Method for producing calcium nitride powder

A technology of calcium nitride powder and calcium metal, which is applied in the production of calcium nitride powder and the field of calcium nitride production, can solve the problems of expensive raw materials, achieve low cost, stable performance, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

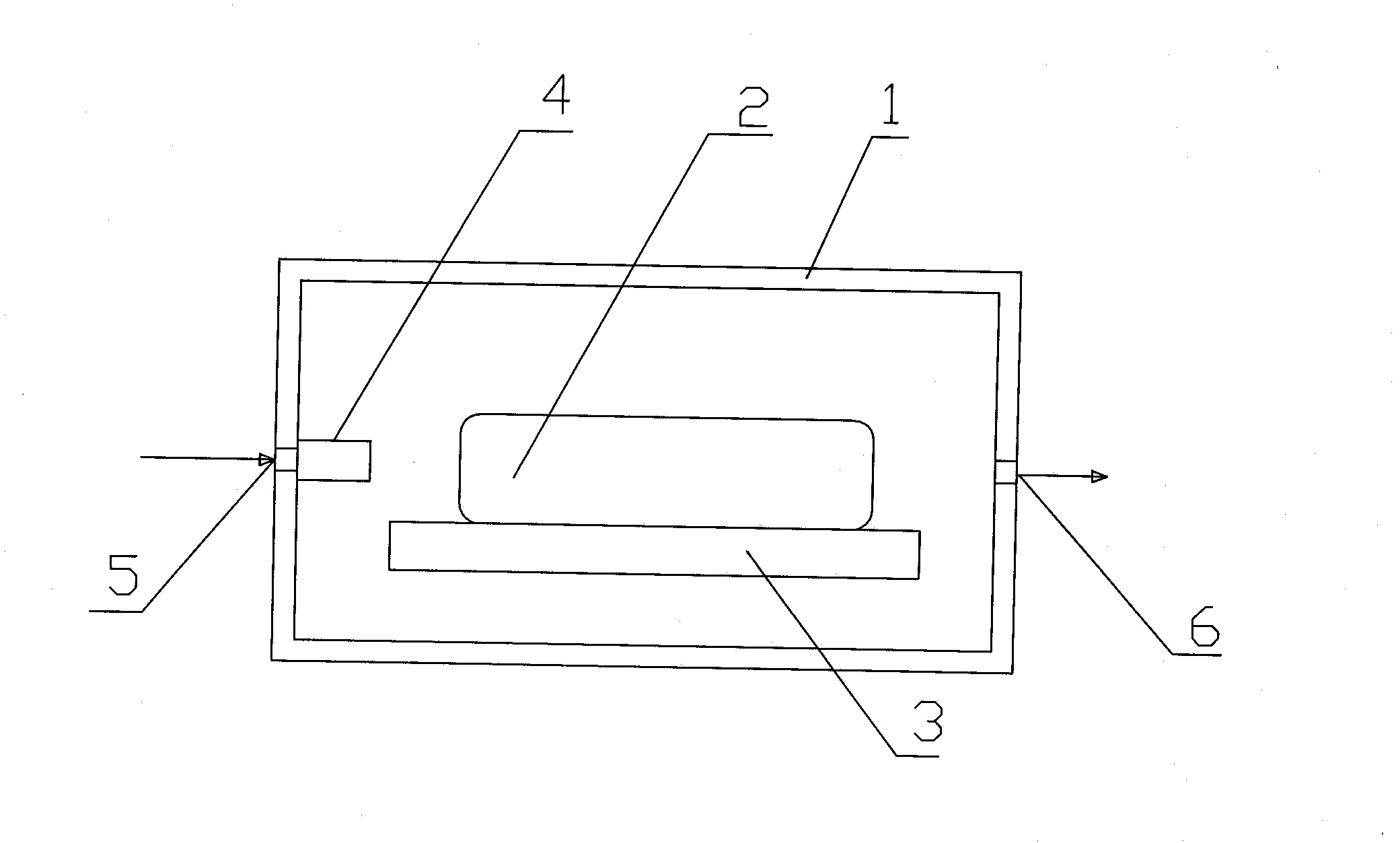

Image

Examples

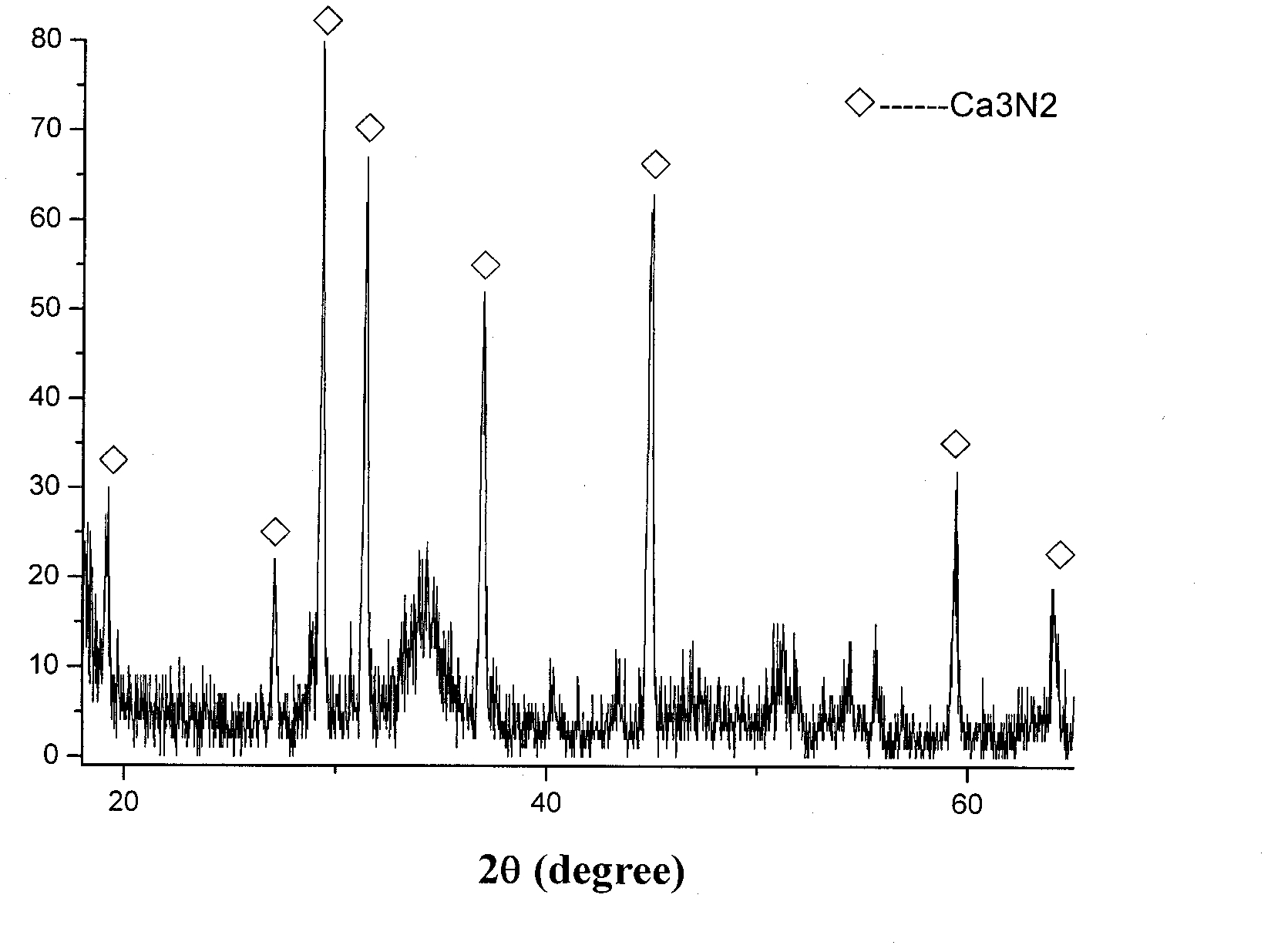

Embodiment 1

[0034] Take by weighing 1000 grams of calcium metal powder (accounting for 50% of the total weight of raw materials) by weight, and the particles of calcium metal powder are 100 orders, with a purity>99%; 800 grams of calcium nitride powder (accounting for 50% of the total weight of raw materials) 40%), the calcium nitride powder has an average particle size of 20 μm and a purity of >98%; weigh ammonium carbonate (NH 4 ) 2 CO 3 200 grams (accounting for 10% of raw material gross weight), after mixing, with silicon nitride (chemical formula: Si3N4) ball is ball milling medium, and silicon nitride ball diameter is 20 millimeters, is placed in the polyurethane tank of 8 liters, above-mentioned raw material and The weight ratio of the silicon nitride grinding balls is 1:10, and they are placed on a pot mill for dry ball milling for 1 hour. The pot mill in this embodiment is produced by GM8 from Zibo Qimingxing New Material Co., Ltd., and the mechanized dry mixing is carried out....

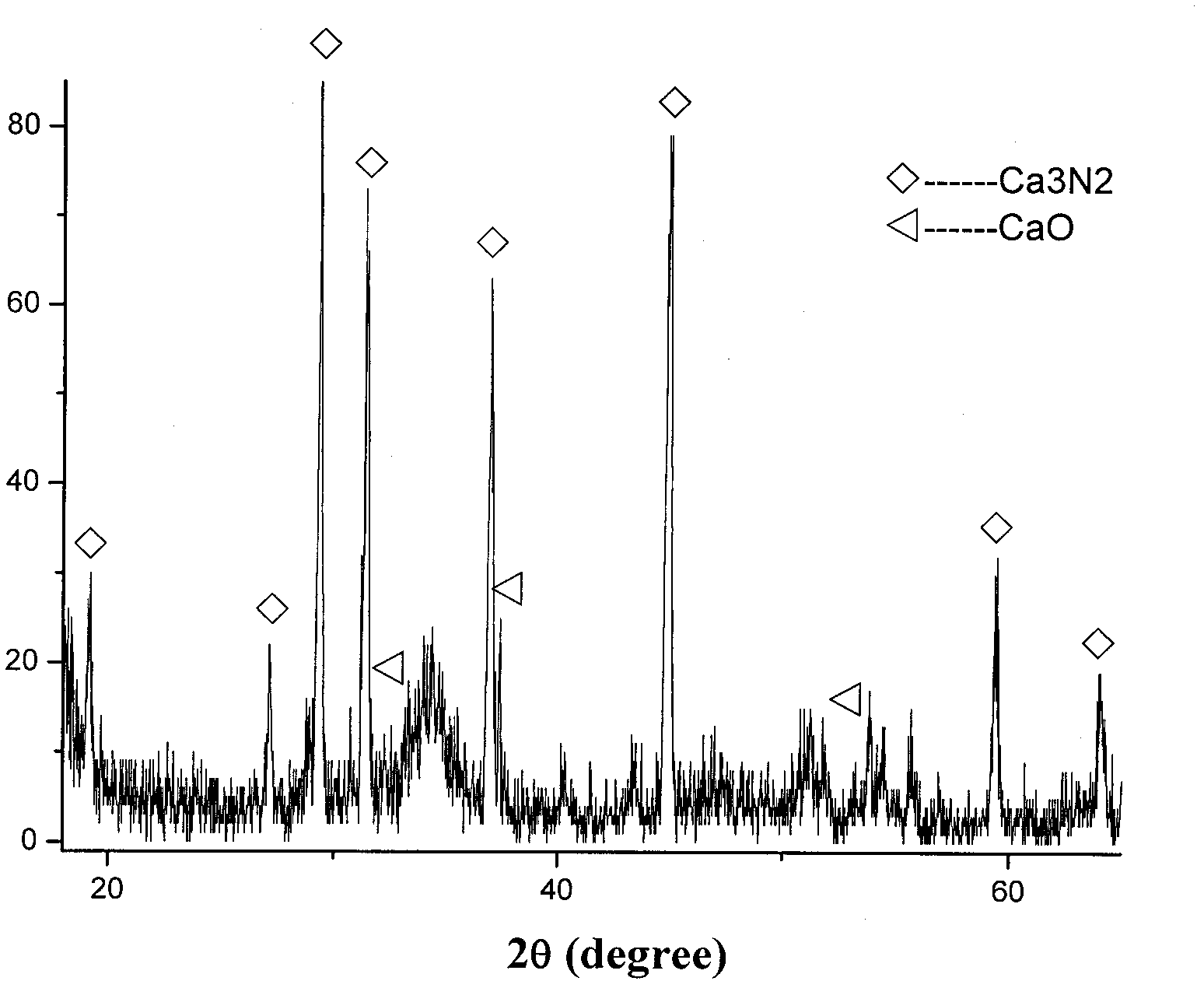

Embodiment 2

[0037]Take by weighing 600 grams of calcium metal powder (accounting for 30% of gross raw material weight) by weight ratio, this metallic calcium powder particle is 600 orders, purity>95%; Take by weighing 1000 grams of calcium nitride powder (accounting for 30% of raw material gross weight) 50%), the average particle size of the calcium nitride powder is 20 μm, and the purity is >98%; 400 grams of ammonium chloride (NH 4 ) 2 Cl (accounting for 20% of the total weight of the raw materials), after mixing, the aluminum oxide balls with a diameter of 10 mm are used as the ball milling medium and placed in a polyurethane tank. Ball mill on the machine for 4 hours, and the evenly mixed material passes through a 60-mesh sieve, and the sieved material is evenly placed in a porous semi-cylindrical graphite boat, and then put into a self-propagating synthesis reactor, and then vacuumed to 600Pa , filled with 4MPa high-purity nitrogen, using a tungsten wire with a diameter of 0.6 mm as...

Embodiment 3

[0040] Take by weight 900 grams of calcium metal powder (accounting for 45% of the total weight of raw materials), the calcium metal powder particles are 240 orders, purity>97%; take by weighing 700 grams of calcium nitride powder (accounting for 45% of the total weight of raw materials) 35%), the average particle size of the calcium nitride powder is 10 μm, and the purity is >98%; 400 grams of urea CO (NH 2 ) 2 (accounting for 20% of the total weight of the raw materials), after mixing, the zirconia balls with a diameter of 5 mm are used as the ball milling medium, placed in a polyurethane tank, and the weight ratio of the above-mentioned raw materials to the zirconia balls is 1:8, and placed on a tank mill Ball mill for 3 hours, and the uniformly mixed material passes through a 60-mesh sieve. The sieved material is evenly placed in a porous semi-cylindrical graphite boat, and then placed in a self-propagating synthesis reactor. After vacuuming to 600Pa, Fill with 6MPa high-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com