Preparation method of porous graphene and applications of finished product thereof

A porous graphene and graphene oxide technology, applied in electrical components, electrochemical generators, battery electrodes, etc., can solve problems such as the unoptimized arrangement of graphene sheets, the unobstructed Li transmission path, and the spontaneous stacking of materials. , to achieve the effect of improved reversible capacity and cycle performance, controllable morphology and size, and abundant voids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

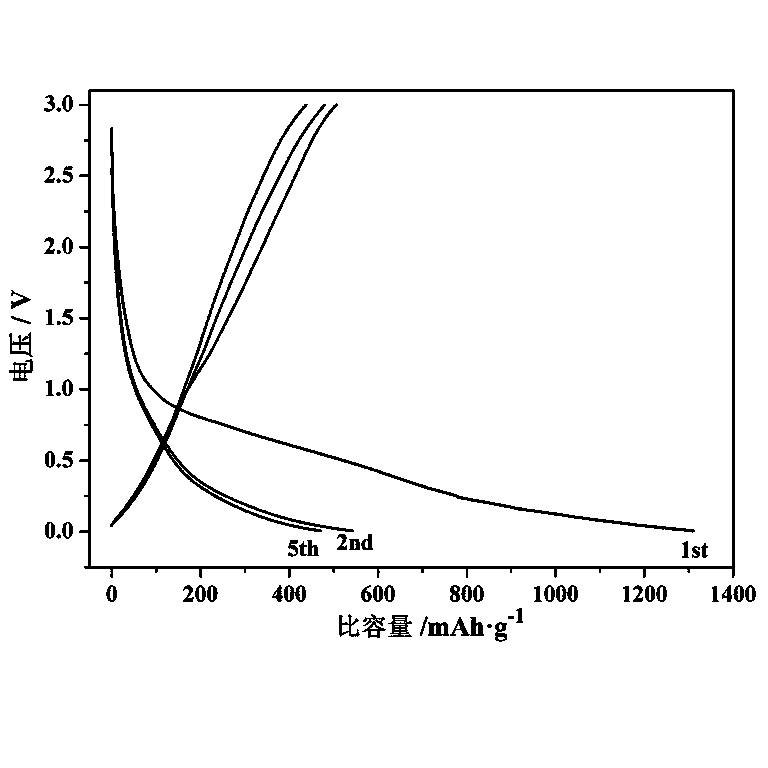

[0027] Take 90mg of graphene oxide and add it into 60mL of deionized water for ultrasonic dispersion for 1h; weigh 0.01mol, that is, 2.703g of FeCl 3 ·6H 2 O was dissolved in 10 mL of deionized water to make a 1M solution, and slowly added dropwise to the above 60 mL graphene oxide solution under constant stirring with a magnetic stirrer, and stirred for 2 h. The resulting mixture was centrifuged at 5000-15000 rpm, washed with ethanol, and this process was repeated three times. The resulting precipitate was collected in a petri dish and dried at a temperature of 60° C. for 10 h. After drying, the prepared precursor sample was placed in a quartz boat and placed in a tube furnace, heated at a heating rate of 20°C / min, controlled at a nitrogen flow rate of 300mL / min, and calcined at a constant temperature of 1050°C for 2 hours, and the solid product was collected after cooling . Treat the solid product with dilute hydrochloric acid or dilute sulfuric acid, the volume ratio of w...

Embodiment 2

[0030] Take 90mg graphene oxide and add it into 60mL deionized water for ultrasonic dispersion for 2h; weigh 0.01mol (2.9081g) Ni(NO 3 ) 2 ·6H 2 O was dissolved in 20mL of deionized water to make a 0.5M solution, and slowly added dropwise to the above 60mL graphene oxide solution under constant stirring with a magnetic stirrer, and stirred for 2h. The resulting mixture was centrifuged and washed with deionized water, and this process was repeated three times. The resulting precipitate was collected in a petri dish and dried at a temperature of 110° C. for 2 h. After drying, the prepared precursor samples were placed in a quartz boat and placed in a tube furnace, heated at a heating rate of 10 °C / min, controlled at a nitrogen flow rate of 100 mL / min, calcined at a constant temperature of 700 °C for 20 h, and collected after cooling solid product. The solid product is treated with hot sulfuric acid to remove NiO, filtered and washed with water until neutral, and dried to obta...

Embodiment 3

[0033] Take 90mg graphene oxide and add it into 60mL deionized water for ultrasonic dispersion for 4h; weigh 0.02mol (5.821g) Co(NO 3 ) 2 ·6H 2 O was dissolved in 20 mL of deionized water to make a 1M solution, and slowly added dropwise to the above 60 mL graphene oxide solution under constant stirring with a magnetic stirrer, and stirred for 2 h.

[0034] The resulting mixture was centrifuged and washed with ethanol, and this process was repeated three times. The resulting precipitate was collected in a petri dish and dried at a temperature of 80° C. for 10 h. After the drying is completed, put the prepared precursor sample in a quartz boat and put it into a tube furnace, heat it at a heating rate of 15°C / min, control the nitrogen flow rate at 200mL / min, and calcinate at a constant temperature of 800°C for 20h, and collect the solid product after cooling . Treat the solid product with dilute sulfuric acid, the volume ratio of the two is 1:10, remove cobalt oxide, filter an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com