Modified composite material containing silicon-based material, preparation method thereof and use thereof in lithium ion battery

A technology of composite materials and silicon-based materials, applied in battery electrodes, secondary batteries, active material electrodes, etc., can solve the problems of carbon tubes lack of ductility, unable to prevent and delay particle pulverization, and unable to effectively absorb, etc., to achieve improved Overall performance, improved cycle performance, and reduced electrode crushing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

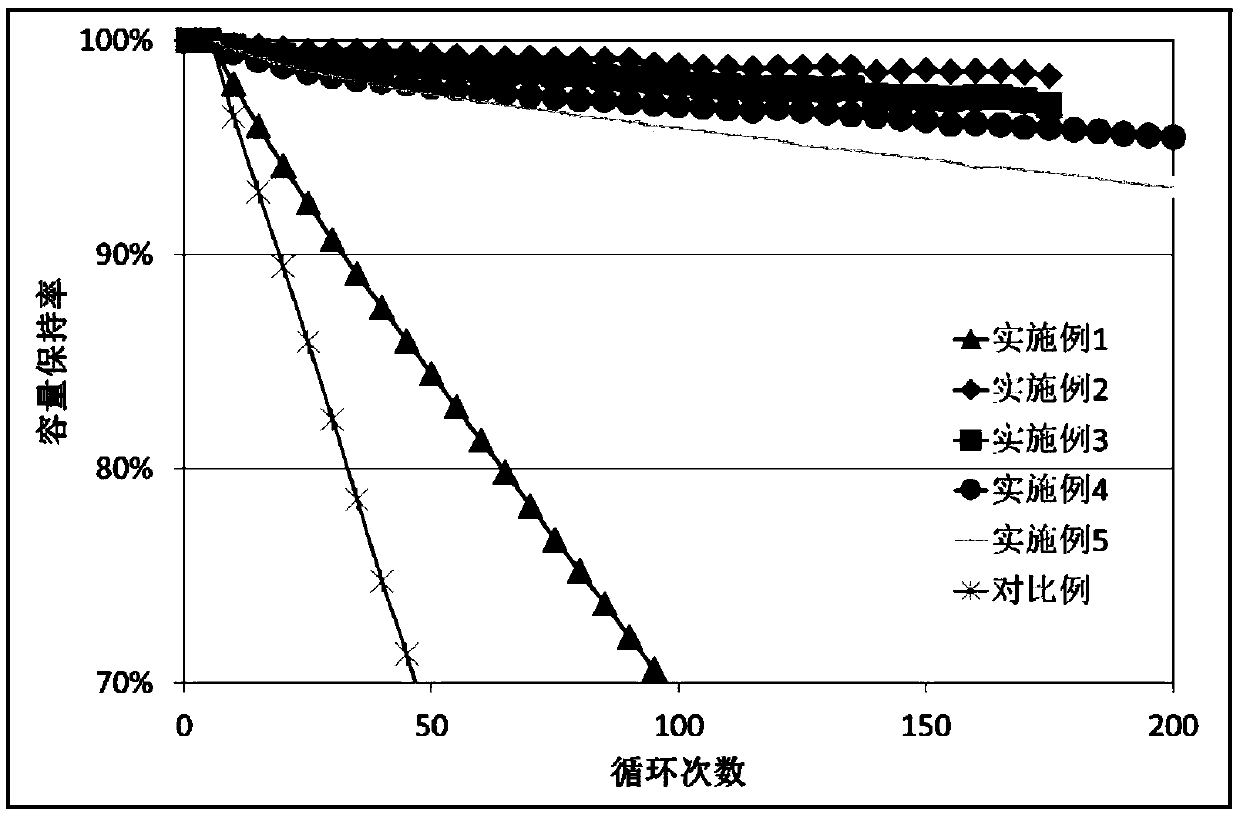

Embodiment 1

[0051] This embodiment provides a modified composite material containing a silicon-based material, the composite material is: a SiO core, and a polymer coating layer coated on the surface of the core core, the composition of the polymer coating layer is Polyvinylidene fluoride;

[0052] The particle size D50 of the SiO inner core is 5 μm, and the thickness of the polyvinylidene fluoride cladding layer is 10 nm;

[0053] Based on the total mass of the modified composite material being 100 wt%, the mass percentage of the polyvinylidene fluoride coating layer is 3 wt%.

[0054] Preparation:

[0055] (1) Disperse the polymer in the NMP liquid solvent, and uniformly disperse it by stirring, vibrating, ultrasonic and other methods to obtain a slurry;

[0056] (2) Add the SiO negative electrode material into the slurry, and achieve uniform solid-liquid mixing by stirring, vibration, ultrasonic and other methods;

[0057] (3) Use methods such as filtration and evaporation to remove...

Embodiment 2

[0063] This embodiment provides a modified composite material containing silicon-based materials, the composite material is: SiO 1.5 An inner core, and a polymer cladding layer coated on the surface of the inner core, the composition of the polymer cladding layer is: a combination of CMC, SBR and polyaniline in a mass ratio of 1:4:5;

[0064] The particle size D50 of the SiO core is 5 μm to 10 μm, and the thickness of the polymer coating is 10 nm to 25 nm;

[0065] Based on the total mass of the modified composite material being 100 wt%, the mass percentage of the polymer coating layer is 3 wt%.

[0066] Preparation:

[0067] (1) Disperse CMC, SBR and polyaniline in water, and uniformly disperse them by stirring, vibrating, ultrasonic and other methods to obtain a slurry;

[0068] (2) SiO 1.5 The negative electrode material is added to the slurry, and the solid-liquid is uniformly mixed by stirring, vibrating, ultrasonic and other methods;

[0069] (3) Use filtration, evap...

Embodiment 3

[0074] This embodiment provides a modified composite material containing a silicon-based material, the composite material is: a SiO core, and a polymer coating layer coated on the surface of the core core, the composition of the polymer coating layer is : CMC, SBR, sodium alginate and PAA in a 1:4:1:1 combination;

[0075] The particle size D50 of the SiO core is 10 μm to 15 μm, and the thickness of the polymer coating is 30 nm to 50 nm;

[0076] Based on the total mass of the modified composite material being 100 wt%, the mass percentage of the polymer coating layer is 5 wt%.

[0077] Preparation:

[0078] (1) Disperse CMC, SBR, sodium alginate and PAA in water, and uniformly disperse them by stirring, vibrating, ultrasonic and other methods to obtain a slurry;

[0079] (2) Add the SiO negative electrode material into the slurry, and achieve uniform solid-liquid mixing by stirring, vibration, ultrasonic and other methods;

[0080] (3) Use methods such as filtration and eva...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com