Patents

Literature

42 results about "Calcium nitride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Calcium nitride is the inorganic compound with the chemical formula Ca₃N₂. It exists in various forms (isomorphs), α-calcium nitride being more commonly encountered.

Glass matrix type slow-release compound fertilizer and preparation method thereof

ActiveCN102093127ASolve the costSolve complexityFertilizer mixturesEcological environmentNitrogen gas

The invention relates to a glass matrix type slow-release compound fertilizer and a preparation method thereof. The compound fertilizer is prepared from the following components in parts by mass: 10-30 parts of waste glass, 40-60 parts of calcium carbide, 1-30 parts of phosphate fertilizer, 0-30 parts of potash fertilizer, 0-10 parts of filler and 300-400 cubic meter of nitrogen per ton of fertilizer (standard atmospheric pressure). The glass matrix type slow-release compound fertilizer has the functions of regulating the pH value of soil and improving the acidified soil, and can decrease therelease rate of the fertilizer nutrients, increase the utilization ratio of the nutrients, reduce the fertilizer loss and relieve the environmental pressure caused by fertilizer application; and the glass matrix type slow-release compound fertilizer has favorable ecological environment benefits, and solves the problem that the element nitrogen can not be easily added into the existing glass fertilizer by directly synthesizing calcium nitride at high temperature.

Owner:INST OF SOIL & FERTILIZER FUJIAN ACADEMY OF AGRI SCI

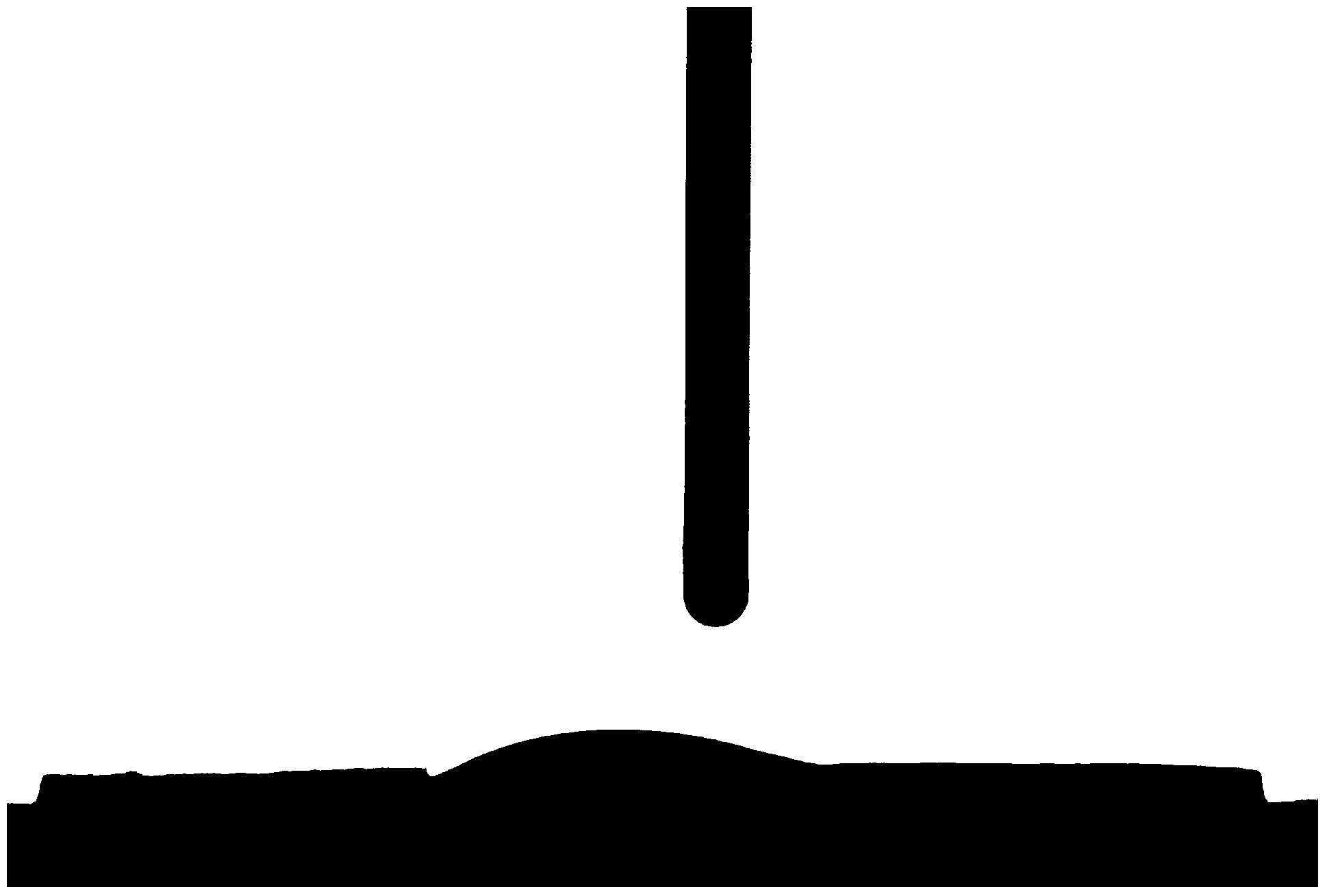

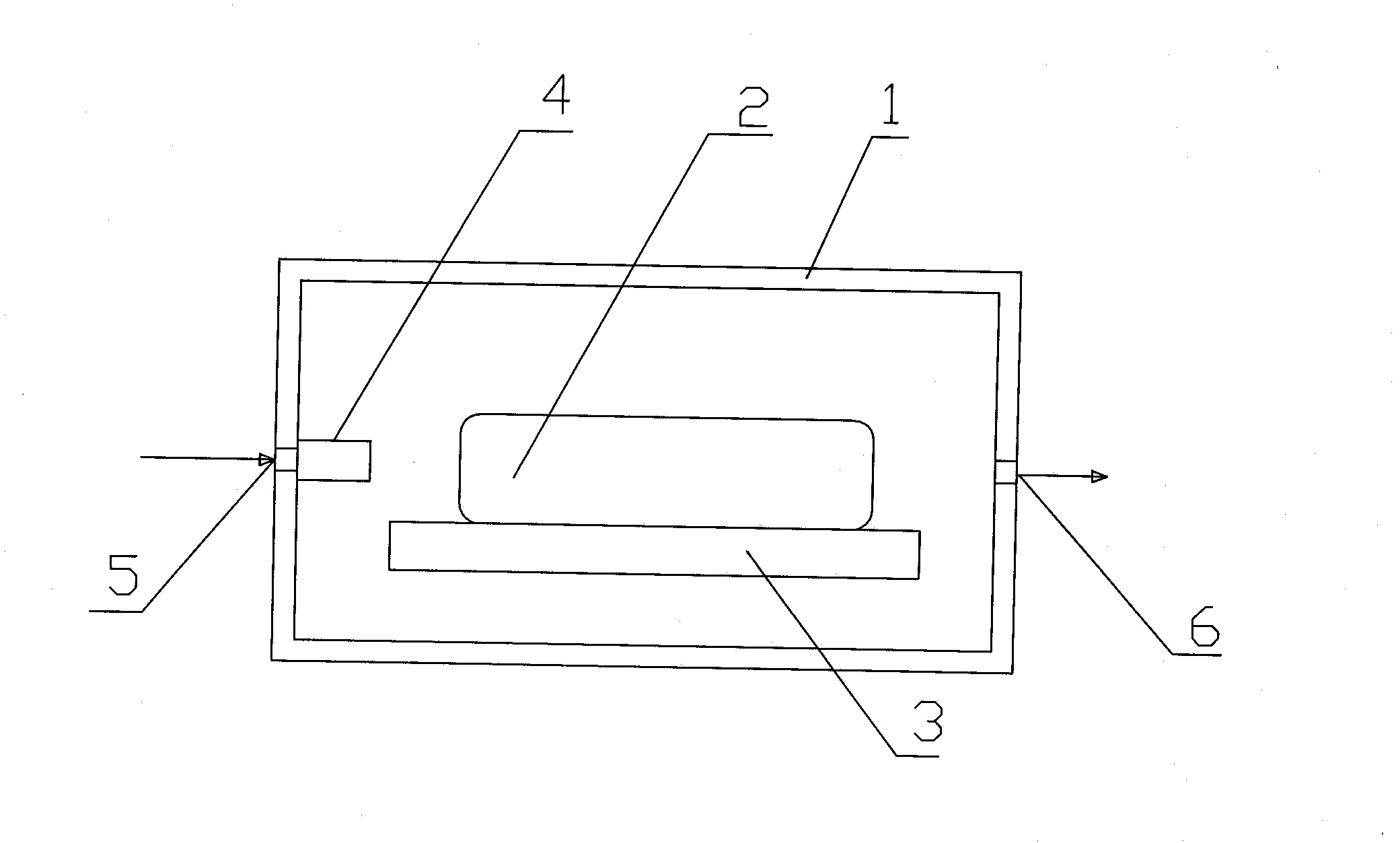

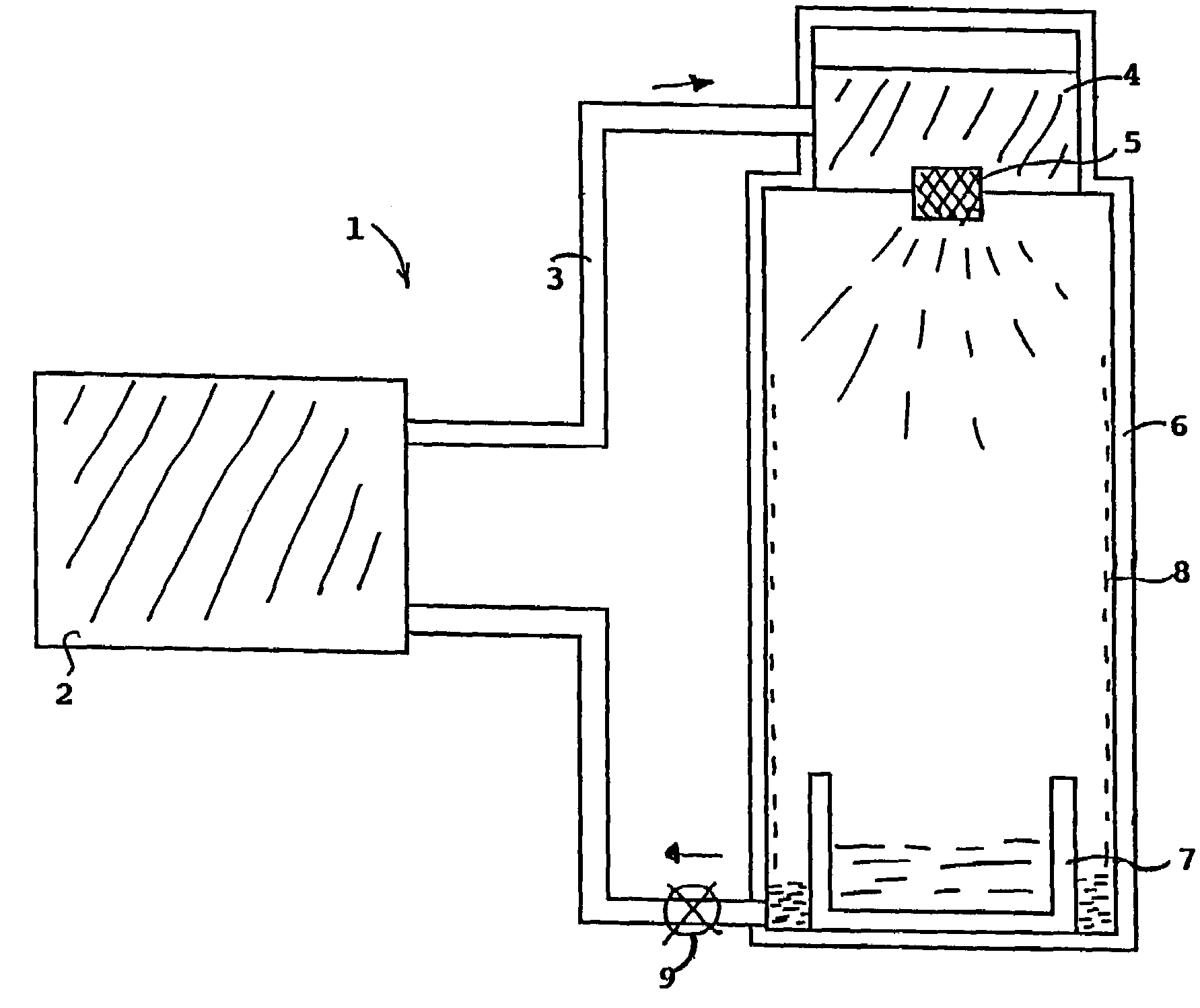

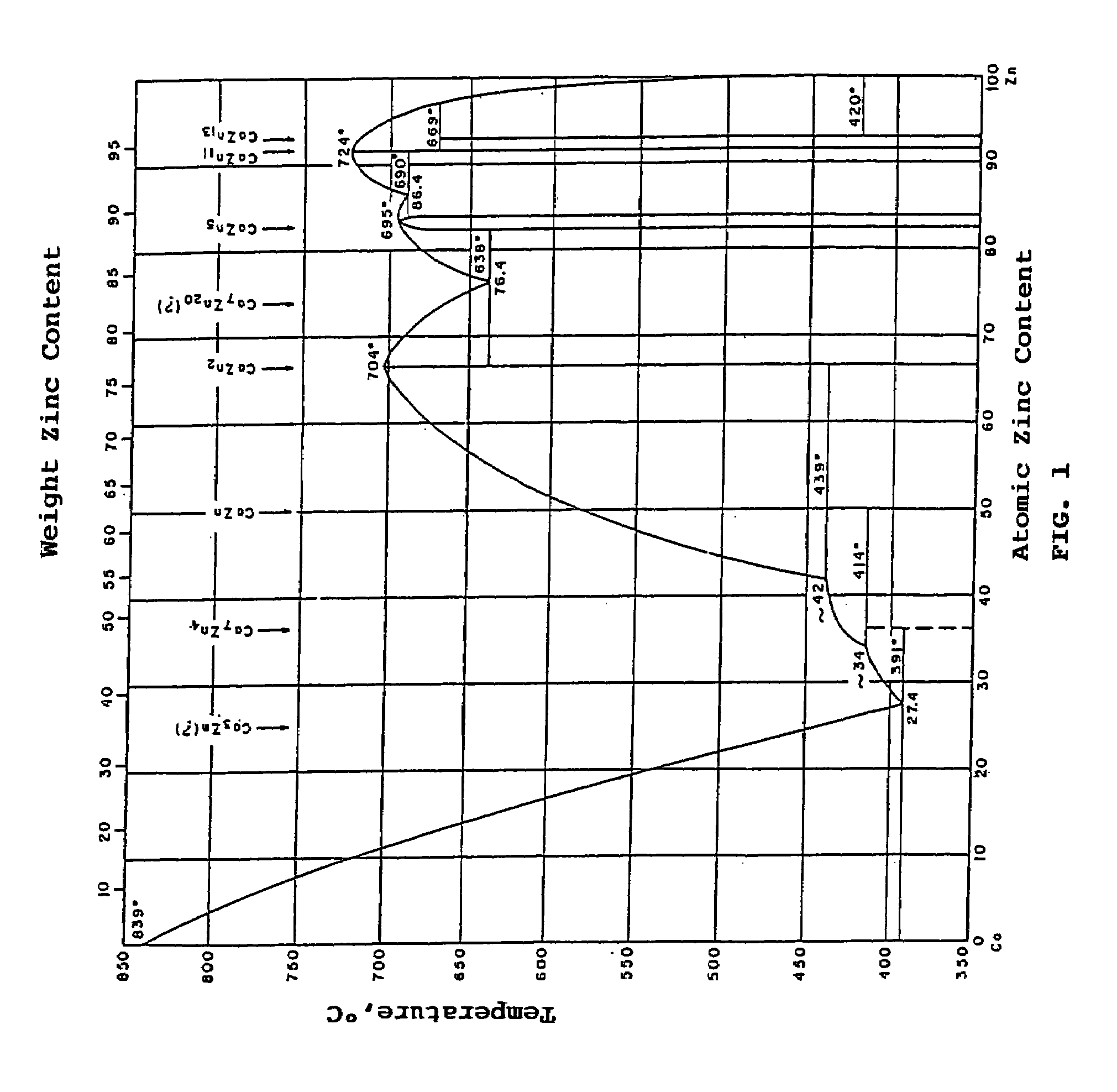

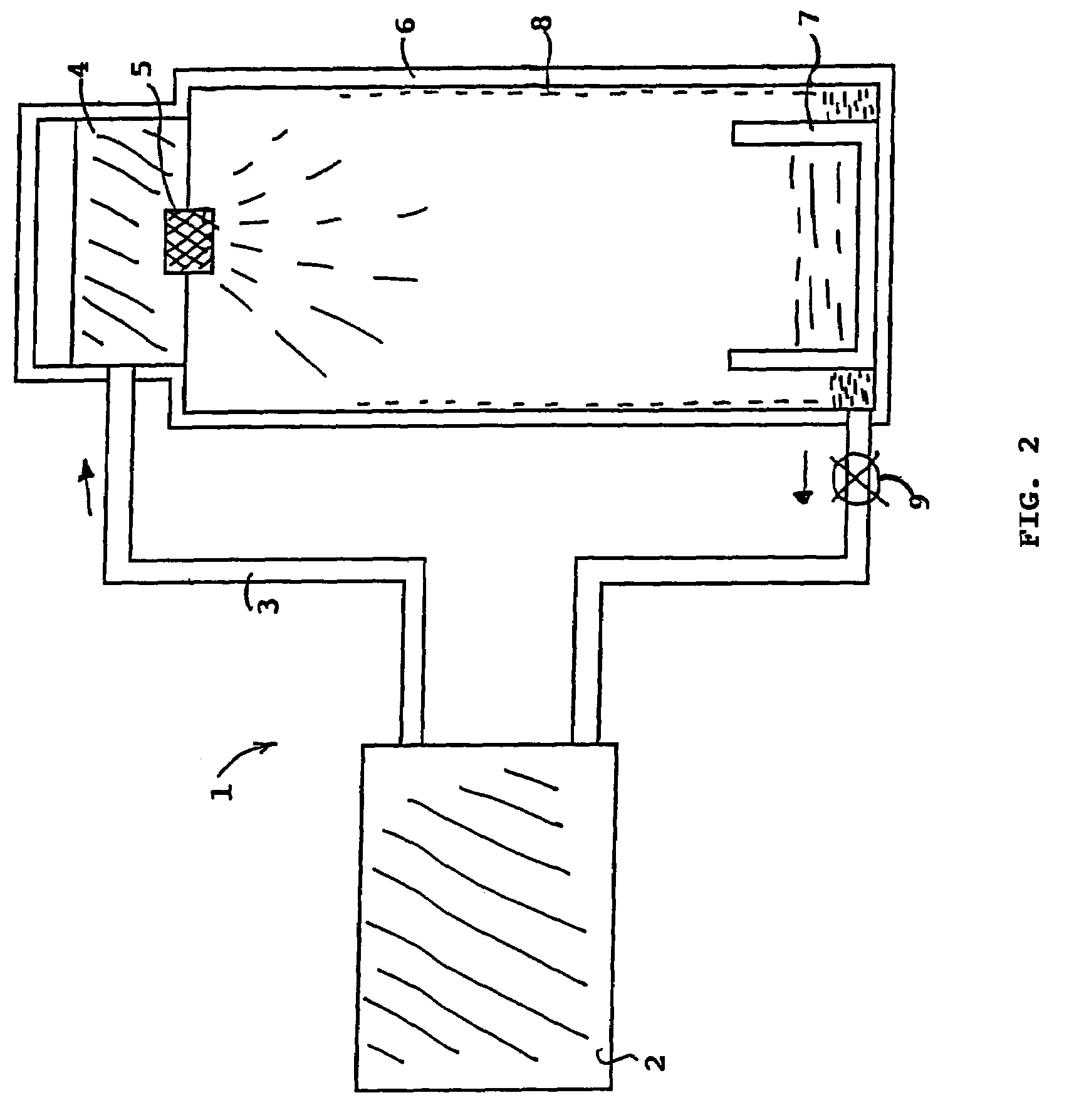

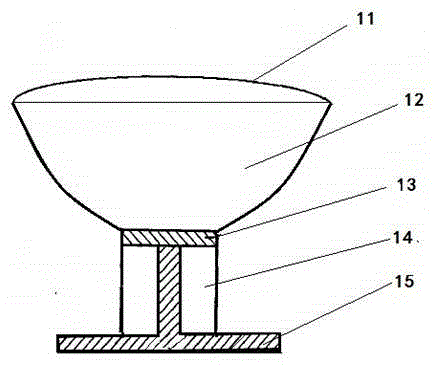

Method for calcium nitride synthesis

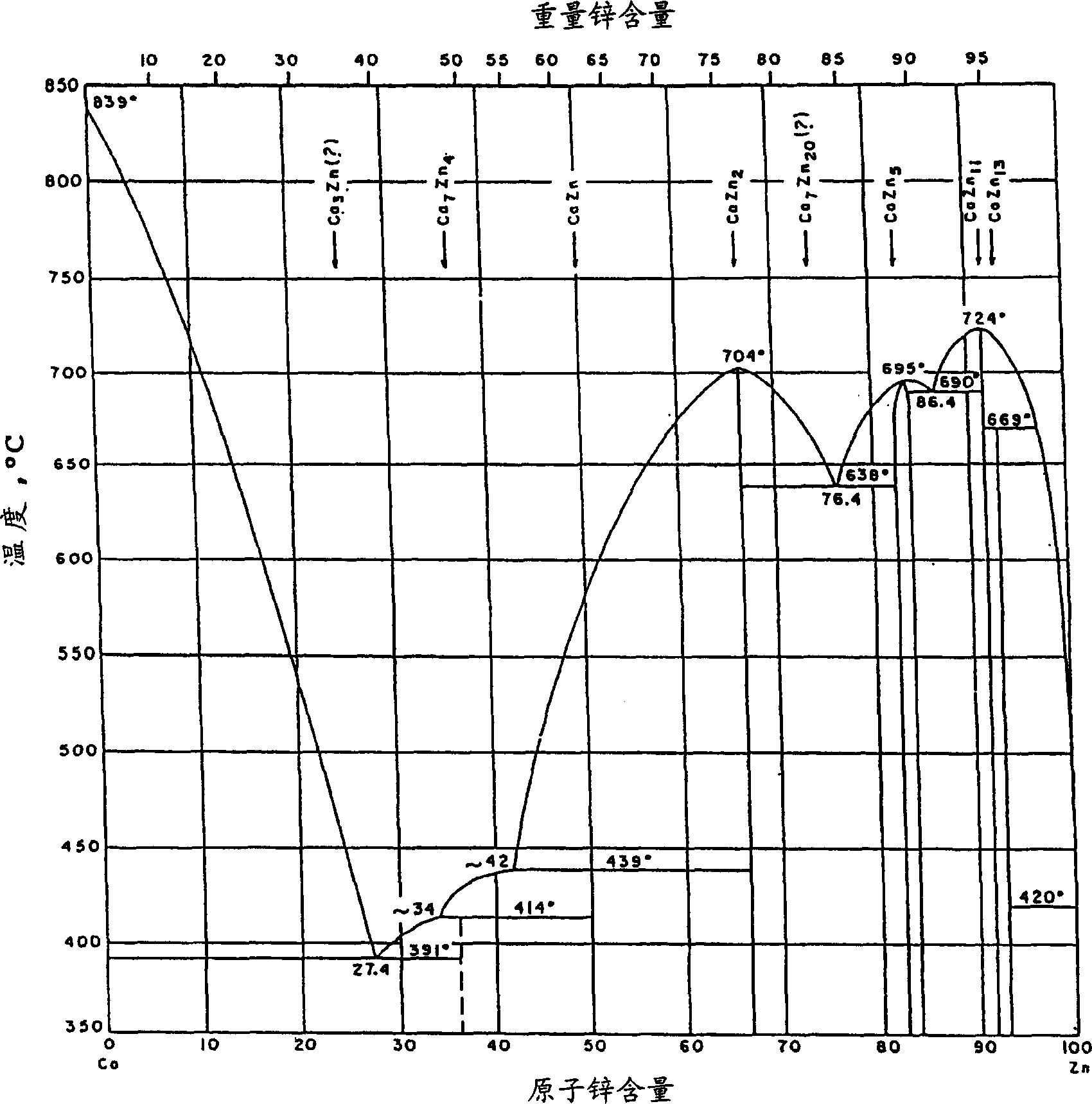

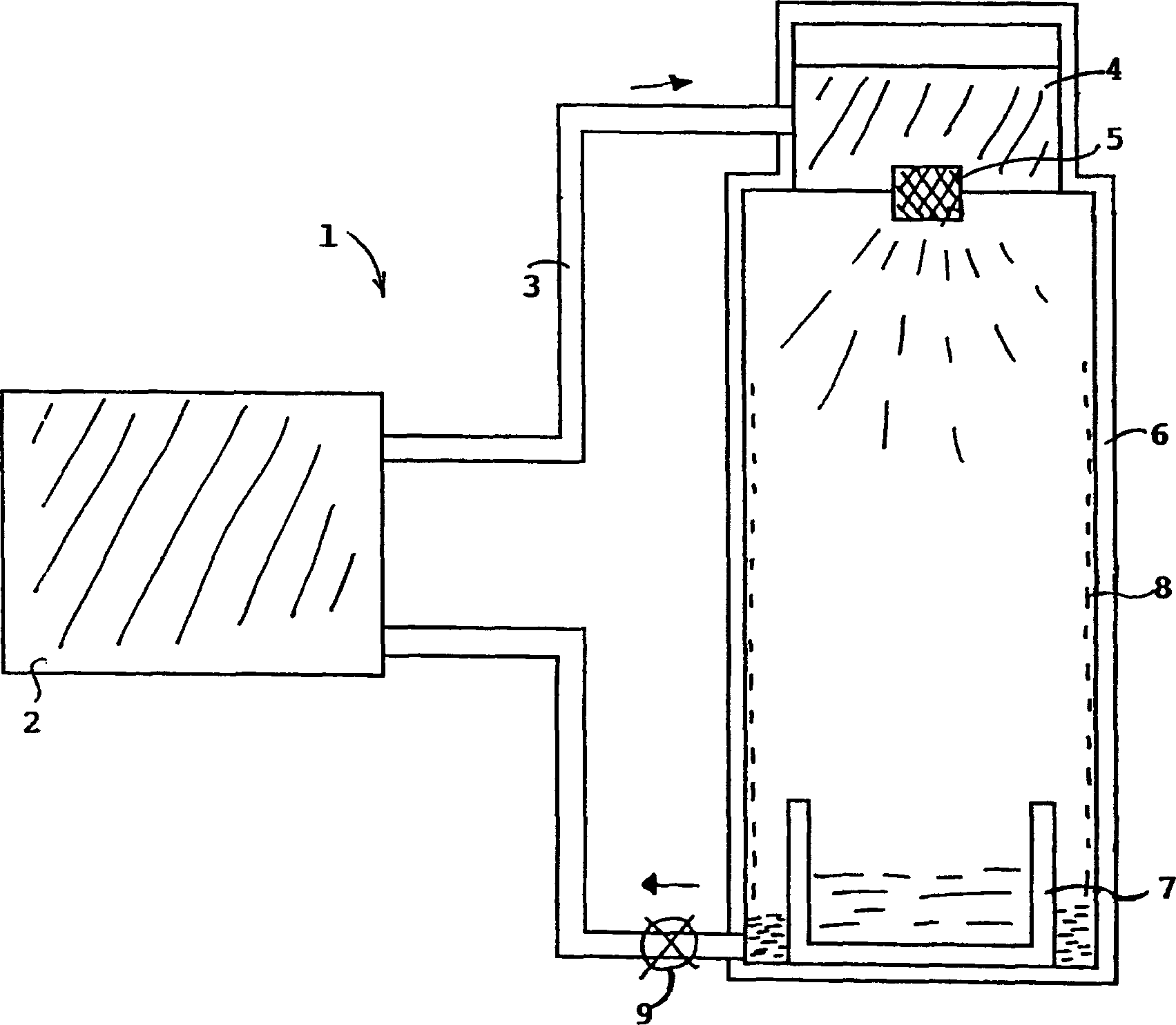

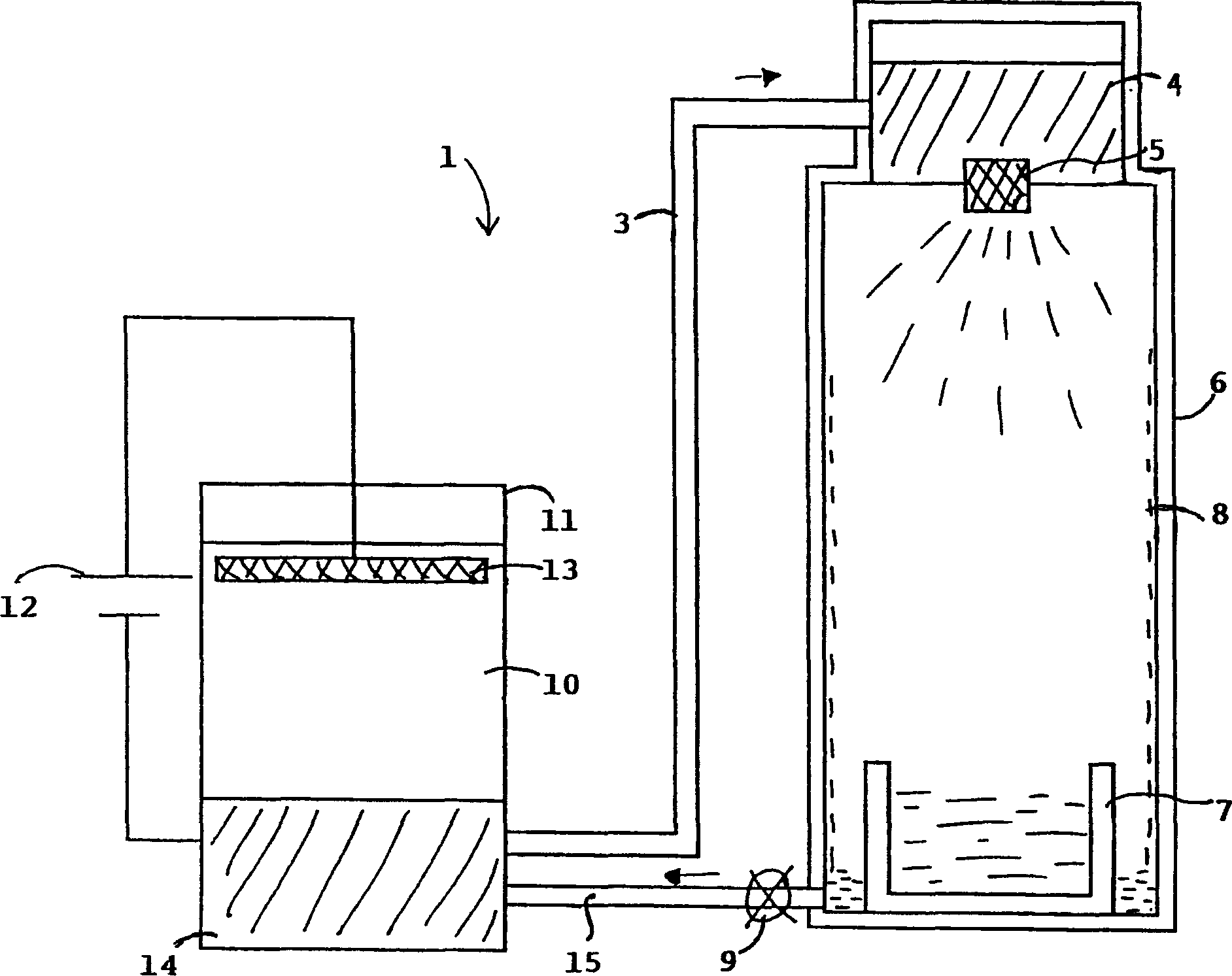

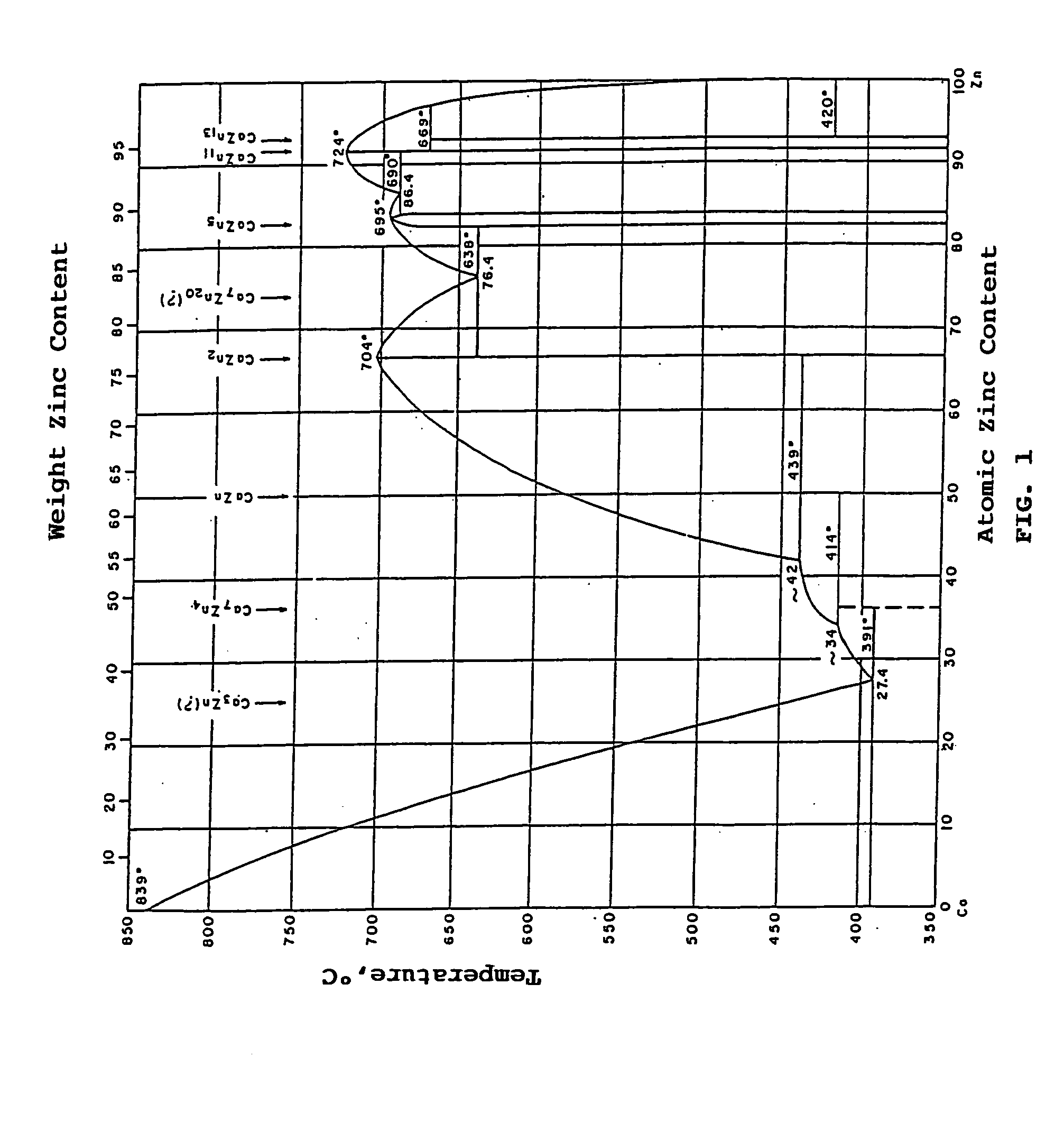

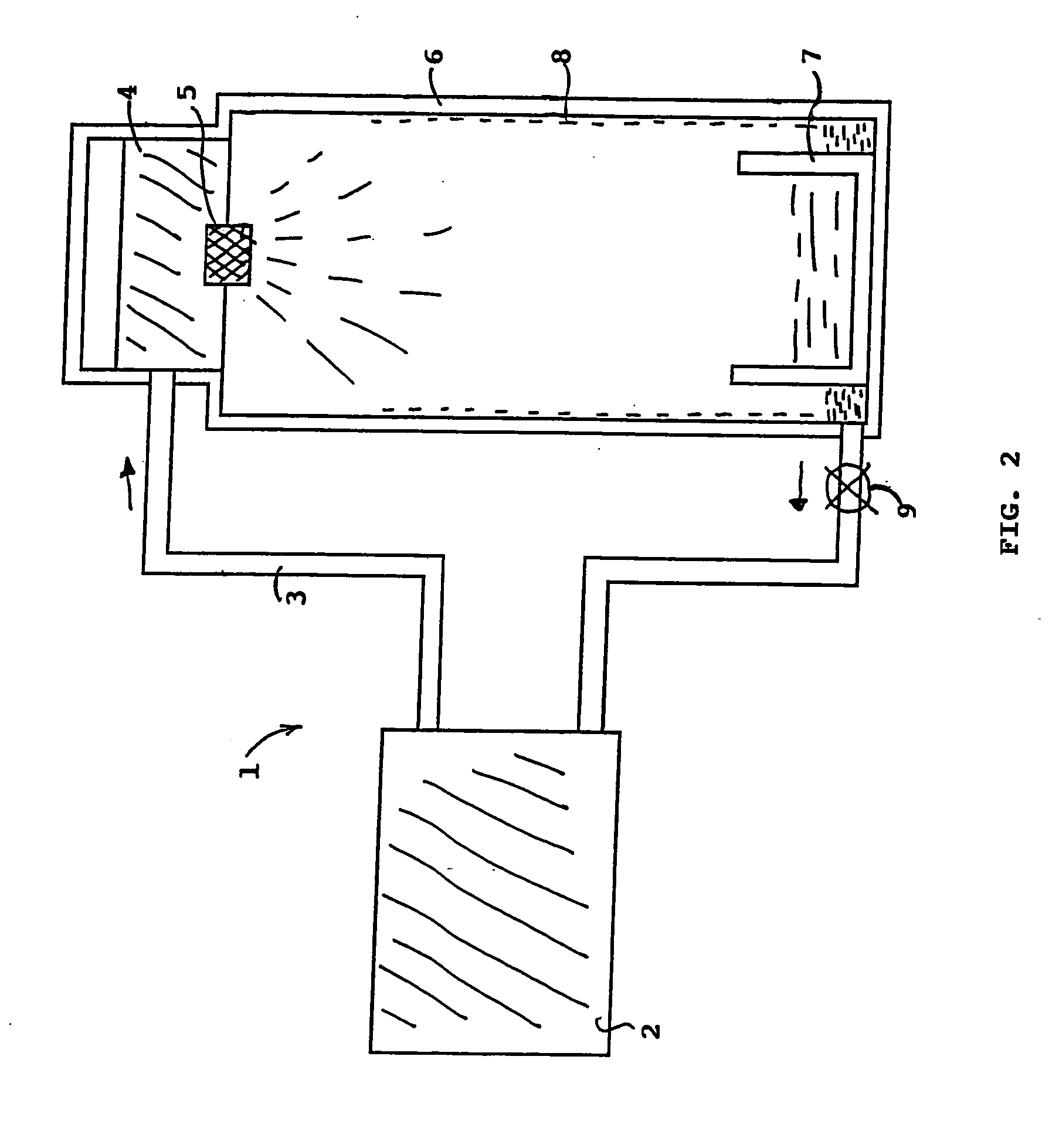

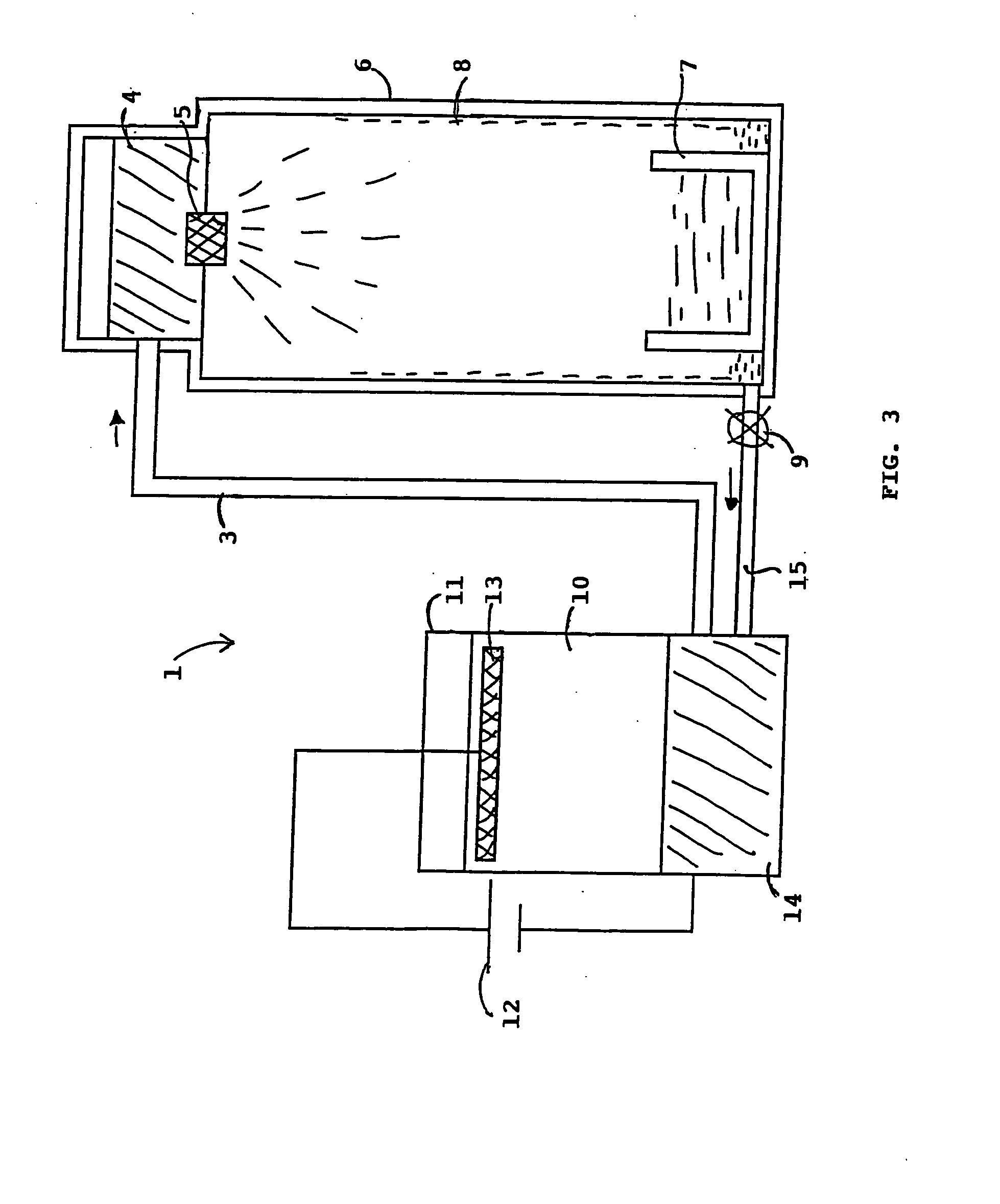

The invention concerns a method for calcium nitride synthesis which consists in spraying in form of droplets, by means of a sprayer (5), a molten zinc-calcium alloy into a reactor (6) containing nitrogen at high temperature. The resulting calcium nitride is collected in a collector unit (7) at the lower part of the reactor (6). The zinc contained in the droplets is evaporated and condensed on the cooled walls of the reactor (6) and can be reused for preparing another alloy. The zinc-calcium alloy is obtained by electrolysis of calcium chloride in an electrolytic cell (11) whereof the cathode (14) is a solution containing molten zinc.

Owner:佛朗科伊斯·拉科斯特

Method for preparing potassium nitride from calcium nitride byproduct of nitro phosphate

InactiveCN102502719ASolve processing problemsAlkali metal nitrate preparationHigh concentrationPhosphate

The invention relates to a potassium nitride preparation method, in particular to a method for preparing potassium nitride from a calcium nitride byproduct of nitro phosphate, which belongs to the technical field of production of agricultural potassium nitride fertilizers. The method includes steps of a, firstly, adding water in a dissolving tank, starting to stir and dissolve after industrial potassium chloride or potassium sulfate is poured, preparing the potassium chloride or potassium sulfate into saturated solution and pumping the saturated solution into a potassium nitride reaction tank; b, secondly, metering wet calcium nitride crystals, adding the wet calcium nitride crystals into the potassium nitride reaction tank, mixing and stirring the wet calcium nitride crystals with the solution obtained in the step a to carry out double replacement reaction, and preparing potassium nitride reaction liquid; and c, finally, crystallizing the potassium nitride reaction liquid prepared in the step b, and then separating potassium nitride crystals. The method solves problems of treatment of calcium nitride industrial byproducts of nitro phosphate, simultaneously, produces high-quality high-concentration potassium nitride fertilizers, and cannot produce waste difficult to be treated in a procedure.

Owner:YUNNAN CHEM RES INST +1

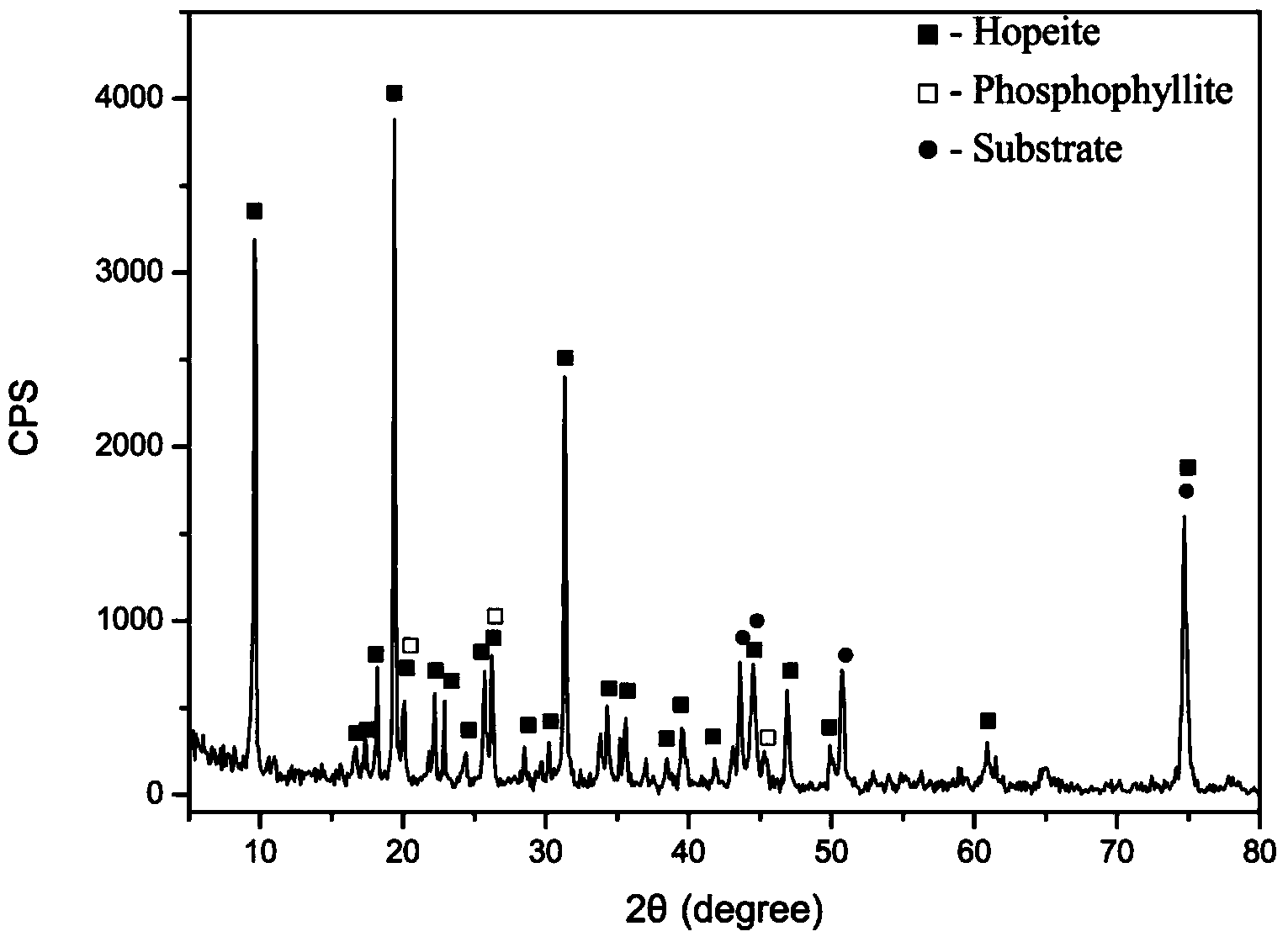

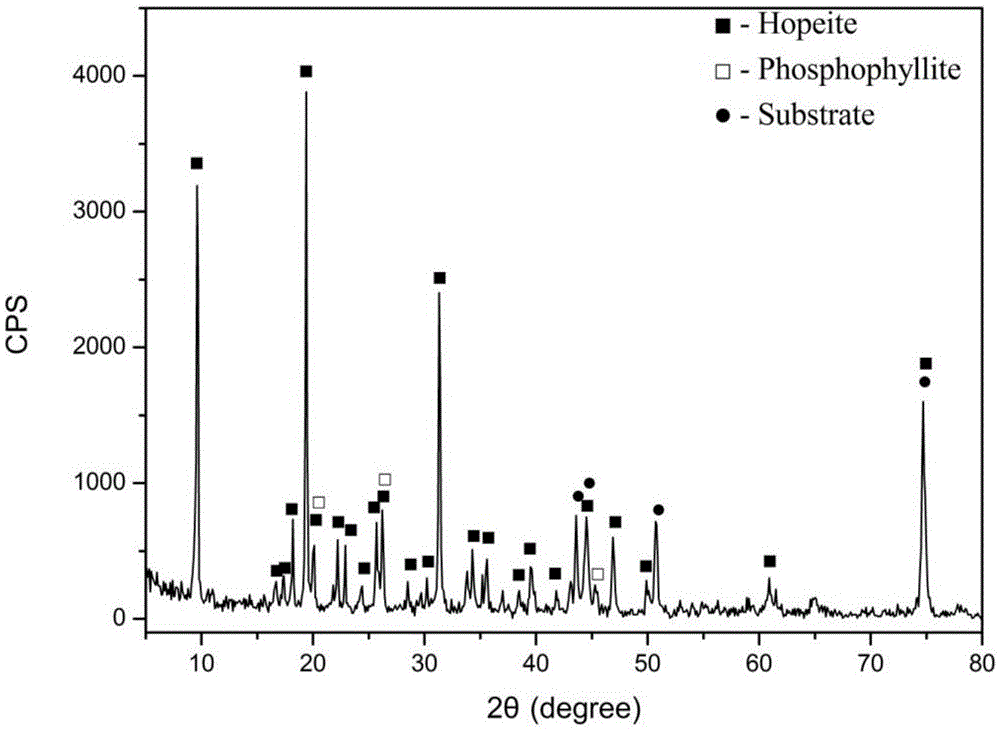

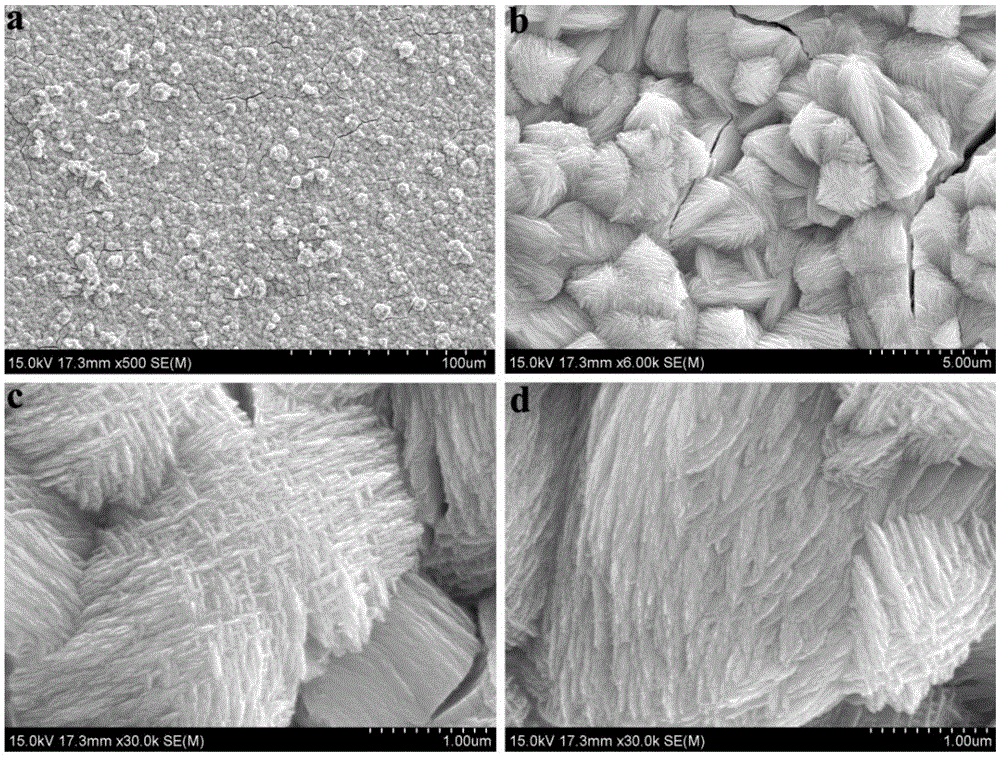

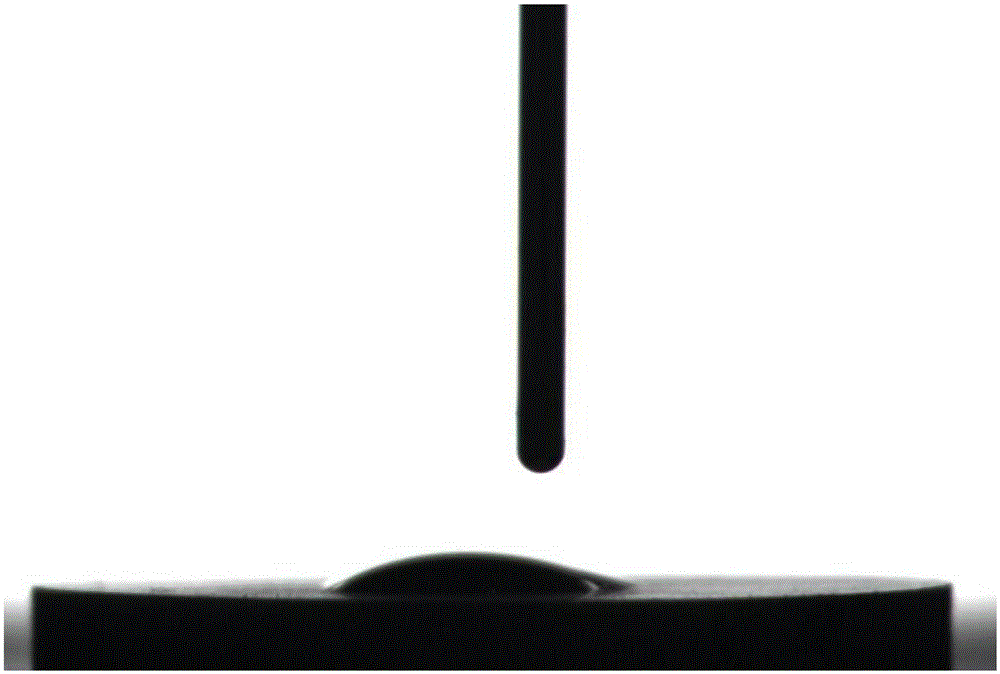

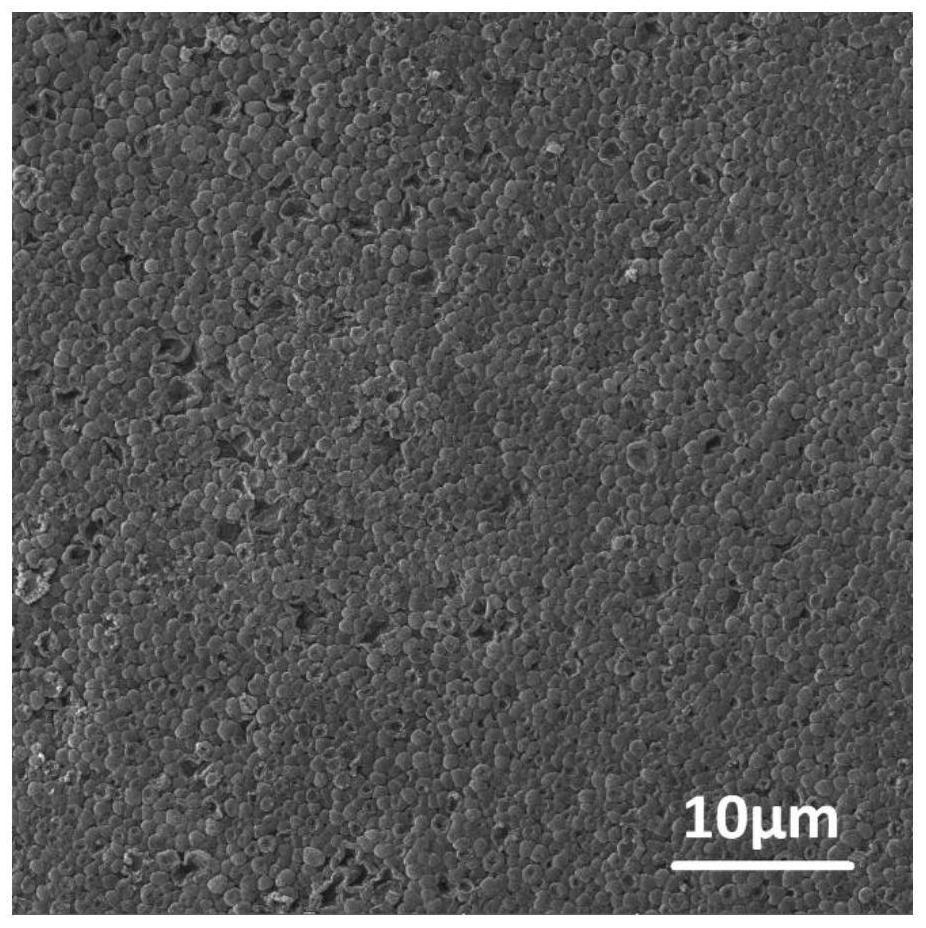

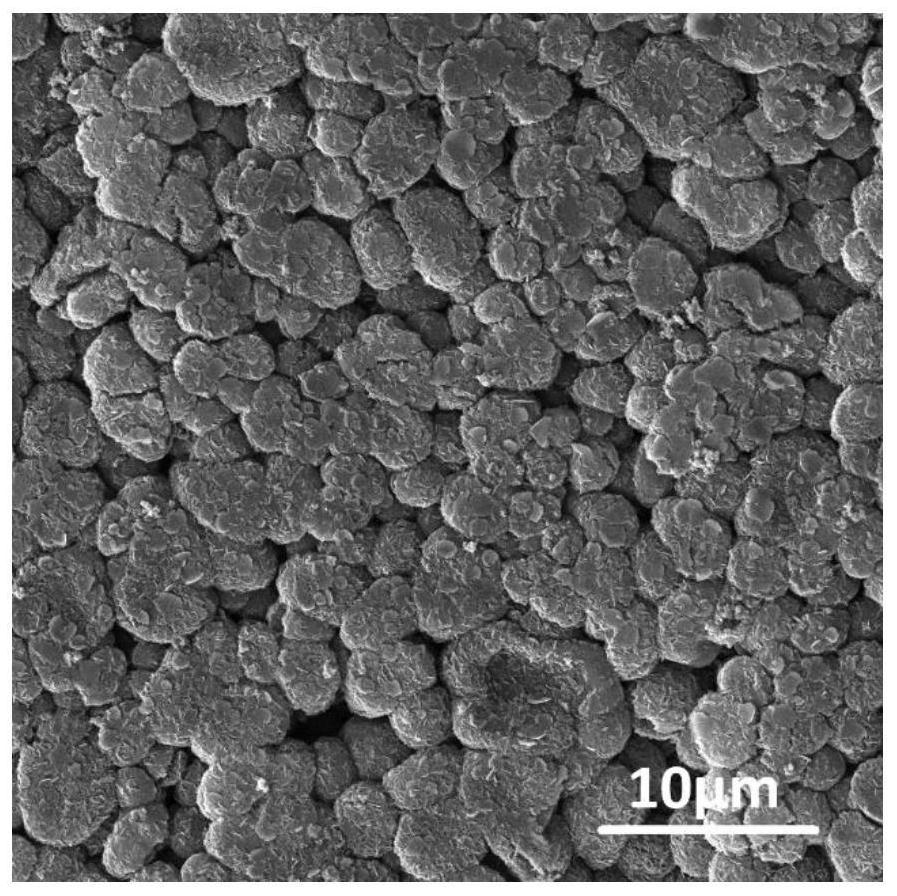

Preparation method of zinc phosphate chemical conversion coating in hierarchical structure

ActiveCN103924226AImprove performanceImprove corrosion resistanceMetallic material coating processesEtchingPhosphoric acid

The invention relates to a preparation method of a zinc phosphate chemical conversion coating in a hierarchical structure. The preparation method of the zinc phosphate chemical conversion coating comprises the following steps: preparing a chemical conversion basis solution A, wherein concentration of zinc oxide is 20-28g / L, the concentration of nitric acid is 25-35ml / L, the concentration of phosphoric acid is 10-15ml / L, the concentration of calcium nitride is 5-20g / L, and the concentration of critic acid is 18-22g / L; adding iron powder in to the chemical conversion basis solution, and curing for 12-24 hours at room temperature, so that a curing liquid A1 is obtained; carrying out acidic etching and activation on a stainless steel matrix; placing the activated matrix into the curing liquid A1, carrying out chemical conversion for 15-45 minutes at the temperature of 65-75 DEG C and pH value of 2.5-3.0, and carrying out water washing, so that the zinc phosphate chemical conversion coating is obtained. By adopting the preparation method of the zinc phosphate chemical conversion coating, a uniform dense conversion coating composed of spherical zinc phosphate aggregate which is 2-4 microns in size and composed of nanocrystals is prepared on the surface of medical stainless steel, wettability between a coating layer and simulated body fluid (SBF) is good, and corrosion resistance is good.

Owner:SHANDONG UNIV

Nutritional medium and culture method of cordyceps militaris

InactiveCN103183564AIncrease productionImprove qualityHorticultureFertilizer mixturesCordycepsCordyceps militaris

The invention particularly relates to a nutritional medium and a culture method of cordyceps militaris. The nutritional medium is prepared by taking rice meal and silkworm chrysalis meal as main materials, and added with calcium nitride, magnesium sulfate, 2,4-dichlorophenylacetic acid and other substances, so as to reduce bad heteromorphosis during the reproductive process of the cordyceps militaris, and accelerate the growth rate. The culture method is simple to operate, but can not pollute the environment. The obtained cordyceps militaris is high in yield and good in quality, can be produced by industrialization to promote market economy.

Owner:李向军

Method for producing hexagonal boron nitride single crystal and hexagonal boron nitride single crystal

InactiveUS20080011224A1Quality improvementSmall sizeFrom gel stateFrom solid stateHexagonal boron nitrideNitrogen

An object of the present invention is to provide a novel method of growing hexagonal boron nitride single crystal. It is found that hexagonal boron nitride single crystal is grown in calcium nitride flux by heating, or heating and then slowly cooling, boron nitride and calcium series material in atmosphere containing nitrogen. Bulk of hexagonal boron nitride single crystal can thereby successfully be grown.

Owner:NGK INSULATORS LTD +1

High-strength ceramic chopsticks and preparation technology thereof

The invention provides high-strength ceramic chopsticks and a preparation technology thereof. Each high-strength ceramic chopstick comprises a chopstick blank body and glaze, wherein the chopstick blank body is prepared from the following raw materials in parts by weight: 15 to 22 parts of potassium feldspar, 20 to 25 parts of vermiculite powder, 45 to 53 parts of quartz, 12 to 15 parts of serpentine, 5 to 8 parts of shale, 6 to 10 parts of amphibole, 3 to 5 parts of medical stone powder, 2 to 4 parts of Kanuma soil, 5 to 7 parts of lanthanum oxide, 1 to 3 parts of calcium nitride and 2 to 5 parts of magnesium carbonate; the glaze is prepared from the following raw materials in parts by weight: 35 to 42 parts of transparent frit, 10 to 15 parts of red halloysite, 25 to 30 parts of Dehua quartz, 12 to 18 parts of sodium feldspar, 8 to 12 parts of dolomite, 5 to 8 parts of lepidolite, 3 to 5 parts of molybdenum ore powder, 4 to 6 parts of phosphorus slag powder, 5 to 7 parts of volcanic soil and 1 to 3 parts of a dispersant; the transparent frit is prepared from the following chemical components in percentage by mass: 42 percent to 48 percent of SiO2, 17 percent to 23 percent of Al2O3, 2 percent to 3 percent of K2O, 5 percent to 8 percent of Na2O, 8.6 percent to 9.8 percent of MgO, 5.6 percent to 6.4 percent of Fe2O3, 2.2 percent to 4.6 percent of Ca3N2, 1.5 percent to 2.8 percent of Dy2O3, 3 percent to 3.7 percent of La2O3 and 1.2 percent to 2.6 percent of CaF2.

Owner:德化县如瓷生活文化有限公司

Once-moulded thin-tire ceramic and preparation technology thereof

The invention discloses a once-moulded thin-tire ceramic and a preparation technology thereof. The once-moulded thin-tire ceramic comprises a blank and glaze, wherein the blank comprises the followingraw materials in parts by weight: 16-22 parts of albite, 12-18 parts of montmorillonite, 46-52 parts of a quartz powder, 8-12 parts of rutile, 3-5 parts of a molybdenum ore powder, 1-3 parts of a silica brick powder, 5-8 parts of diopside, 3-6 parts of magnesium oxide, 1-3 parts of light calcium carbonate and 2-5 parts of a sintering aid; the glaze comprises the following raw materials in parts by weight: 10-15 parts of albite, 16-22 parts of red halloysite, 35-46 parts of quartz, 5-8 parts of titanium dioxide, 3-6 parts of a glass powder, 3-5 parts of red jade soil, 1-3 parts of bentonite, 2-5 parts of calcium nitride, 1-3 parts of dysprosium oxide and 1-2 parts of magnesium carbonate.

Owner:CERAMICS SCI & TECH RES INST QUANZHOU +1

Acidified soil conditioner

InactiveCN109777432APromote improvementReduce or improve acidityAgriculture tools and machinesOther chemical processesMethacrylateSodium Bentonite

The invention provides acidified soil conditioner. The acidified soil conditioner is prepared from the following components in parts by weight: 52-58 parts of bamboo carbon, 1-5 parts of a microbial agent, 2-4 parts of hydroxymethyl cellulose, 11-15 parts of bentonite, 10-14 parts of manure, 2-6 parts of polypotassium methacrylate, 1-5 parts of nanosilicon dioxide powder, 2-4 parts of a urease inhibitor, 3-5 parts of carbon calcium nitride, 2-4 parts of nano-zinc oxide, and 3-5 parts of alkali accessories. The invention provides the acidified soil conditioner which is safe and effective, has good improvement effect on the acidified soil, and cannot influence the soil after being applied for a long time. The soil conditioner is low in cost, non-hazardous, capable of promoting the agricultural sustainable development and suitable for popularizing and applying in large scale.

Owner:PINGDINGSHAN UNIVERSITY

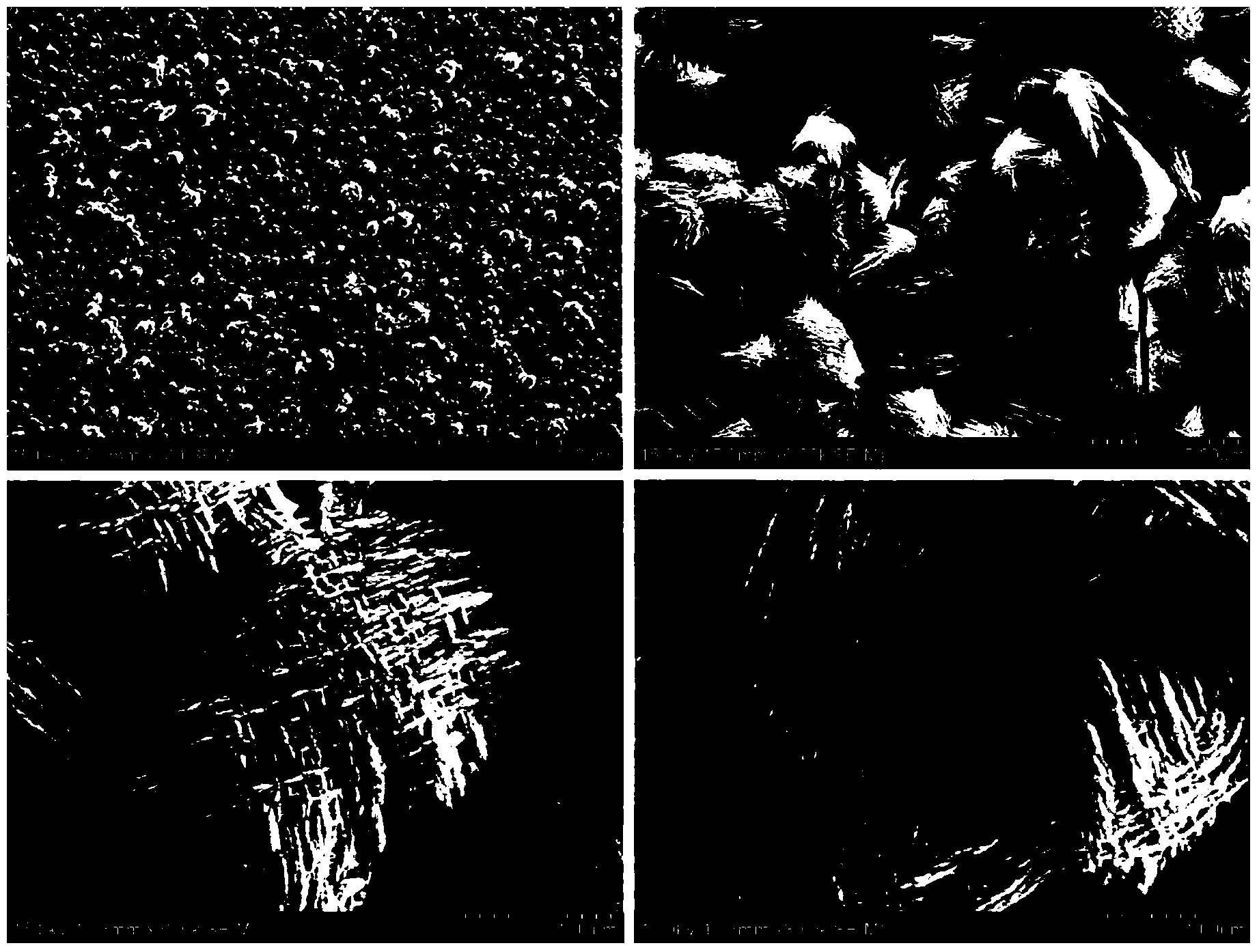

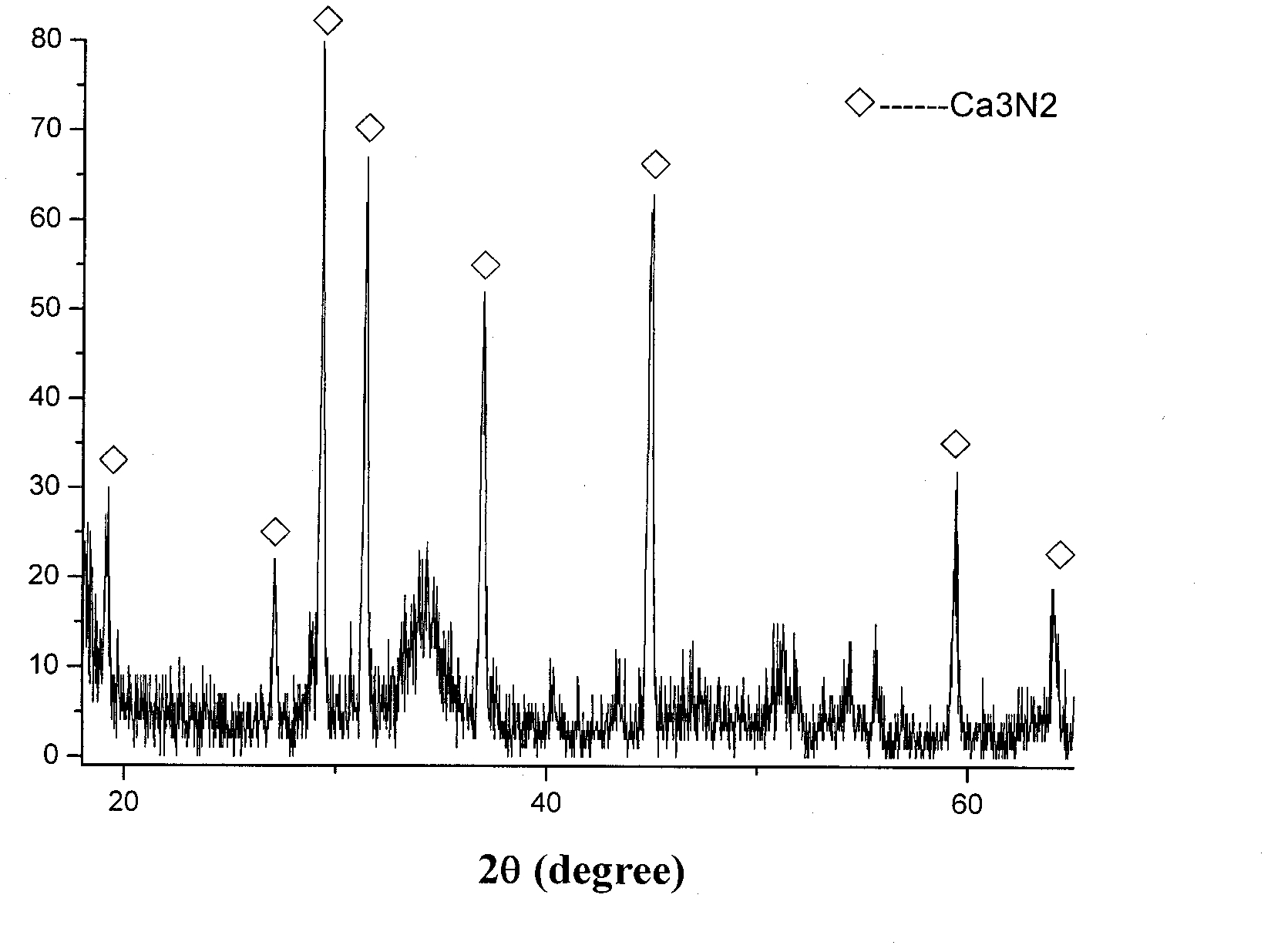

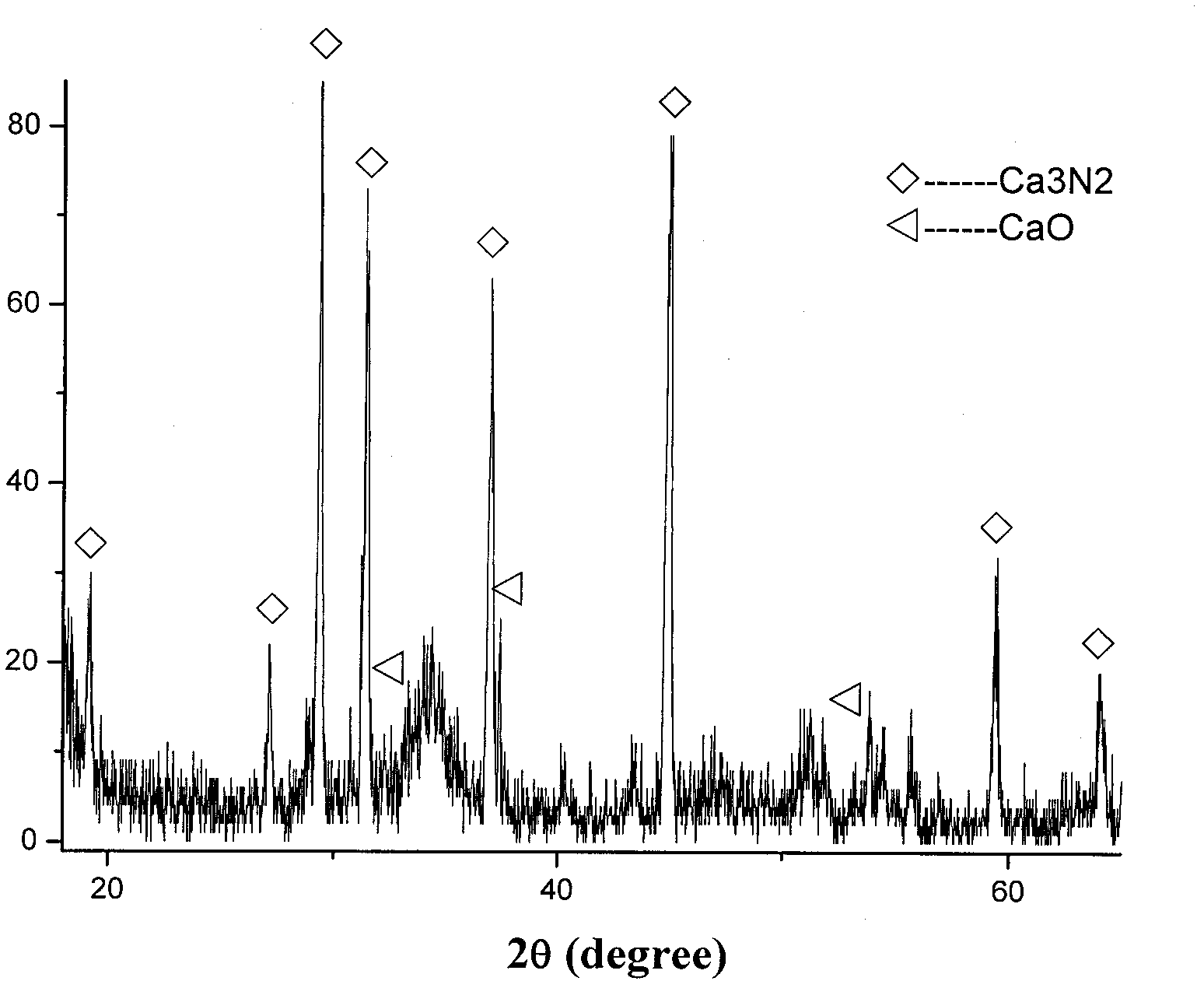

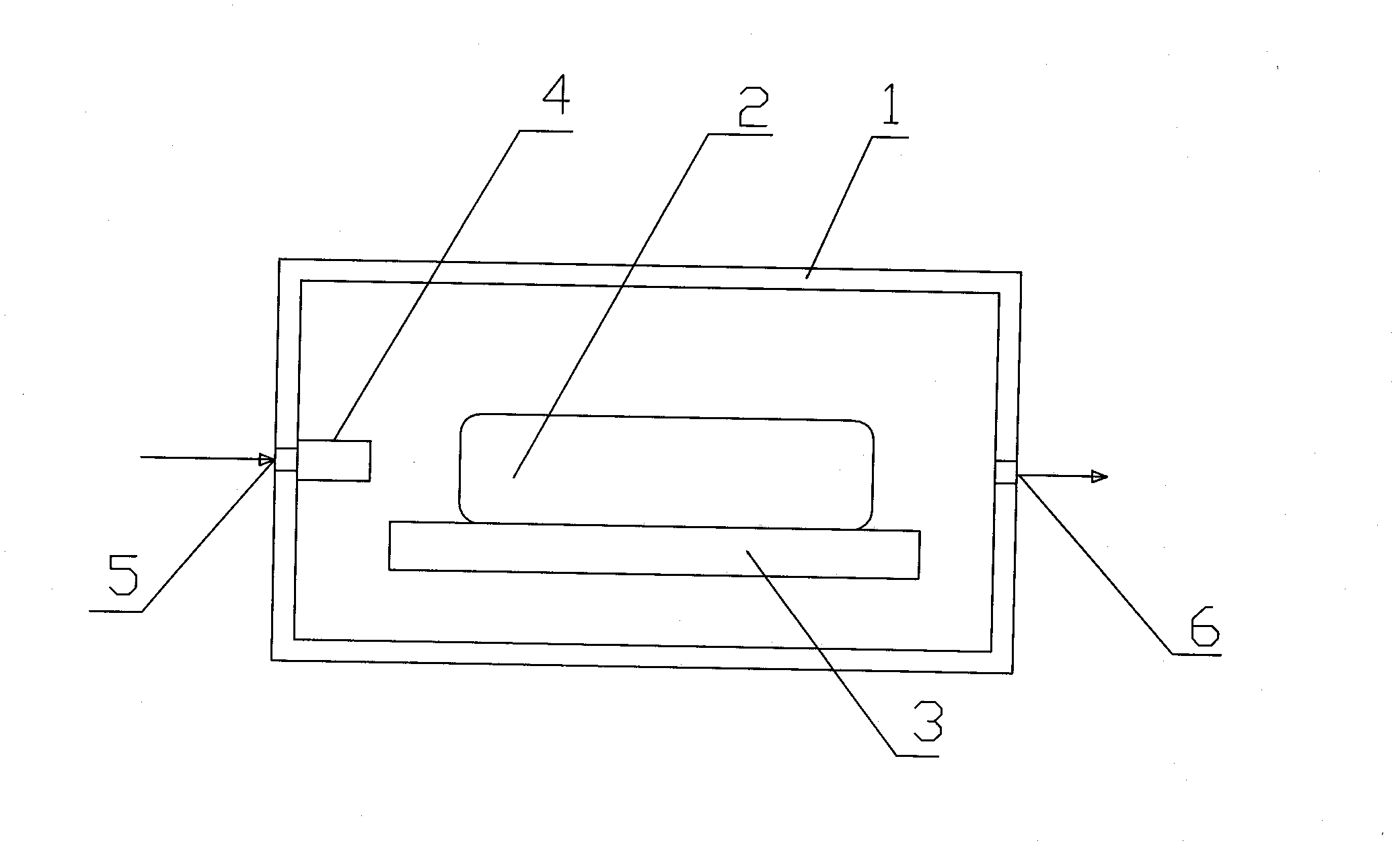

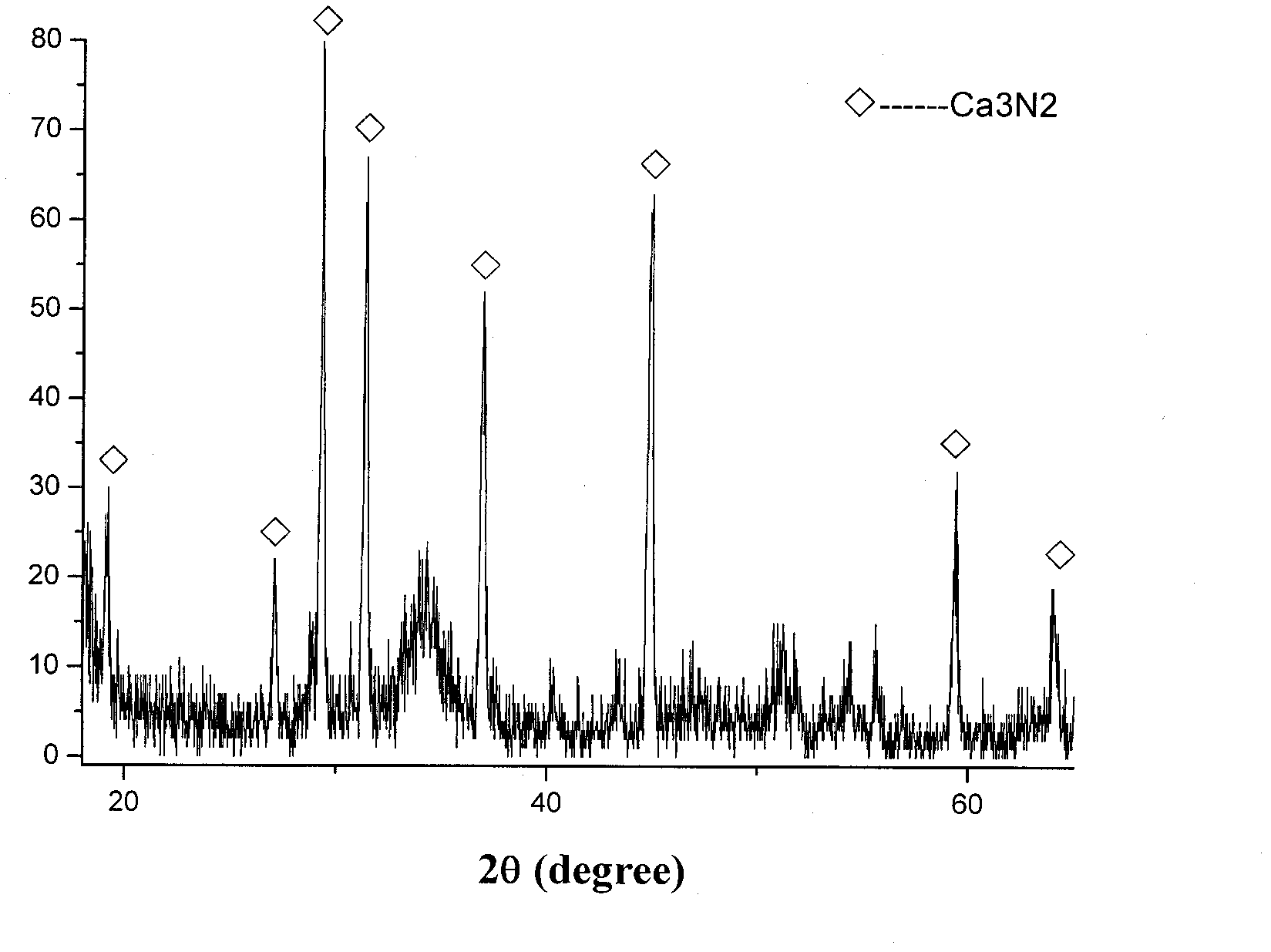

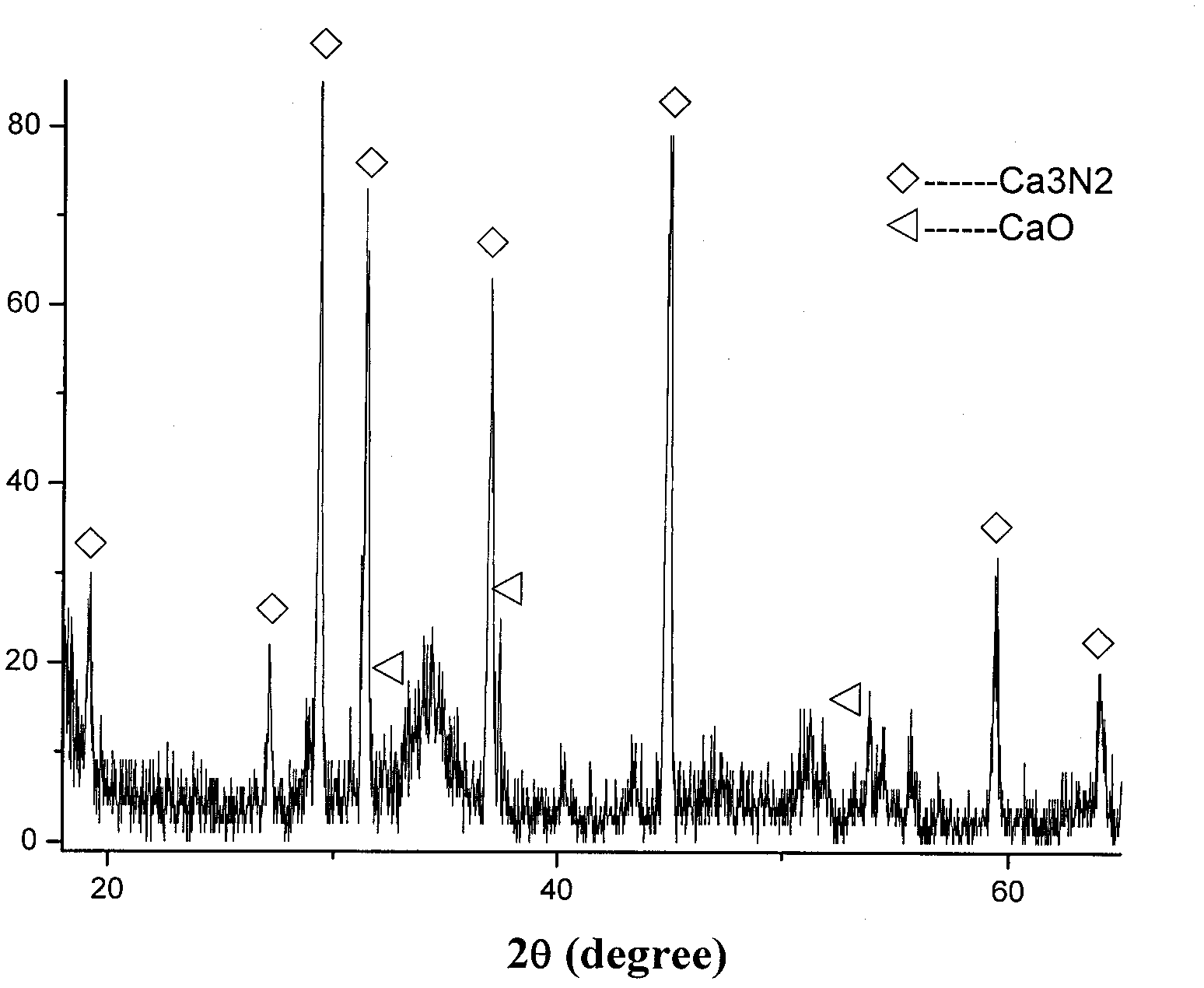

Method for producing calcium nitride powder

ActiveCN102417168AGrain ruleImprove performanceNitrogen-metal/silicon/boron binary compoundsNitrogenGraphite

The invention discloses a method for producing calcium nitride powder. The method comprises the following steps: adding the following components by weight percent: 30-50% of metal calcium powder, 30-50% of diluting agent and 10-20% of additive, wherein the metal calcium powder is used as a raw material; placing a proportioned mixture in a polyurethane tank to carry out ball milling for 1-4 hours, and sieving with a screen after ball milling; putting the mixture powder in a graphite boat, and then placing the graphite boat in a self-propagating reactor; vacuumizing to 400-600 Pa, and then introducing nitrogen, maintaining the pressure in the self-propagating reactor to be 4-8MPa, igniting and carrying out self-propagating synthesis; and when the pressure in the self-propagating reactor is reduced to 4-8MPa, finishing the self-propagating reaction, releasing the gas in the reactor, and then introducing nitrogen to the self-propagating reactor for 1-5 minutes, and opening the reactor so as to obtain the calcium nitride powder finished product. The calcium nitride powder prepared by using the method disclosed by the invention has wide raw material resources, high phase content and high purity; the method disclosed by the invention has simple and reliable process; and by using the method, energy is saved.

Owner:烟台同立高科新材料股份有限公司

Method for producing hexagonal boron nitride single crystal and hexagonal boron nitride single crystal

InactiveUS7815733B2Quality improvementSmall sizeFrom gel stateFrom solid stateHexagonal boron nitrideNitrogen

A method of growing hexagonal boron nitride single crystal is provided. Hexagonal boron nitride single crystal is grown in calcium nitride flux by heating, or heating and then slowly cooling, boron nitride and a calcium series material in an atmosphere containing nitrogen. Bulk hexagonal boron nitride single crystal can thereby successfully be grown.

Owner:NGK INSULATORS LTD +1

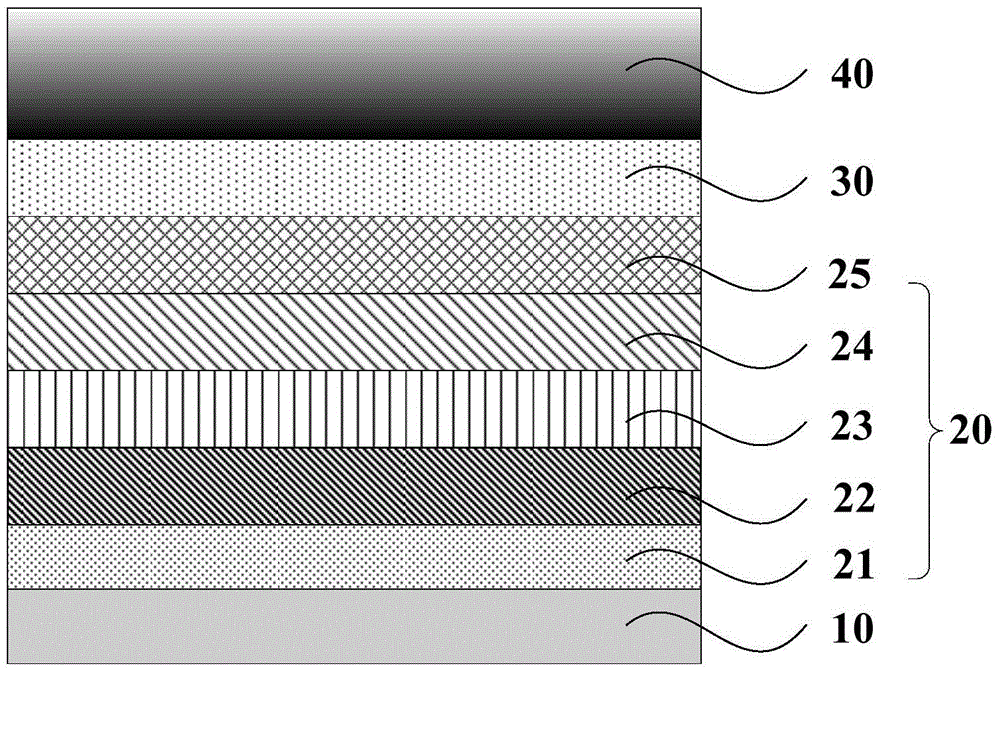

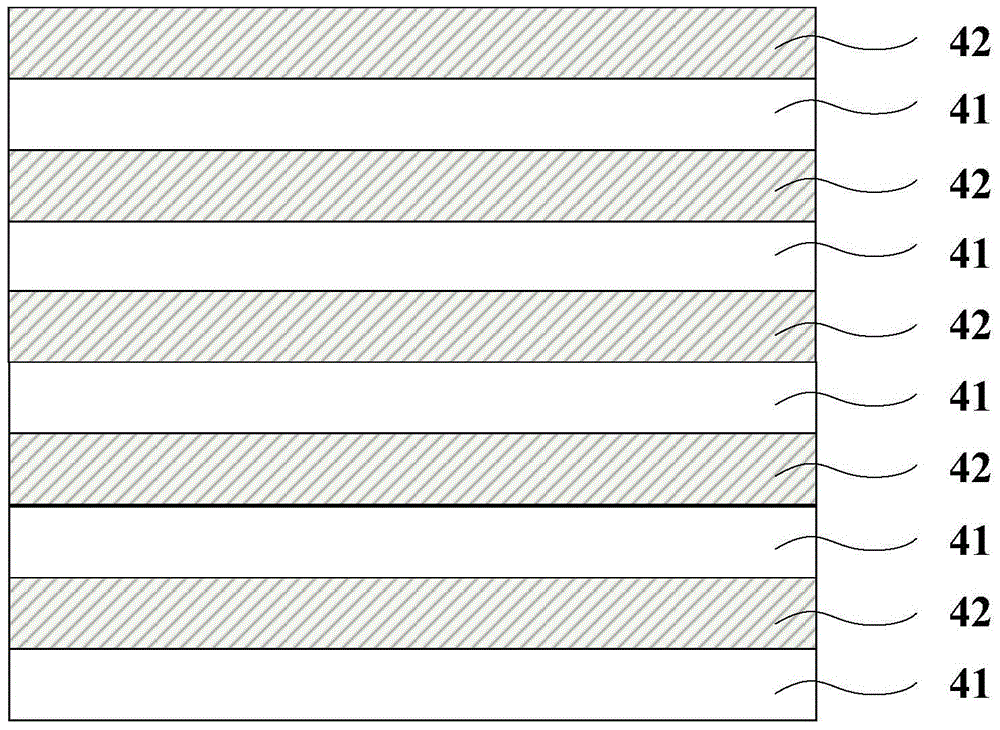

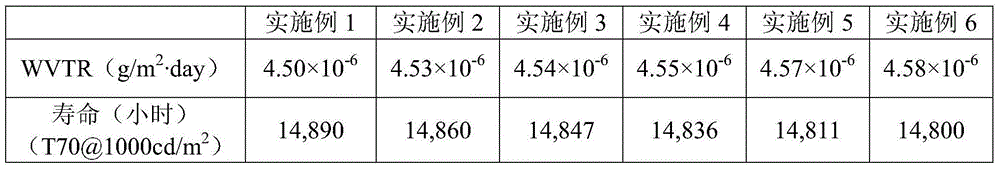

Organic electroluminescent device and preparation method thereof

InactiveCN104882560AReduce erosionExtend your lifeSolid-state devicesSemiconductor/solid-state device manufacturingAlkaline earth metalWater vapor

The invention provides an organic electroluminescent device which comprises an anode conductive substrate, an organic light emitting functional layer, a cathode layer and a packaging layer; wherein the anode conductive substrate, the organic light emitting functional layer, the cathode layer and the packaging layer are successively laminated. The packaging layer comprises an organic barrier layer and inorganic barrier layer which are successively laminated. The organic barrier layer is made of a Hydrogenated carbon nitrogen compound. The inorganic barrier layer is made of an alkaline earth metal nitride. The alkaline earth metal nitride is beryllium nitride, magnesium nitride, calcium nitride, strontium nitride or barium nitride. The packaging layer of the organic electroluminescent device has high obstruction for oxygen and water vapor and furthermore has a high stress releasing function. After packaging, the lowest water vapor transmission rate of the organic electroluminescent device after packaging is only 4.50*10<-6>g / m<2>*day, and the service life is more than 14800 hours (T70@1000cd / m<2>. The invention further provides a preparation method for the organic electroluminescent device. The preparation method is particularly suitable for packaging a flexible organic electroluminescent device.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

Refining agent for waste aluminum to improve performance of aluminum castings

InactiveCN108179298AEliminate microporosityImprove production yieldAluminum magnesium silicateHydroxypropyltrimethyl ammonium chloride chitosan

The invention belongs to the technical field of waste aluminum smelting refining agents, and particularly relates to a refining agent for waste aluminum to improve the performance of aluminum castings. The refining agent comprises, by weight, 3-6 parts of modified graphite, 6-10 parts of nanometer calcium nitride, 2-4 parts of titanium dioxide, 1-3 parts of ammonium tetraborate, 0.8-1.6 parts of stellerite powders, 0.4-0.8 parts of aluminum oxide, 0.1-0.3 parts of sulphur, 4-6 parts of H-mordenite powders, and 0.1-0.3 parts of aluminum magnesium silicate; the modified graphite is modified by 2-hydroxypropyltrimethyl ammonium chloride chitosan as a modifying agent. Compared with the prior art, the refining agent for the waste aluminum to improve the performance of the aluminum castings hasthe advantages that the refining agent can obtain high-quality waste aluminum alloy molten fluid and reduce the microporosity of the obtained castings, and mechanical properties of the refining agentcan also be increased significantly.

Owner:安徽玉成光华铝业有限公司

Plant growth regulator and preparation method as well as application thereof

ActiveCN103583568AWide time rangeAvoid repeated sprayingBiocidePlant growth regulatorsEffective actionPotassium

The invention belongs to the technical field of fruit tree production, and relates to a plant growth regulator and a preparation method as well as application thereof. The plant growth regulator comprises lanolin as a matrix and 2.5-3 percent of GA(3+4+7), 2-5 percent of calcium nitride, 2.2-2.8 percent of boric acid, 1-5 percent of potassium nitride and 290-310 ppm of CCPU serving as ointment. The growth regulator is convenient to manufacture, the use method is simple, the nutrients required for development of fruits is fully guaranteed, the efficacy is lasting, the single fruit weight of pears is obviously improved, the weight is increased by 36.6 percent, the inherent quality of the fruits is not reduced, and the appearance quality is improved to a certain extent. Compared with the common plant growth regulators on the market, the plant growth regulator has the advantages that the single fruit weight of the pears is obviously increased, the content of mineral elements of the fruits is increased, and the problems of shorter effective action time and short shelf life of the pears after treatment of other plant growth regulators are solved.

Owner:NANJING AGRICULTURAL UNIVERSITY

Transparent ceramic material and preparation method thereof

The invention relates to a transparent ceramic material and a preparation method thereof. The transparent ceramic material comprises, by weight, 65-80 parts of silica, 15-25 parts of alumina, 0.3-0.5part of ferric oxide, 0.5-1 part of calcium oxide, 1-2 parts of potassium oxide, 1-4 parts of lanthana, 3-5 parts of magnesium oxide, 2-5 parts of lithium oxide, 2-4 parts of phosphorus trioxide and 6-8 parts of calcium nitride. The transparent ceramic material has the advantages of high light transmittance, few ceramic production processes, low energy consumption and low cost.

Owner:桂林市晟博科技服务有限公司

Magnesium alloy surface conversion coating treating fluid and treating process thereof

InactiveCN101824614AThe process is simple and easy to controlImprove corrosion resistanceMetallic material coating processesPhosphatePhosphoric acid

The invention provides a magnesium alloy surface conversion coating treating fluid and a treating process thereof. The treating fluid takes water as a solvent, and per liter of the treating fluid has 0.8-1.2g of calcium oxide, 6-10ml of phosphoric acid, 0-11g of accelerator calcium nitride, 0-1.5g of accelerator sodium metanitrobenzene sulfonate and 0-0.8g of solution stabilizer calcium nitrite. The process flow is as follows: degreasing, rinsing, converting, rinsing and drying, wherein the conversion temperature is 30-60 DEG C, and the conversion time is 20-40 min. Due to the treatment process, a delicate and uniform phosphate conversion coating with good protection performance can be formed on the magnetism alloy surface. The treating fluid takes calcium salts as the main component, has the advantages of safety, environment protection and wide application, can be used in independent protection (immersion oil, grease, wax, and the like), and can be used as protection among working procedures and base for organic coatings such as paint, doup and the like. The conversion coating formed by the treating fluid has strong adhesive force and stable components, and can improve anti-corrosion performance of magnetism alloy parts and prolong the service life thereof.

Owner:JILIN UNIV

Method for calcium nitride synthesis

InactiveUS7141228B2Rapid productionAvoid small quantitiesNitrogen-metal/silicon/boron binary compoundsNitrogenAlloy

The invention concerns a method for calcium nitride synthesis which consists in spraying in form of droplets, by means of a sprayer, a molten zinc-calcium alloy into a reactor containing nitrogen at high temperature. The resulting calcium nitride is collected in a collector unit at the lower part of the reactor. The zinc contained in the droplets is evaporated and condensed on the cooled walls of the reactor and can be reused for preparing another alloy. The zinc-calcium alloy is obtained by electrolysis of calcium chloride in an electrolytic cell whereof the cathode is a solution containing molten zinc.

Owner:FRANCOIS LACOSTE

Blast furnace tapping channel main channel castable

The invention relates to the technical field of refractory materials, in particular to a blast furnace tapping channel main channel castable which comprises the following components in parts by mass: 20-30 parts of alumina particles, 30-40 parts of brown fused alumina, 10-25 parts of silicon carbide, 5-10 parts of alumina micro powder, 1-4 parts of high-alumina cement, 1-4 parts of carbon, 0-3 parts of calcium nitride fine powder, 0.1-0.5 part of a dispersing agent and 0.1-1 part of an antioxidant. By changing the components and the proportion of the raw materials, the problems that in the prior art, in the preparation process of the main runner castable of the blast furnace tapping channel, the temperature is suddenly changed, so that an iron runner material is damaged, and the scouring resistance of the tapping channel to high-temperature molten iron is caused are solved.

Owner:北京利尔高温材料股份有限公司

Method for producing calcium nitride powder

The invention discloses a method for producing calcium nitride powder. The method comprises the following steps: adding the following components by weight percent: 30-50% of metal calcium powder, 30-50% of diluting agent and 10-20% of additive, wherein the metal calcium powder is used as a raw material; placing a proportioned mixture in a polyurethane tank to carry out ball milling for 1-4 hours, and sieving with a screen after ball milling; putting the mixture powder in a graphite boat, and then placing the graphite boat in a self-propagating reactor; vacuumizing to 400-600 Pa, and then introducing nitrogen, maintaining the pressure in the self-propagating reactor to be 4-8MPa, igniting and carrying out self-propagating synthesis; and when the pressure in the self-propagating reactor is reduced to 4-8MPa, finishing the self-propagating reaction, releasing the gas in the reactor, and then introducing nitrogen to the self-propagating reactor for 1-5 minutes, and opening the reactor so as to obtain the calcium nitride powder finished product. The calcium nitride powder prepared by using the method disclosed by the invention has wide raw material resources, high phase content and high purity; the method disclosed by the invention has simple and reliable process; and by using the method, energy is saved.

Owner:烟台同立高科新材料股份有限公司

Corrosion-resistant engineering polymer material and preparation method thereof

The invention discloses a corrosion-resistant engineering polymer material and a preparation method thereof. The material is prepared from the following components in parts by weight: 18-23 parts of polyether ether ketone resin, 7-11 parts of polyacrylonitrile, 5-8 parts of polytrifluorochloroethylene, 4-7 parts of polyvinyl cinnamate, 4-6 parts of polyethylene glycol dimethacrylate, 4-5 parts of glycidyl neodecanoate, 6-7 parts of polyglycerol polyricinoleate, 4-5 parts of chlorohydrin rubber, 5-8 parts of trioctyl citrate and 3-4 parts of calcium nitride. The preparation method comprises the following steps: (1) adding the components into a stirring machine to be mixed and stirred; (2) performing melt extrusion on the uniformly stirred components obtained in the step (1), pelletizing, and cooling to obtain the corrosion-resistant engineering polymer material. The prepared corrosion-resistant engineering polymer material is resistant to acid and alkali, as well as bending, and wide in the application range.

Owner:苏州凯欧曼新材料科技有限公司

Method for calcium nitride synthesis

InactiveUS20050118087A1Produce in largeAvoid small quantitiesNitrogen-metal/silicon/boron binary compoundsNitric oxideNitrogenAlloy

The invention concerns a method for calcium nitride synthesis which consists in spraying in form of droplets, by means of a sprayer, a molten zinc-calcium alloy into a reactor containing nitrogen at high temperature. The resulting calcium nitride is collected in a collector unit at the lower part of the reactor. The zinc contained in the droplets is evaporated and condensed on the cooled walls of the reactor and can be reused for preparing another alloy. The zinc-calcium alloy is obtained by electrolysis of calcium chloride in an electrolytic cell whereof the cathode is a solution containing molten zinc.

Owner:FRANCOIS LACOSTE

A kind of preparation method of zinc phosphate chemical conversion film with hierarchical structure

ActiveCN103924226BImprove performanceImprove corrosion resistanceMetallic material coating processesEtchingPhosphoric acid

The invention relates to a preparation method of a zinc phosphate chemical conversion coating in a hierarchical structure. The preparation method of the zinc phosphate chemical conversion coating comprises the following steps: preparing a chemical conversion basis solution A, wherein concentration of zinc oxide is 20-28g / L, the concentration of nitric acid is 25-35ml / L, the concentration of phosphoric acid is 10-15ml / L, the concentration of calcium nitride is 5-20g / L, and the concentration of critic acid is 18-22g / L; adding iron powder in to the chemical conversion basis solution, and curing for 12-24 hours at room temperature, so that a curing liquid A1 is obtained; carrying out acidic etching and activation on a stainless steel matrix; placing the activated matrix into the curing liquid A1, carrying out chemical conversion for 15-45 minutes at the temperature of 65-75 DEG C and pH value of 2.5-3.0, and carrying out water washing, so that the zinc phosphate chemical conversion coating is obtained. By adopting the preparation method of the zinc phosphate chemical conversion coating, a uniform dense conversion coating composed of spherical zinc phosphate aggregate which is 2-4 microns in size and composed of nanocrystals is prepared on the surface of medical stainless steel, wettability between a coating layer and simulated body fluid (SBF) is good, and corrosion resistance is good.

Owner:SHANDONG UNIV

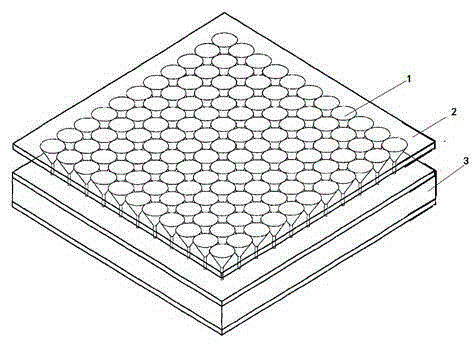

A kind of preparation method of smooth blocking type tft anodized aluminum oxide insulating layer

InactiveCN108505051BDoes not affect the anodizing processAvoid formingAnodisationVacuum evaporation coatingNano structuringInsulation layer

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

UVA (ultraviolet a) power generation device

InactiveCN105207604AIncrease current densityImprove capture abilityPhotovoltaicsPhotovoltaic energy generationHigh energyUltraviolet

The invention relates to a UVA (ultraviolet a) power generation device. UVA is utilized as an energy source, and UVA light with high energy is converted into electric energy through a photoelectric effect; compared with a common solar power generation system, the UVA power generation device using UVA as the energy source has the advantages of large current density, relatively stable energy source and the like; a UVA capturing membrane is a complex adopting a graphene material and a silicon carbide or zinc oxide porous membrane, and has very strong capturing ability for UV rays; a fused quartz lens array has a very strong aggregation effect for UV light; a cobalt-free P-type calcium nitride has a good photoelectric converting effect.

Owner:蒋安为

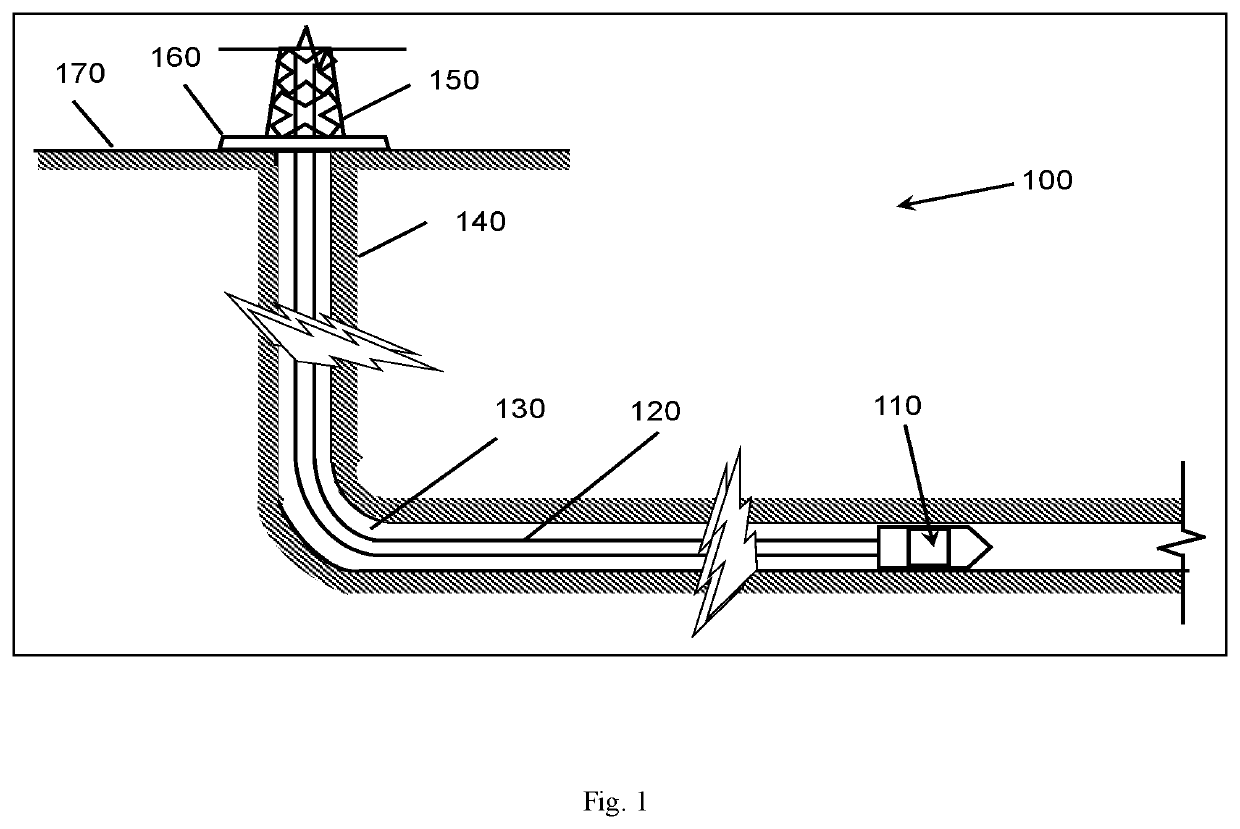

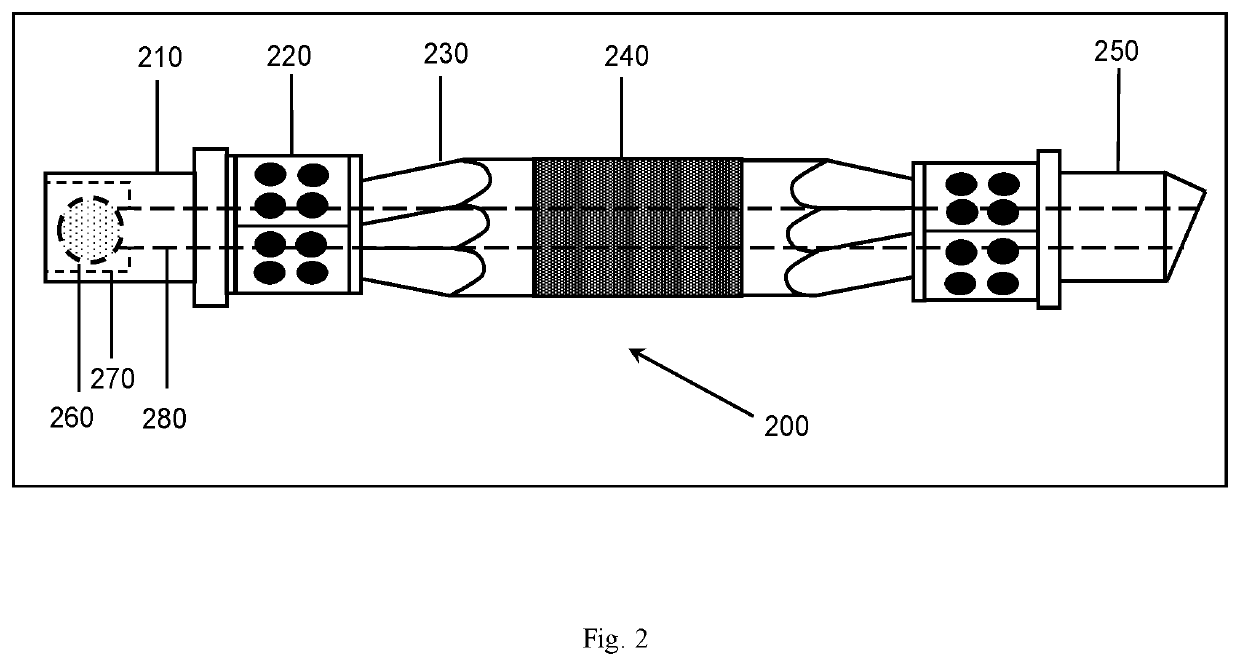

Downhole Tools Comprising Degradable Components

A component of a downhole tool utilized in oil and natural gas exploration and production comprises inorganic hydrolysable compound-containing materials. The inorganic hydrolysable compounds grant the component the degradability / dissolution in aqueous environment. The inorganic hydrolysable compounds include, but not are limited to, hydrolysable carbides, nitrides, and sulfides, such as aluminum carbide (Al4C3), calcium carbide (CaC2), magnesium carbide (Mg2C3 or MgC2), manganese carbide (Mn3C), aluminum nitride (AlN), calcium nitride (Ca3N2), magnesium nitride (Mg3N2), aluminum sulfide (Al2S3), aluminum magnesium carbide (AldMgC2), and aluminum zinc carbide (Al4Zn2C3).

Owner:JIANG WENHUI

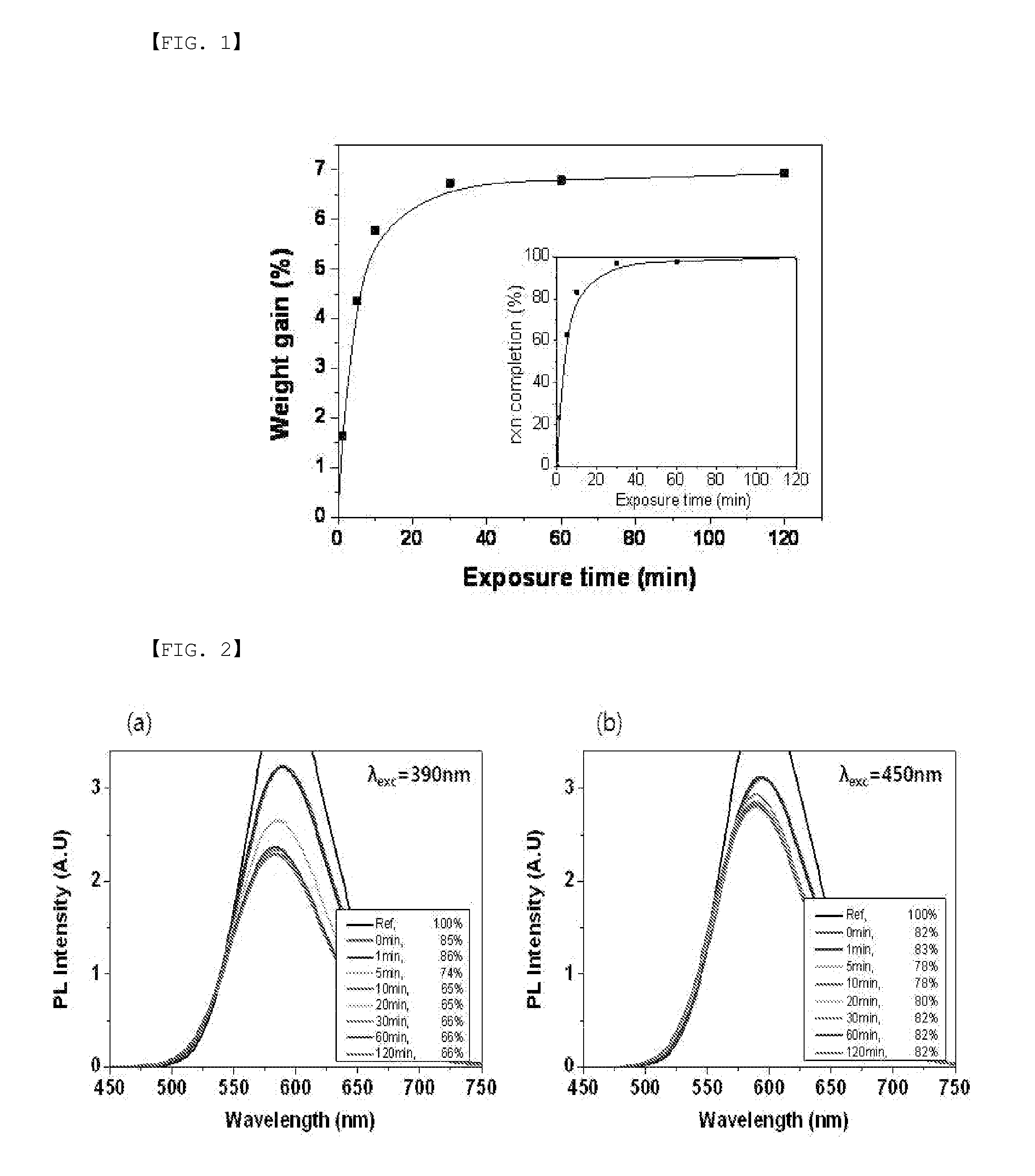

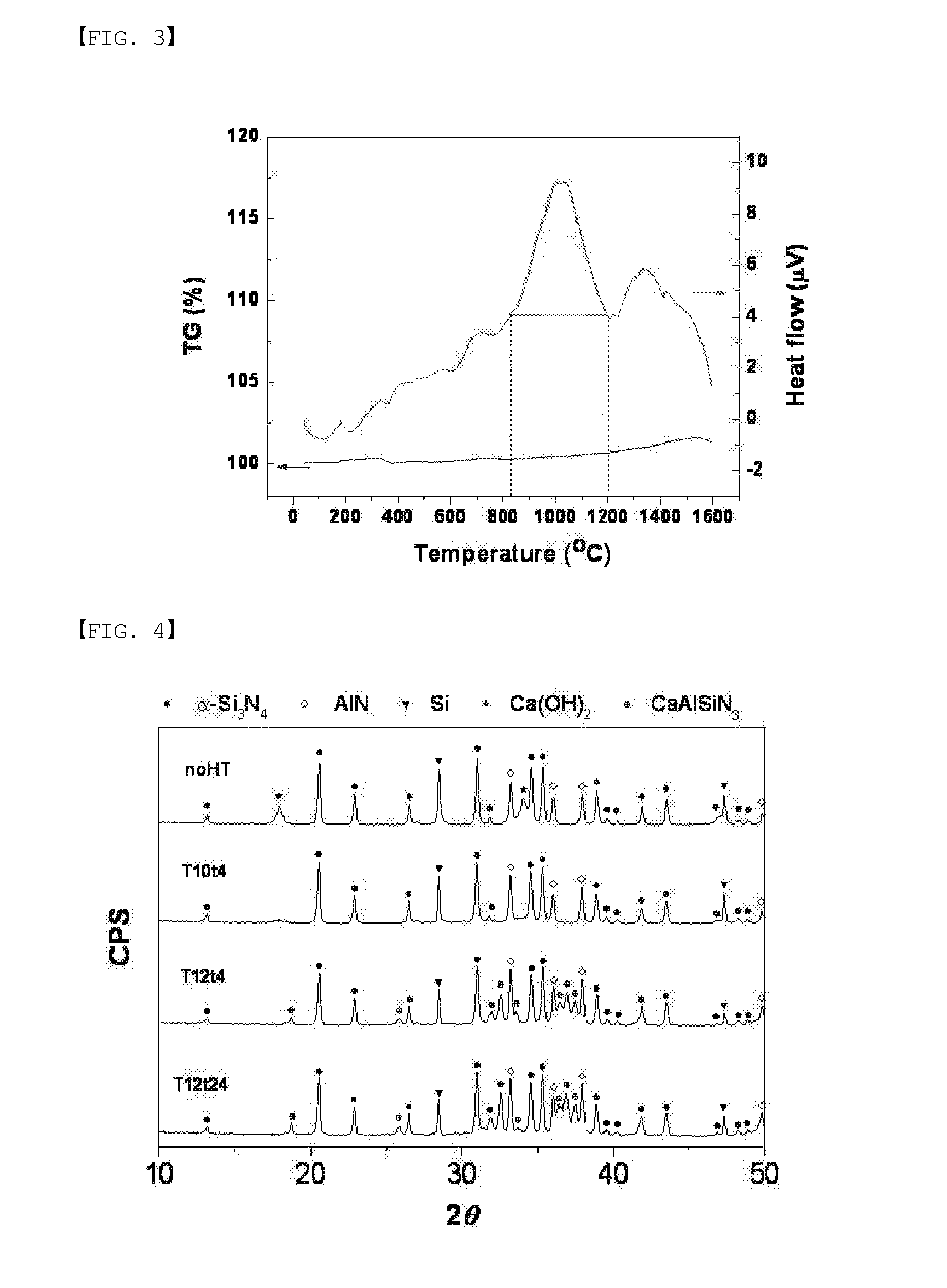

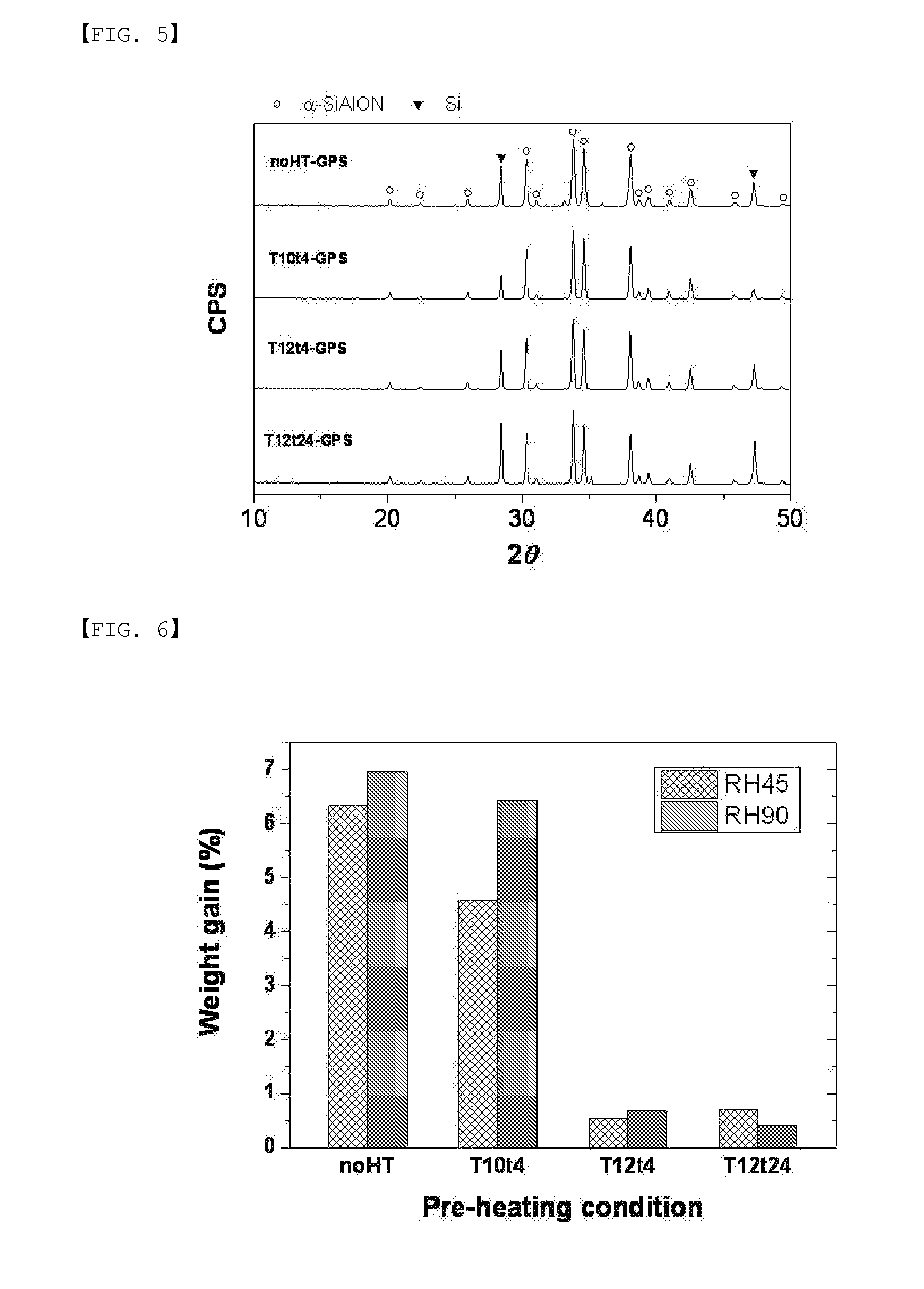

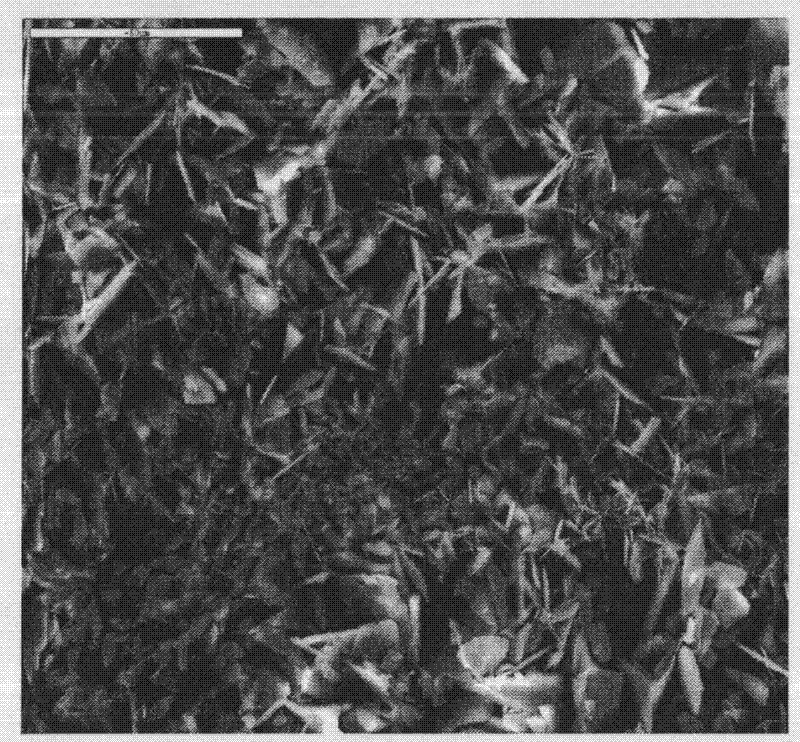

Method of stabilizing alph-sialon phosphor raw powder, alph-sialon phosphor composition obtained therefrom, and method of manufacturing alpha-sialon phosphor

Disclosed herein is a method of stabilizing alpha-sialon phosphor raw powder, including the steps of: mixing alpha-sialon phosphor raw powder including Si3N4, AlN, a rare-earth metal oxide and calcium nitride (Ca3N2) as a calcium source and having Composition Formula represented by CaxSi12−m−nAlm+nOnN16−n:Rey (here, Re is an activator and is at least one selected from the group consisting of Eu, Ce, Tb, Yb, Sm and Dy, 0.3≦m≦1.0, 0.02≦y≦0.15, m=2x+3y); and heat-treating the alpha-sialon phosphor raw powder to convert the calcium source into a Ca—Al—Si—N based compound. This method is advantageous in that a reliable alpha-sialon phosphor having high photoluminescence intensity can be manufactured regardless of weather, season, environment and the like.

Owner:KOREA INST OF MACHINERY & MATERIALS

Magnesium alloy surface conversion coating treating fluid and treating process thereof

InactiveCN101824614BThe process is simple and easy to controlImprove corrosion resistanceMetallic material coating processesPhosphatePhosphoric acid

The invention provides a magnesium alloy surface conversion coating treating fluid and a treating process thereof. The treating fluid takes water as a solvent, and per liter of the treating fluid has 0.8-1.2g of calcium oxide, 6-10ml of phosphoric acid, 0-11g of accelerator calcium nitride, 0-1.5g of accelerator sodium metanitrobenzene sulfonate and 0-0.8g of solution stabilizer calcium nitrite. The process flow is as follows: degreasing, rinsing, converting, rinsing and drying, wherein the conversion temperature is 30-60 DEG C, and the conversion time is 20-40 min. Due to the treatment process, a delicate and uniform phosphate conversion coating with good protection performance can be formed on the magnetism alloy surface. The treating fluid takes calcium salts as the main component, hasthe advantages of safety, environment protection and wide application, can be used in independent protection (immersion oil, grease, wax, and the like), and can be used as protection among working procedures and base for organic coatings such as paint, doup and the like. The conversion coating formed by the treating fluid has strong adhesive force and stable components, and can improve anti-corrosion performance of magnetism alloy parts and prolong the service life thereof.

Owner:JILIN UNIV

Nitrogen-containing semiconductor graphite and preparation method thereof

InactiveCN111986832AConductiveImprove conductivityCarbon-silicon compound conductorsCable/conductor manufactureMetal fiberCalcium nitride

The invention belongs to the technical field of preparation of nitrogen-containing semiconductor graphite and particularly relates to nitrogen-containing semiconductor graphite and a preparation method thereof. The objective of the invention is to solve problems that graphite preparation modes in the prior art are complex, nitrogen-containing semiconductor graphite is not contained, conductivity of existing graphite is not limited by materials, and conductivity is poor. According to the invention, the graphite comprises the following components: 10-20 parts of nitrogen source, 40-50 parts of graphite, 2-4 parts of nickel-coated carbon fiber carbon black, 2-6 parts of metal powder, 3-6 parts of metal fiber, 3-7 parts of carbon fiber, 2-4 parts of phosphor copper powder, 5-10 parts of a thickening agent, 3-6 parts of a dispersing agent and 2-5 parts of a preservative, and a nitrogen source comprises nitrogen, silicon nitride, magnesium nitride, calcium nitride and carbon nitride. The nickel-coated carbon fiber carbon black, the metal powder, the metal fiber, the carbon fiber and the phosphor copper powder all have conductivity. The preparation method is convenient to operate, nitrogen-containing semiconductor graphite can be prepared, and the conductivity of the graphite can be improved.

Owner:DATONG XINCHENG NEW MATERIAL CO LTD

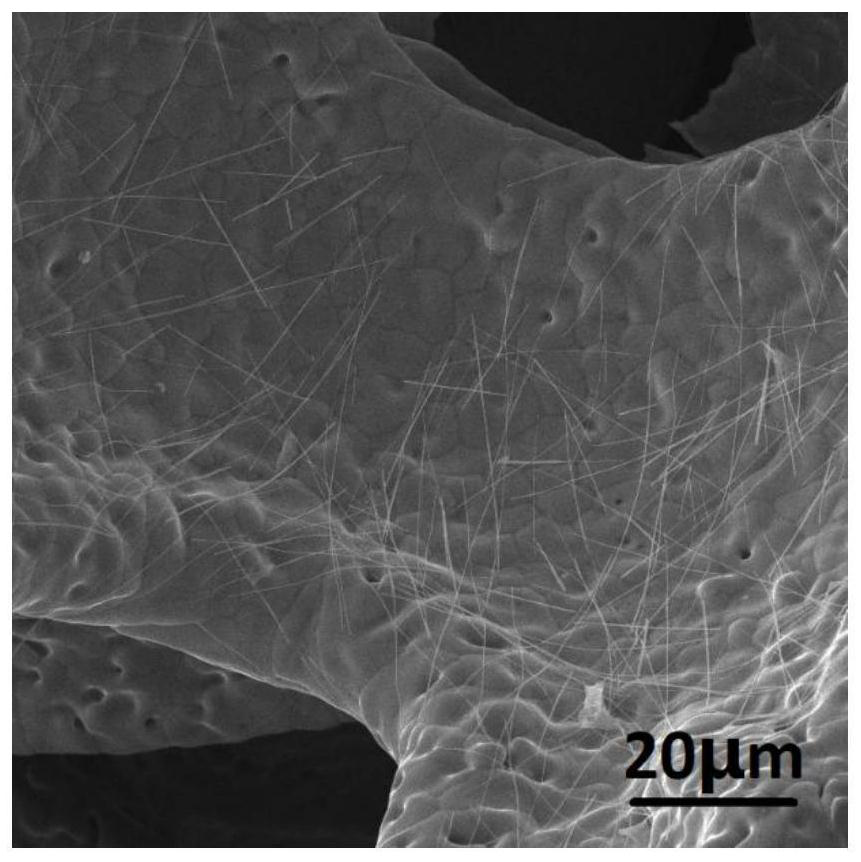

Electrolyte for Stable Lithium Metal Deposition and Its Application in Lithium Metal Batteries

ActiveCN111786019BAddressing inhomogeneityImproved deposition stabilityLi-accumulatorsOrganic electrolytesMetallic lithiumElectrolytic agent

The invention belongs to the field of lithium metal batteries, and specifically discloses an electrolyte for stable metal lithium deposition; an organic solution comprising conductive lithium salts, organic solvents and additives; the additives are nano-scale boron nitride, One or more of aluminum nitride, calcium nitride, magnesium nitride, silicon nitride, titanium nitride, vanadium nitride, tungsten nitride, niobium nitride, and tantalum nitride. The present invention also includes the application of the electrolyte and a lithium metal battery containing the electrolyte. The electrolyte solution of the invention has simple formula, low cost and is suitable for large-scale industrialization. The electrolyte solution of the present invention can realize uniform lithium deposition, effectively avoid lithium dendrites in the charging and discharging process, and greatly improve its cycle performance and safety performance. The electrolyte solution can be used in lithium-sulfur batteries, lithium-air batteries and other energy storage devices with metal lithium as the negative electrode to achieve long-term cycle stability.

Owner:CENT SOUTH UNIV

Preparation method of flat barrier-type TFT anodic aluminum oxide insulation layer

InactiveCN108505051ADoes not affect the anodizing processAvoid formingAnodisationVacuum evaporation coatingNano structuringInsulation layer

The invention belongs to the field of nano structure materials, particularly provides a preparation method of a flat barrier-type TFT anodic aluminum oxide insulation layer. After an aluminum membraneis plated in a magnetron sputtering manner, the secondary sputtering is performed directly under a vacuum condition, a thin layer of magnesium nitride, magnesium sulfide, magnesium oxide, calcium oxide, calcium peroxide, calcium nitride or calcium sulfide film is continuously plated on the surface of pure aluminum, so that the contact between the pure aluminum surface which is just plated and aircan be effectively prevented from rapidly forming an amorphous natural aluminum oxide film; and moreover, the secondarily-sputtered magnesium nitride, magnesium sulfide, magnesium oxide, calcium oxide, calcium peroxide, calcium nitride or calcium sulfide film contacts weak-acidic electrolyte, the film is hydrolyzed to generate trace alkaline substance dissolved in the weak-acidic electrolyte, sothat the subsequent anode oxidation process of the aluminum is not influenced; and not only can the highly-flat barrier-type anode aluminum oxide film be obtained, but also the instantaneous strippingrisk in the anode oxidation process can be avoided, the process is simple, and the cost is low.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com