A cross-linked lithium-ion battery positive electrode material binder generated in situ, its preparation method and lithium-ion secondary battery

A technology for lithium ion batteries and positive electrode materials, applied in the field of electrochemistry, can solve the problems of particle agglomeration inside the electrode, battery performance decline, pole piece falling off, etc., and achieve the effects of reducing capacity decay, easy operation, and time saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Prepare the binder:

[0040] Take by weighing 0.0050g polyethylene maleic anhydride and 0.0050g polypropylene alginate, add in the 10mL beaker immediately after weighing, then add 2mL N-methylpyrrolidone (NMP) to dissolve it and place it on a magnetic stirrer Stirring is carried out at 25° C., and the reaction time is 12 hours. After the stirring is completed, a binder solution is obtained in situ, which is an NMP solution of a cross-linked polymer PM-PG containing carboxyl groups, ester groups and hydroxyl groups.

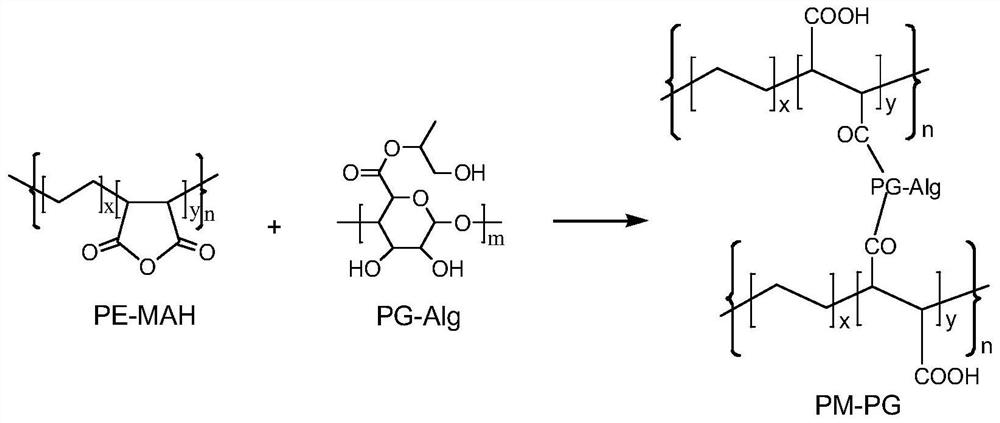

[0041] The reaction formula of polyethylene maleic anhydride and polypropylene alginate is as follows figure 1as shown, figure 1 Among them, PE-MAH represents polyethylene maleic anhydride, and PG-Alg represents polypropylene alginate. The process of utilizing the above-mentioned binder to prepare the slurry of lithium-ion battery cathode material is:

[0042] 0.1500g lithium iron phosphate (LiFePO 4 ), 0.0400g acetylene black was added in the above-men...

Embodiment 2

[0045] Similar to the process of preparing the adhesive in Example 1, 0.0150 g of polyethylene maleic anhydride and 0.0150 g of poly(trimethylene alginate) were weighed and reacted to prepare an NMP solution of the adhesive PM-PG. 0.2100g lithium iron phosphate (LiFePO 4 ), 0.0600g acetylene black is added in the above-mentioned binder solution, wherein, lithium ferrous phosphate: acetylene black: binder=70wt%: 20wt%: 10wt%, stir 24h, obtain the slurry of lithium-ion battery cathode material , and then coated on the aluminum foil of the current collector. After coating, it was dried in an ordinary oven at 60°C for 6 hours, and then dried in a vacuum oven at 60°C for 24 hours. After drying, it was cut into circular electrode pieces with a diameter of 15mm.

Embodiment 3

[0047] Example 3 The process of preparing the adhesive is the same as that of Example 1. Weigh 0.0045 g of polyethylene maleic anhydride and 0.0045 g of polypropylene alginate to react to prepare an NMP solution of the adhesive PM-PG. 0.2410g lithium iron phosphate (LiFePO 4 ), 0.0600g acetylene black is added in the above-mentioned binder solution, wherein, lithium ferrous phosphate: acetylene black: binder=77wt%: 20wt%: 3wt%, stir 24h, obtain the slurry of lithium-ion battery cathode material , and then coated on the aluminum foil of the current collector. After coating, it was dried in an ordinary oven at 60°C for 6 hours, and then dried in a vacuum oven at 60°C for 24 hours. After drying, it was cut into circular electrode pieces with a diameter of 15mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com