A low-oxygen porous silicon composite powder material and its preparation and application

A composite material and porous silicon technology, applied in the preparation/purification of silicon oxide, carbon, structural parts, etc., can solve the problems of low initial efficiency and poor cycle performance of silicon oxide negative electrode materials, and achieve improved initial efficiency and improved Electrochemical properties, effects from a wide range of sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

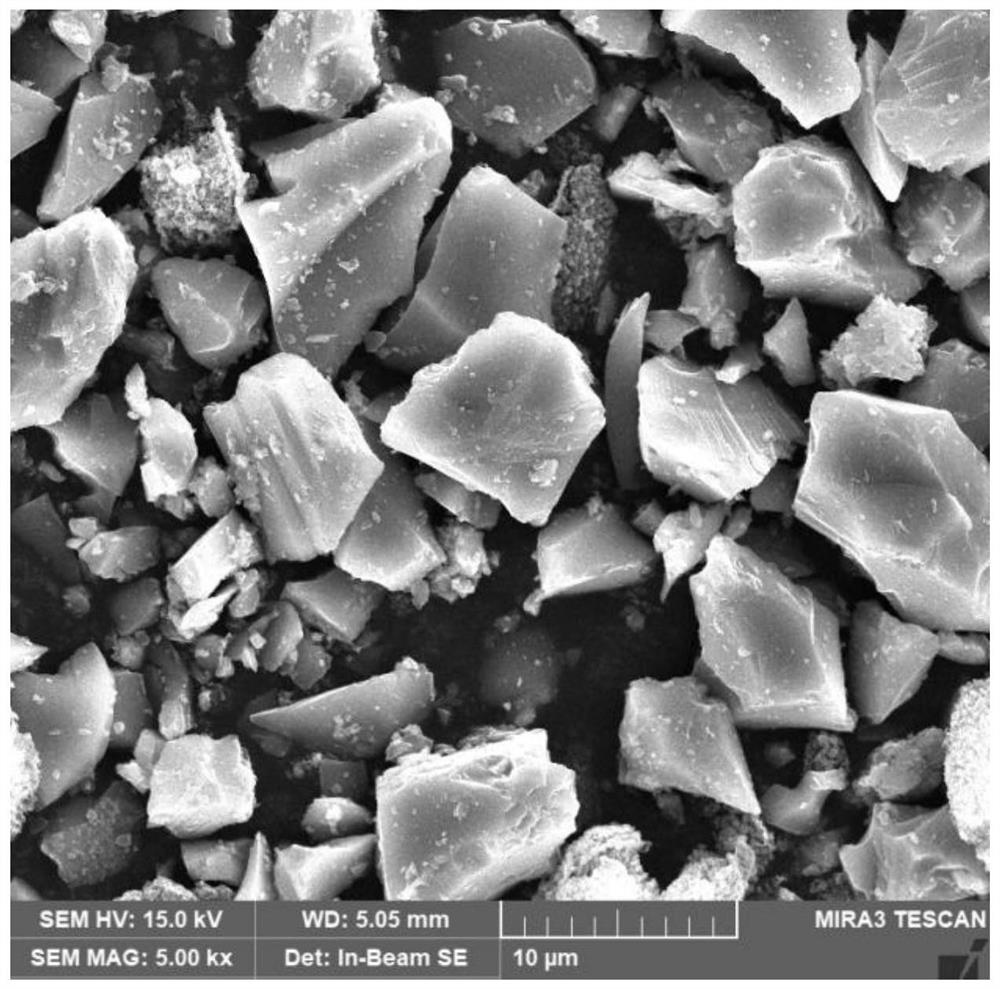

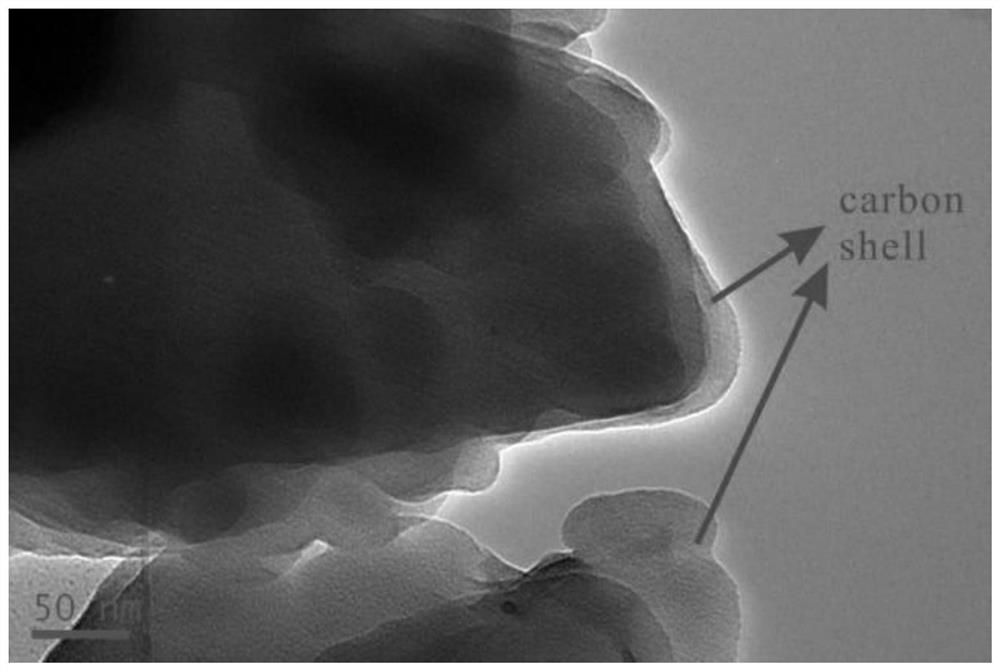

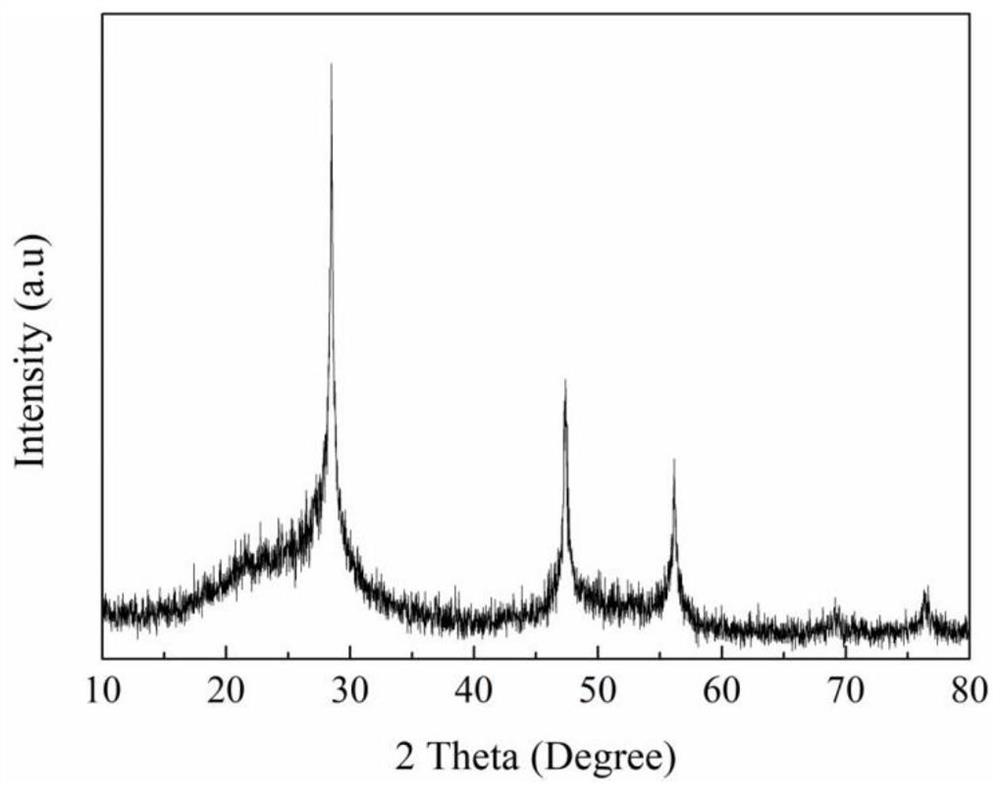

[0063] Using SiO coarse powder with an average particle size of 5 mm as raw material, after crushing and crushing, SiO fine powder with an average particle size of 8 μm is obtained; chemical vapor deposition method is used, acetylene is used as raw material gas, hydrogen is used as carrier gas, and the deposition temperature is 650 ° C , the holding time is 1h, the gas flow rate is 150ml / min of acetylene, and 50ml / min of hydrogen, and a thin carbon layer is coated on the surface of the SiO fine powder to obtain silicon monoxide particles (SiO@C) wrapped with a thin layer of carbon; SiO@C particles , metal Mg, non-metal B powder, mixed salt (LiCl:NaCl molar ratio 7:3, eutectic point 570°C) according to the mass ratio of 1:0.2:0.05:1, mixed and granulated by extrusion granulation method to obtain Composite precursor: put the composite precursor into a sintering boat and place it in a muffle furnace, and carry out sintering reaction under an argon atmosphere, at a rate of 5°C / min,...

Embodiment 2

[0067] Using SiO coarse powder with an average particle size of 0.5 mm as raw material, after crushing and crushing, SiO fine powder with an average particle size of 1 μm is obtained; chemical vapor deposition method is used, methane is used as raw material gas, argon is used as carrier gas, and the deposition temperature is at 550°C, holding time 1h, gas flow rate of acetylene 80ml / min, argon 20ml / min, coating a thin carbon layer on the surface of SiO fine powder to obtain silicon monoxide particles (SiO@C) wrapped in a thin layer of carbon; SiO @C particles, metallic Mg, non-metallic B powder, mixed salt (LiCl:NaCl molar ratio 7:3, eutectic point 570°C) were mixed and granulated by extrusion granulation according to the mass ratio of 1:0.2:0.05:1 pellets to obtain a composite precursor; put the composite precursor into a sintering boat and place it in a muffle furnace for sintering reaction under an argon atmosphere, and heat up to 700°C at a speed of 5°C / min, react for 6 hou...

Embodiment 3

[0070] Using SiO coarse powder with an average particle size of 10mm as raw material, after crushing and pulverizing, SiO fine powder with an average particle size of 16 μm is obtained; chemical vapor deposition method is used, acetylene is used as raw material gas, and the mixed gas of argon and hydrogen (volume ratio 9:1) is the carrier gas, the deposition temperature is 850°C, the holding time is 2h, the gas flow rate is 240ml / min of acetylene, the mixed gas of argon and hydrogen (carrier gas) is 80ml / min, and a thin carbon layer is coated on the surface of SiO fine powder , to obtain silicon monoxide particles wrapped in thin carbon (SiO@C); SiO@C particles, metal Mg, non-metal B powder, mixed salt (LiCl:NaCl molar ratio 7:3, eutectic point 570°C) according to 1 : The mass ratio of 0.2:0.05:1 is mixed and granulated by extrusion granulation to obtain a composite precursor; At a rate of 5°C / min, heat up to 700°C, react for 6 hours, and after natural cooling, wash the water-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com