Nano silicon, preparation method thereof and application of nano silicon in silicon carbon composite cathode material and lithium ion battery

A negative electrode material, silicon-carbon composite technology, applied in the direction of battery electrodes, secondary batteries, circuits, etc., can solve the problems of long time and high price of silicon nanomaterials, to improve electronic conductivity, reduce side reactions, and improve structural stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

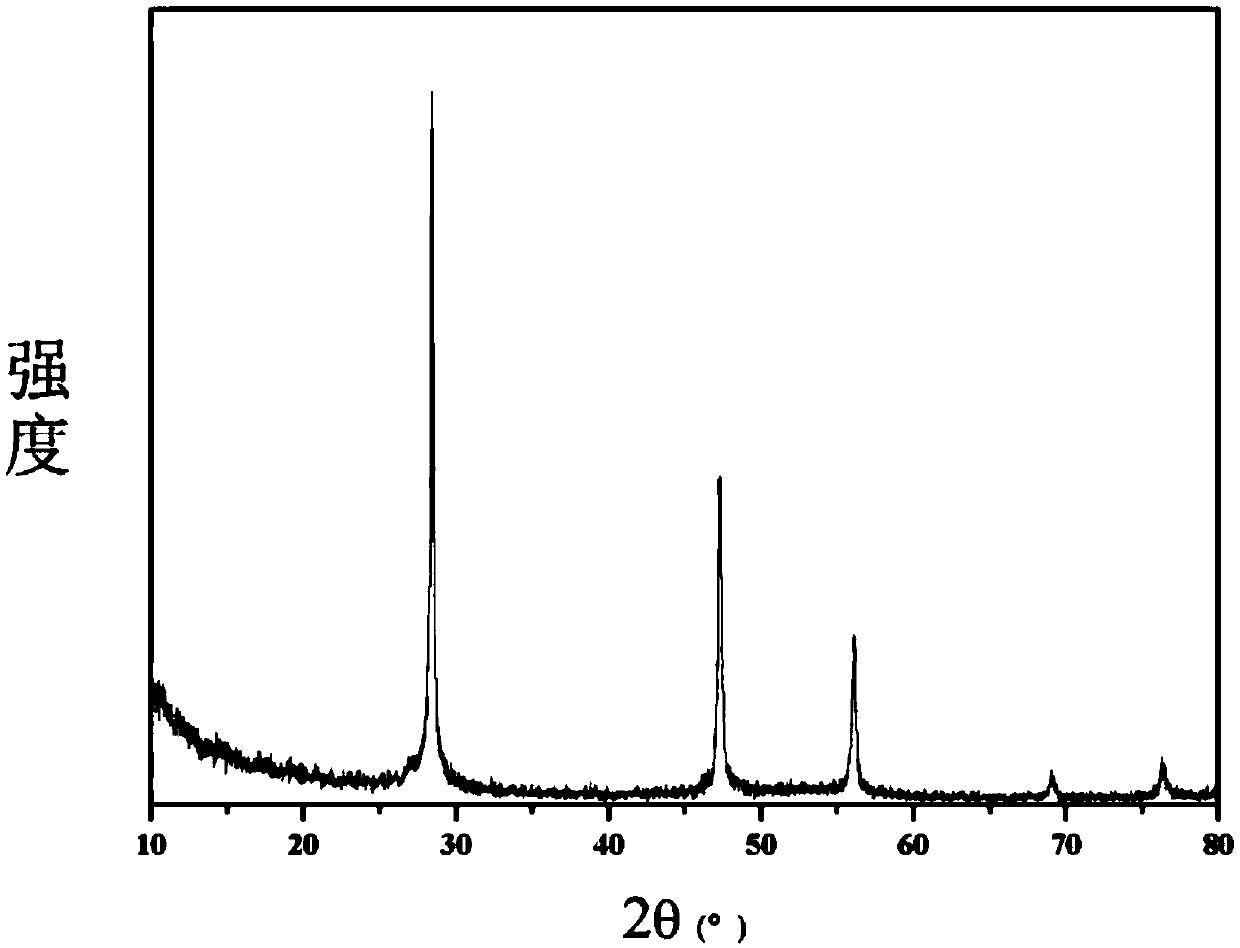

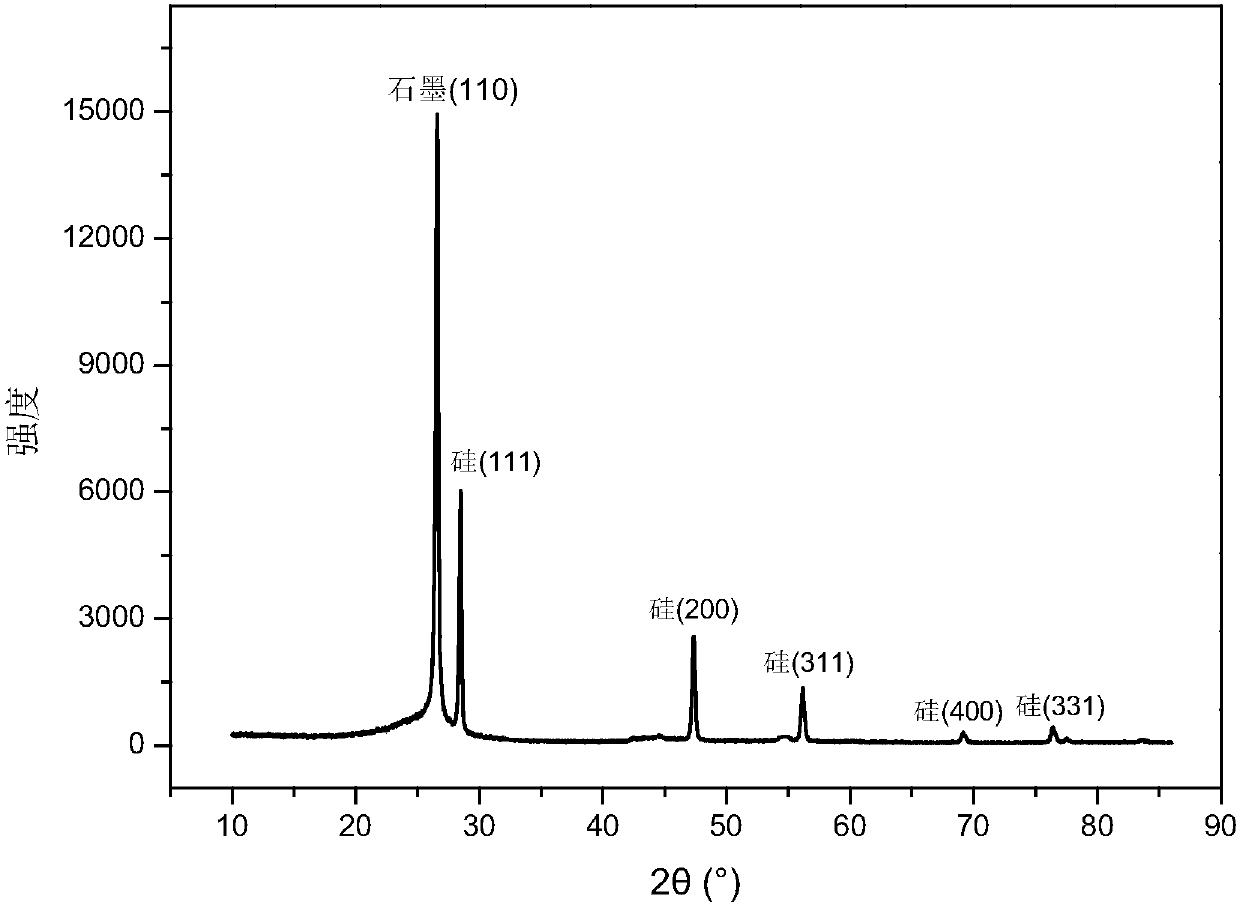

[0067] This embodiment provides a nano-silicon and a method for preparing a silicon-carbon composite negative electrode material for a lithium-ion battery using the nano-silicon as a silicon source:

[0068] Preparation of nano silicon:

[0069] (1) 5 parts by weight of AlCl 3 Mix with 2 parts by weight of magnesium powder and put it into a stainless steel pressure cooker, then take 1 part by weight of SiCl 4 Put it into a pressure cooker, and the above process is carried out in an environment full of nitrogen. Then the pressure cooker is immediately sealed and heated, and the temperature is raised to 400°C at a rate of 2°C / min for 6 hours. 4 Reduction is carried out to obtain a precipitate containing nano-silicon;

[0070] (2) Wash the precipitate cooled to room temperature with 0.1M hydrochloric acid, then wash with deionized water and ethanol, and finally soak the sample in diluted ethanol-solvented HF solution for 30min, and dry it in vacuum at 50°C to obtain a pure sil...

Embodiment 2

[0079] This embodiment provides a nano-silicon and a method for preparing a silicon-carbon composite negative electrode material for a lithium-ion battery using the nano-silicon as a silicon source:

[0080] Preparation of nano silicon:

[0081] (1) 5 parts by weight of AlCl 3 Mix with 3 parts by weight of sodium powder and put it into a stainless steel pressure cooker, then take 1 part by weight of SiO 2 Put it into a pressure cooker, and the above process is carried out in an environment full of nitrogen. Then the pressure cooker is immediately sealed and heated, and the temperature is raised to 200°C at a rate of 5°C / min for 10 hours. 2 Reduction is carried out to obtain a precipitate containing nano-silicon;

[0082] (2) Wash the precipitate cooled to room temperature with 0.2M hydrochloric acid, then wash with deionized water and ethanol, and finally soak the sample in diluted ethanol-solvented HF solution for 40min, and dry it in vacuum at 40°C to obtain a pure silico...

Embodiment 3

[0088] This embodiment provides a nano-silicon and a method for preparing a silicon-carbon composite negative electrode material for a lithium-ion battery using the nano-silicon as a silicon source:

[0089] Preparation of nano silicon:

[0090] (1) 6 parts by weight of AlCl 3 Mix it with 3 parts by weight of magnesium powder and put it into a stainless steel pressure cooker, then take 1.5 parts by weight of artificial glass fiber and put it into the pressure cooker. The above process is carried out in an environment full of nitrogen. Then the pressure cooker is immediately sealed and heated, and the temperature is raised to 300°C at a rate of 3°C / min for 8 hours. The magnesium powder reduces the artificial glass fiber to obtain a precipitate containing nano-silicon;

[0091] (2) Wash the precipitate cooled to room temperature with 0.15M hydrochloric acid, then wash with deionized water and ethanol, and finally soak the sample in diluted ethanol-solvented HF solution for 20mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com