Array type metal sulfide composite electrode material and preparation method thereof

A metal sulfide, composite electrode technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of large volume expansion changes, poor cycle stability, low actual capacity, etc., to achieve buffer volume expansion, stable electrode structure, low Electronegativity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The invention provides a method for preparing an array type metal sulfide composite electrode material.

[0033] A method for preparing an array-type metal sulfide composite electrode material, comprising the following steps:

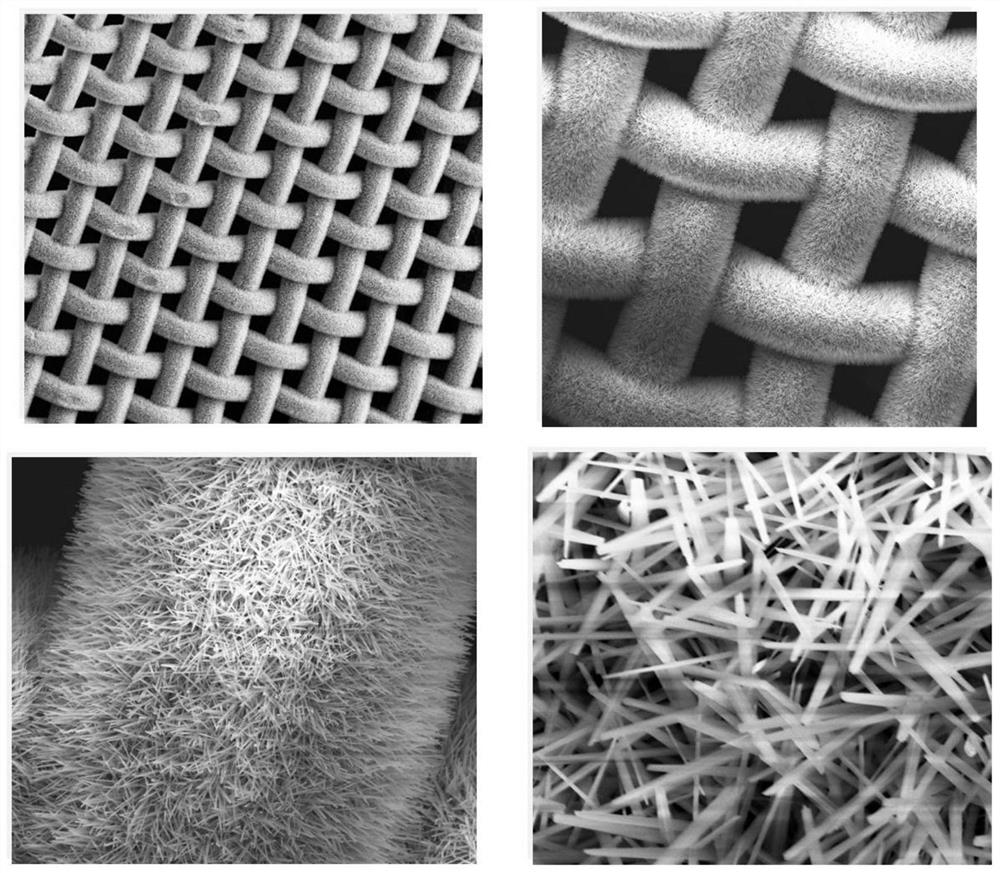

[0034] Step 1, take the copper mesh substrate slice, dry it after ultrasonic cleaning and set aside, specifically, slice the copper mesh into 1×2cm, then put it into acetone and ultrasonically clean it for 20min, then put it into an oven for drying at 60° for standby;

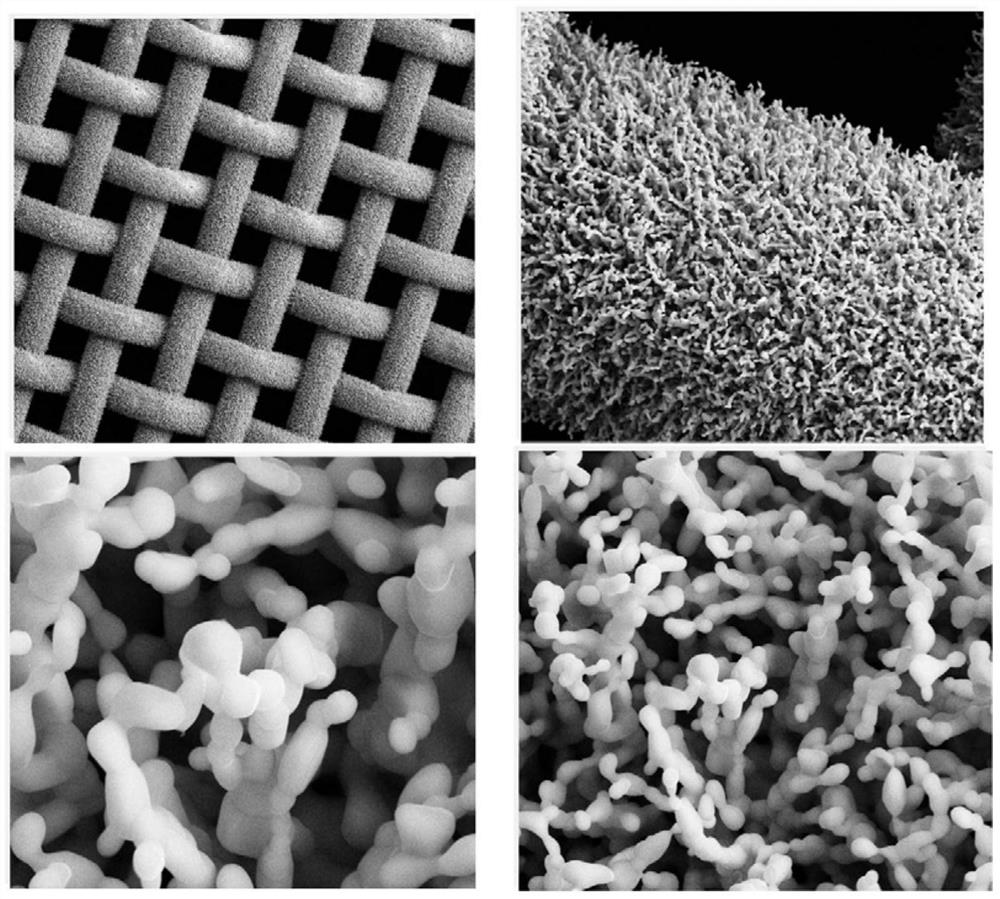

[0035] Step 2, adopt electrochemical workstation, adopt constant current mode, use foamed copper as working electrode, mercury oxide as reference electrode, platinum sheet as counter electrode, sodium hydroxide (NaOH) as electrolyte, electroplating prepares copper hydroxide (Cu (OH)2) nano-array, specifically, adopt electrochemical workstation, adopt constant current mode, take foam copper as working electrode, mercuric oxide reference electrode, platinum sheet is counter electrod...

Embodiment 2

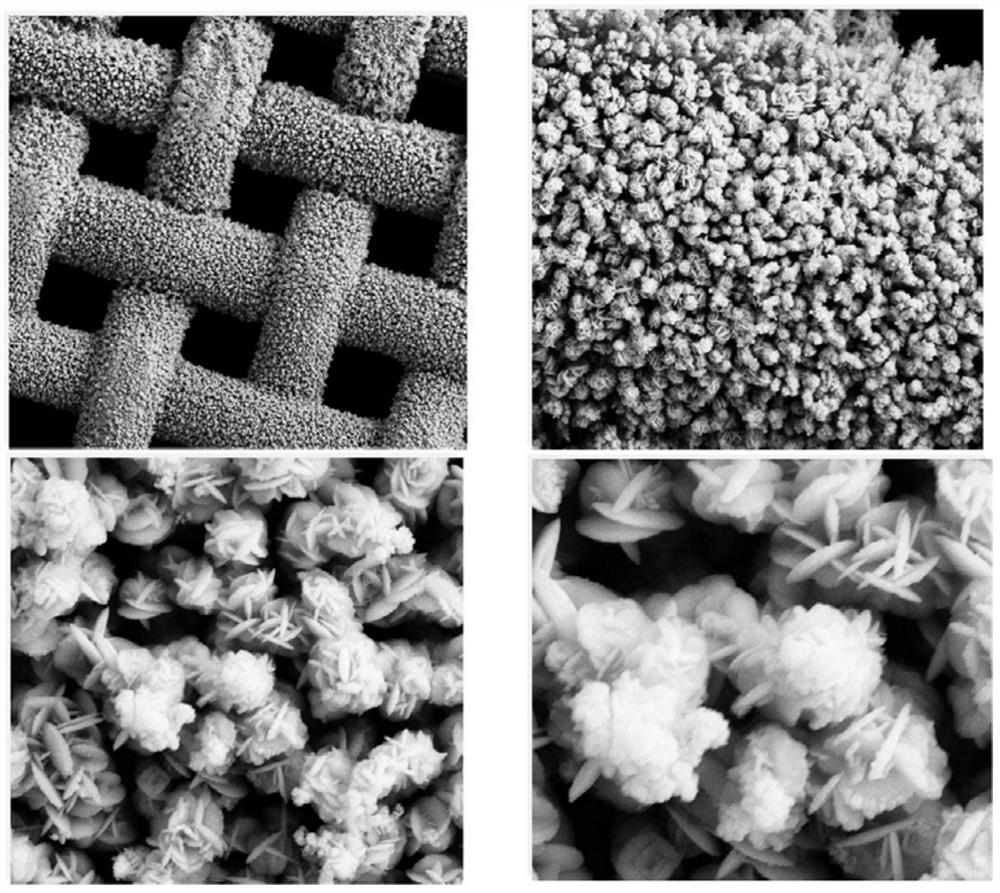

[0041] An array-type metal sulfide composite electrode material, the array-type metal sulfide composite electrode material has a nanosheet structure, and the array-type metal sulfide composite electrode material is vertically grown on a substrate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com