a cauldron and subjected to carbonization heat treatment at 950° C. for 2 hours under an argon atmosphere. After cooling, disperse with a jet mill to obtain a silicon-carbon intermediate with an average particle size of 13 μm; carry out particle size grading with artificial graphite with a particle size of 20 μm in a mass ratio of 1:1 to obtain the high-compact silicon-carbon composite negative electrode material .

[0101] The silicon carbon negative plate was assembled into a CR2032 lithium-ion button battery, and the electrochemical performance was tested in the voltage range of 0.01-2V at room temperature, and ...

Embodiment 3

[0103] Mix the low-oxygen porous silicon prepared in Example 1, artificial graphite powder with a particle size of 2 μm, phenolic resin with a particle size of 1 μm, and acetone at a mass ratio of 1:2:0.2:8 and mix them uniformly in a high-speed disperser. Then spray granulation was carried out to obtain the silicon-carbon precursor; the silicon-carbon precursor was placed in a cauldron and subjected to carbonization heat treatment at 800° C. for 4 hours under an argon atmosphere. After cooling, disperse with a jet mill to obtain a silicon-carbon intermediate with an average particle size of 8 μm; carry out particle size grading with artificial graphite with a particle size of 15 μm in a mass ratio of 1:1 to obtain the high-pressure compacted silicon-carbon composite negative electrode material .

[0104] The silicon carbon negative plate was assembled into a CR2032 lithium-ion button battery, and the electrochemical performance was tested in the voltage range of 0.01-2V at ro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com