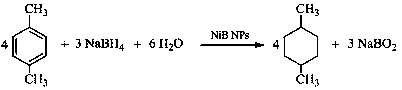

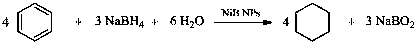

A method for sodium borohydride reduction of aromatic hydrocarbons or derivatives thereof

A technology of sodium borohydride and derivatives, which is applied in hydrogenation hydrocarbon production, chemical instruments and methods, carbon compound catalysts, etc., can solve problems such as cumbersome operation, safety hazards, and expensive platinum, and achieves avoiding safety hazards and controllable reduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

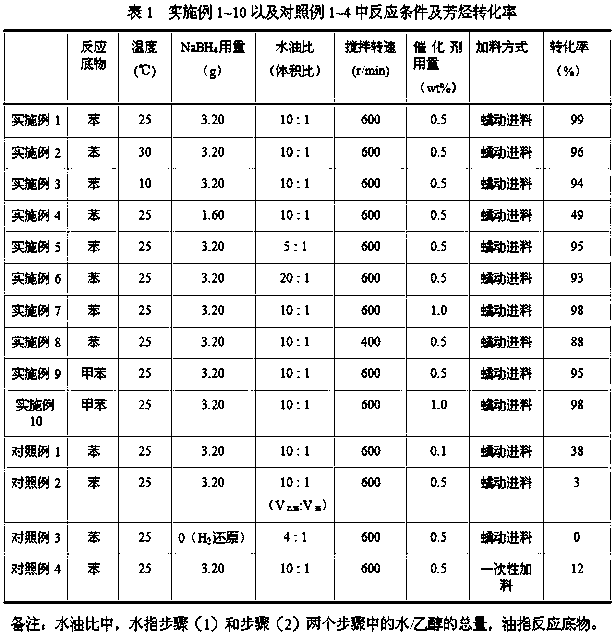

Examples

Embodiment 1

[0026] A method for sodium borohydride reduction of benzene, the steps are as follows:

[0027] (1) Transfer 10 mL of benzene, 40 mL of deionized water, and catalyst NiB nano-amorphous alloy with a mass fraction of 0.5 wt% of benzene into a three-necked flask, and mechanically stir at 25 °C under normal pressure and control the stirring speed to 600 r / min;

[0028] (2) Weigh 3.20 g NaBH 4 and 0.40 g NaOH were dissolved in a beaker containing 60 mL of deionized water, and transferred to an Erlenmeyer flask for ice bath;

[0029] (3) Use a peristaltic pump to feed the NaBH stored in the ice bath in step (2) 4 The alkaline aqueous solution of the solution was added dropwise into the three-necked flask in step (1). After the dropwise addition was completed, the stirring was continued for 0.5 h, and the product was detected by gas chromatography mass spectrometry.

Embodiment 2

[0031] The difference from Example 1 is that in step (1), the reaction temperature is changed to 30 °C, and the others are the same as in Example 1.

Embodiment 3

[0033] The difference from Example 1 is that in step (1), the reaction temperature is changed to 10°C, and the others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com