Preparation method of manganese sesquioxide hierarchical-structure material

A manganese trioxide, hierarchical structure technology, applied in manganese oxide/manganese hydroxide, nanotechnology for materials and surface science, structural parts, etc., can solve the problem of less research on preparation methods, and achieve easy control of operation. , Low preparation cost, rich void effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Manganese nitrate and oxalic acid were formulated into aqueous solutions, and the manganese nitrate aqueous solution was added dropwise to the oxalic acid aqueous solution at 20°C and the stirring speed was 150 rpm. The molar concentration of manganese nitrate aqueous solution is 0.05 mol / L, and the molar concentration of oxalic acid aqueous solution is 0.5 mol / L. The molar ratio of manganese nitrate and oxalic acid is 1:10. The rate of dropping manganese nitrate aqueous solution is 180 drops / min, and the reaction time under stirring condition is 10 minutes. After the reaction is completed, filter and wash with water and dry. The drying time is 3 hours, the drying temperature is 60°C, and the heating rate is 10°C. / minute. Then calcination was carried out in a muffle furnace, the calcination temperature was 400 °C, the calcination time was 2 h, and the heating rate was 10 °C / min. After natural cooling, the target product is obtained.

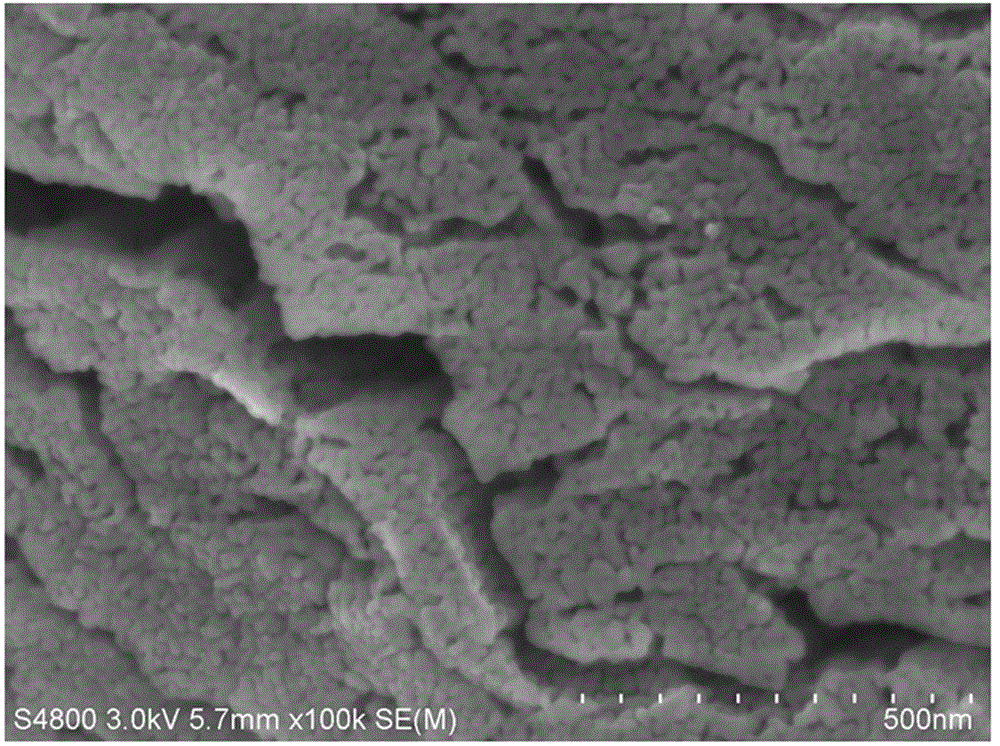

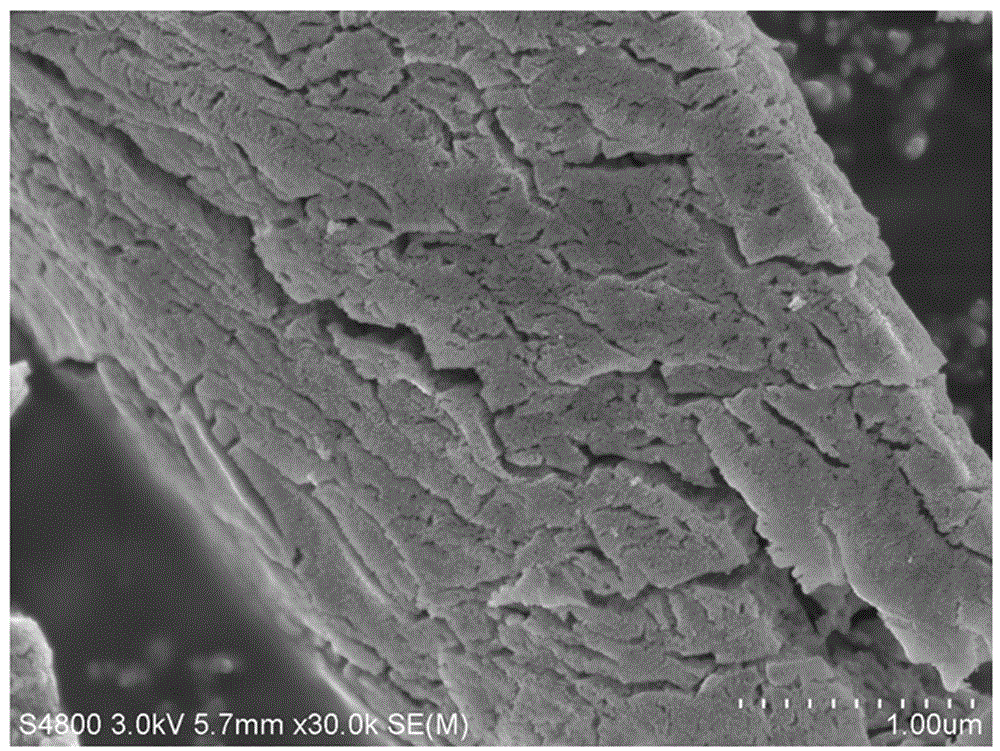

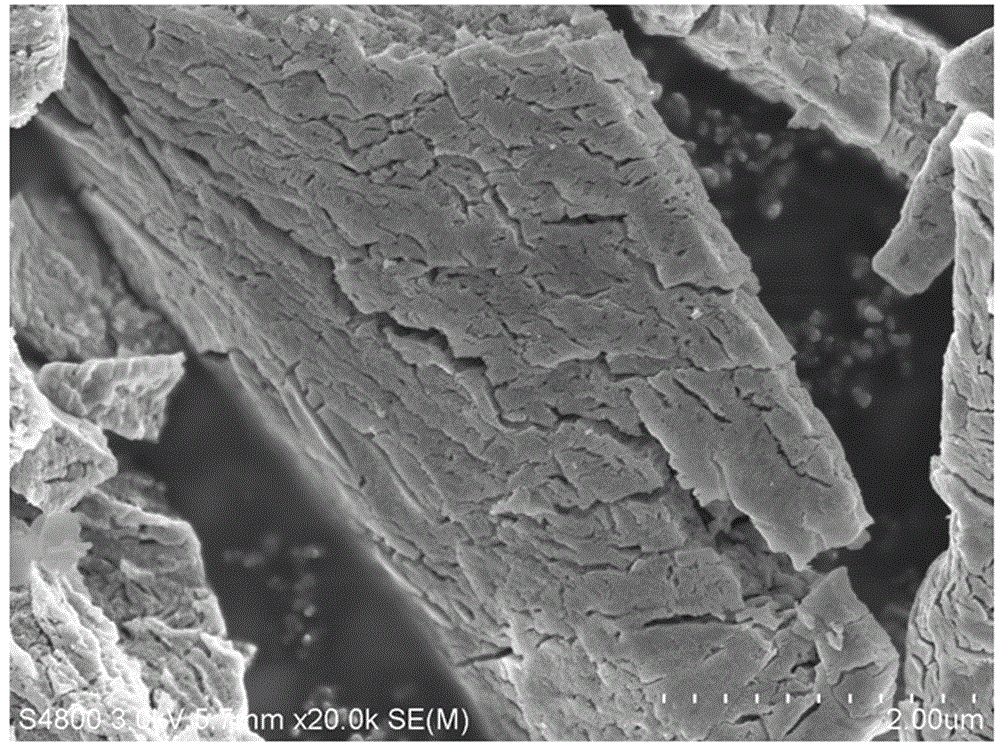

[0034] The product is a sheet-l...

Embodiment 2

[0036] Manganese chloride and oxalic acid were formulated into aqueous solutions, and the manganese chloride aqueous solution was added dropwise to the oxalic acid aqueous solution at 20°C and the stirring speed was 150 rpm. The molar concentration of manganese chloride aqueous solution is 0.1 mol / L, and the molar concentration of oxalic acid aqueous solution is 0.5 mol / L. The molar ratio of manganese chloride and oxalic acid is 1:50. The rate of dropping the manganese chloride aqueous solution is 180 drops / min, and the reaction time under the stirring condition is 10 minutes. °C / min. Calcination was then carried out in a muffle furnace, the calcination temperature was 350 °C, the calcination time was 3 h, and the heating rate was 10 °C / min. After natural cooling, the target product is obtained.

[0037]The product is a sheet-like grade structure material assembled from a large number of manganese oxide nanoparticles. The size of the flakes is between 15-20 μm, and the siz...

Embodiment 3

[0039] Manganese chloride and oxalic acid were formulated into aqueous solutions, and the manganese chloride aqueous solution was added dropwise to the oxalic acid aqueous solution at 20°C and the stirring speed was 120 rpm. The molar concentration of manganese chloride aqueous solution is 1.0 mol / L, and the molar concentration of oxalic acid aqueous solution is 2.0 mol / L. The molar ratio of manganese chloride and oxalic acid is 1:10. The rate of dropping the manganese chloride aqueous solution is 180 drops / min, and the reaction time under the stirring condition is 10 minutes. °C / min. Then calcination was carried out in a muffle furnace, the calcination temperature was 400 °C, the calcination time was 2 h, and the heating rate was 20 °C / min. After natural cooling, the target product is obtained.

[0040] The product is a sheet-like grade structure material assembled from a large number of manganese oxide nanoparticles. The size of the flakes is between 15-20 μm, and the si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com