Adhesive chuck member, pattern forming method thereof, substrate clamping method and system

A chuck plate and substrate technology, applied in the direction of internal accessories, electrical components, electric solid devices, etc., can solve the problems of reduced stability, damage to the substrate, inability to separate the substrate and the chuck plate, etc., and achieve minimization due to deformation, The effect of flexible lifting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0121] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the drawings.

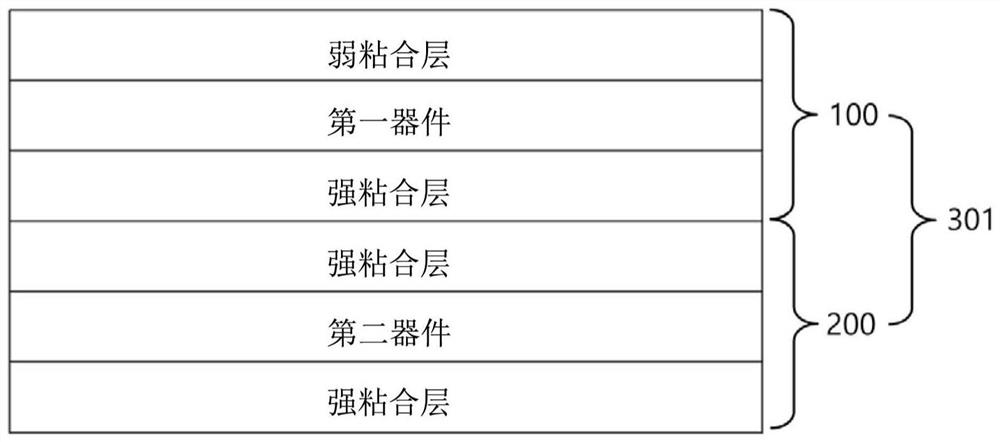

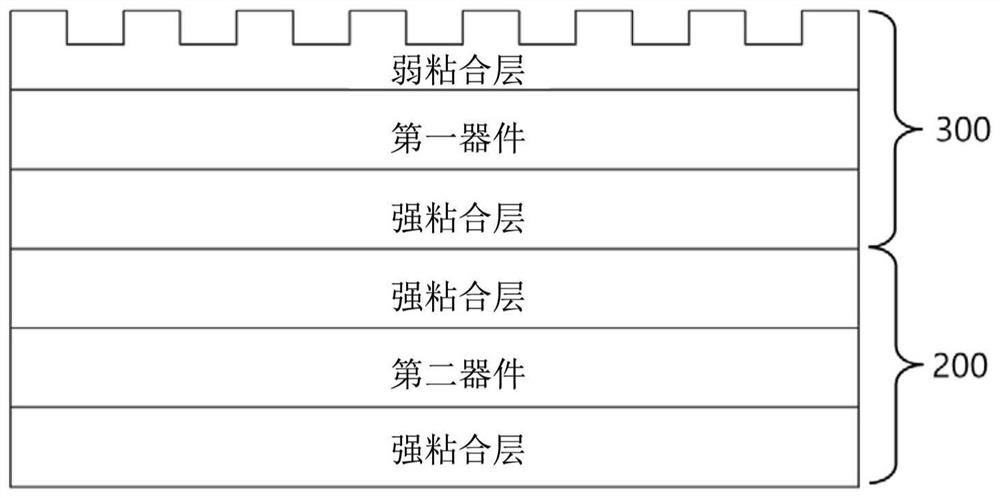

[0122] figure 2 It is a sectional view showing the structure of the bonded chuck member in which the upper surface has a patterned structure according to the present invention.

[0123] The adhesive chuck member of the present invention is formed by bonding the patterned adhesive layer 300 to the strong adhesive sheet 200 .

[0124] In the patterned adhesive layer 300, a strong adhesive layer is formed under the first device and a weak adhesive layer is formed above the first device. Unlike the prior art, the weak adhesive layer is patterned to have a concavo-convex structure. The strong adhesive layer of the first device is bonded to the strong adhesive sheet 200, which is a sheet with strong adhesive layers formed on both the upper and lower sides of the second device.

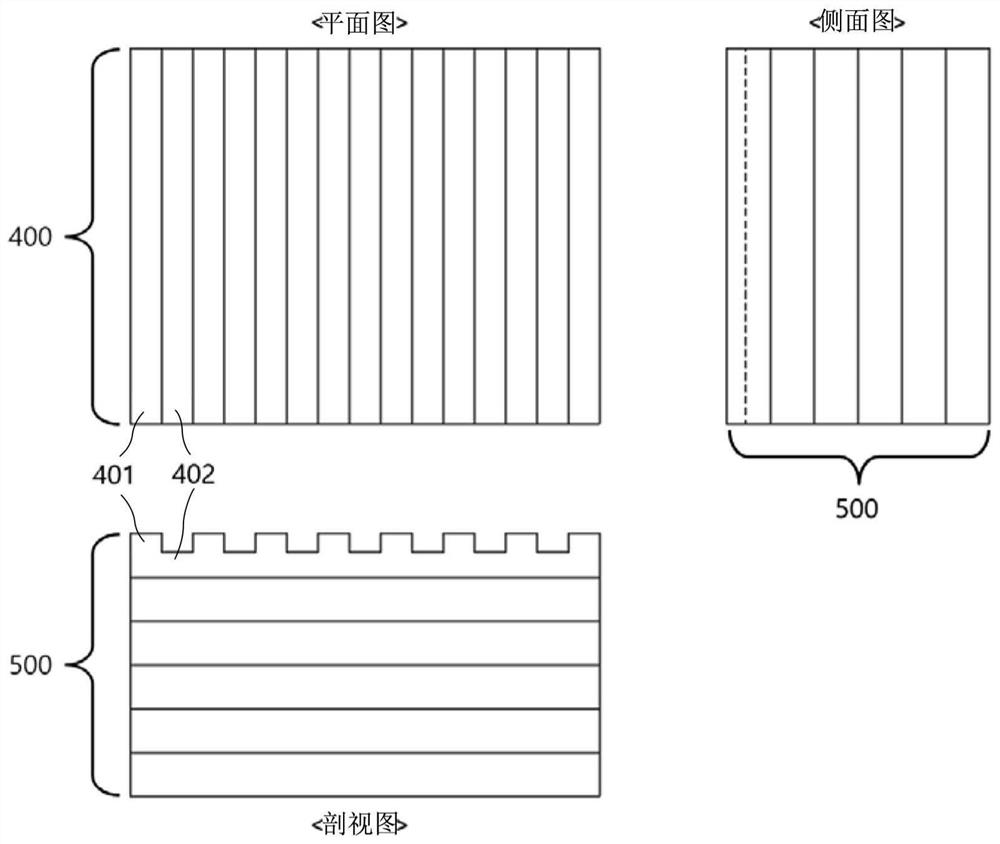

[0125] image 3 is a stripe-shaped adhesive chuck member 500 showing the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com