Method for calcium nitride synthesis

一种合成工艺、氮化钙的技术,应用在氮化合物、氮-金属/硅/硼二元化合物、无机化学等方向,能够解决不适合大规模生产等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] According to the present invention, the synthesis of calcium nitride is accomplished by reacting nitrogen with molten zinc-calcium alloy in one reactor. The nitrogen is first heated to a temperature above or equal to the melting point of the zinc-calcium alloy.

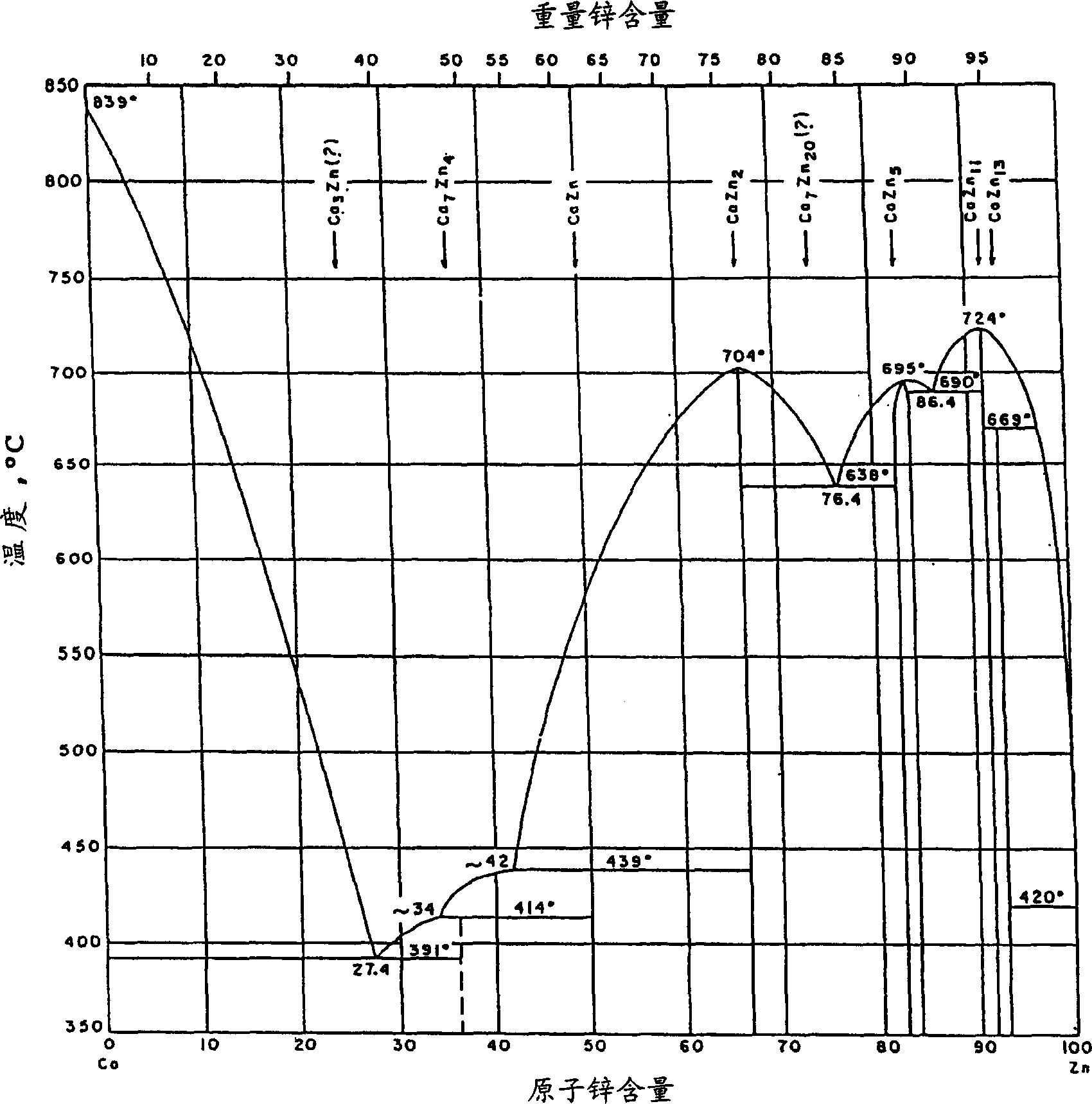

[0019] The use of zinc-calcium alloys as calcium raw materials in the nitriding process is of particular interest because, as taught by R.Juza et al. (Z.Anorg.Chem., 239 p273, 1938), zinc nitride (Ca 3 N 2 ) cannot be formed by the direct reaction of hot metallic zinc on nitrogen. And, as in figure 1 As shown in the figure of , zinc-calcium alloys with higher calcium content have a much lower melting point than pure calcium. The zinc-calcium alloy preferably has an atomic calcium content of greater than or equal to 50%, more particularly between 50% and 80% atomic calcium.

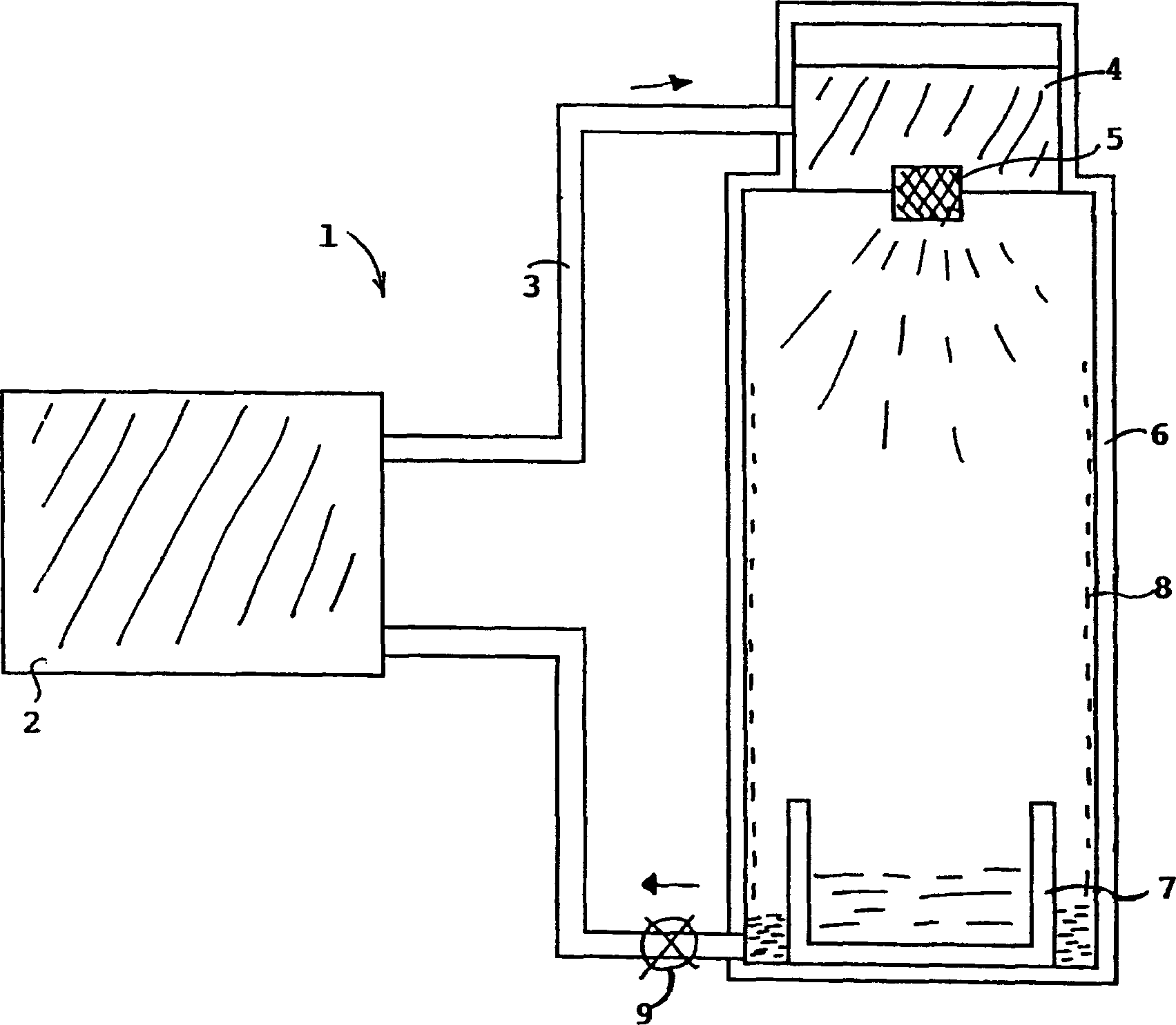

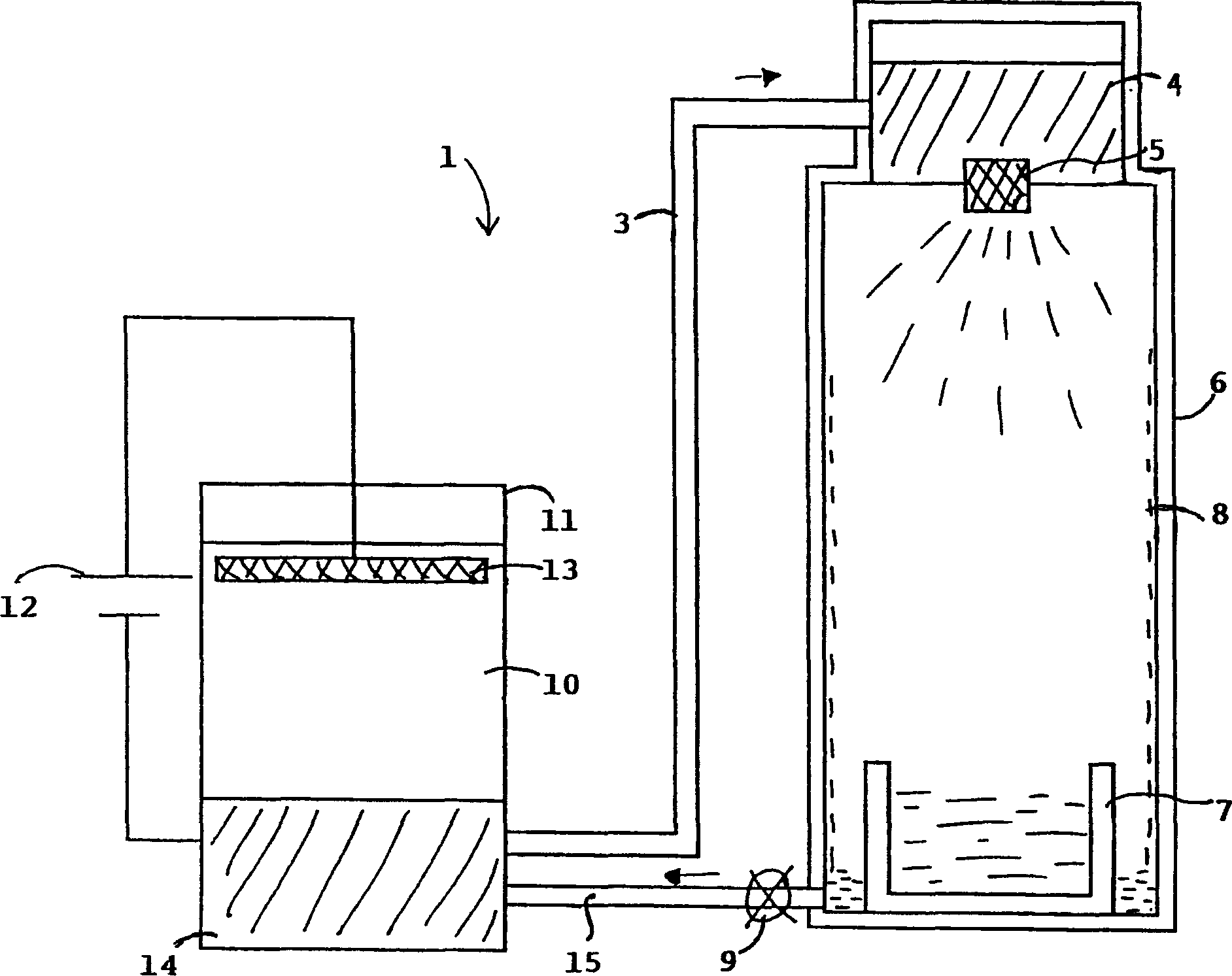

[0020] In a specific example, such as figure 2 As shown, an apparatus 1 capable of performing the synthesis of calcium nitride comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com