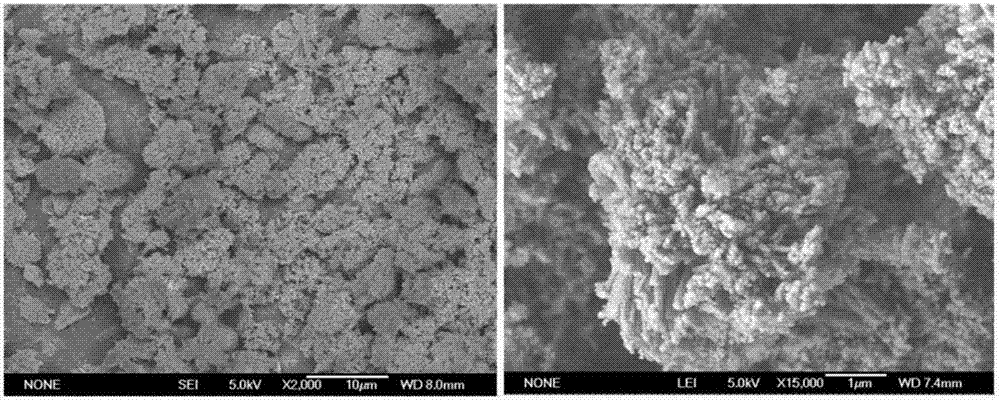

Sea-urchin-shaped hiberarchy cobaltosic oxide nanosphere and preparing method thereof

A technology with nanometer and hierarchical structure of cobalt tetroxide, applied in the directions of cobalt oxide/cobalt hydroxide, nanotechnology, nanotechnology, etc., can solve the problems of complicated process, increased cost, impurity of the final product, etc., and achieves simple process, saving production cost, The effect of high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] (1) Synthesis process: Add 2.5mmol of cobalt chloride to the mixed solution of 20ml distilled water and 20ml glycerol at room temperature and fully dissolve; add 5mmol of urea to the above solution as a precipitant and fully dissolve; put the mixed solution Put it into an autoclave, and react for 20 hours at a temperature of 180°C.

[0042] (2) Centrifugal washing process: centrifuge the synthesized precipitate at a speed of 3000r / min; wash 5 times with distilled water and 5 times with absolute ethanol; dry in a vacuum oven at 80°C for 20 hours to obtain a sea urchin-like hierarchical structure of cobalt tetroxide Precursor.

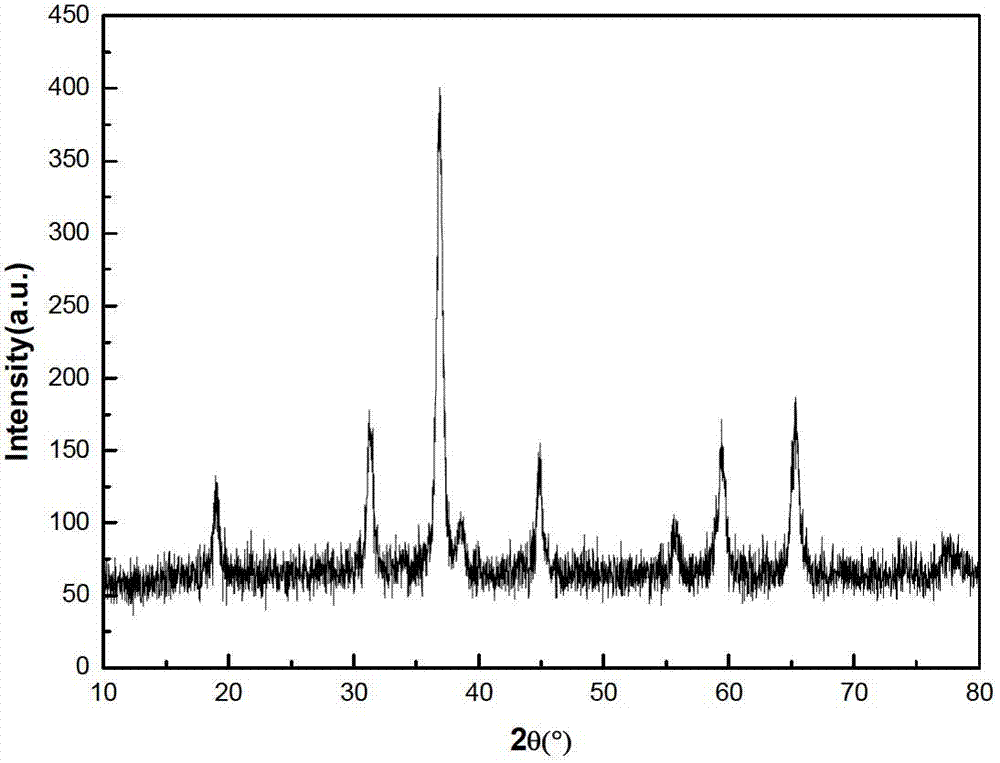

[0043] (3) Calcination process: heat the precursor obtained in the centrifugal washing process at 350°C in a muffle furnace for 3.5 hours, and cool to room temperature. The cobalt content is 74.35~74.45%.

Embodiment 2

[0045] (1) Synthesis process: Add 5mmol of cobalt chloride into the mixed solution of 35ml distilled water and 5ml glycerol at room temperature, fully dissolve; add 6.5mmol of urea as a precipitant to the above solution, fully dissolve; put the mixed solution in into an autoclave, and reacted for 5 hours at a temperature of 110°C.

[0046] (2) Centrifugal washing process: centrifuge the synthesized precipitate at 6000r / min; wash with distilled water for 3 times and absolute ethanol for 5 times; dry in a vacuum oven at 80°C for 12 hours to obtain a sea urchin-like hierarchical structure of cobalt tetroxide Precursor.

[0047] (3) Calcination process: heat the precursor obtained in the centrifugal washing process at 300°C in a muffle furnace for 2 hours and cool to room temperature. The cobalt content is 74.32~74.42%.

Embodiment 3

[0049] (1) Synthesis process: Add 3.5mmol of cobalt chloride to the mixed solution of 30ml distilled water and 10ml glycerol at room temperature and fully dissolve; add 8mmol of urea to the above solution as a precipitant and fully dissolve; put the mixed solution in Put it into an autoclave, and react for 24 hours at a temperature of 180°C.

[0050] (2) Centrifugal washing process: Centrifuge the synthesized precipitate at a speed of 3000r / min; wash 5 times with distilled water and 5 times with absolute ethanol; dry in a vacuum oven at 70°C for 12 hours to obtain a sea urchin-like hierarchical structure of cobalt tetroxide Precursor.

[0051] (3) Calcination process: heat the precursor obtained in the centrifugal washing process at 400°C in a muffle furnace for 4 hours, and cool to room temperature. The cobalt content is 74.31~74.45%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com