Organic electroluminescent device and preparation method thereof

An electroluminescent device and luminescent technology, which is applied in the fields of electric solid-state devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problem that the barrier performance of plastic substrates cannot reach OLED packaging, flexible packaging cannot be realized, and the surface of the cathode layer is damaged, etc. problems, to achieve the effect of easy large-area preparation and mass production, good bending stress and thermal stress, and reduced erosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

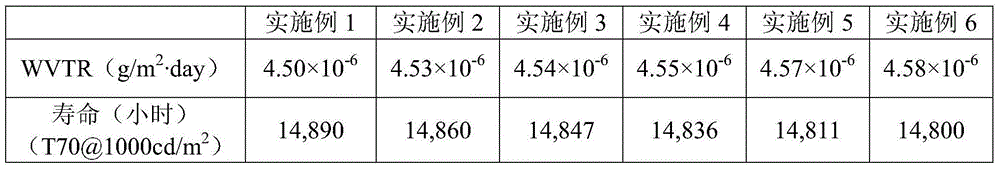

Embodiment 1

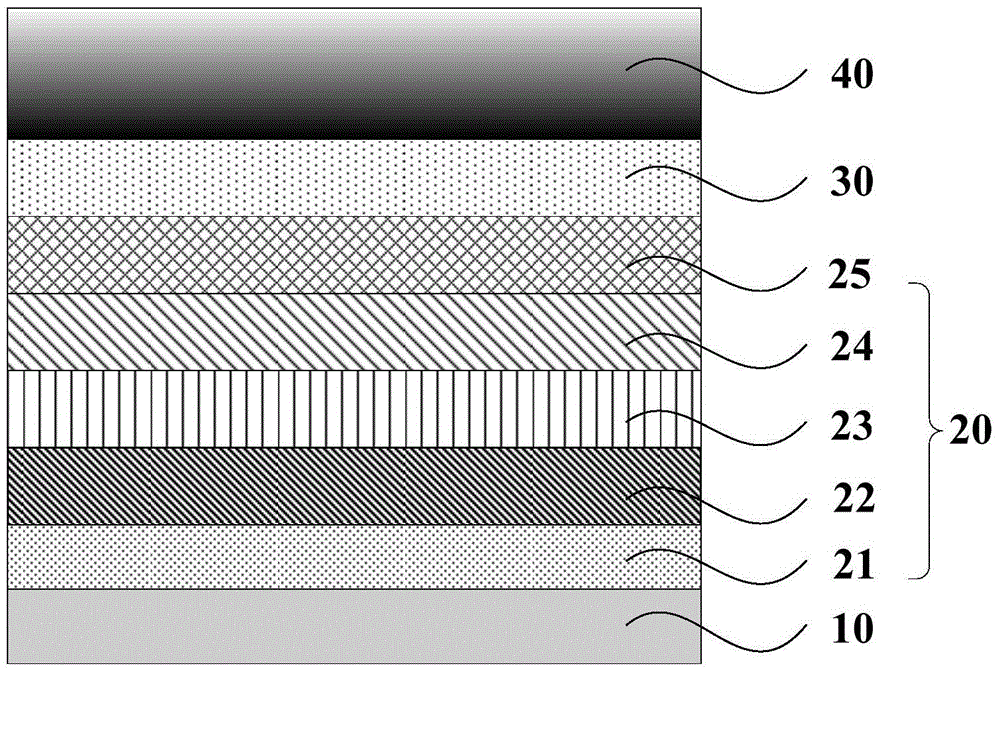

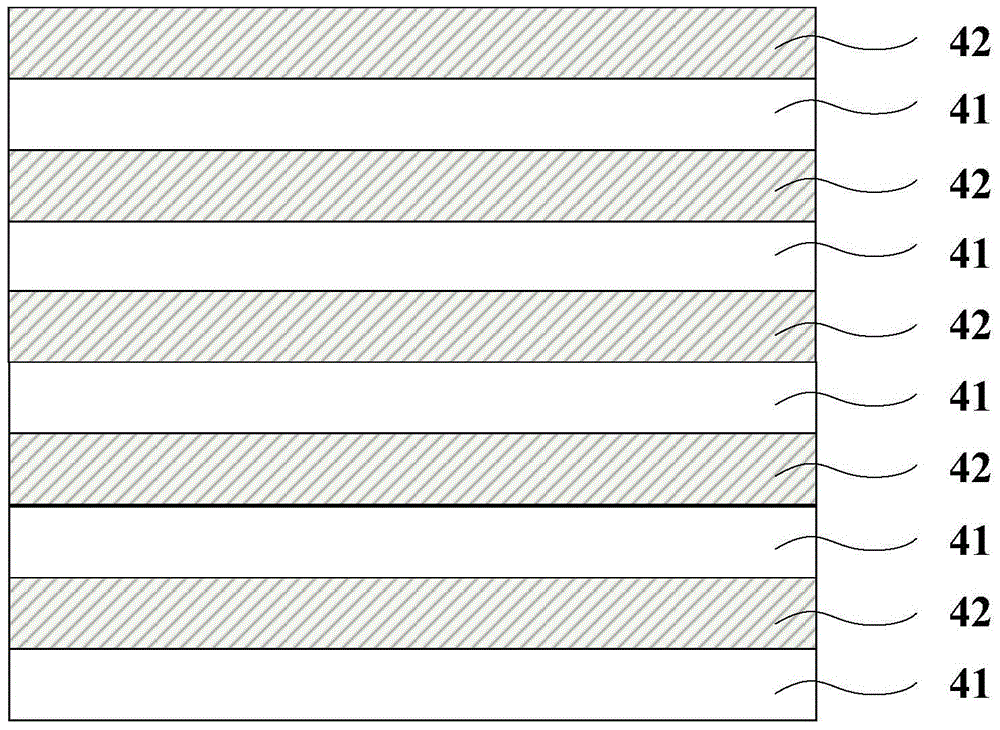

[0038] figure 1 It is a schematic structural diagram of an organic electroluminescent device provided in this embodiment. like figure 1 As shown, the organic electroluminescent device includes a conductive glass substrate 10 , an organic light-emitting functional layer 20 , a cathode layer 30 and an encapsulation layer 40 which are stacked sequentially from bottom to top. Wherein, the organic light-emitting functional layer 20 includes a hole injection layer 21 , a hole transport layer 22 , a light-emitting layer 23 , an electron transport layer 24 and an electron injection layer 25 stacked sequentially from bottom to top. figure 2 Yes figure 1 Schematic diagram of the structure of the encapsulation layer, such as figure 2 As shown, the encapsulation layer 40 includes an organic barrier layer 41 and an inorganic barrier layer 42 stacked in sequence, the organic barrier layer 41 and the inorganic barrier layer 42 form a structural unit, and the encapsulation layer 40 is co...

Embodiment 2

[0054] A method for preparing an organic electroluminescent device, comprising the following steps:

[0055] (1), (2) are the same as embodiment 1;

[0056] (3) Preparation of encapsulation layer:

[0057] (a) Preparation of organic barrier layer: The organic barrier layer was prepared on the surface of the cathode layer by plasma-enhanced chemical vapor deposition; CH 4 and N 2 As a reactive gas, control CH 4 The flow is 12sccm, N 2 The flow rate is 10sccm, the working pressure is 20Pa, and the RF power is 0.3W / cm 2 , the deposition thickness is 550nm;

[0058] (b) Preparation of the inorganic barrier layer: the inorganic barrier layer was prepared on the surface of the organic barrier layer by atomic layer deposition, the working pressure was controlled at 10Pa, and the deposition temperature was 40°C; the material of the inorganic barrier layer was Mg 3 N 2 ; Bis(ethylcyclopentadiene) beryllium (Mg(CpEt) 2 ) and NH 3 As a precursor, N 2 As carrier gas; controls Be...

Embodiment 3

[0063] A method for preparing an organic electroluminescent device, comprising the following steps:

[0064] (1), (2) are the same as embodiment 1;

[0065] (3) Preparation of encapsulation layer:

[0066] (a) Preparation of organic barrier layer: The organic barrier layer was prepared on the surface of the cathode layer by plasma-enhanced chemical vapor deposition; CH 4 and N 2 As a reactive gas, control CH 4 The flow rate is 8sccm, N 2 The flow rate is 10sccm, the working pressure is 60Pa, and the RF power is 0.4W / cm 2 , the deposition thickness is 450nm;

[0067] (b) Preparation of the inorganic barrier layer: the inorganic barrier layer was prepared on the surface of the organic barrier layer by atomic layer deposition, the working pressure was controlled at 50 Pa, and the deposition temperature was 60°C; the material of the inorganic barrier layer was Ca 3 N 2 ; using bis(ethylcyclopentadiene) calcium (Ca(CpEt) 2 ) and NH 3 As a precursor, N 2 As carrier gas; cont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Deposition thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com