Preparation method for gamma-AlON transparent ceramic powder

A technology for transparent ceramics and powders, which is applied in the preparation of pure-phase γ-AlON transparent ceramic powders and γ-AlON transparent ceramic powders by carbothermal reduction of α-Al2O3, which can solve the problem of poor light transmittance of AlON powders, gas Difficult to control the discharge speed, difficult to discharge the adsorbed gas, etc., to achieve the effect of shortening the required time, saving vacuuming time and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

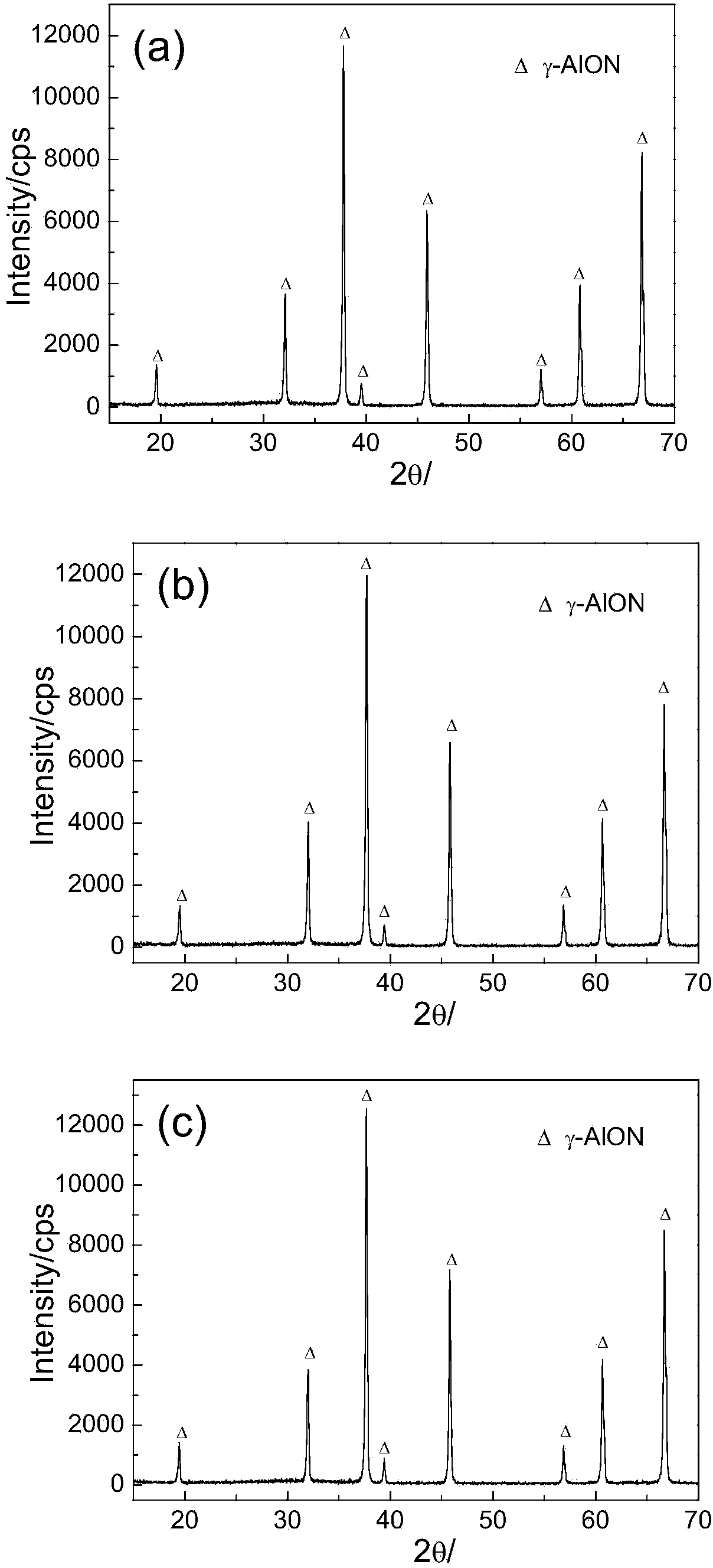

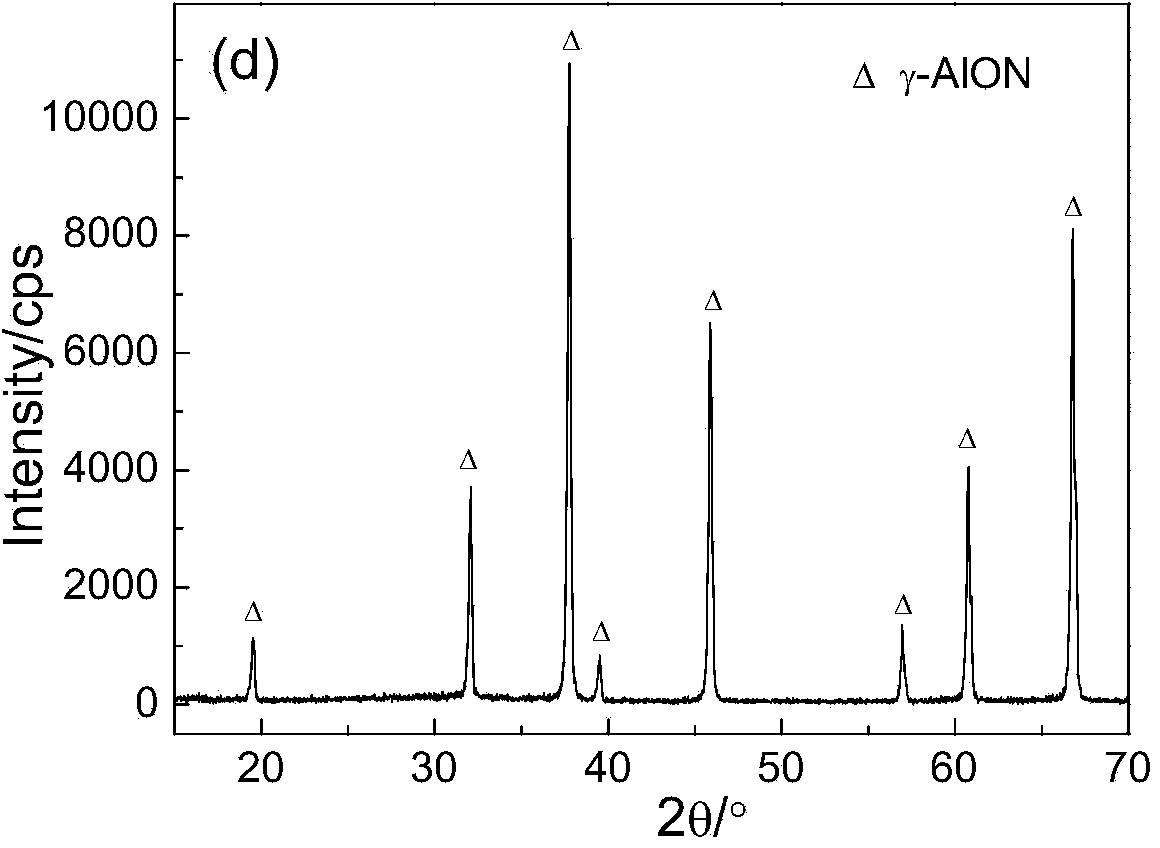

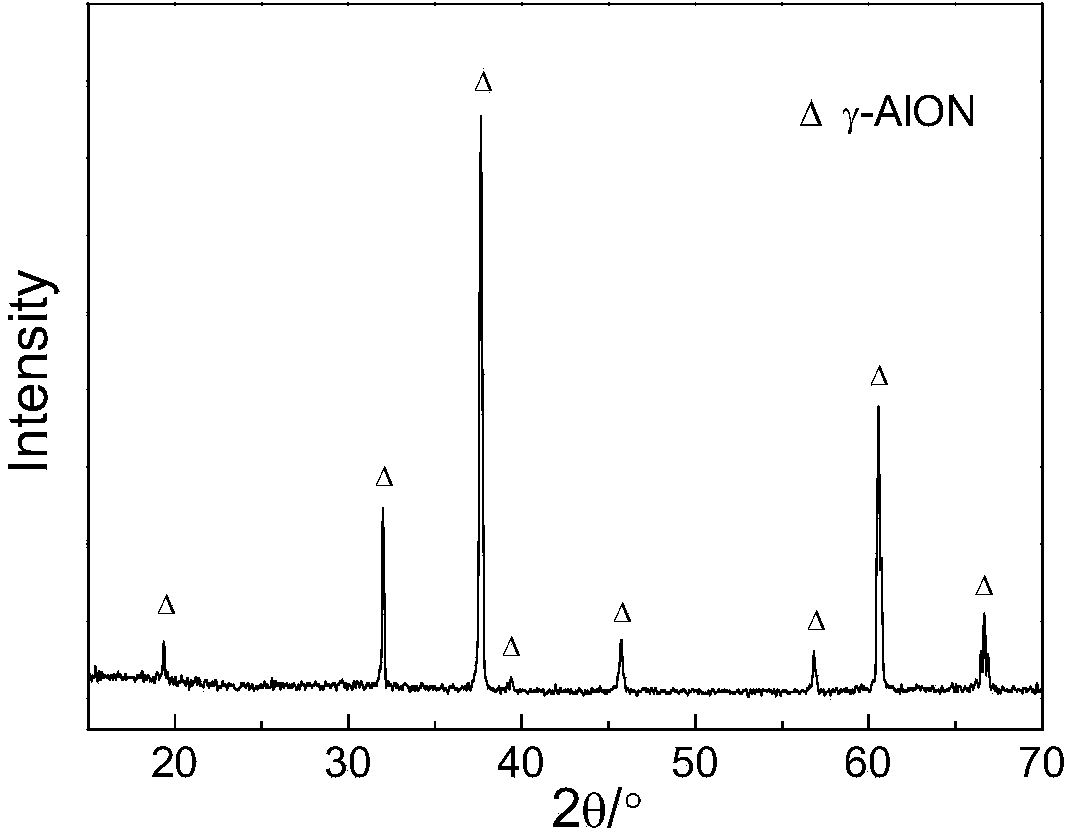

Image

Examples

Embodiment 1

[0036] ① Ingredients: α-Al with an average particle size of 30nm 2 o 3 And analytically pure activated carbon particles are used as raw materials, the content of activated carbon (analytical pure) in the raw material is 5.6wt.%, absolute ethanol is used as the ball milling medium, and the mixed powder is mixed at a speed of 170r / min for 24h;

[0037] ②Drying: Put the slurry obtained in step ① into an open container, heat the slurry until it boils, so that the absolute ethanol can be discharged quickly, and then pass the dried mixed powder through a 50-mesh sieve to obtain a specific surface area of 56m 2 / g of α-Al 2 o 3 Mix powder with activated carbon;

[0038] ③Charging: Lay an alumina plate on the bottom of the graphite crucible, loosely load the mixed powder obtained in step ② into the above-mentioned graphite crucible, the powder filling height is 30mm, and set air holes through the top and bottom of the powder on the mixed powder to the alumina plate , the pore di...

Embodiment 2

[0043] Example 2 According to the method of Example 1, the difference is that step 1. the mixed powder is mixed at 250r / min for 24h, and the specific surface area of the mixed powder obtained after step 2. is dried is 73m 2 / g. The XRD results of the prepared powder are shown in figure 1 (d), is pure phase γ-AlON.

Embodiment 3~4

[0045] Examples 3-4 The AlON ceramic powder is sintered according to the method of Examples 1-2, except that the carbon removal process is 620° C. for 5 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com