A samarium cobalt 1:5 type permanent magnet material and its preparation method

A permanent magnet material, samarium cobalt technology, applied in magnetic materials, inductance/transformer/magnet manufacturing, magnetic objects, etc., can solve the problem that mass-produced products are difficult to break through, and achieve the effect of inhibiting the formation of high-temperature cobalt-rich impurity phases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

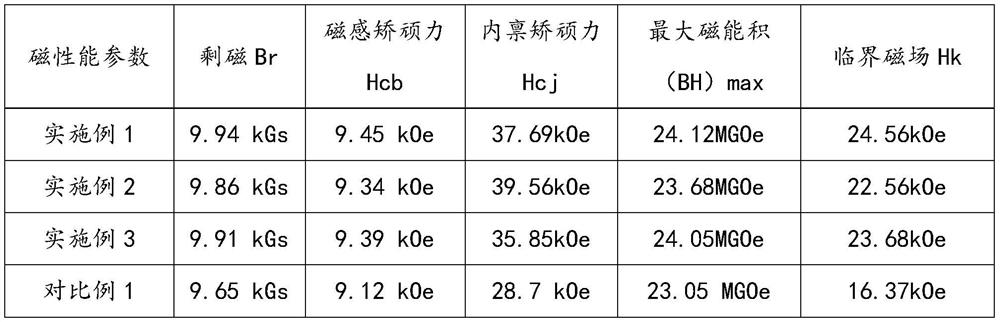

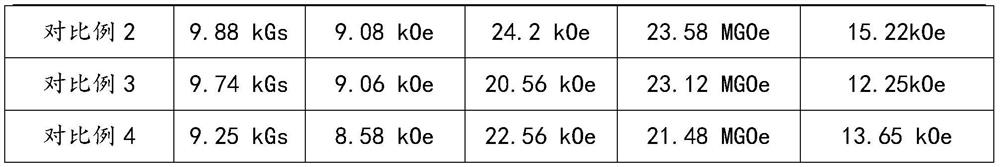

Examples

Embodiment 1

[0027] (1) Ingredients: 34% by weight of samarium metal with a purity of 99.95%, and 66% by weight of electrolytic cobalt with a purity of 99.98%;

[0028] (2) Smelting: The prepared raw materials containing samarium and cobalt are smelted in a vacuum quick-setting throwing belt furnace. The smelting temperature is controlled at 1630°C, and heat preservation and refining are carried out. The refining time is 4 minutes. Casting is carried out after refining, and the rotation speed of the copper roller is adjusted. It is 28 turns / min, and then the alloy liquid is cast onto the copper roller and quenched to obtain a samarium-cobalt quick-setting strip sheet with a thickness of 0.8mm;

[0029] (3) Homogenization treatment of cast slabs: Homogenize the samarium-cobalt quick-setting strip sheet, heat it to a homogenization treatment temperature of 950°C at a heating rate of 5°C / min, and keep it warm for 6 hours. Rapid cooling treatment, the cooling time from the highest temperature ...

Embodiment 2

[0034] (1) Ingredients: 35% by weight of samarium metal with a purity of 99.95%, and 65% by weight of electrolytic cobalt with a purity of 99.98%;

[0035] (2) Smelting: The prepared raw materials containing samarium and cobalt are smelted in a vacuum quick-setting throwing belt furnace. The smelting temperature is controlled at 1600°C, and heat preservation and refining are carried out. The refining time is 3 minutes. Casting is carried out after refining, and the rotation speed of the copper roller is adjusted. It is 36 turns / min, and then the alloy liquid is casted onto the copper roller for rapid cooling to obtain a samarium-cobalt quick-setting strip sheet with a thickness of 0.4mm;

[0036] (3) Homogenization treatment of cast slabs: Homogenize the samarium-cobalt quick-setting strip sheet, heat it to the homogenization treatment temperature 900°C at a heating rate of 5°C / min, and keep it warm for 8 hours. Rapid cooling treatment, the cooling time from the highest temper...

Embodiment 3

[0041] (1) Ingredients: 36% by weight of samarium metal with a purity of 99.95%, and 64% by weight of electrolytic cobalt with a purity of 99.98%;

[0042] (2) Smelting: The prepared raw materials containing samarium and cobalt are smelted in a vacuum quick-setting throwing belt furnace. The smelting temperature is controlled at 1650°C, and heat preservation and refining are carried out. The refining time is 5 minutes. Casting is carried out after refining, and the rotation speed of the copper roller is adjusted. It is 32 turns / min, and then the alloy liquid is cast on the copper roller and quenched to obtain a samarium-cobalt quick-setting strip sheet with a thickness of 0.6mm;

[0043] (3) Homogenization treatment of cast slabs: Homogenize the samarium-cobalt quick-setting strip sheet, heat it to the homogenization treatment temperature of 920°C at a heating rate of 5°C / min, and keep it warm for 4 hours. Rapid cooling treatment, the cooling time from the highest temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic energy product | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com