Closed mesoporous silicon oxide and preparation method of same

A mesoporous silica, closed-cell technology, applied in chemical instruments and methods, inorganic chemistry, silicon compounds, etc., can solve the problem of narrow selection of raw materials, incomplete closed-pore mesoporous silica is difficult to apply, and cannot hinder the entry of resin matrix. problems such as mesoporous silica channels, to achieve excellent comprehensive performance, high specific surface area, and good universality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

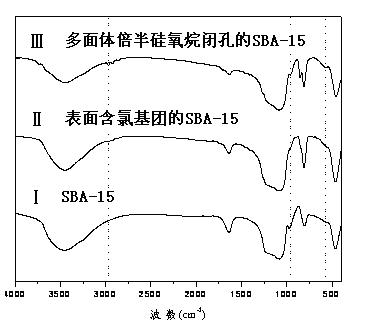

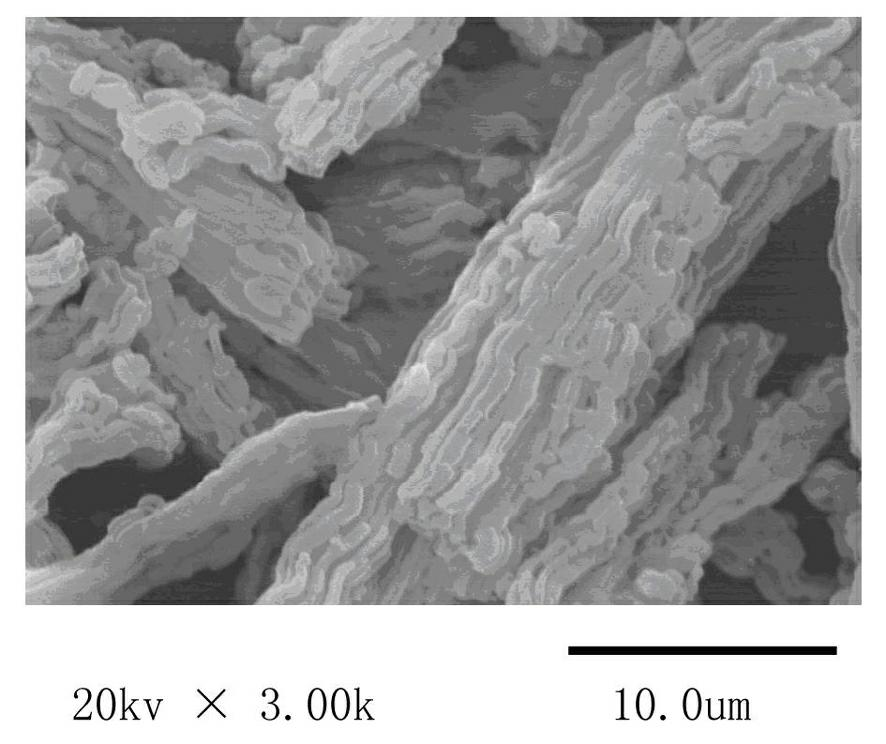

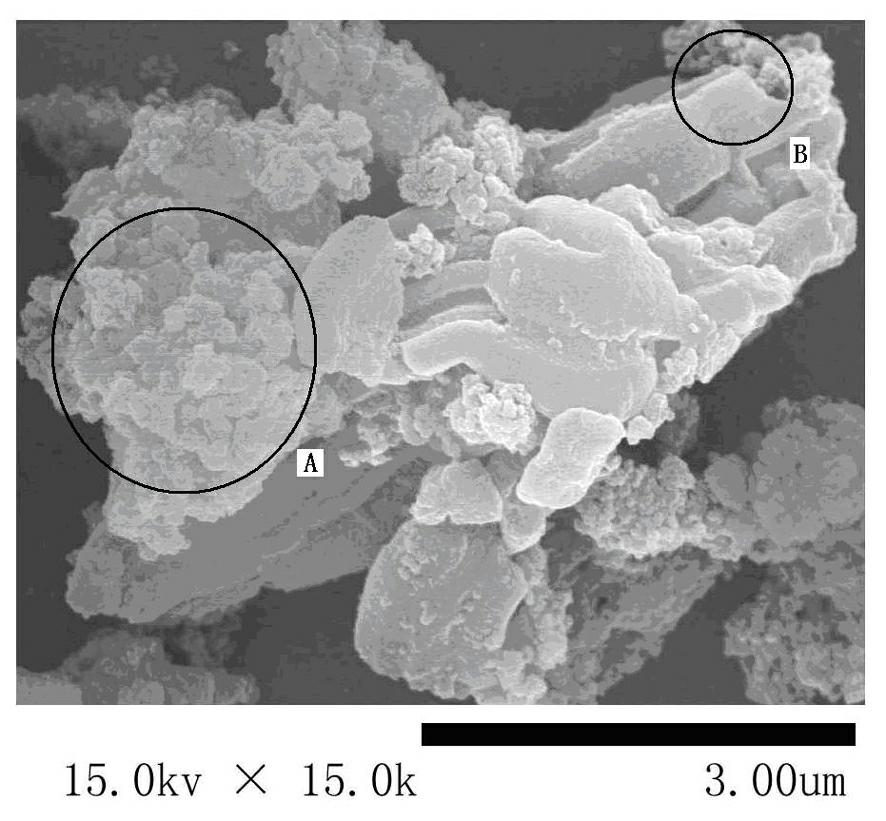

[0025] 5 g of mesoporous silica SBA-15 was kept at 110° C. for 2 hours to obtain dry SBA-15. 150 ml of anhydrous toluene was added to dry SBA-15, stirred, and 10.75 g of dimethyldichlorosilane was slowly added dropwise at 40°C. After the dropwise addition, the reaction was carried out at 40°C for 6 hours. Anhydrous toluene and unreacted polychlorosilane were removed by vacuuming to obtain a white powder, which was washed twice with anhydrous toluene to obtain a crude product. The crude product was dried at 55°C for 7 hours to obtain mesoporous silica with chlorine groups on the surface. Its infrared spectrum and scanning electron microscope (SEM) are shown in the attached figure 1 , 2 shown.

[0026] Add 0.3 g of mesoporous silica containing chlorine groups on the surface to 30 ml of anhydrous acetone to form solution A; add 0.3 g of octapoly(tetramethylammonium) silicate to 10 ml of anhydrous methanol to form solution B . Solutions A and B were mixed and the mixture was...

Embodiment 2

[0041] 5 g of mesoporous silica SBA-15 was kept at 110° C. for 2 hours to obtain dry SBA-15. 150 ml of anhydrous toluene was added to dry SBA-15, stirred, and 10.75 g of dimethyldichlorosilane was slowly added dropwise at 40°C. After the dropwise addition, the reaction was carried out at 40°C for 6 hours. Anhydrous toluene and unreacted polychlorosilane were removed by vacuuming to obtain a white powder, which was washed twice with anhydrous toluene to obtain a crude product. The crude product was dried at 55°C for 7 hours to obtain mesoporous silica with chlorine groups on the surface.

[0042] Add 0.6g of mesoporous silica containing chlorine groups on the surface to 60ml of anhydrous acetone to form solution A; add 0.6g of octapoly(tetramethylammonium)silicate to 20ml of anhydrous methanol to form solution B . Solutions A and B were mixed and the mixture was sonicated at 40°C for 20 min to form solution C. Solution D was formed by adding 5.4 g of octapoly(tetramethylamm...

Embodiment 3

[0044] 5 g of mesoporous silica SBA-15 was kept at 120° C. for 3 hours to obtain dry SBA-15. 150ml of anhydrous toluene was added to dry SBA-15, stirred, and 13.63g of (chloromethyl)methyldichlorosilane was slowly added dropwise at 30°C. After the dropwise addition, the reaction was continued for 8 hours. After the reaction, anhydrous toluene and unreacted polychlorosilane were removed by vacuuming to obtain a white powder and water, which was washed twice with anhydrous toluene to obtain a crude product. The crude product was dried at 55°C for 7 hours to obtain mesoporous silica with chlorine groups on the surface.

[0045] Add 0.3 g of mesoporous silica containing chlorine groups on the surface to 40 ml of anhydrous acetone to form solution A; add 0.3 g of octapoly(tetramethylammonium) silicate to 20 ml of methanol-free solution to form solution B. Solutions A, B were mixed and sonicated at 30°C for 30 min to form solution C. Solution D was formed by adding 2.7 g of octap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com