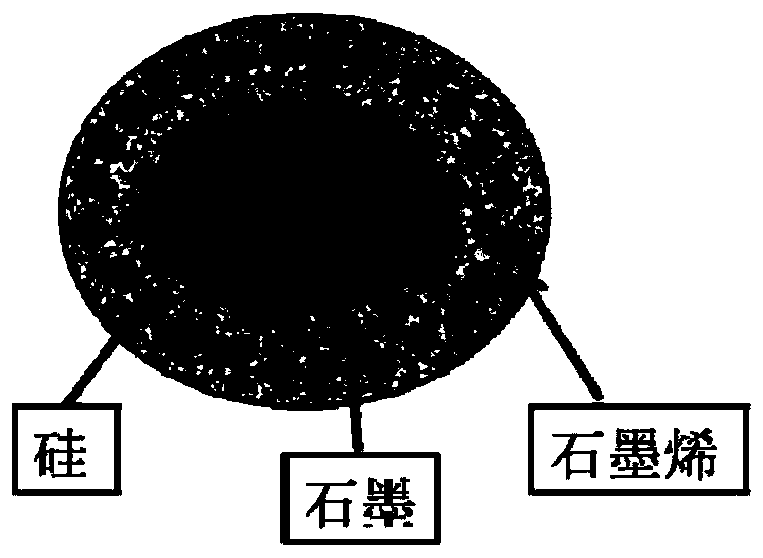

A kind of lithium-ion battery silicon-carbon composite negative electrode material and preparation method thereof

A silicon-carbon composite and negative electrode material technology, applied in the field of lithium-ion batteries, can solve problems such as the decrease in cycle performance of electrode materials, the reduction of the capacity of silicon-based composite materials, and the easy agglomeration of nano-silicon to achieve rapid electronic conduction and thermal evacuation. Performance and Conductivity Mitigation, Cost-Effective Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

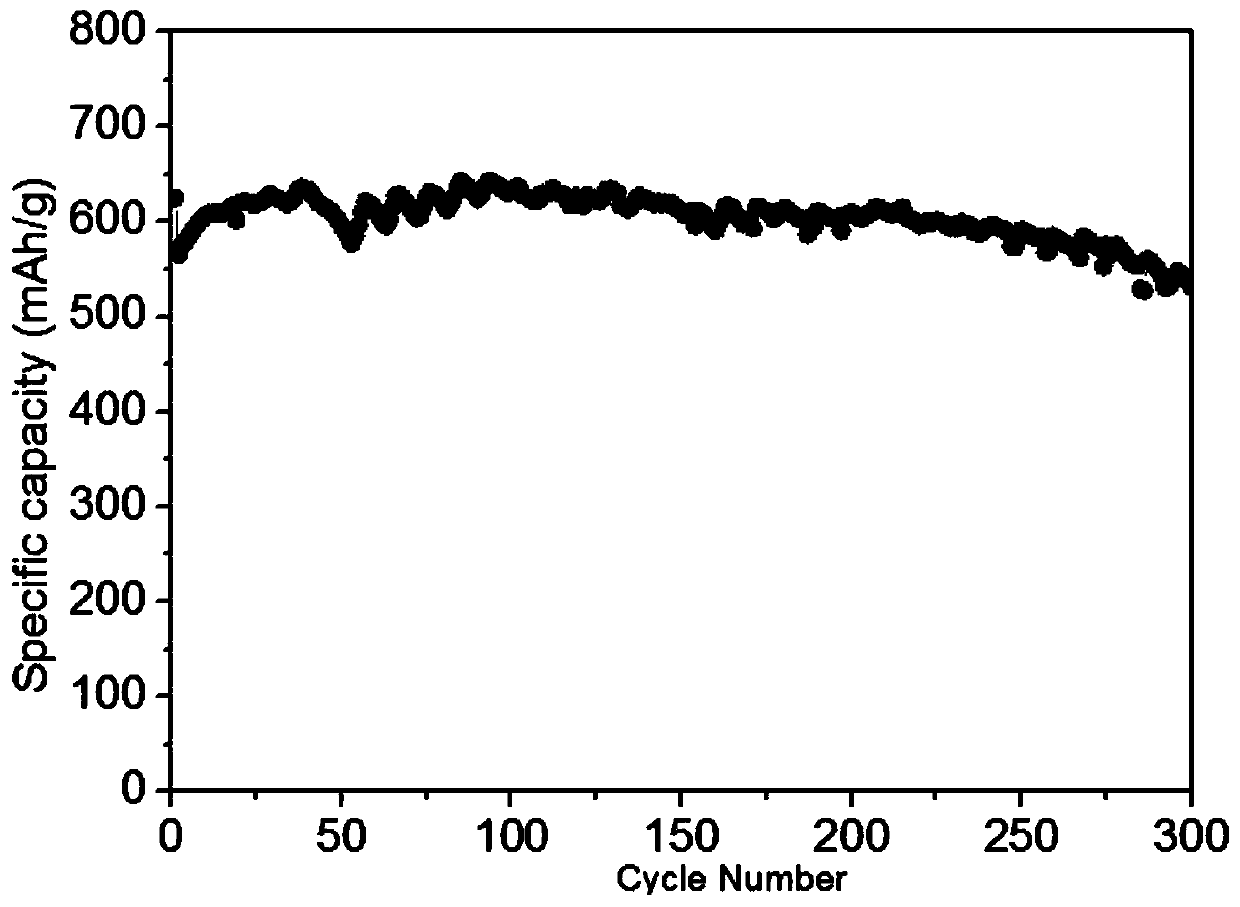

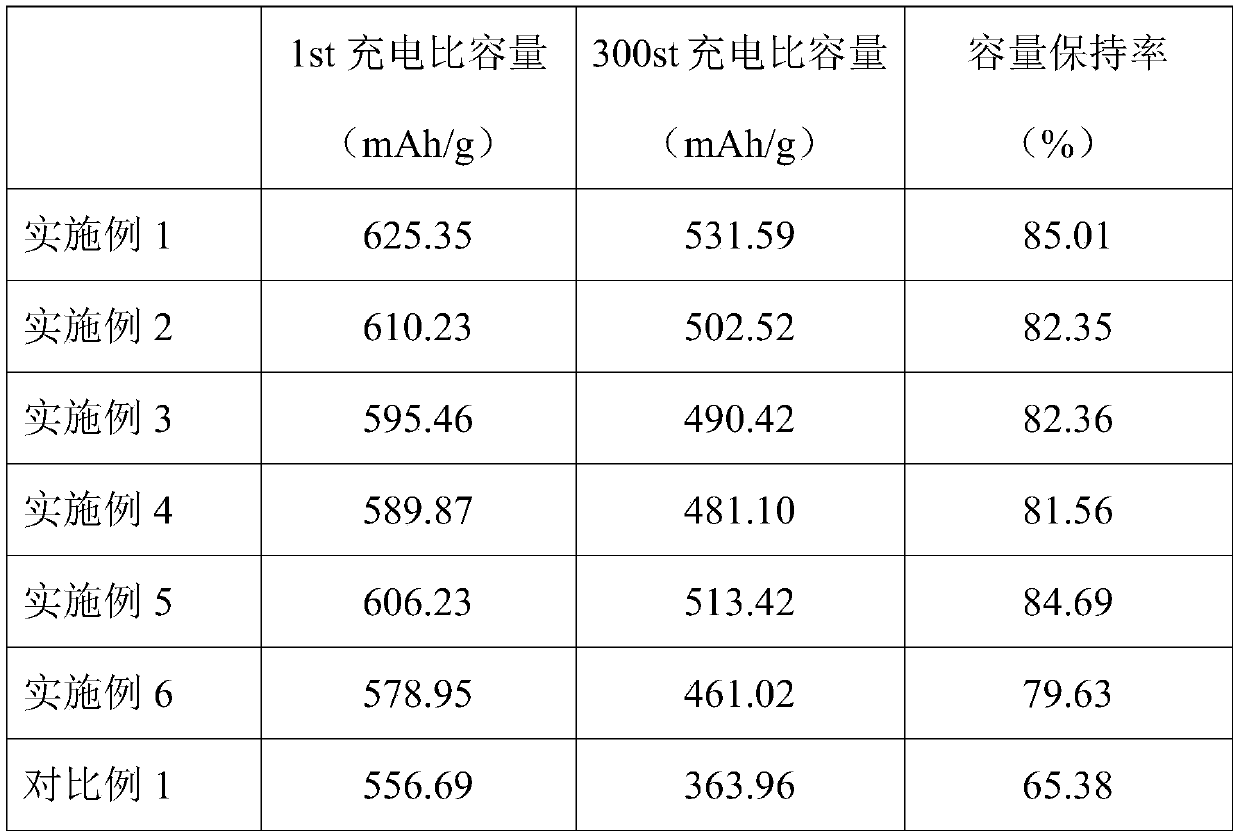

Embodiment 1

[0056] Dissolve 1g of sucrose and 10g of ammonium carbonate in 30mL of deionized water and stir for 30 minutes, then add 3g of graphite with a D50 of 10μm and 0.5g of nano-silicon with a D50 of 50nm and stir for 1h, then place in a blast drying oven at 90°C and dry After 12 hours, a lump was obtained, and the above-mentioned lump solid was compacted into a green body by a film forming equipment, the pressure used was 8 mPa, and the pressure was maintained for 3 minutes. The above green body is placed in the constant temperature zone of the tube furnace, and under the protection of nitrogen, the temperature is raised to 300°C at a heating rate of 2°C / min for 3 hours, and then the temperature is continued to rise to 1000°C for 3 hours, and finally the temperature is naturally cooled to room temperature, and the sample is taken out. The sample is crushed and sieved to obtain a silicon-carbon composite negative electrode material with a median particle size D50 of 12.5 μm

Embodiment 2

[0058] 1g of sucrose and 10g of ammonium nitrate were dissolved in 30mL of water and stirred for 30 minutes, then 3g of graphite with a D50 of 10μm and 0.5g of nano-silicon with a D50 of 80nm were added and stirred for 1h, then placed in a blast drying oven and dried at 85°C to obtain Lumpy body, the above-mentioned lumpy solid is compacted into a green body by a film forming equipment, the pressure used is 10mPa, and the pressure is maintained for 6min. The above green body was placed in the constant temperature zone of the tube furnace, and under the protection of nitrogen, the temperature was raised to 120°C at a heating rate of 2°C / min for 3 hours, and then the temperature was continued to rise to 1000°C for 3 hours, and finally the temperature was naturally cooled to room temperature, and the samples were taken out. The sample was crushed and sieved to obtain a silicon-carbon composite negative electrode material with a median particle diameter D50 of 12.5 μm.

Embodiment 3

[0060] Dissolve 2g of glucose and 10g of ammonium bisulfate in 30mL of water and stir for 30min, then add 3g of 10μm graphite and 0.5g of nano-silicon with a D50 of 80nm and stir for 2h, then dry the above solution in a blast drying oven at 90°C to obtain a block. The body is compacted into a green body by a film forming equipment, the pressure used is 10mPa, and the pressure is maintained for 3min. The above green body is placed in the constant temperature zone of the tube furnace, and the above green body is placed in the constant temperature zone of the tube furnace. Under the protection of nitrogen, the temperature is raised to 220°C at a heating rate of 2°C / min and kept for 3h, and then continued to heat up to 1000°C for 3h. Finally, the temperature was naturally lowered to room temperature, and the sample was taken out. The above sample was crushed and sieved to obtain a silicon-carbon composite negative electrode material with a median particle size D50 of 12.5 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com