Electric core used for secondary lithium battery and preparation

A secondary lithium battery and cell technology, applied in secondary batteries, battery electrodes, electrode carriers/current collectors, etc., can solve the problems of inability to meet industrial needs, inability to coat battery pole pieces, and low battery energy density, etc. Achieve the effect of low manufacturing cost, high cost and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0059] Example 1

[0060] reference figure 1 , To make a battery for a secondary lithium battery, including: a positive electrode, a negative electrode and a separator; the positive / negative electrode is on the positive / negative current collector, and the electrode mixture material is uniformly pressed on the positive / negative electrode through an extrusion process. On one surface of the negative electrode current collector, or evenly pressed on both surfaces of the positive / negative electrode current collector, a battery cell of a secondary lithium battery with an inner lining layer or both inner and outer lining layers is formed. The specific preparation steps of the battery as follows:

[0061] 1). First make a mold, which is a square box;

[0062] 2). Prepare the positive electrode mixture material used in the secondary lithium battery, calculate by weight percentage, and weigh according to the following formula:

[0063] a. The positive electrode active material lithium mang...

Example Embodiment

[0076] Example 2

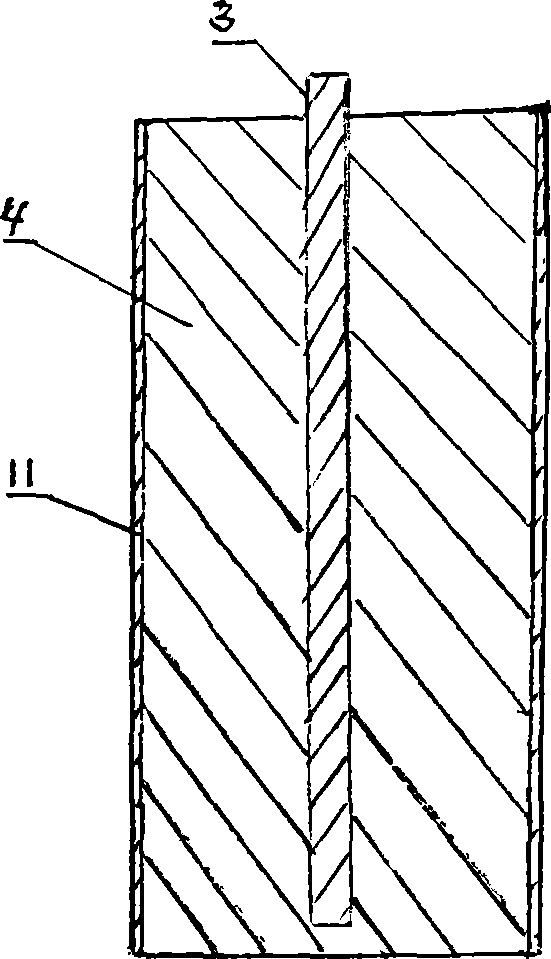

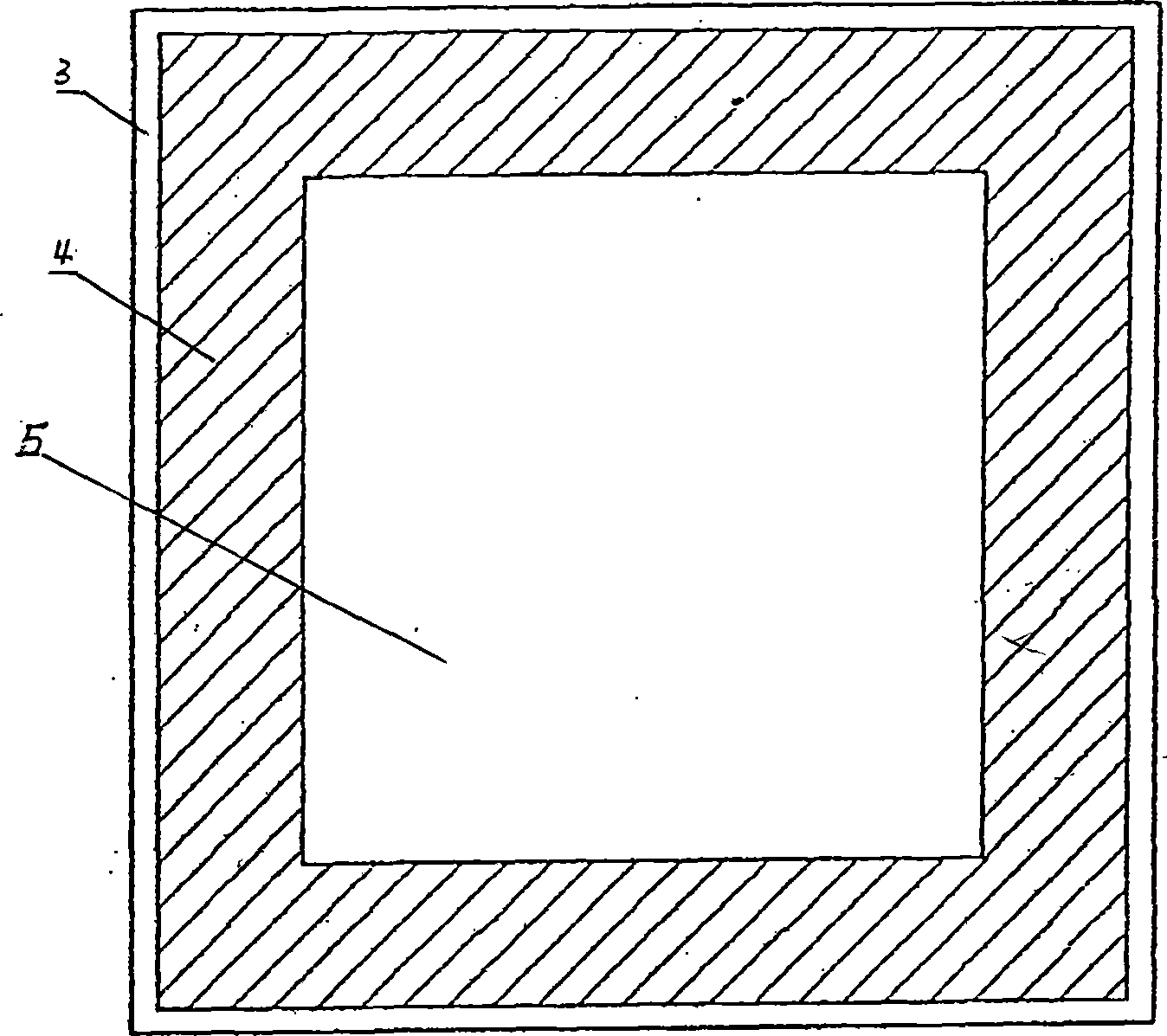

[0077] reference image 3 with 4 , Make a negative case of a square battery, the negative current collector 3 is a 0.2 mm thick copper plate, the negative current collector 3 is made into a square case with a side length of 30 mm, the square case is hollow, and the side length is 18.6 mm Positive electrode cavity: A layer of negative electrode mixed material with a thickness of 6 mm is pressed on the inner wall of a square shell made of a negative electrode current collector through an extrusion forming process to form a negative electrode 10 with a “concave”-shaped shell lining (such as image 3 Shown).

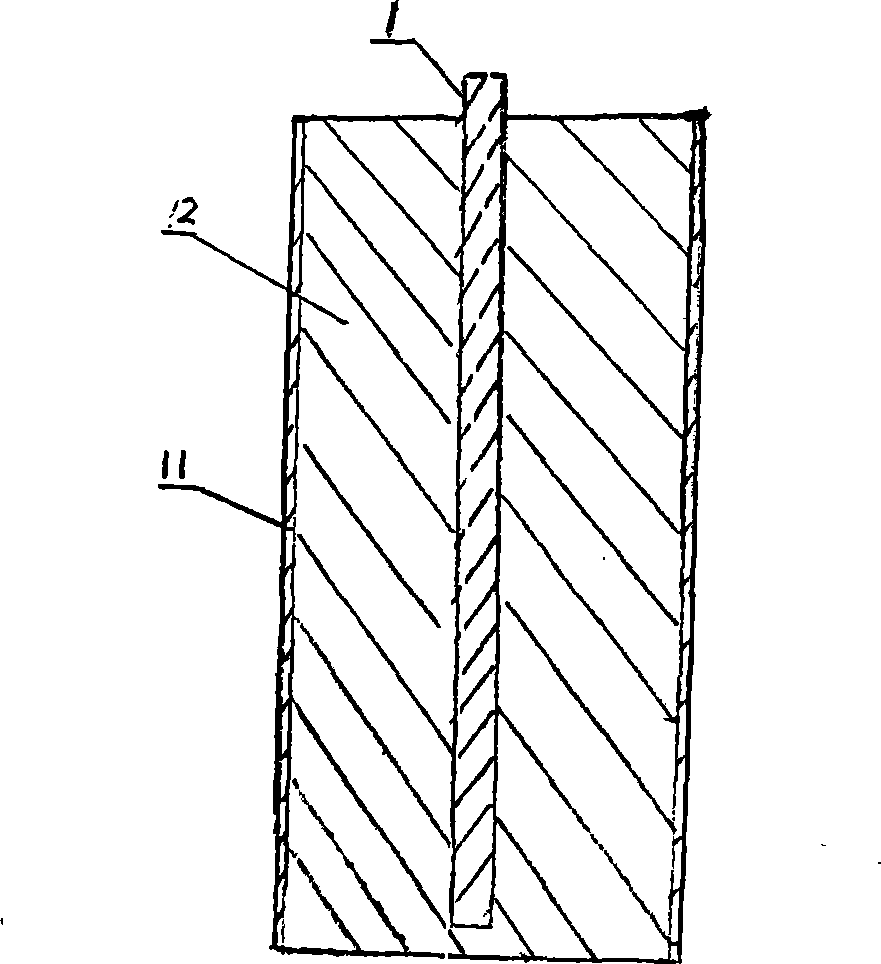

[0078] reference Figure 5 , Make a positive electrode of a square battery, in which the positive electrode collector 1 uses a round or square copper rod, and a layer of positive electrode composite material is pressed around the positive electrode collector 1 to form a square with a side length of 18 mm. The composite material is wrapped with a 40-micron thic...

Example Embodiment

[0091] Example 3

[0092] reference Figure 8 This embodiment is to make a cell for a spherical battery. The negative current collector 1 is a copper shell with a thickness of 0.1 mm and two hemispherical shells with a radius of 8 mm are made, and the negative material is uniformly pressed into the hemispherical shell through an extrusion process In the inner wall, a hemispherical inner wall is uniformly extruded with a layer of 2 mm thick negative electrode mixed material, and the two hemispherical shells are butted together to form a positive electrode cavity with a middle radius of 5.9 mm (such as Figure 8 Shown).

[0093] The positive electrode mixed material and the positive electrode current collector. The positive electrode current collector 3 is an aluminum rod with a radius of 0.8 mm and pressed together to form a spherical positive electrode with a rod with a radius of 5.5 mm. The upper end of the aluminum rod of the positive electrode current collector 3 protrudes from...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com