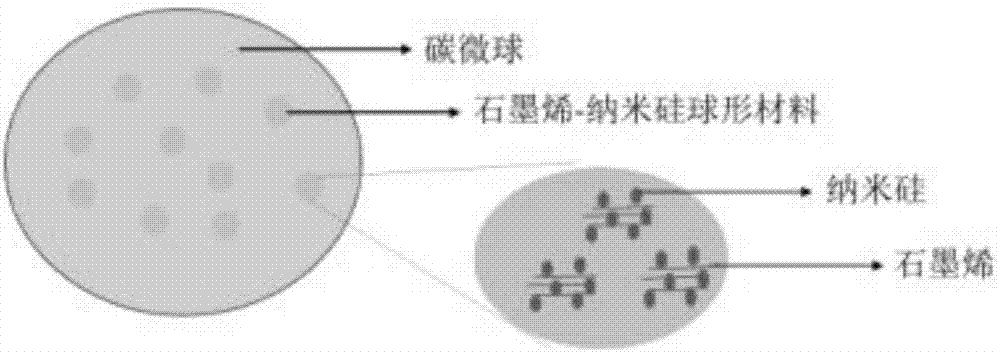

Preparation method of graphene-silicon carbon lithium ion battery negative electrode material

A technology of lithium-ion batteries and negative electrode materials, applied in battery electrodes, nanotechnology for materials and surface science, secondary batteries, etc., can solve problems such as low capacity and poor cycle, and achieve stable electrode structure and compaction density High and stable cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A preparation method for a graphene-silicon carbon lithium ion battery negative electrode material, comprising the steps of:

[0035] 1) Graphene coating of nano-silicon particles: sand-mill micron-level silicon powder, then add graphene solution to continue sand-grinding to obtain graphene-nano-silicon mixture, and then obtain graphene-nano-silicon mixture by spray drying. Nano silicon spherical particles;

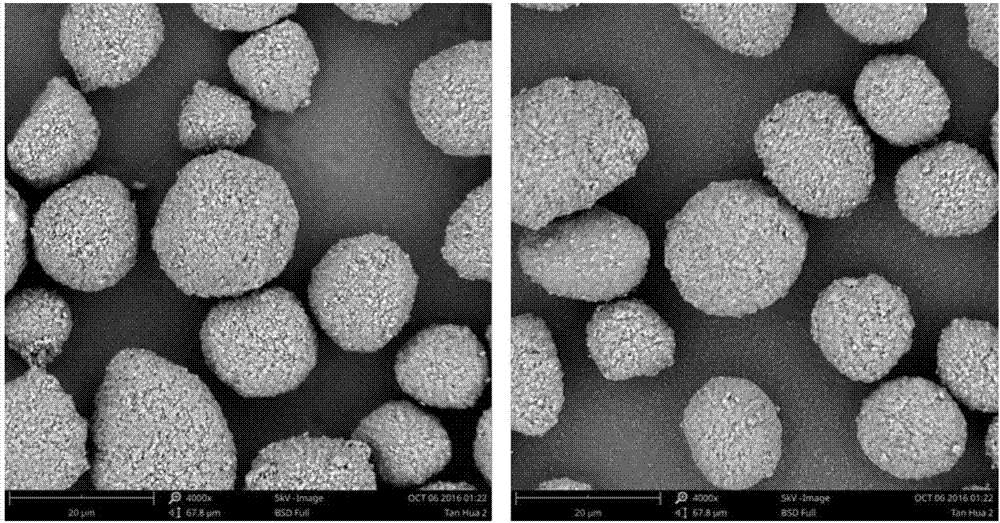

[0036] 2) Carbon-coated primary composite material: heat-treat the graphene-nano-silicon spherical particles obtained in step 1), and the heat-treated graphene-silicon nanoparticles are uniformly dispersed in the asphalt, and then the internal uniform dispersion can be obtained by high-temperature reaction Carbon microspheres coated with graphene-silicon nanoparticles;

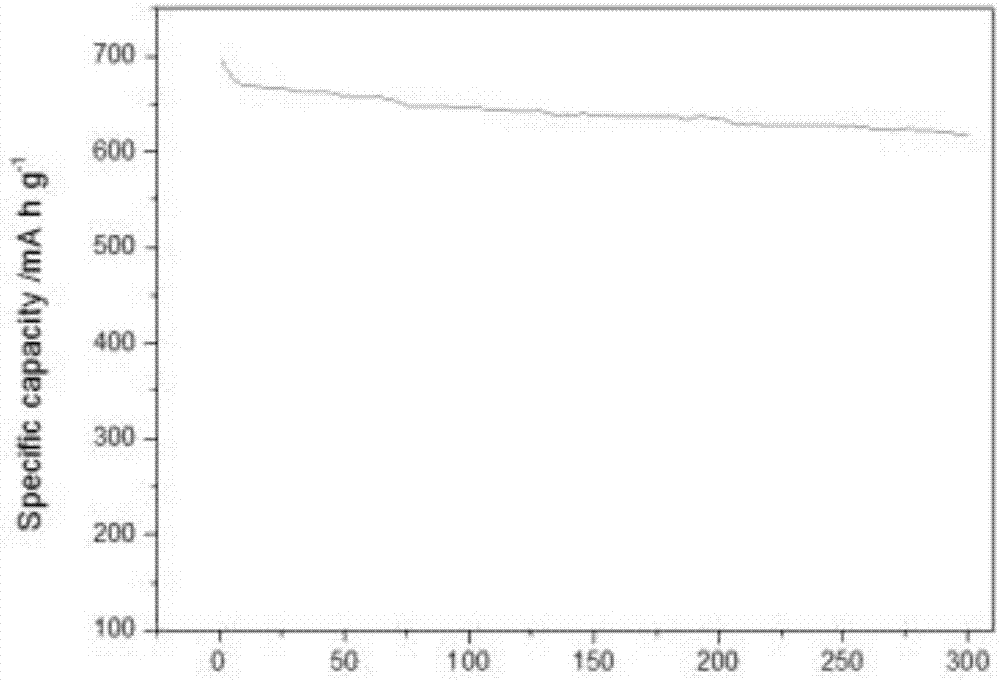

[0037] 3) Carbonization and mixing: the carbon microspheres obtained in step 2) are carbonized, and then mixed with other carbon materials to obtain a graphene-silicon carbon negative electrode ma...

Embodiment 2

[0046] A preparation method for a graphene-silicon carbon lithium ion battery negative electrode material, comprising the steps of:

[0047] 1) Graphene coating of nano-silicon particles: sand-mill micron-level silicon powder, then add graphene solution to continue sand-grinding to obtain graphene-nano-silicon mixture, and then obtain graphene-nano-silicon mixture by spray drying. Nano silicon spherical particles;

[0048] 2) Carbon-coated primary composite material: heat-treat the graphene-nano-silicon spherical particles obtained in step 1), and the heat-treated graphene-silicon nanoparticles are uniformly dispersed in the asphalt, and then the internal uniform dispersion can be obtained by high-temperature reaction Carbon microspheres with graphene-nano-silicon particles;

[0049] 3) Carbonization and mixing: the carbon microspheres obtained in step 2) are carbonized, and then mixed with other carbon materials to obtain a graphene-silicon carbon negative electrode material...

Embodiment 3

[0057] A preparation method for a graphene-silicon carbon lithium ion battery negative electrode material, comprising the steps of:

[0058] 1) Graphene coating of nano-silicon particles: sand-mill micron-level silicon powder, then add graphene solution to continue sand-grinding to obtain graphene-nano-silicon mixture, and then obtain graphene-nano-silicon mixture by spray drying. Nano silicon spherical particles;

[0059] 2) Carbon-coated primary composite material: heat-treat the graphene-nano-silicon spherical particles obtained in step 1), and the heat-treated graphene-silicon nanoparticles are uniformly dispersed in the asphalt, and then the internal uniform dispersion can be obtained by high-temperature reaction Carbon microspheres with graphene-nano-silicon particles;

[0060] 3) Carbonization and mixing: the carbon microspheres obtained in step 2) are carbonized, and then mixed with other carbon materials to obtain a graphene-silicon carbon negative electrode material...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com