Antibacterial high-water-absorption linen and preparation method thereof

A technology of high water absorption and linen, which is applied in the direction of liquid repellent fiber, biochemical fiber treatment, fiber type, etc., and can solve problems such as unsatisfactory water absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

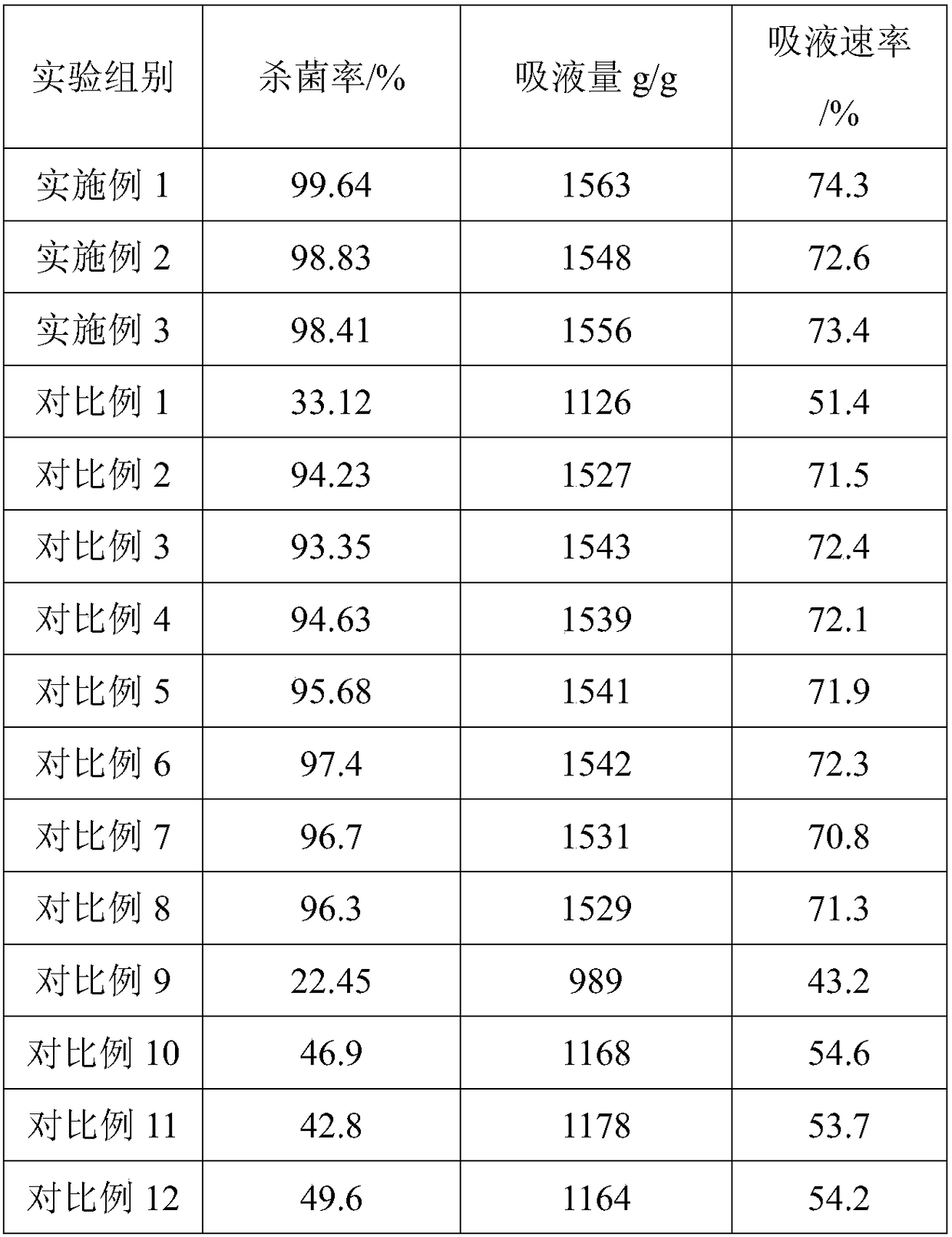

Examples

preparation example Construction

[0027] The preparation method of the antibacterial superabsorbent linen comprises the following steps:

[0028] S1: Hydrogel, acrylamide, potassium persulfate, N,N`-methylenebisacrylamide, cinnamon extract, carbon nanotubes, chitosan, antibacterial enhancement additives, water absorption enhancement additives, silane Mix the coupling agent KH-570 evenly, raise the temperature to 80-90°C, keep it warm for 20-40min, then add polylactic acid and sodium alginate and mix evenly, stir at 1500-2500r / min for 20-40min to form material I;

[0029] S2: Mix material I and polyester fiber material at a weight ratio of 1:50 and soak for 2-3 days to obtain an antibacterial outer layer. The hemp fiber layer is made of warp and weft yarns made of hemp fiber, and the inner base layer is made of spandex fiber. Then weave the hemp fiber layer and the inner base layer first, and finally weave the antibacterial outer layer, and finally obtain the antibacterial superabsorbent linen.

Embodiment 1

[0031] An antibacterial superabsorbent linen cloth, comprising an antibacterial outer layer, a hemp fiber layer, and an inner base layer, the antibacterial outer layer is a polyester fiber material soaked in an antibacterial agent, the inner layer of the antibacterial outer layer is a hemp fiber layer, and the hemp fiber layer is The fiber layer is made by interweaving warp and weft yarns made of hemp fiber, and an inner base layer is inside the hemp fiber layer, and the inner base layer is made of spandex fiber.

[0032] The antibacterial agent, in parts by weight, includes the following raw materials: 6.3 parts of hydrogel, 5.9 parts of attapulgite, 6.4 parts of sodium alginate, 5.8 parts of acrylamide, 3.2 parts of potassium persulfate, N,N`- 2.6 parts of methylbisacrylamide, 17.8 parts of cinnamon extract, 4.3 parts of carbon nanotubes, 5.2 parts of chitosan, 7.4 parts of antibacterial enhancement additives, 11.3 parts of water absorption enhancement additives, and 2.3 part...

Embodiment 2

[0039] An antibacterial superabsorbent linen cloth, comprising an antibacterial outer layer, a hemp fiber layer, and an inner base layer, the antibacterial outer layer is a polyester fiber material soaked in an antibacterial agent, the inner layer of the antibacterial outer layer is a hemp fiber layer, and the hemp fiber layer is The fiber layer is made by interweaving warp and weft yarns made of hemp fiber, and an inner base layer is inside the hemp fiber layer, and the inner base layer is made of spandex fiber.

[0040] The antibacterial agent, in parts by weight, includes the following raw materials: 4 parts of hydrogel, 8 parts of attapulgite, 4 parts of sodium alginate, 8 parts of acrylamide, 2 parts of potassium persulfate, N,N`- 4 parts of methylbisacrylamide, 12 parts of cinnamon extract, 6 parts of carbon nanotubes, 2 parts of chitosan, 10 parts of antibacterial enhancement additive, 8 parts of water absorption enhancement additive, and 3 parts of silane coupling agent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com