Preparation method of nano ferrous sulfide/graphene composite positive electrode material

A graphene composite, ferrous sulfide technology, applied in graphene, nano-carbon, battery electrodes and other directions, can solve the problems of poor volume change, poor electronic conductivity, difficult to mass production, and needs to be further improved, etc., to achieve accelerated electron transfer, excellent Electrochemical performance, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

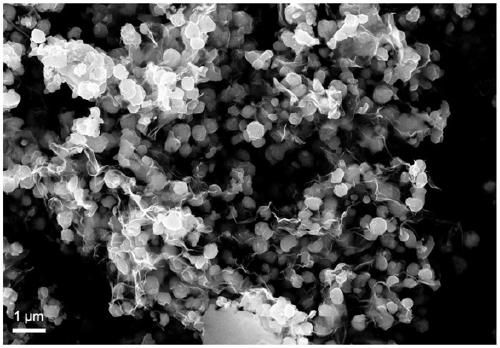

[0020] In an Ar atmosphere, 0.05 g of ferric oxide / graphene and 0.14 g of sulfur powder were mixed evenly, and the mixed powder was placed in a stainless steel sealed tube. The stainless steel sealed tube obtained above is placed in a tube furnace and fed with Ar gas with a gas flow rate of 40 sccm, heat-treated at 600° C. for 2 hours, and finally obtains a ferrous sulfide / graphene composite material;

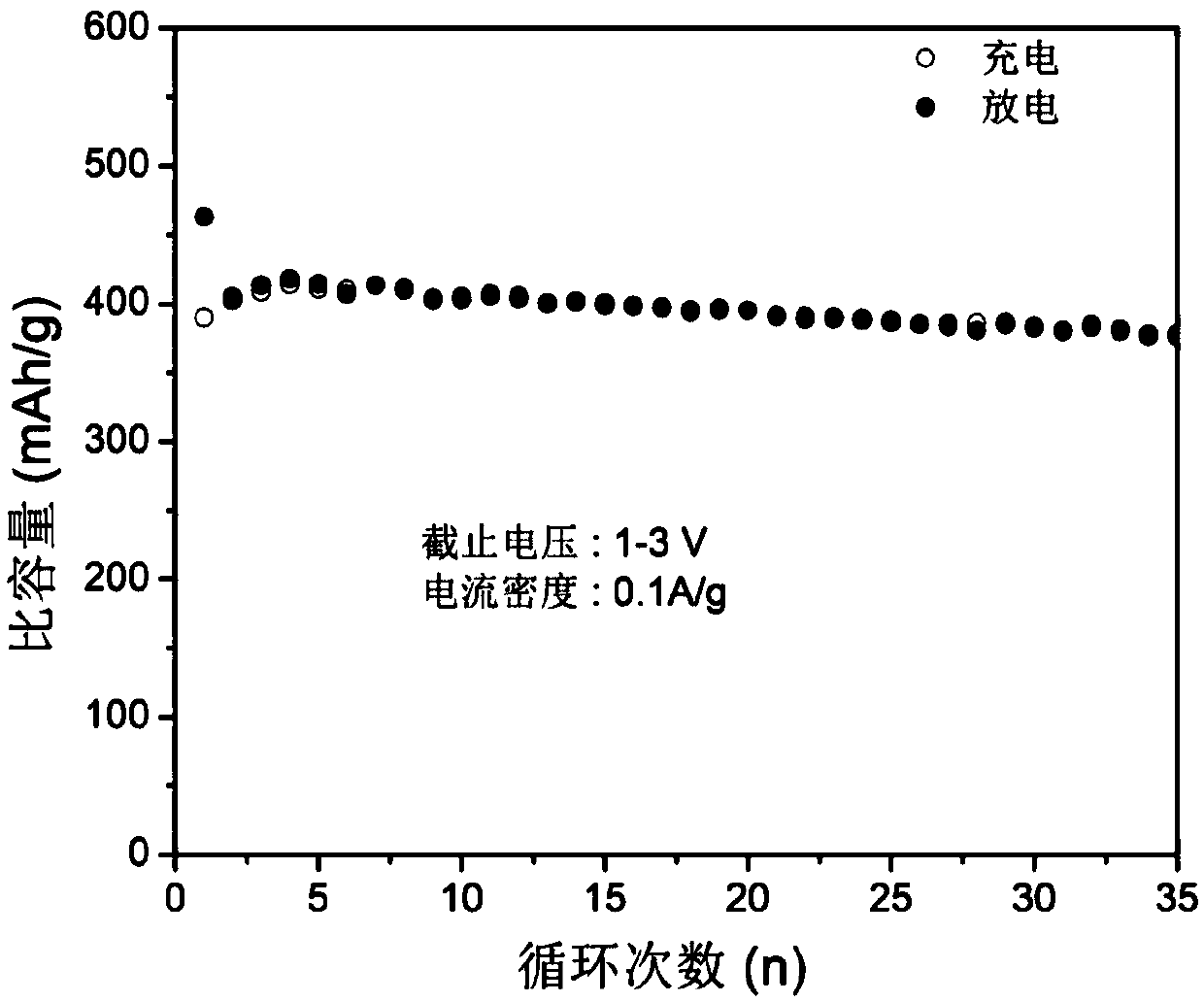

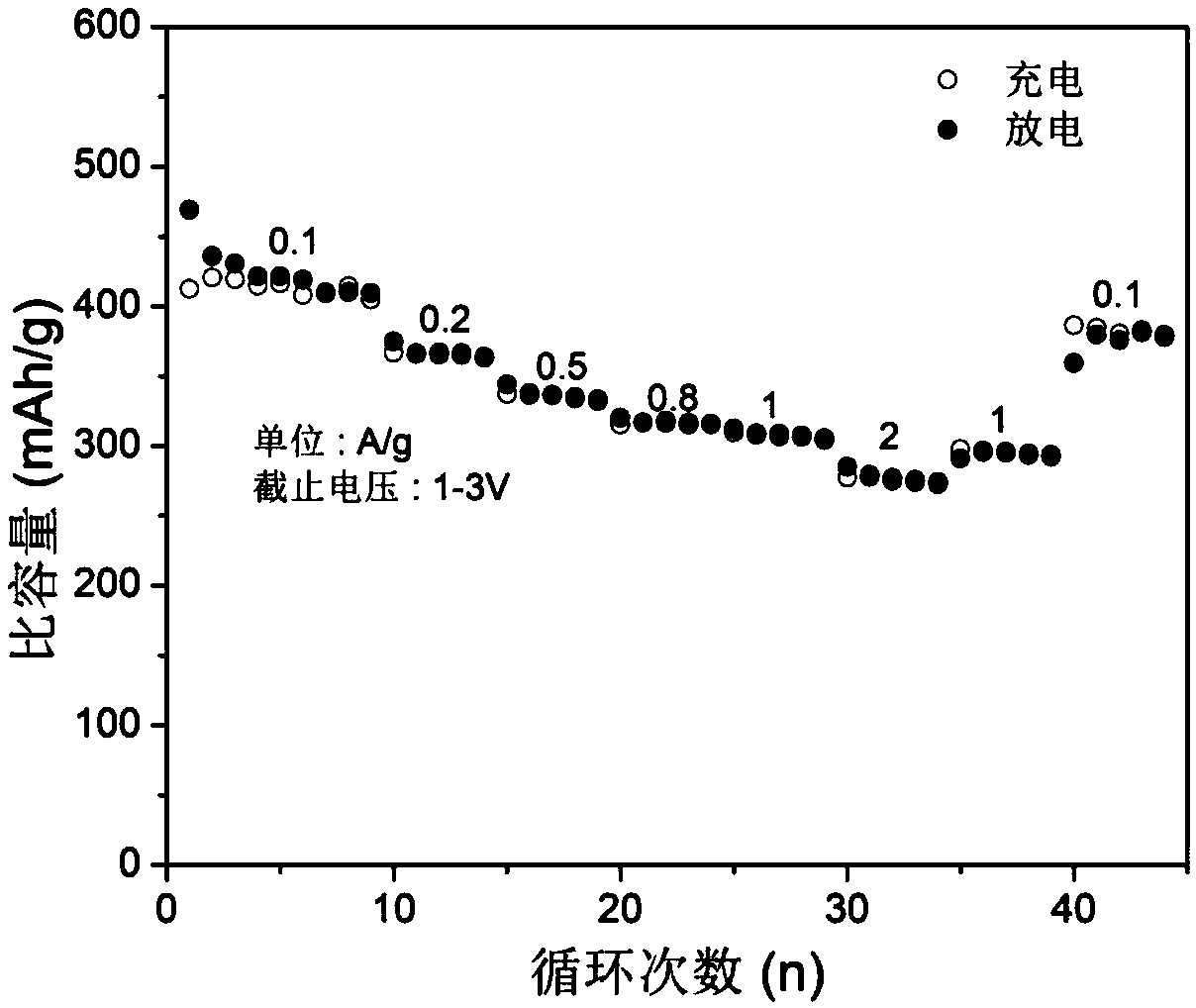

[0021] Mix 70wt% ferrous sulfide / graphene composite material, 15wt% acetylene black, and 15wt% CMC evenly to make a slurry, coat it evenly on copper foil, and punch it into a circular electrode piece after vacuum drying , with metal lithium as the counter electrode, 1mol / L LiPF 6 / EC+DEC+DMC (volume ratio 1:1:1) is the electrolyte, Celgard 2400 is the separator, and assembled into a button battery. The constant current charge and discharge test was carried out on the battery, and the charge and discharge voltage range was 1.0 to 3.0V. The results showed that the electrode show...

Embodiment 2

[0023] In an Ar atmosphere, 0.1 g of ferric oxide / graphene and 0.05 g of thioacetamide powder were mixed evenly, and the mixed powder was placed in a stainless steel sealed tube. The stainless steel sealed tube obtained above is placed in a tube furnace into an Ar gas with a gas flow rate of 40 sccm, heat treated at 400 ° C for 1 h, and finally obtains a ferrous sulfide / graphene composite material;

[0024] Mix 70wt% ferrous sulfide / graphene composite material, 15wt% acetylene black, and 15wt% CMC evenly to make a slurry, coat it evenly on copper foil, and punch it into a circular electrode piece after vacuum drying , with metal lithium as the counter electrode, 1mol / L LiPF 6 / EC+DEC+DMC (volume ratio 1:1:1) is the electrolyte, Celgard 2400 is the separator, and assembled into a button battery. The constant current charge and discharge test was carried out on the battery. The charge and discharge voltage range was 1.0-3.0V. The results showed that it had poor electrochemical ...

Embodiment 3

[0026] In an Ar atmosphere, 0.15 g of ferric oxide / graphene and 0.41 g of thiourea powder were mixed evenly, and the mixed powder was placed in a stainless steel sealed tube. The stainless steel sealed tube obtained above was placed in a tube furnace into Ar gas with a gas flow rate of 40 sccm, and heat treated at 900 ° C for 8 hours to finally obtain a FeS / rGO composite material;

[0027] Mix 70wt% FeS / graphene composite material, 15wt% acetylene black, and 15wt% CMC uniformly to make a slurry, coat it evenly on copper foil, and punch it into a circular electrode pole piece after vacuum drying. Lithium metal is the counter electrode, 1mol / LLiPF 6 / EC+DEC+DMC (volume ratio 1:1:1) is the electrolyte, Celgard 2400 is the separator, and assembled into a button battery. The constant current charge and discharge test was carried out on the battery. The charge and discharge voltage range was 1.0-3.0V. The results showed that it had poor electrochemical performance: at a current den...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com