Lithium ion battery anode material based on metal oxide and preparation method thereof

A technology for lithium ion batteries and negative electrode materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of large irreversible capacity loss of metal oxides for the first time, poor conductivity of metal oxides, loss of electrochemical activity, etc. First Coulombic Efficiency and Cycling Stability, Stable Electrode Structure, and Effect of Improving Cycling Stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

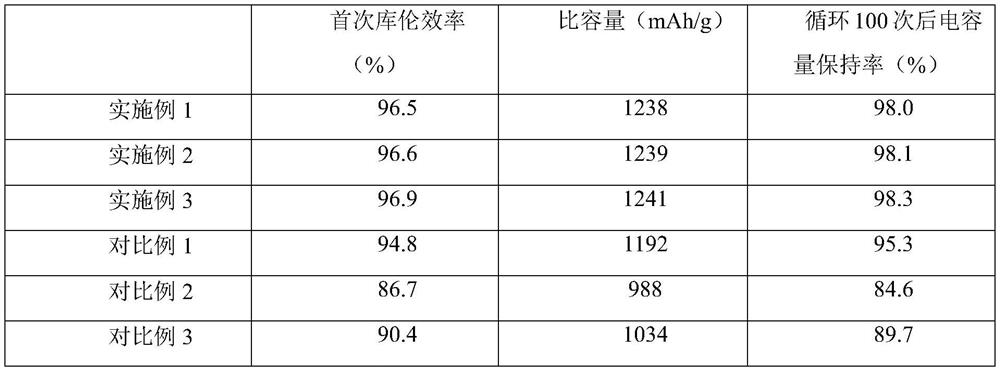

Examples

Embodiment 1

[0040] The preparation method of the negative electrode material of lithium ion battery based on metal oxide, concrete steps are as follows:

[0041] (1) take hydroxyethyl methacrylate, α-bromoisobutyryl bromide, and mercaptoethanol as raw materials to react to generate hydroxyl-terminated hyperbranched polyacrylate;

[0042](2) Then add hydroxyl-terminated hyperbranched polyacrylate, aluminum nitrate nonahydrate, and copper nitrate hexahydrate into methanol, and disperse evenly with ultrasonic waves to obtain a mixed solution, which is transferred to a reaction kettle and reacted at 150°C for 16 hours, followed by post-treatment, namely Aluminum and copper oxide microspheres were obtained;

[0043] (3) Under the atmosphere of carbon dioxide gas, aluminum, copper oxide microspheres and lithium hydride are mixed ball milled, heated to dehydrogenate, and pretreated aluminum and copper oxide microspheres are obtained;

[0044] (4) Finally, the pretreated aluminum, copper oxide m...

Embodiment 2

[0064] The preparation method of the negative electrode material of lithium ion battery based on metal oxide, concrete steps are as follows:

[0065] (1) take hydroxyethyl methacrylate, α-bromoisobutyryl bromide, and mercaptoethanol as raw materials to react to generate hydroxyl-terminated hyperbranched polyacrylate;

[0066] (2) Then add hydroxyl-terminated hyperbranched polyacrylate, aluminum nitrate nonahydrate, and copper nitrate hexahydrate into methanol, and disperse evenly with ultrasonic waves to obtain a mixed solution, which is transferred to a reaction kettle and reacted at 170°C for 13 hours, followed by post-treatment. Aluminum and copper oxide microspheres were obtained;

[0067] (3) Under the atmosphere of carbon dioxide gas, aluminum, copper oxide microspheres and lithium hydride are mixed ball milled, heated to dehydrogenate, and pretreated aluminum and copper oxide microspheres are obtained;

[0068] (4) Finally, the pretreated aluminum, copper oxide microsp...

Embodiment 3

[0088] The preparation method of the negative electrode material of lithium ion battery based on metal oxide, concrete steps are as follows:

[0089] (1) take hydroxyethyl methacrylate, α-bromoisobutyryl bromide, and mercaptoethanol as raw materials to react to generate hydroxyl-terminated hyperbranched polyacrylate;

[0090] (2) Then add hydroxyl-terminated hyperbranched polyacrylate, aluminum nitrate nonahydrate, and copper nitrate hexahydrate into methanol, and ultrasonically disperse evenly to obtain a mixed solution, which is transferred to a reaction kettle and reacted at 160°C for 15 hours, and post-treated, that is Aluminum and copper oxide microspheres were obtained;

[0091] (3) Under the atmosphere of carbon dioxide gas, aluminum, copper oxide microspheres and lithium hydride are mixed ball milled, heated to dehydrogenate, and pretreated aluminum and copper oxide microspheres are obtained;

[0092] (4) Finally, the pretreated aluminum, copper oxide microspheres and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com