Thienyl-containing phosphite compound and application thereof

A phosphite and compound technology, applied in the field of chemical synthesis, can solve the problems of SEI film damage, material lattice collapse, deterioration of battery performance, etc., and achieve the effects of inhibiting dissolution, high yield and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

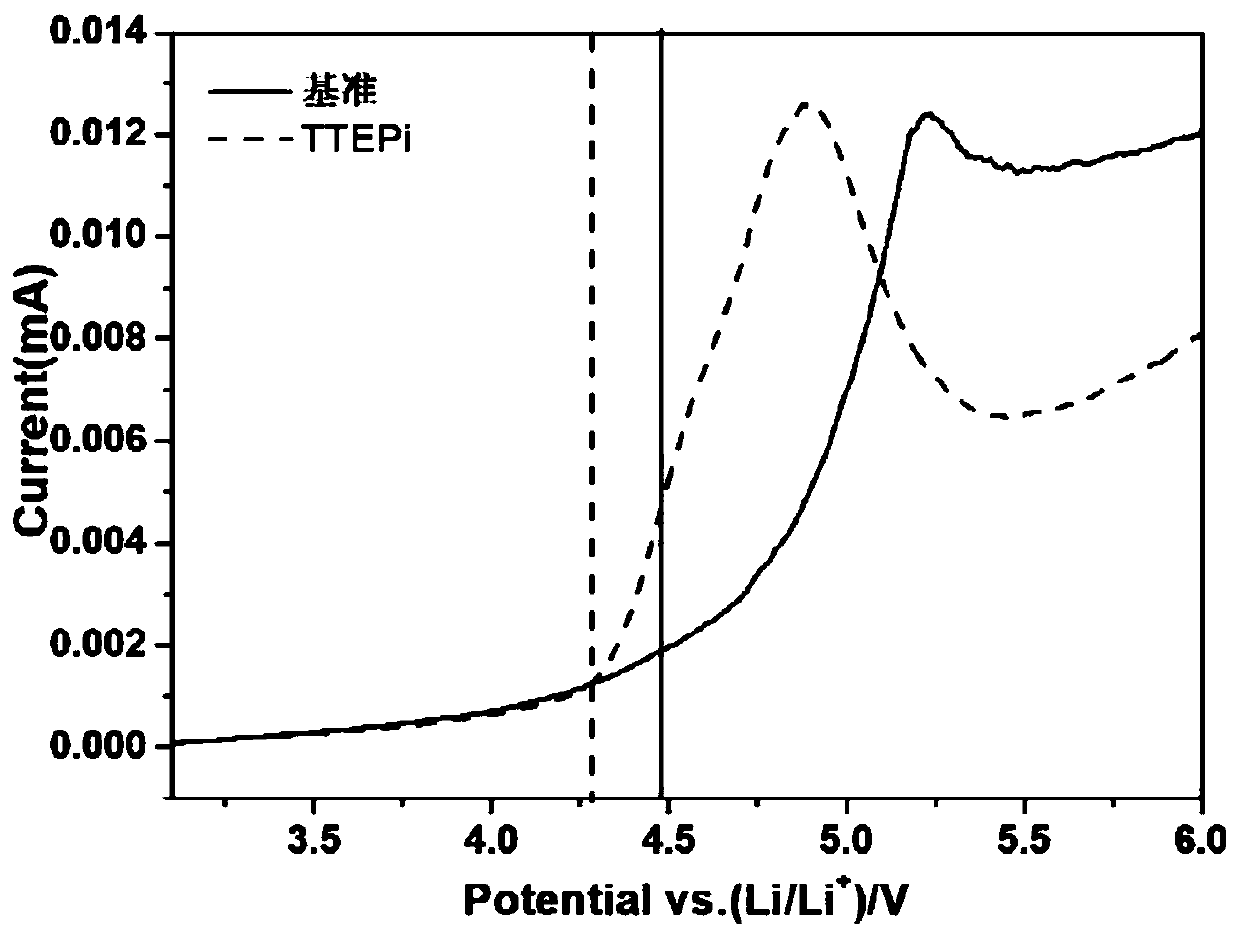

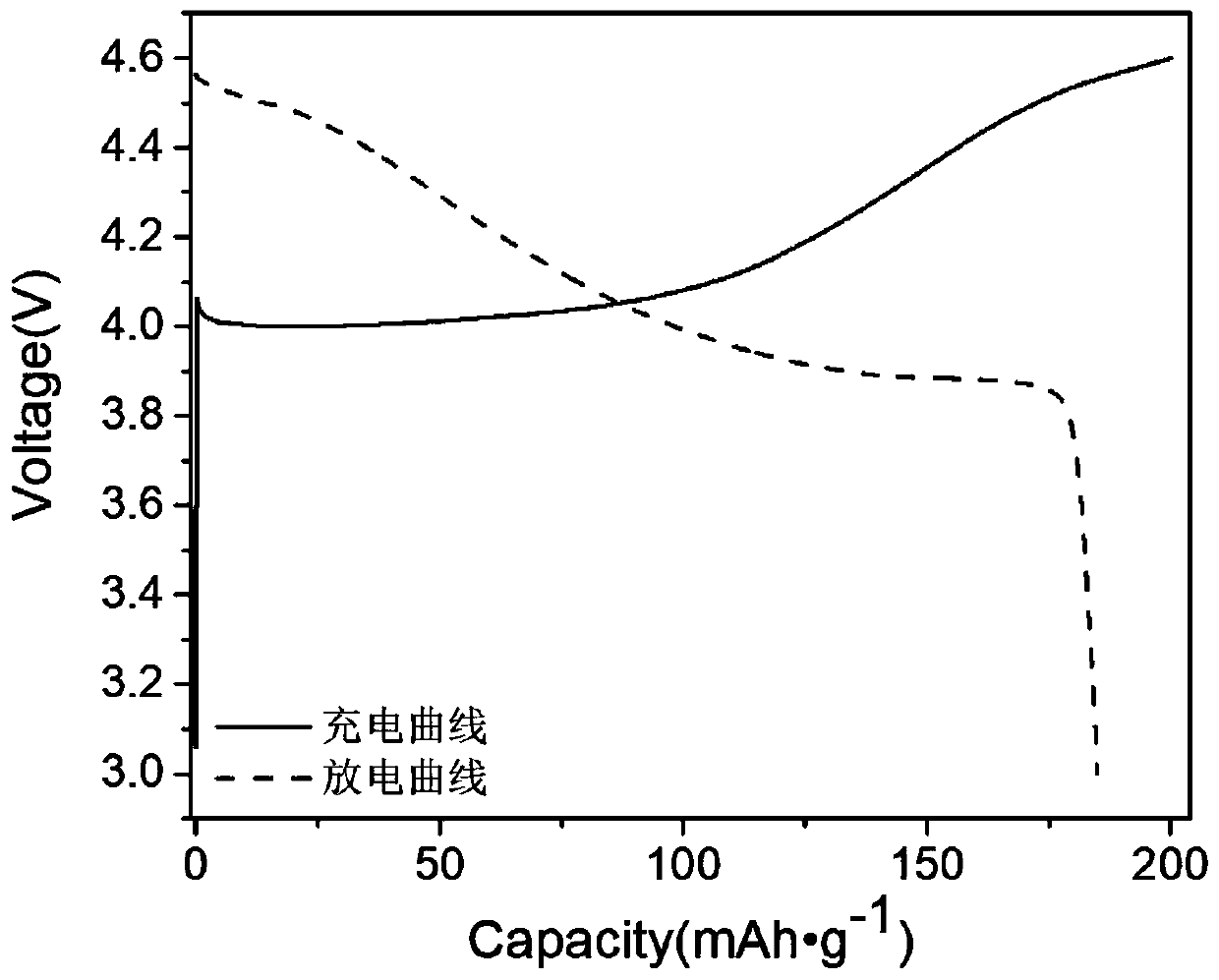

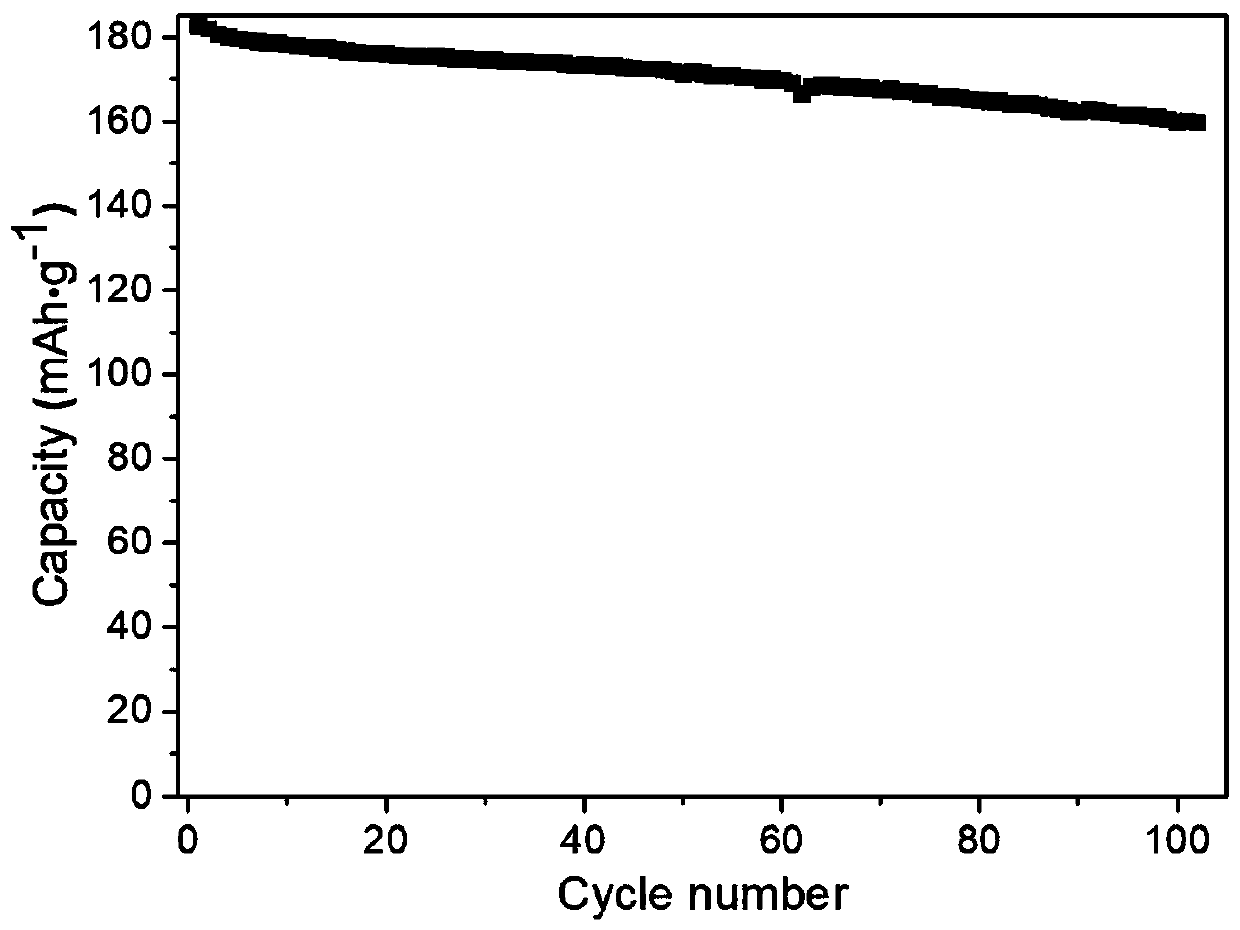

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1: Preparation of thienyl-containing phosphite compound A tris (2-(thiophen-2-yl) ethyl) phosphite (TTEPi)

[0037] Compound A phosphite tris (2-(thiophen-2-yl) ethyl) ester (TTEPi) is shown in formula (II):

[0038]

[0039] The specific reaction principle is as follows:

[0040]

[0041] Concrete preparation steps are:

[0042] (1) Raw material pretreatment: THF is heated and distilled, and at the same time, it is dried with sodium metal to remove water, so that the purity of THF is greater than 99.9%, and the water content is reduced to below 50ppm. Triethylamine is heated and fractionated to obtain a colorless and transparent triethylamine solution, and then activated 4A molecular sieves are added to make the triethylamine moisture lower than 50ppm. 2-thiophene ethanol and phosphorus trichloride are respectively added to the activated 4A molecular sieve, so that the moisture in the 2-thiophene ethanol and phosphorus trichloride is lower than 50ppm...

Embodiment 2

[0048] Example 2: Preparation of thienyl-containing phosphite compound B propyl bis (2-(thiophen-2-yl) ethyl) phosphite (PBTEPi)

[0049] Compound B propyl bis (2-(thiophen-2-yl) ethyl) phosphite (PBTEPi) is shown in formula (III):

[0050]

[0051] The specific reaction principle is as follows:

[0052]

[0053] Concrete preparation steps are:

[0054] (1) Raw material pretreatment: THF is heated and distilled, and at the same time, it is dried with sodium metal to remove water, so that the purity of THF is greater than 99.9%, and the water content is reduced to below 50ppm. Triethylamine is heated and fractionated to obtain a colorless and transparent triethylamine solution, and then activated 4A molecular sieves are added to make the triethylamine moisture lower than 50ppm. 2-thiophene ethanol, propanol, and phosphorus trichloride are respectively added to activated 4A molecular sieves, so that the moisture in 2-thiophene ethanol, propanol, and phosphorus trichlorid...

Embodiment 3

[0060] Example 3: Preparation of thienyl-containing phosphite compound C ethylpropyl (2-(thiophen-2-yl) ethyl) phosphite (EPBTEPi)

[0061] Compound C ethylpropyl (2-(thiophen-2-yl) ethyl) phosphite (EPBTEPi) is shown in formula (IV):

[0062]

[0063] The specific reaction principle is as follows:

[0064]

[0065] Concrete preparation steps are:

[0066] (1) Raw material pretreatment: THF is heated and distilled, and at the same time, it is dried with sodium metal to remove water, so that the purity of THF is greater than 99.9%, and the water content is reduced to below 50ppm. Triethylamine is heated and fractionated to obtain a colorless and transparent triethylamine solution, and then activated 4A molecular sieves are added to make the triethylamine moisture lower than 50ppm. Add activated 4A molecular sieves to 2-thiophene ethanol, propanol, ethanol, and phosphorus trichloride before use, so that the moisture in 2-thiophene ethanol, propanol, ethanol, and phosphor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com