Preparation method of lithium titanate negative electrode material of lithium ion battery

A lithium-ion battery and negative electrode material technology, applied in battery electrodes, secondary batteries, and secondary battery repair/maintenance, etc., can solve the problems of carbon material structure damage, capacity decay, thermal runaway, etc. Stable and highly conductive, structurally stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

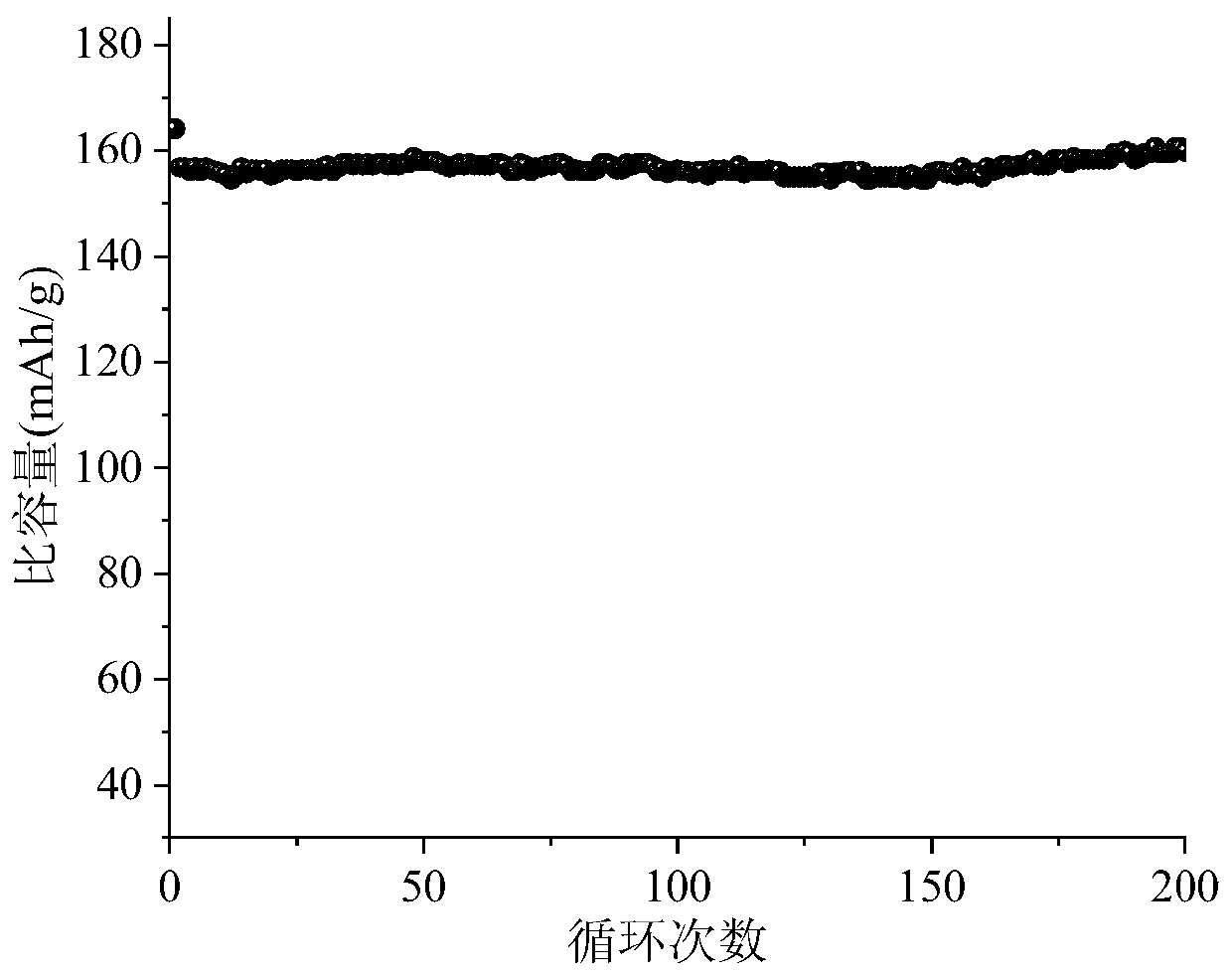

Embodiment 1

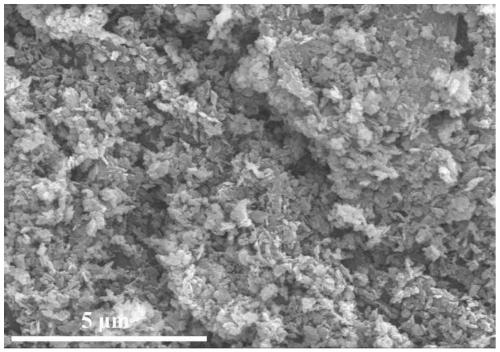

[0029] S1. Add 0.0045mol LiOH·H 2 O and 0.005mol Ti(OC 4 h 9 ) 4 respectively dissolved in 50mL of the first solvent, and then mixed uniformly under stirring conditions to obtain the first mixed solution, wherein the first solvent is a mixture of ethanol, ethylene glycol and glycerin, and the volume ratio of the three is 3:2 :1;

[0030] S2. Add 5mL of 20% hydrogen peroxide solution to the first mixed solution obtained in step S1, and stir vigorously for 30s, then transfer it to a 200mL reactor, then react at 180°C for 11h, collect the solid obtained in the reaction, and use After washing with anhydrous ethanol for 3 times, and calcining for 5 h under air atmosphere, the porous Li 4 Ti 5 o 12 Nanosheets;

[0031] S3. Dissolve 1g of medium-temperature coal tar pitch in 75mL of the second solvent, mix 2g of KOH and K 2 FeO 4 The mixture is dissolved in 75mL of the third solvent, and then the two are mixed to obtain the second mixed solution, wherein the second solvent i...

Embodiment 2

[0035] S1. Add 0.0045mol LiOH·H 2 O and 0.005mol Ti(OC 4 h 9 ) 4 respectively dissolved in 50mL of the first solvent, and then mixed uniformly under stirring conditions to obtain the first mixed solution, wherein the first solvent is a mixture of ethanol, ethylene glycol and glycerin, and the volume ratio of the three is 3:2 :1;

[0036] S2. Add 5mL of 20% hydrogen peroxide solution to the first mixed solution obtained in step S1, and stir vigorously for 30s, then transfer it to a 200mL reactor, then react at 160°C for 11h, collect the solid obtained in the reaction, and use After washing twice with absolute ethanol, calcined for 5 h under air atmosphere, the porous Li 4 Ti 5 o 12 Nanosheets;

[0037] S3. Dissolve 1g of medium-temperature coal tar pitch in 75mL of the second solvent, mix 2g of KOH and K 2 FeO 4 The mixture is dissolved in 75mL of the third solvent, and then the two are mixed to obtain the second mixed solution, wherein the second solvent is a mixture ...

Embodiment 3

[0041] S1. Add 0.0045mol LiOH·H 2 O and 0.005mol Ti(OC 4 h 9 ) 4 respectively dissolved in 50mL of the first solvent, and then mixed uniformly under stirring conditions to obtain the first mixed solution, wherein the first solvent is a mixture of ethanol, ethylene glycol and glycerin, and the volume ratio of the three is 3:2 :1;

[0042] S2. Add 5mL of 20% hydrogen peroxide solution to the first mixed solution obtained in step S1, stir vigorously for 30s, then transfer to a 200mL reaction kettle, then react at 200°C for 11h, collect the solid obtained from the reaction, and use After washing with anhydrous ethanol for 3 times, and calcining for 5 h under air atmosphere, the porous Li 4 Ti 5 o 12 Nanosheets;

[0043] S3. Dissolve 1g of medium-temperature coal tar pitch in 75mL of the second solvent, mix 2g of KOH and K 2 FeO 4 The mixture is dissolved in 75mL of the third solvent, and then the two are mixed to obtain the second mixed solution, wherein the second solven...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com