A kind of borate compound and preparation method thereof and electrolyte containing same

A boric acid ester and compound technology, which is applied in chemical instruments and methods, compounds containing elements of Group 3/13 of the periodic table, circuits, etc., can solve problems such as unsatisfactory and the electrochemical performance of lithium ion batteries needs to be improved, etc. , to achieve the effect of improving electrochemical performance and safety performance, improving cycle stability and simple synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

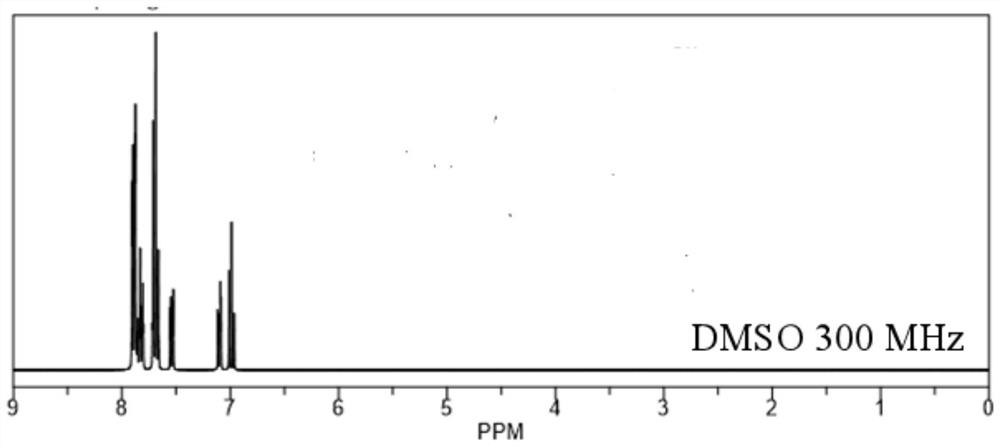

[0055] Preparation Example 1: Preparation of a benzenesulfonyl-containing thiophene boronate compound represented by formula (III)

[0056]

[0057] The specific reaction principle is as follows:

[0058]

[0059] The specific preparation steps are:

[0060] (1) Raw material pretreatment: heat and distill tetrahydrofuran, and use sodium metal to dry and remove water at the same time, so that the purity of tetrahydrofuran is greater than 99.9%, and the water content is reduced to below 50ppm. Triethylamine is heated and fractionated to obtain a colorless and transparent triethylamine solution, and then activated 4A molecular sieve is added to make the triethylamine moisture lower than 50ppm. 2-thiophene boronic acid and benzenesulfonyl chloride were added to activated 4A molecular sieves, respectively, so that the moisture content of 2-thiophene boronic acid and benzenesulfonyl chloride was less than 50 ppm.

[0061] (2) The preparation reaction of the thiophene group-c...

preparation example 2

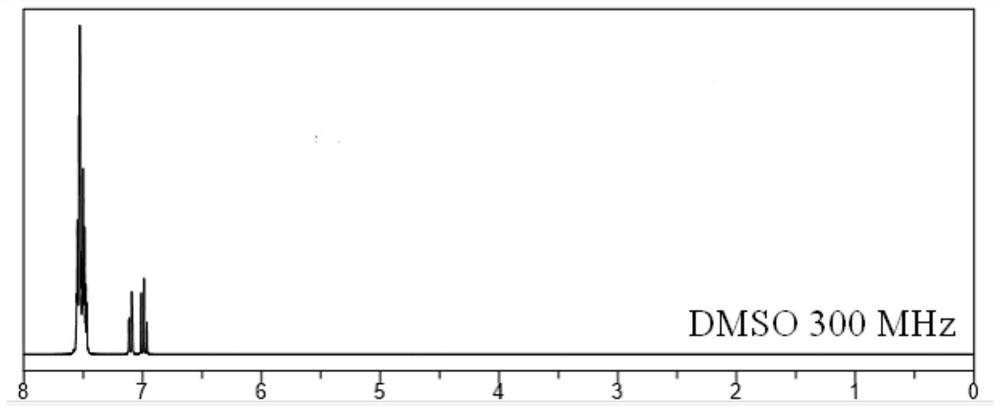

[0067] Preparation Example 2: Preparation of benzenesulfonyl-containing thiophene boronate compound represented by formula (IV)

[0068]

[0069] The specific reaction principle is as follows:

[0070]

[0071] The specific preparation steps are:

[0072] (1) Raw material pretreatment: heat and distill tetrahydrofuran, and use sodium metal to dry and remove water at the same time, so that the purity of tetrahydrofuran is greater than 99.9%, and the water content is reduced to below 50ppm. Triethylamine is heated and fractionated to obtain a colorless and transparent triethylamine solution, and then activated 4A molecular sieve is added to make the triethylamine moisture lower than 50ppm. 2-thiophene boronic acid and benzenesulfinyl chloride were respectively added to activated 4A molecular sieves, so that the moisture content of 2-thiophene boronic acid and benzenesulfinyl chloride was less than 50 ppm.

[0073] (2) The preparation reaction of the thiophene group-conta...

preparation example 3

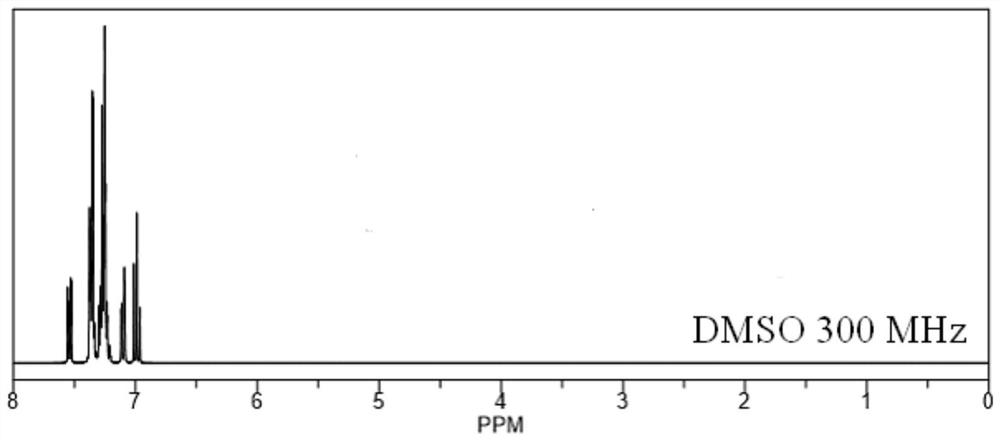

[0079] Preparation Example 3: Preparation of benzenesulfonyl-containing thiophene boronate compound represented by formula (V)

[0080]

[0081] The specific reaction principle is as follows:

[0082]

[0083] The specific preparation steps are:

[0084] (1) Raw material pretreatment: heat and distill tetrahydrofuran, and use sodium metal to dry and remove water at the same time, so that the purity of tetrahydrofuran is greater than 99.9%, and the water content is reduced to below 50ppm. Triethylamine is heated and fractionated to obtain a colorless and transparent triethylamine solution, and then activated 4A molecular sieve is added to make the triethylamine moisture lower than 50ppm. 2-thiophene boronic acid and benzenesulfenyl chloride were added to activated 4A molecular sieves before use, so that the moisture content of 2-thiophene boronic acid and benzenesulfenyl chloride was less than 50 ppm.

[0085] (2) The preparation reaction of the thiophene group-containi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com