Patents

Literature

39results about How to "Increase the number of washes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Novel stainless steel acid-washing passivation liquid

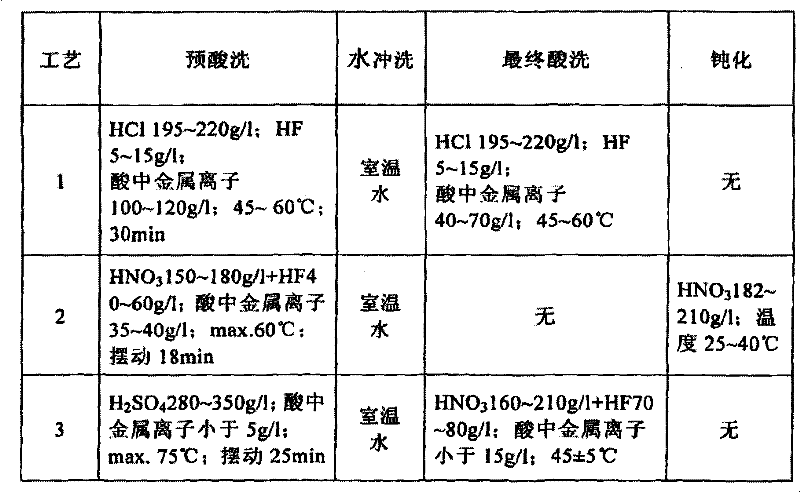

ActiveCN102653868AReduce pollutionLow running costMetallic material coating processesHydrofluoric acidAcid washing

The invention relates to a novel stainless steel acid-washing passivation liquid which comprises inorganic acid, penetrant, oxidant and corrosion inhibitor. The stainless steel acid-washing passivation liquid does not generate violent pungent odor or yellow acid mist in the application process, thereby avoiding hurting the skin, reducing the air pollution and lowering the cost. The stainless steel acid-washing passivation liquid is easy to use: the stainless steel acid-washing passivation liquid is poured into a tank, and soaks the stainless steel at normal temperature without heating; and the washing speed is about 50% higher than those of the acid-washing passivation liquid (paste) in the existing market and the acid-washing passivation liquid containing nitric acid and hydrofluoric acid, and the washing quantity is as 3.2 times or so as the like products in the market. The novel stainless steel acid-washing passivation liquid can complete oil removal, derusting, descaling and acid-washing passivation at one time. The residual liquid after use can be treated by a conventional treatment method, and can also be used for treating dyeing waste water; and the treated dyeing waste water is clear and transparent and achieves the reclamation standard. Thus, the stainless steel acid-washing passivation liquid has the advantages of environment protection and water resource saving, and can recycle water.

Owner:王福平

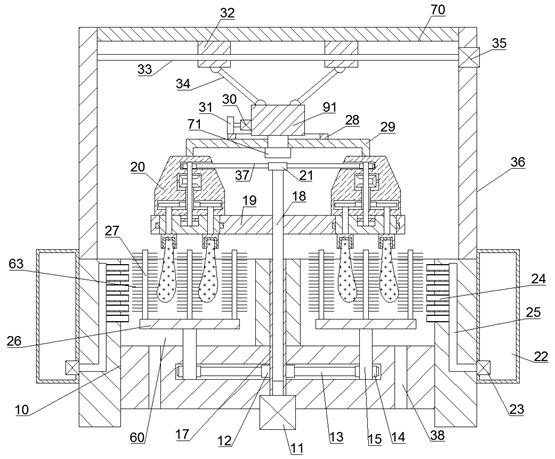

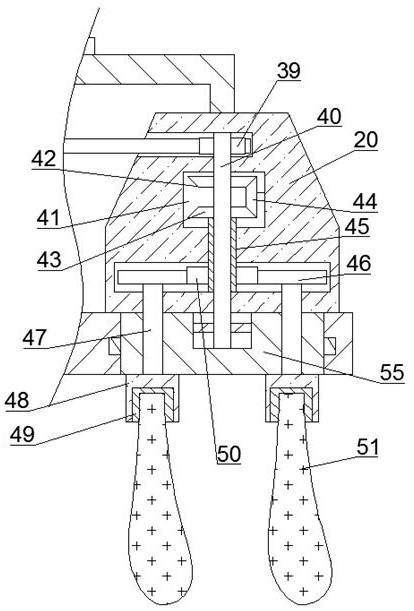

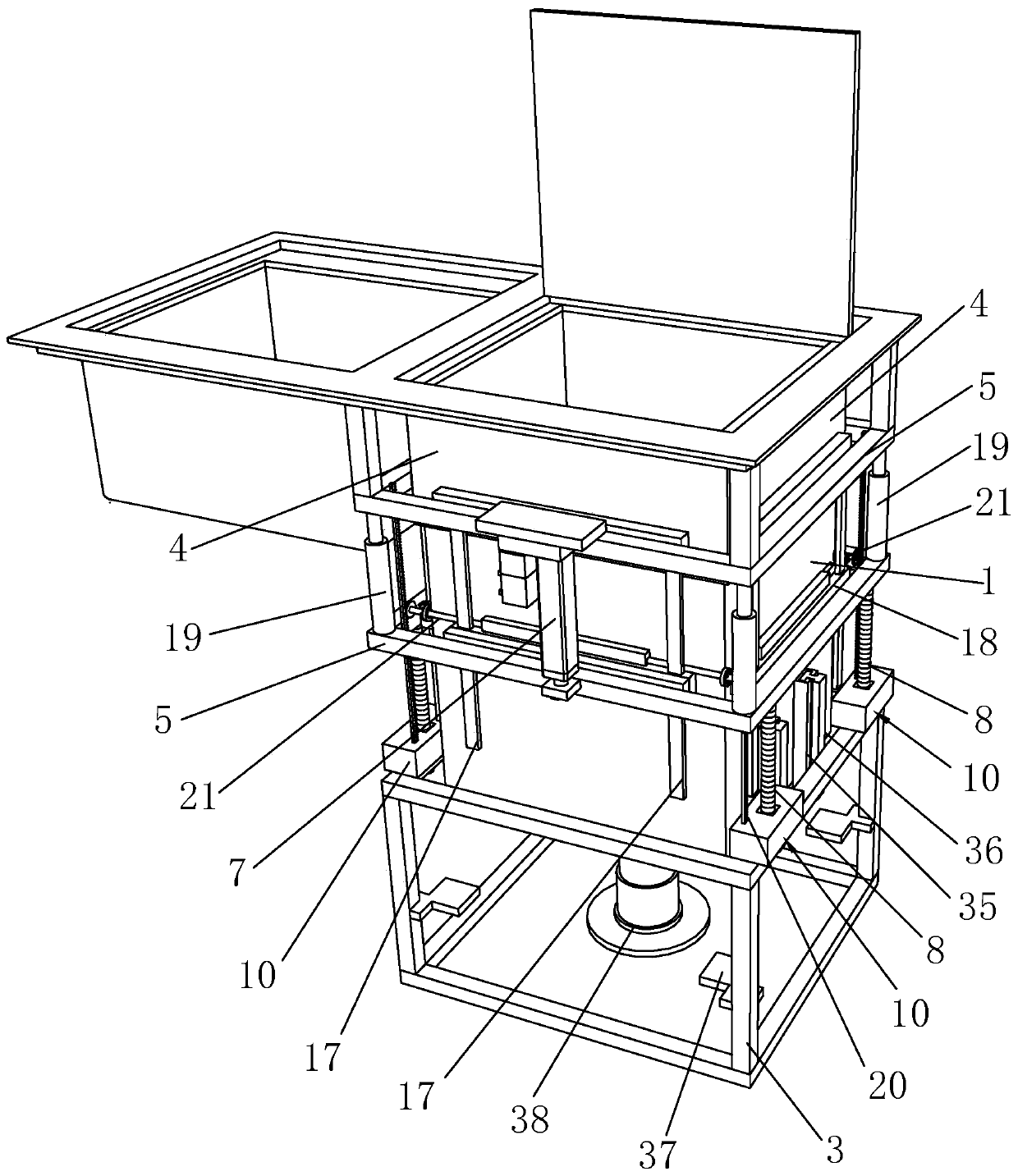

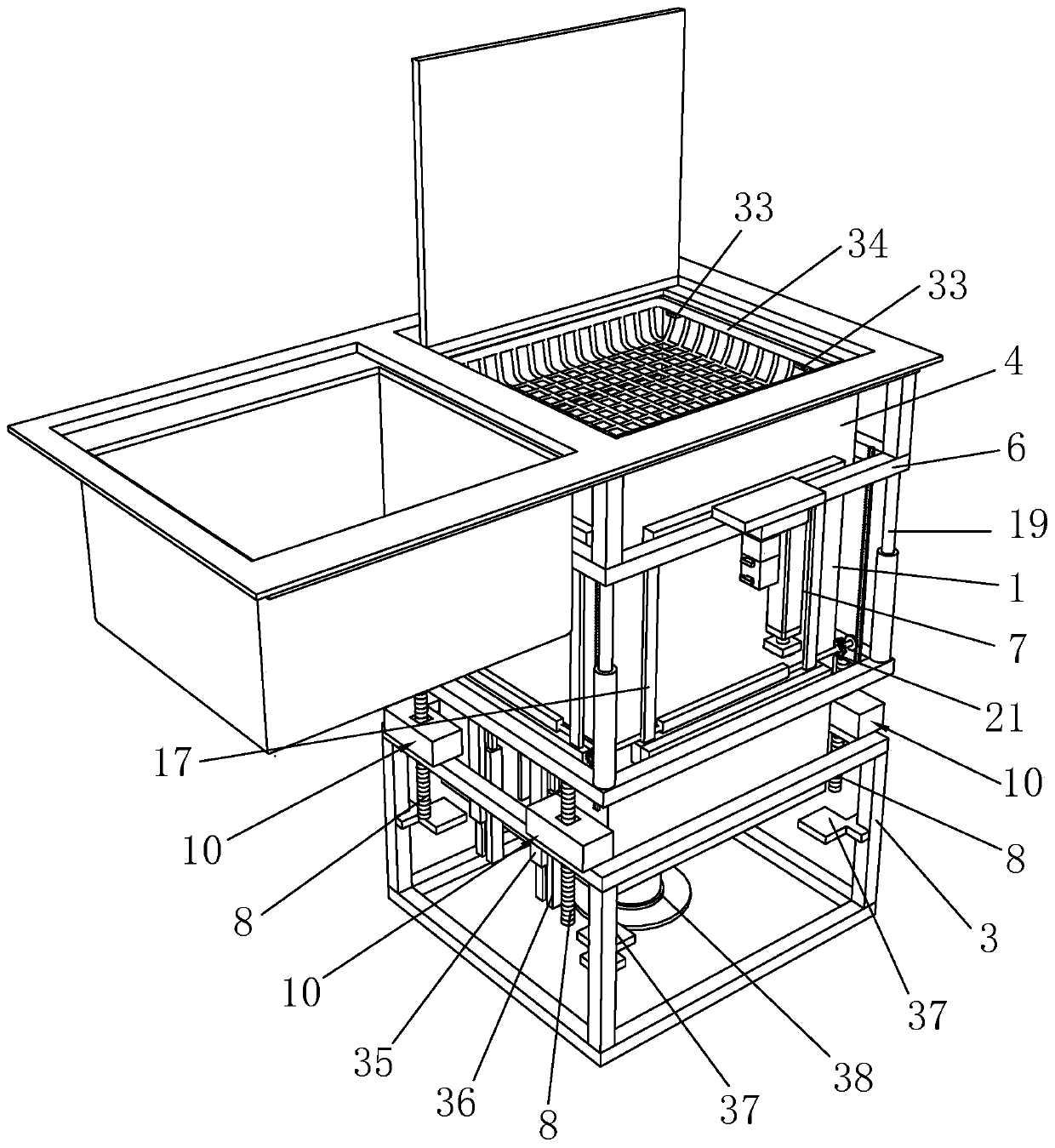

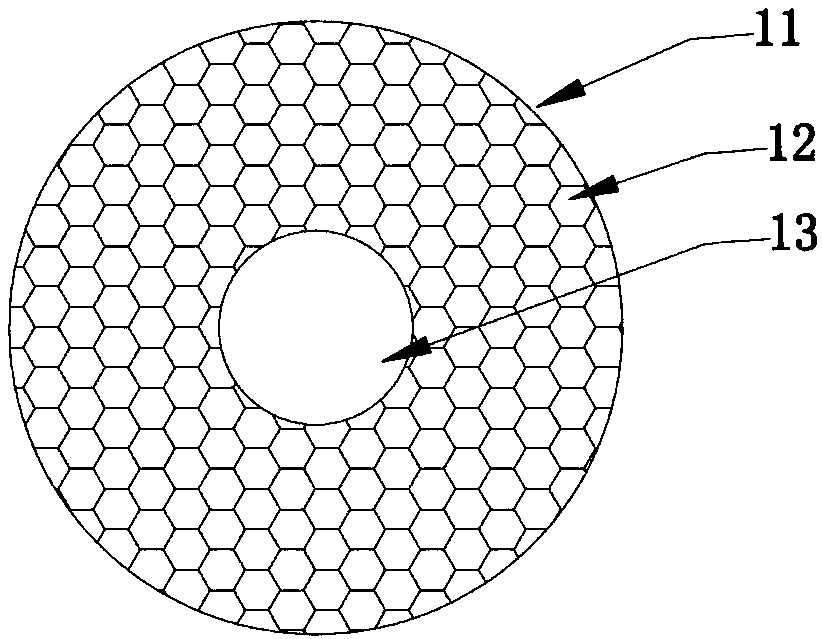

Fan blade cleaning device made of novel carbon fiber materials

ActiveCN111420918AHigh linkageImprove linkage and improve cleaning effectCleaning using toolsCleaning using liquidsFiberCarbon fibers

The invention discloses a fan blade cleaning device made of novel carbon fiber materials. The fan blade cleaning device made of the novel carbon fiber materials comprises a base, two cleaning cavitieswhich are symmetrical left and right are formed in the base, openings of the two cleaning cavities are designed to face upwards, rotating discs are rotationally arranged in the two cleaning cavitiescorrespondingly, three cleaning shafts which are evenly distributed are fixedly arranged on the top faces of the rotating discs, and brushes are fixedly arranged on peripheries of cleaning shafts correspondingly. According to the fan blade cleaning device made of the novel carbon fiber materials, a plurality of blades can be clamped through sliding of a plurality of clamping blocks, the fact thatcleaning the plurality of blades at the same time can be carried out is realized, the cleaning number is greatly increased; when the blades rotate, the blades can be driven by the rotating discs to carry out revolution with a driven shaft as the circle center, and the brushes are driven by the rotating discs to rotate, so that the cleaning speed is greatly increased; and meanwhile, the structure is relatively simple, transmission components are all very common components, the cost is low, and popularization is convenient.

Owner:江苏韩塑新材料有限公司

Method for printing and dyeing cotton fabrics with natural plant as dye

InactiveCN102433771AHealth injuryNo pollution in the processBiochemical fibre treatmentDyeing processColour fastnessEngineering

The invention discloses a method for printing and dyeing cotton fabrics with a natural plant as a dye. According to the invention, through reasonable selection of a mordant and reasonable design of a printing and dyeing process, color fastness of a printed and dyed cotton fabric is improved, and in particular, color fastness to rubbing under wet conditions is substantial improved on the premise that weathering color fastness and color fastness to rubbing under dry conditions are enhanced; therefore, user demands are met, and wash durability of the cotton fabric is enhanced.

Owner:无锡市联盛印染有限公司

Iron removal method of ball clay for electric ceramic industry

The invention provides an iron removal method of ball clay for electric ceramic industry, which relates to the ball clay for electric ceramic industry. The method comprises the following steps of: pulping and separating raw ball clay ore so as to remove coarsely graded sand stone; enabling the ore pulp containing fine sands to enter a spiral classifier so as to obtain an ore pulp; conveying the ore pulp into a separation pool to be separated; enabling the ore pulp coming out the separation pool to enter a concentrating pool; pumping out fine sands at the bottom of the separation pool by usinga mud pump; conveying the ore pulp in the concentrating pool to an iron removing pool; adding water to the ore pulp to adjust the concentration of the ore pulp; adding industrial sulphuric acid to the ore pulp; adding sodium hydrosulfite to the ore pulp so as to carry out chemical reduction reaction; adding oxalic acid to the ore pulp so as to carry out complex reaction; filling up a water pool with c lean water so as to flush the ore pulp; adding polyacrylamide to the ore pulp so as to carry out flocculation reaction; discharging out the water after the pulp material is settled; adding cleanwater to the ore pulp so as to flush the ore pulp until the pH value of the ore pulp is neutral; discharging out the water after the ore pulp is settled; feeding the ore pulp into a stripper by usingthe mud pump so as to ultra-finely stripe the ore pulp; metering and packing the ball clay after the ball clay is filter-pressed and dried; and putting the ball clay into a warehouse for shipment.

Owner:XIAMEN UNIV

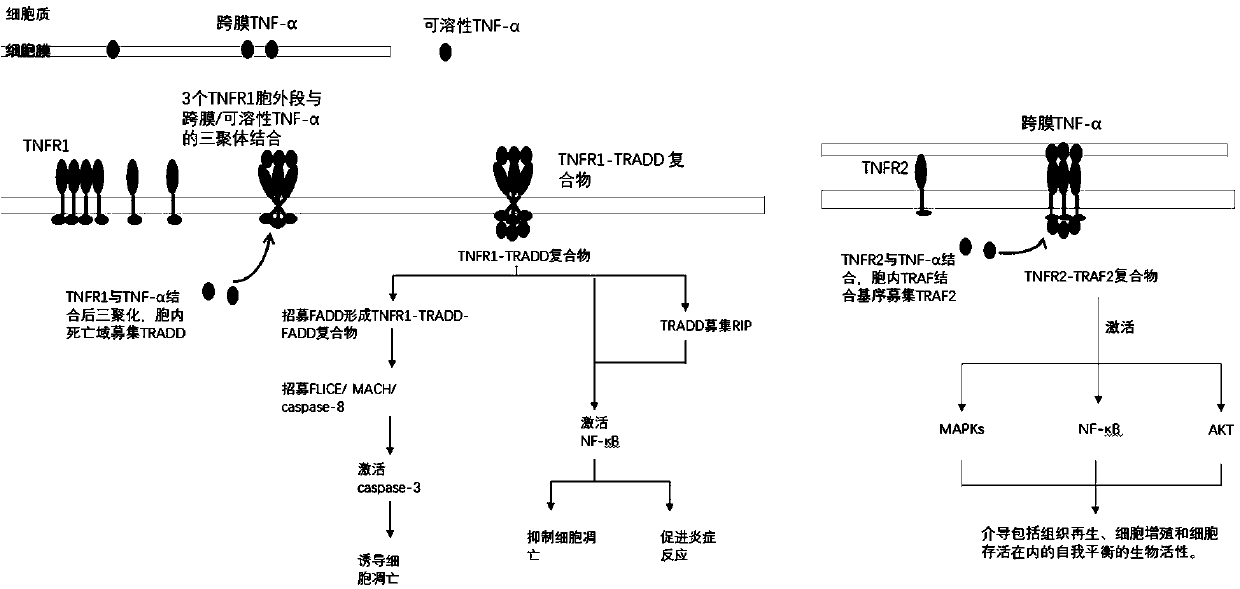

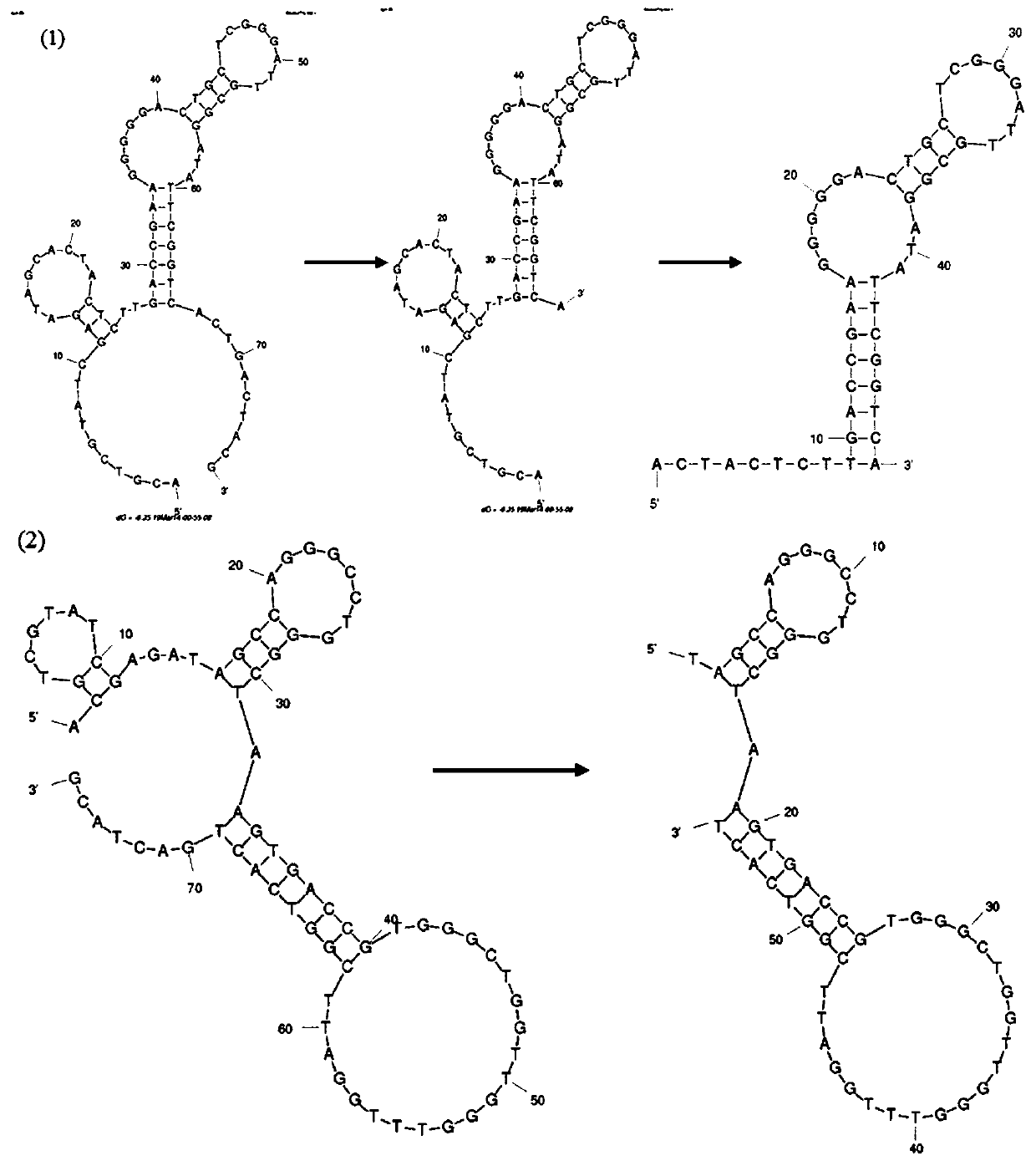

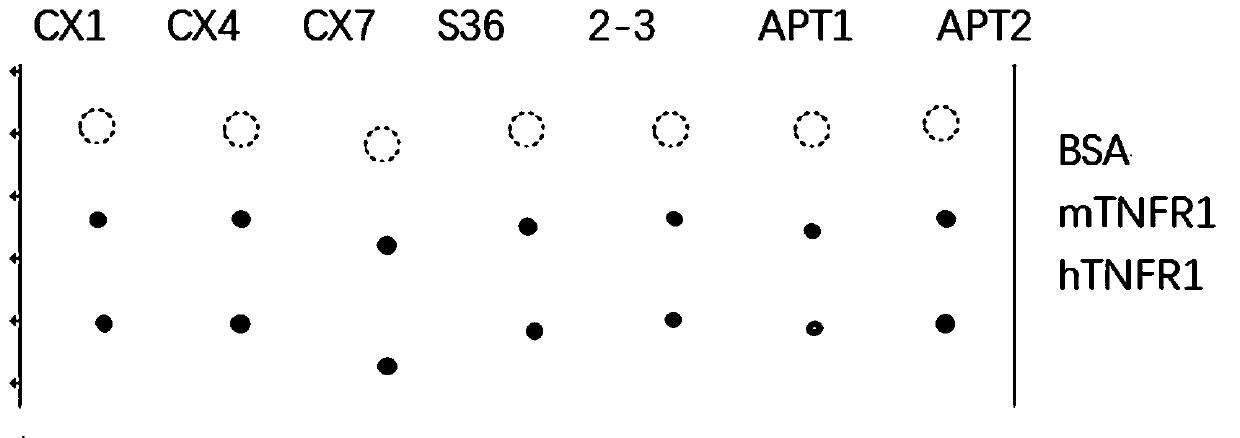

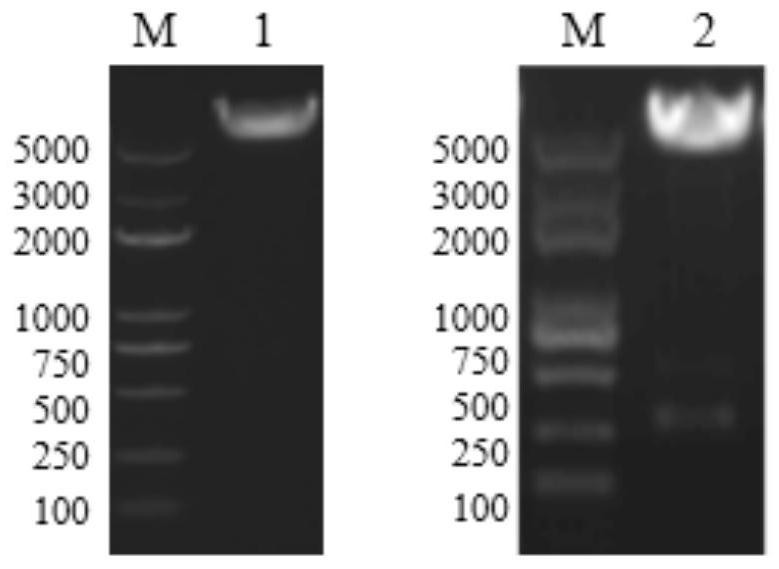

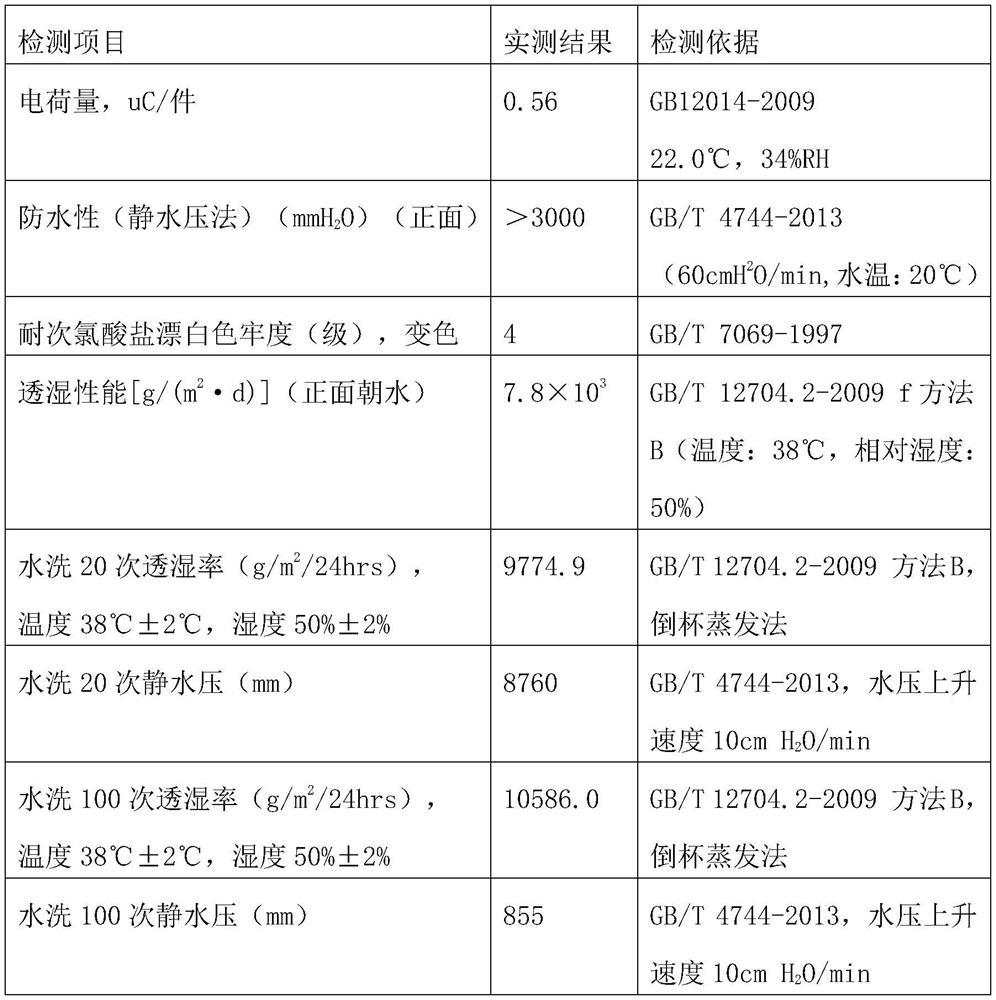

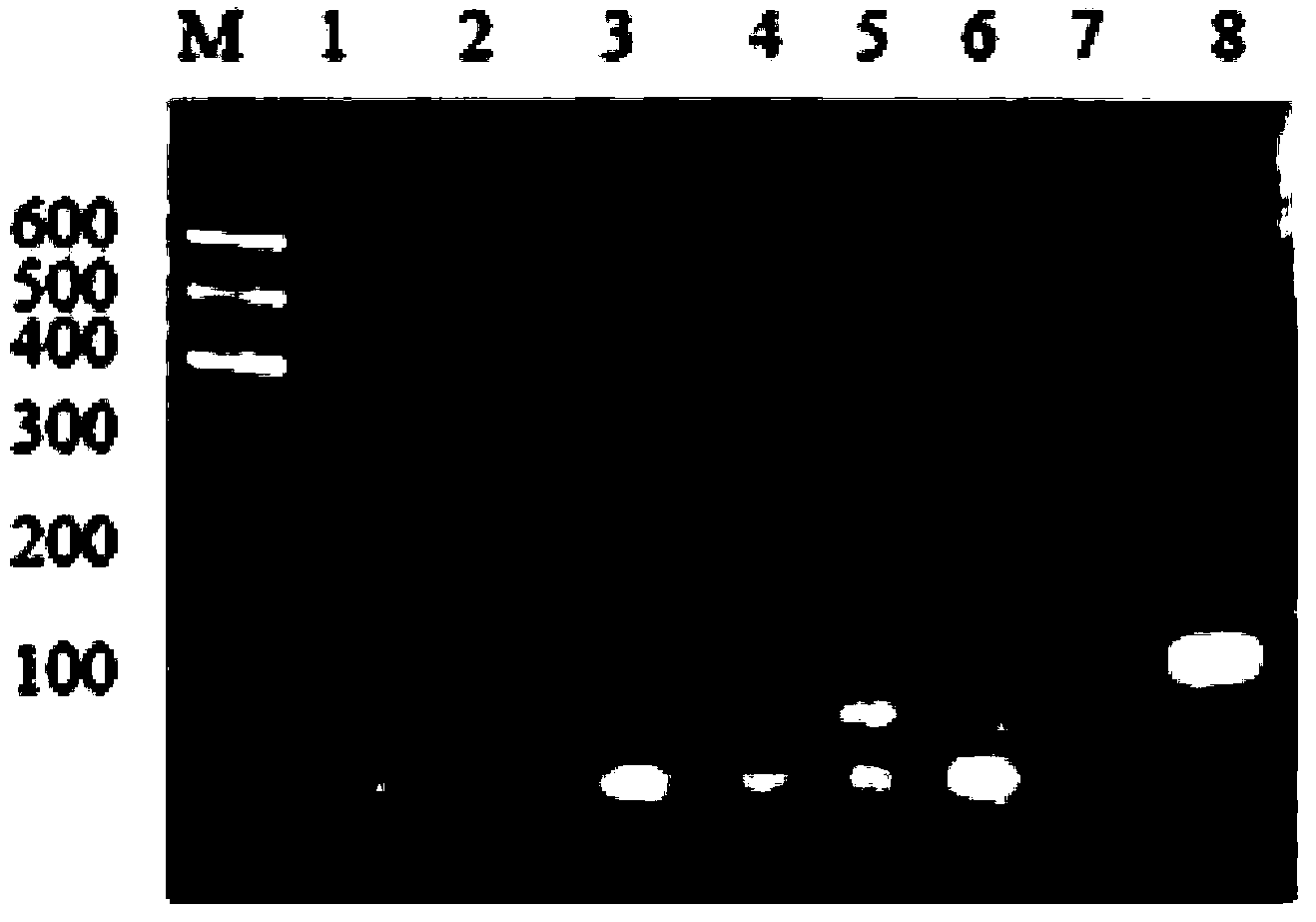

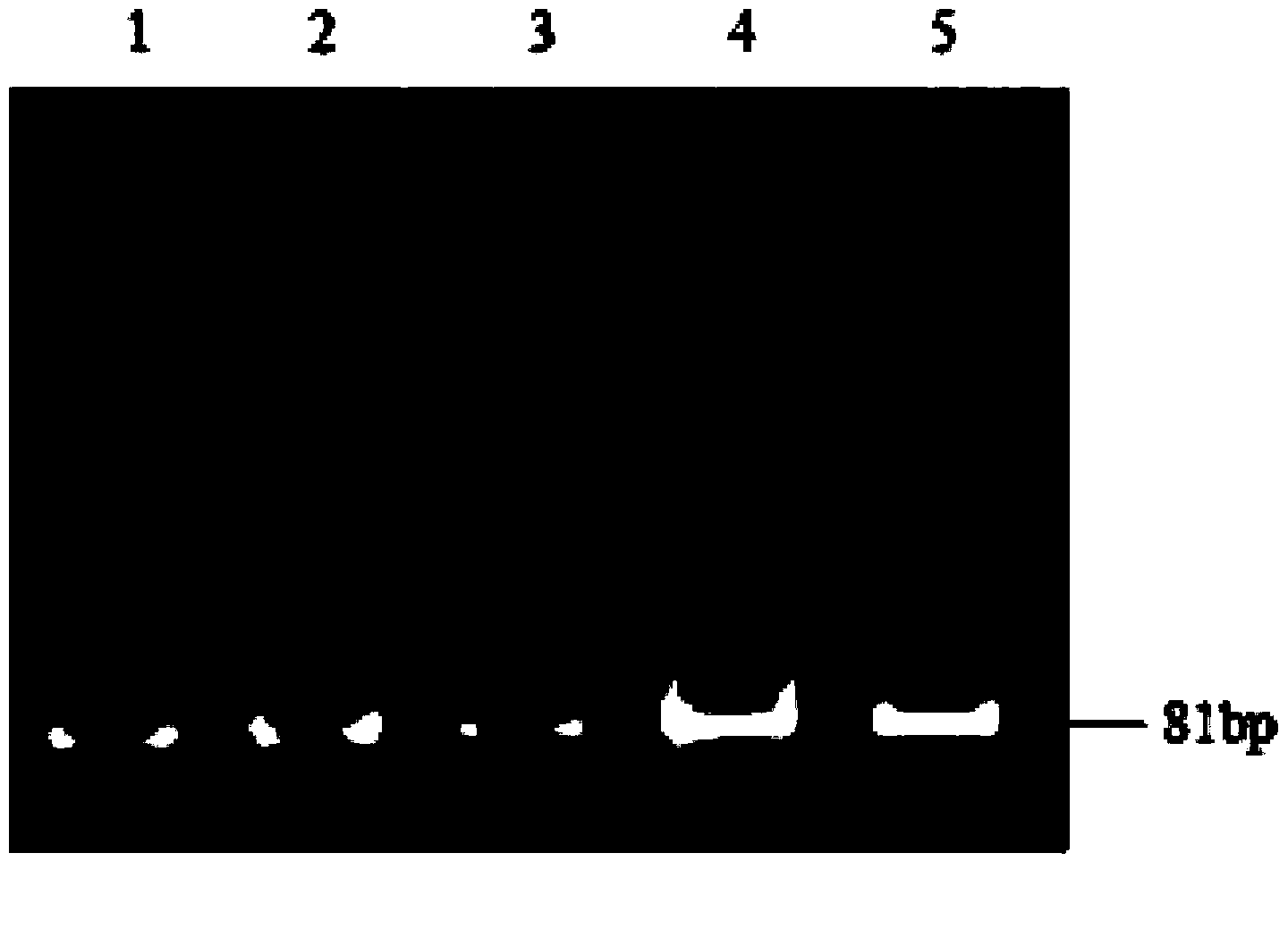

Aptamer specifically combined with TNF-R1 as well as screening method and application of aptamer

PendingCN110938632AImprove bindingStrong specificityOrganic active ingredientsAntipyreticAptamerDNA Aptamers

The invention belongs to the technical field of biological medicines, and relates to an aptamer specifically combined with TNF-R1, in particular to the aptamer specifically combined with TNF-R1 as well as a screening method and an application of the aptamer. The aptamer comprises sequences as shown in SEQ ID No. 1-7 and a plurality of truncated active sequences. The invention also relates to the screening method and the application of the aptamer, seven DNA aptamers capable of being specifically combined with human or mouse TNF receptor protein 1 are screened and separated by using an exponentially enriched ligand phylogenetic technique; the sequence structures are analyzed for further truncation to obtain a DNA fragment with a shortest length for keeping the binding capacity, and throughdot blot hybridization characterization and SPR determination, the seven DNA active sequences can be bound with mouse / human TNFR1 protein, are strong in binding capacity, good in specificity and highin sensitivity, and are not bound with BSA protein.

Owner:ZHENGZHOU UNIV

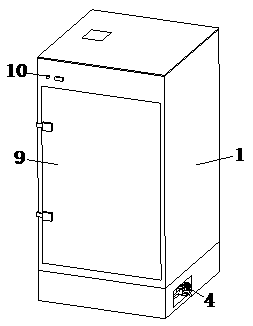

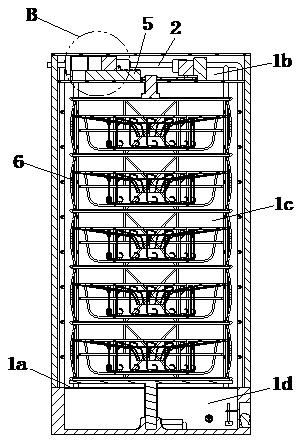

Multilayer upright full-automatic dish washing machine

PendingCN109674418AChange work statusWash thoroughlyTableware washing/rinsing machine detailsAutomatic washing/rinsing machine detectionInterior spaceWater saving

The invention discloses a multilayer upright full-automatic dish washing machine, and belongs to the technical field of dish washing machines. The multilayer upright full-automatic dish washing machine comprises a shell, a cleaning and spraying component, a heating and drying component, an automatic water inlet and discharge component, a quantitative dish washing powder adding component and a dishsupport component, wherein the interior of the shell is of a hollow structure, two clapboards are arranged in the shell and divide the internal space of the shell into a control chamber, a cleaning chamber and a water pool; the cleaning and spaying component is arranged in the cleaning chamber, the heating and drying component is arranged in the water pool, the automatic water inlet and dischargecomponent is arranged in the control chamber and the water pool, the quantitative dish washing powder adding component is arranged in the control chamber, the dish support component is arranged in the cleaning chamber, and a filtering component is arranged in the water pool. The multilayer upright full-automatic dish washing machine can increase the dish cleaning quantity in a single time while ensuring the cleaning effect, does not need a person to watch in the cleaning process, is simple and convenient in operation, and is more water-saving and environment-friendly compared with the prior art.

Owner:谢俊德

Preparation method of knitted underwear fabric

InactiveCN109371554ABright colorGood dimensional stabilityWeft knittingLiquid/gas/vapor article treatmentWrinkle skinEngineering

The invention relates to a preparation method of a knitted underwear fabric. The method comprises the steps that 40S modal precision compact spinning is combined with 30D elaspan spandex as raw materials, a single-face high-speed multi-track circular knitting machine is adopted as a loom, after weaving, gray fabric loosening, presetting, oil removal, scutching, drying, drying, padding and shapingare performed to obtain the knitted underwear fabric. The fabric has softness of cotton, gloss of silk, bright color and washability; the fabric is good in size stability, good in elasticity and goodin underwear shaping performance, has the good wrinkle resistance and the easy-care performance, has the anti-pilling performance, and has the moisturizing and moisture absorbing function, no static electricity is generated when a user wears the underwear, and the underwear fabric is comfortable and is ideal.

Owner:NINGBO BETTER TEXTILE&GARMENTS

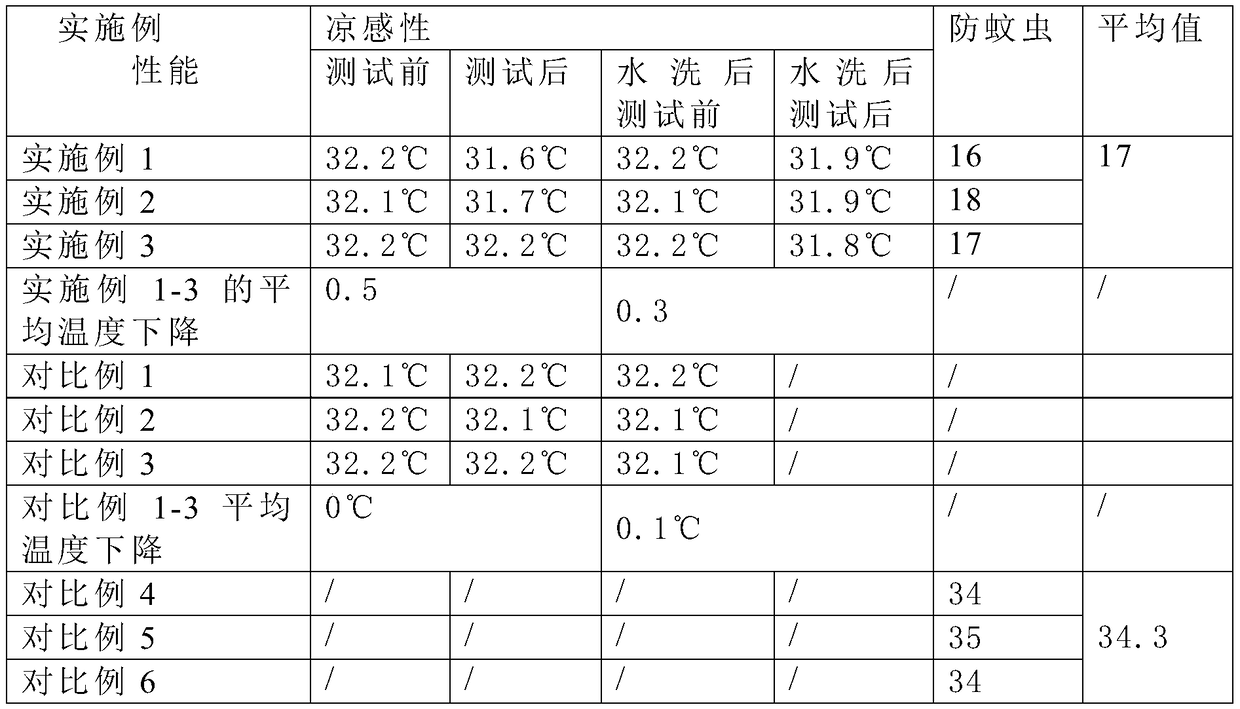

Treatment method of mosquito-preventing fabric having cool hand feel

InactiveCN109137500ALow toxicityIncreased durabilityGrip property fibresAbrasion resistant fibresFiberMonoglyceride

The invention relates to a fabric treatment method and belongs to the technical field of fabrics. A treatment method of a mosquito-preventing fabric having cool hand feel comprises the following stepsthat processed gray cloth is first dried, then a cool feel finishing agent and a mosquito-preventing agent are sequentially added for padding, and finally the finished product fabric is obtained through setting. The cool feel finishing agent comprises, by mass, 5-10% of deep sea fish oil, 5-10% of xylitol, 5-10% of fibroin, 1-5% of undecanol monoglyceride and 65-84% of water. The concentration ofpermethrin contained by the mosquito-preventing agent is 700-1600 mg / m<2>, and the concentration of a fixing agent is 20-40 g / L. The prepared fabric has cool feel and also has an excellent mosquito-preventing effect, the washable times are increased to 100 by adopting polyurethane, and the fabric has soft hand feel, has elasticity, can endow clothing with the soft hand feel and has good fiber friendliness and reproducibility.

Owner:NINGBO MENGHENG LACE CO LTD

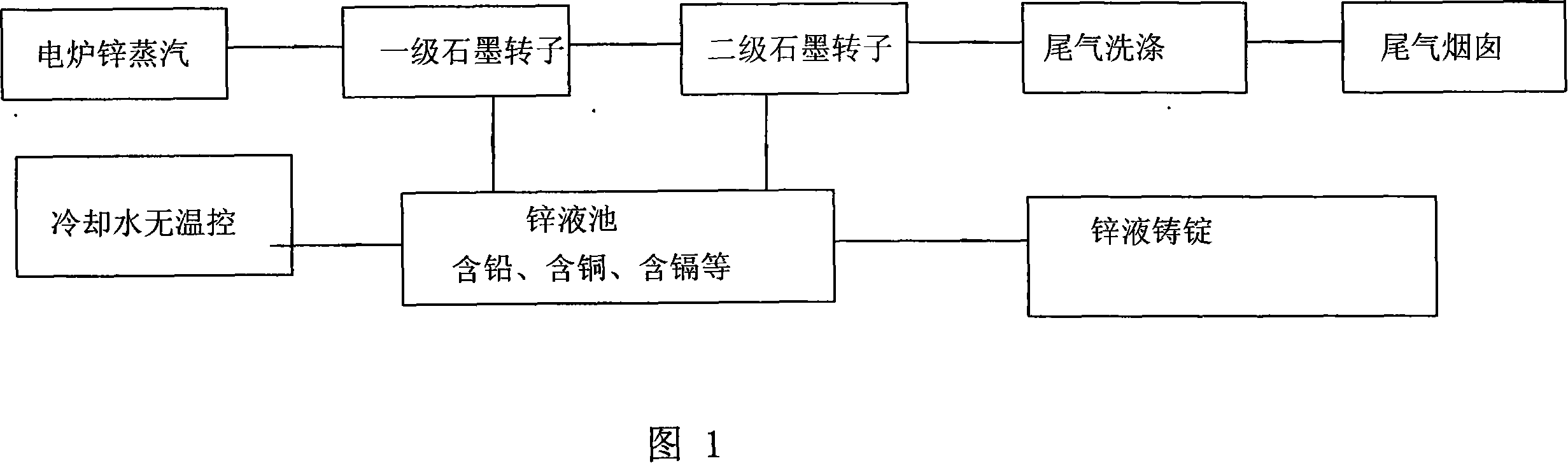

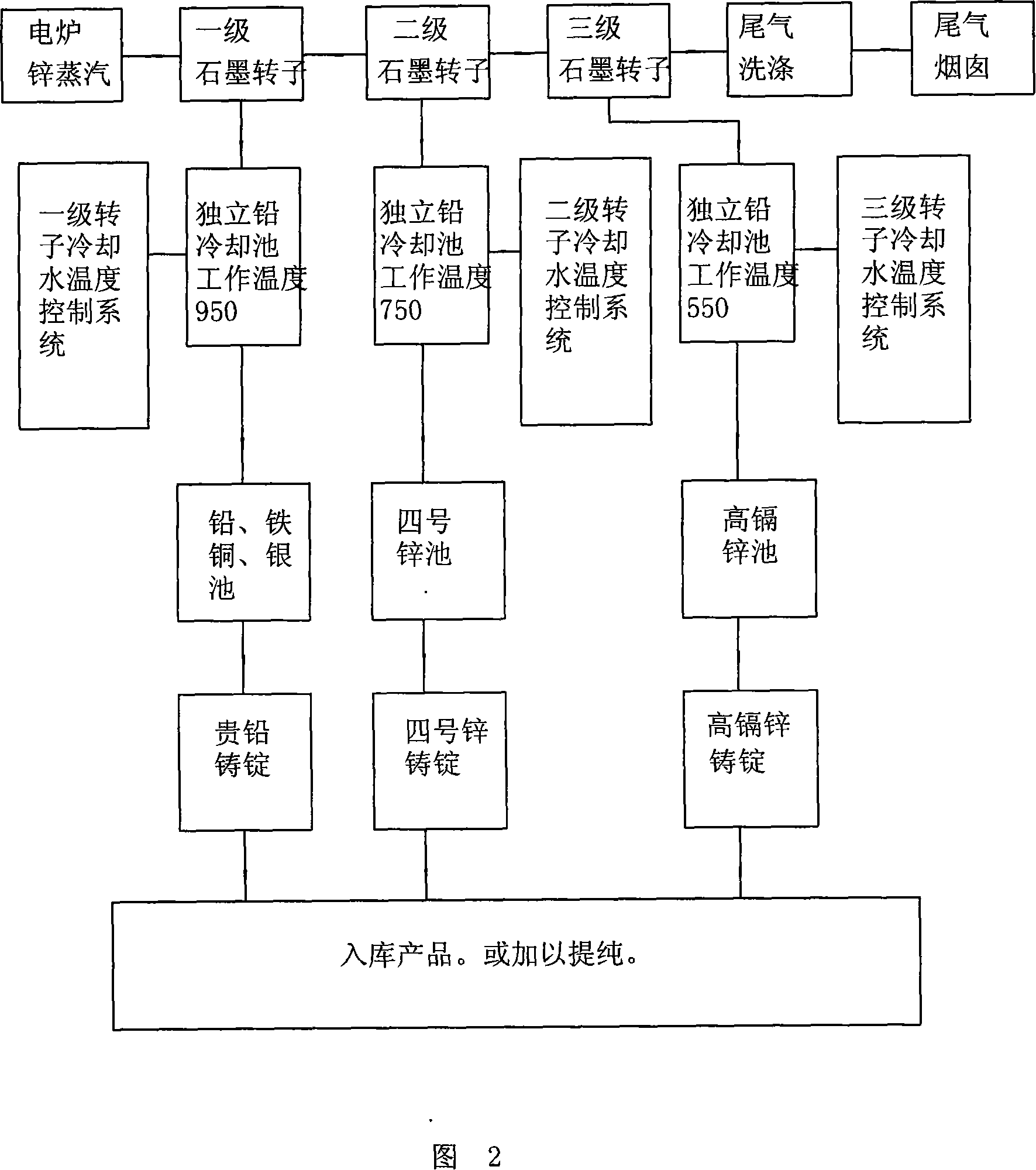

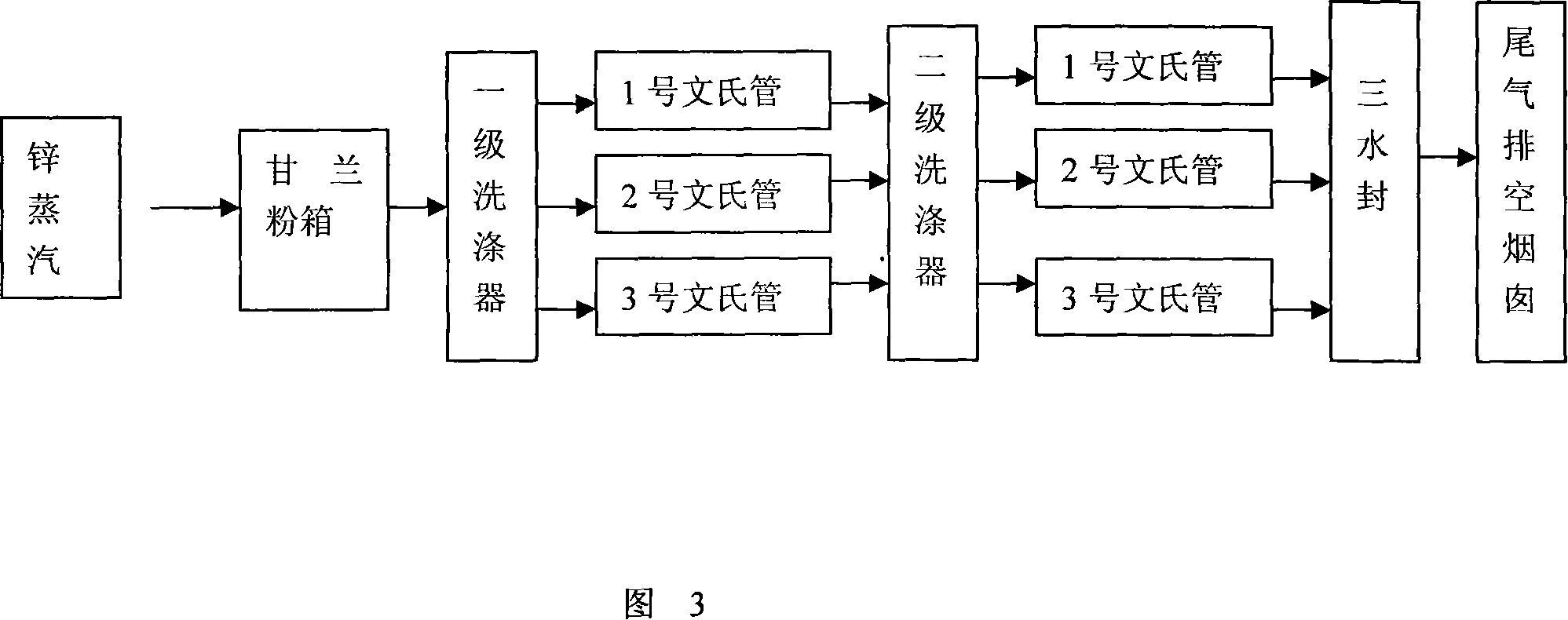

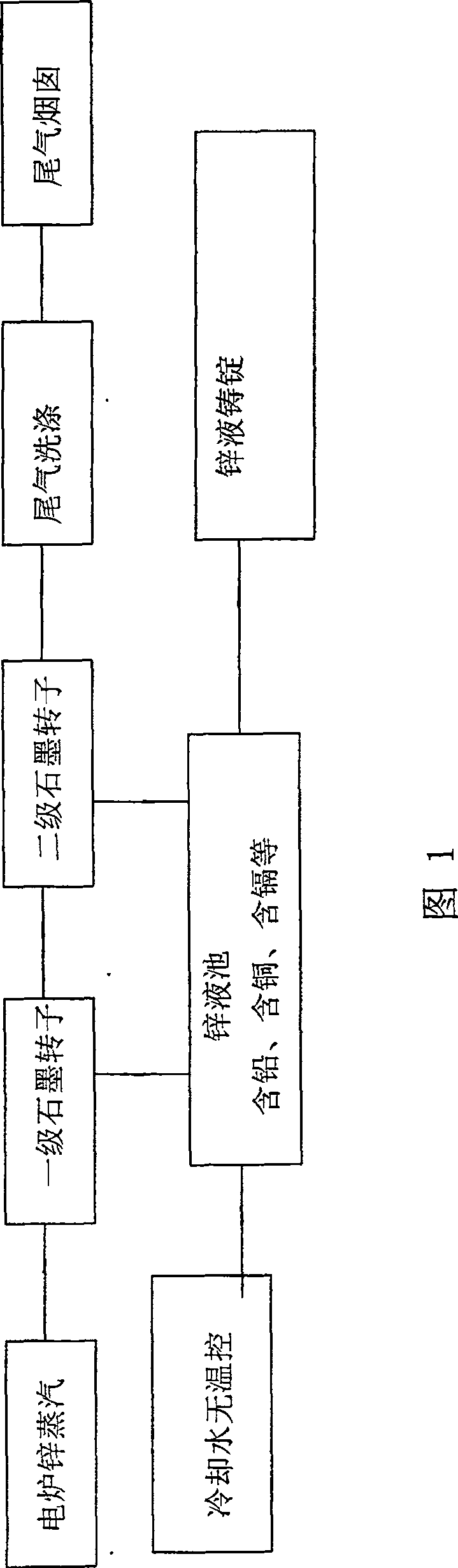

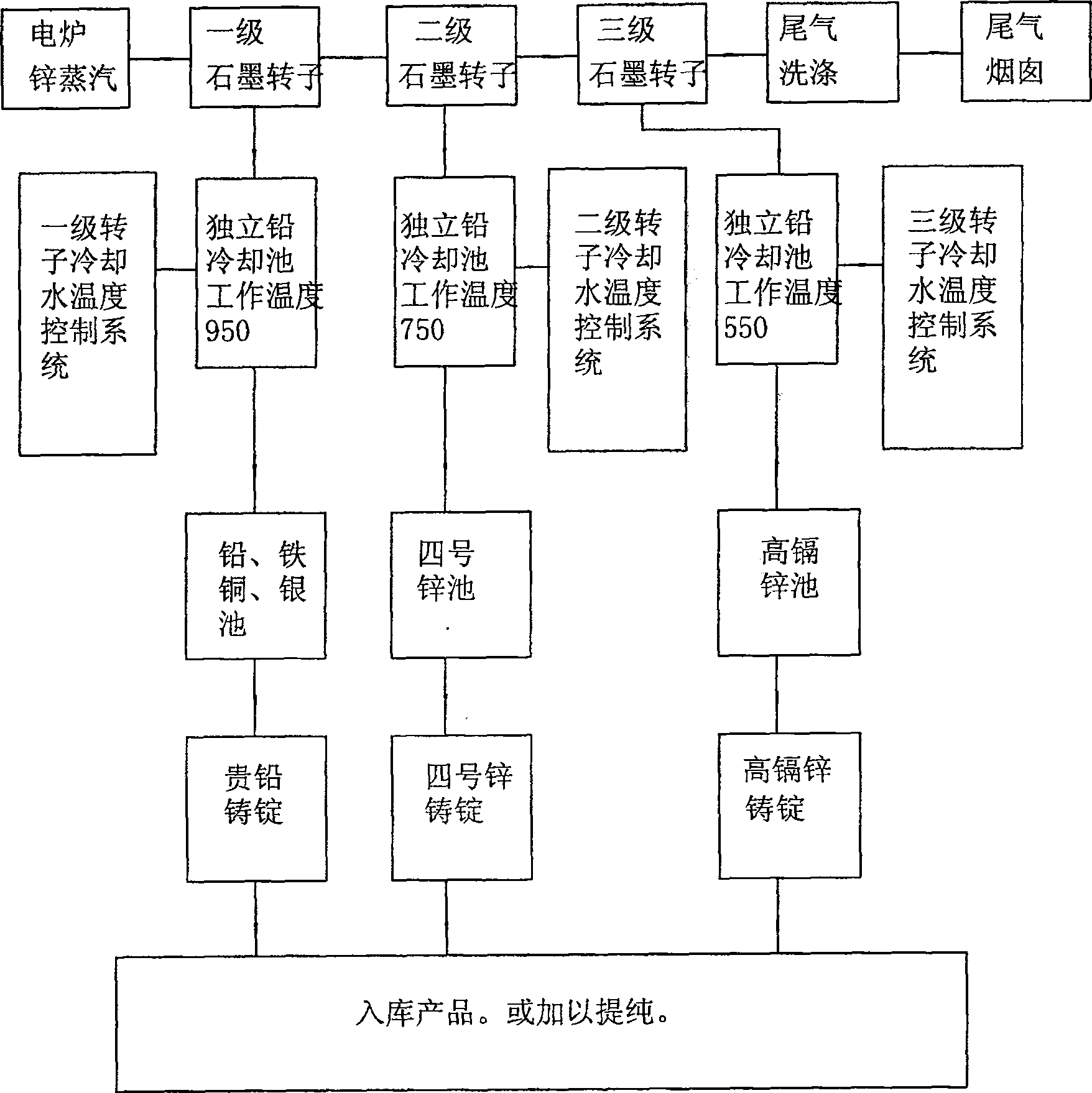

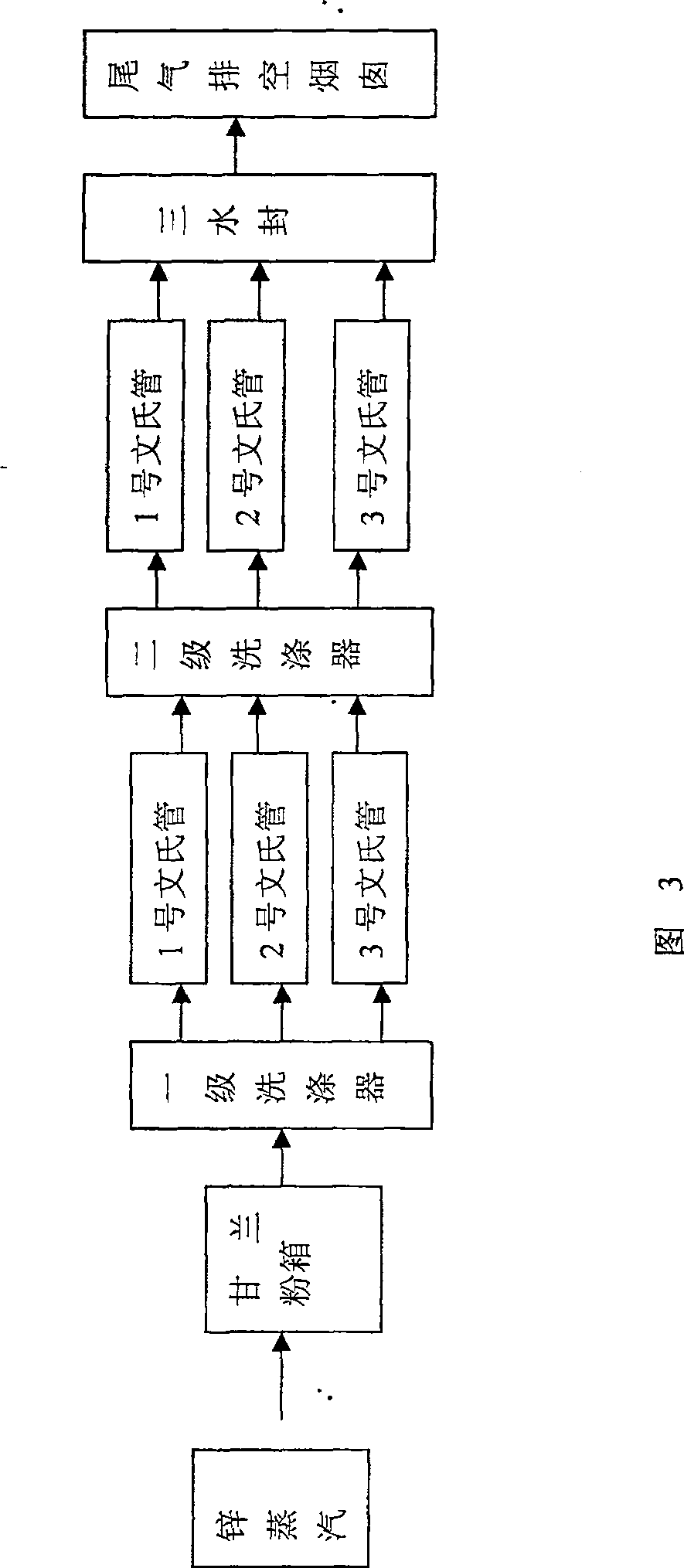

Novel process for cooling of pyrogenic process zinc smelting

The present invention relates to a novel cooling art for the zinc-smelting with the pyrogenic process. The novel cooling art is characterized in that zinc steam in an electric furnace passes through a plurality of black lead rotors having independent cooling ponds, different cooling ponds are controlled to provide different working temperature. By arranging with three rotor independent recovery cooling chambers and controlling the cooling temperature of different cooling chambers, the present invention realizes the respective recovery of the metal such as plumbum, zincum, cadmium, and argentum, thereby improving the production quality and the yield, and increasing greatly the added value of the product and the profit margin of the corporation. The art can recover and enrich the metal such as plumbum, zincum, cadmium, argentums, and indium on the basis that any energy sources are not increased. Compared with the present rectifying art in the zincum and plumbum and cadmium metallurgy column with the pyrogenic process, one ton of zincum can save about over 600 RMB of fuel bills, and about 500 RMB of the manpower secondary processing damage, the two are added, one ton of zincum can save over 1100 RMB of the production cost; however, the production cost of one ton of zincum of adding additionally one rotor only has tens RMB.

Owner:姜洪金

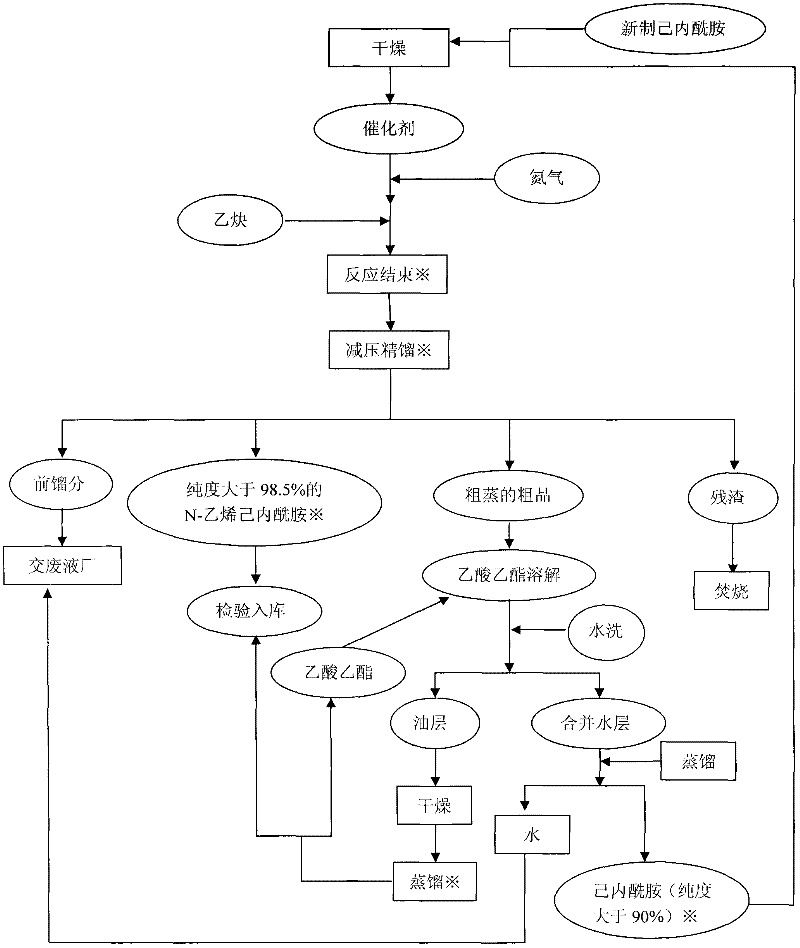

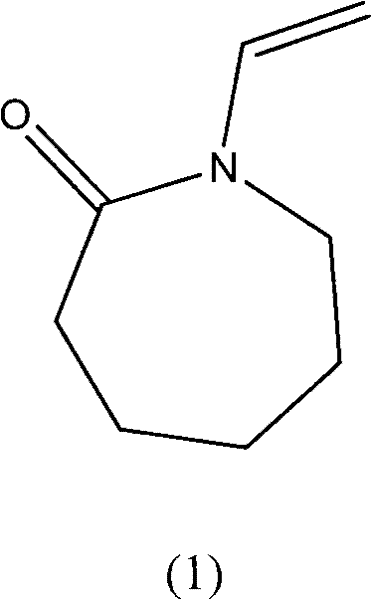

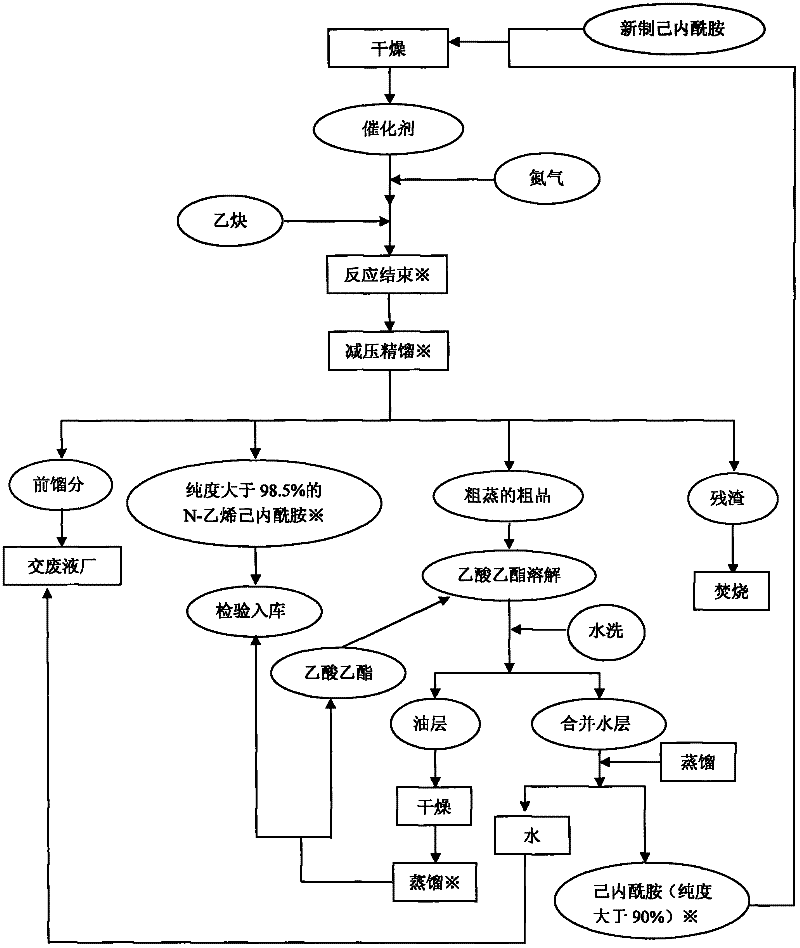

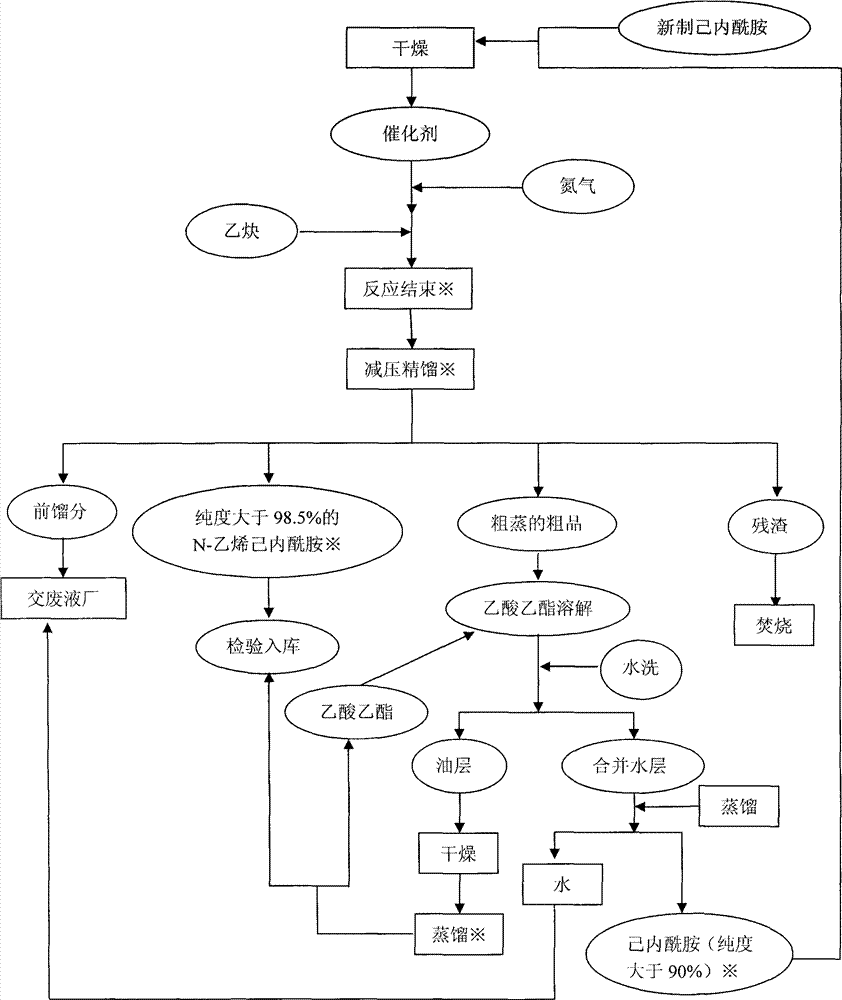

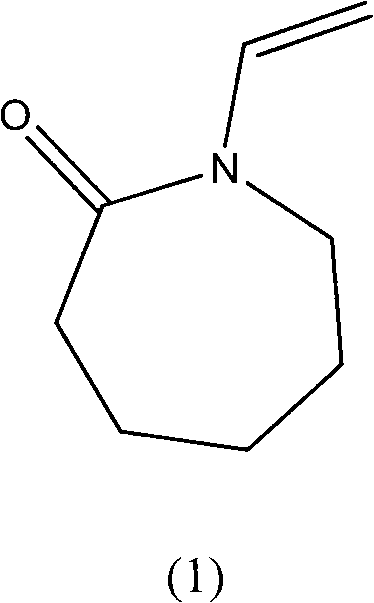

Preparation method for N-vinyl caprolactam capable of recycling raw materials

ActiveCN102532025AShort reaction timeLower reaction conditionsOrganic chemistryChemistryDistillation

The invention relates to a preparation method for N-vinyl caprolactam capable of recycling raw materials, wherein the method for preparing high-purity N-vinyl caprolactam can save cost, is high in productivity and efficiency, is eco-friendly, and is suitable for large-scale industrialized production by the steps of synthesis, rectification, simple distillation and recovery.

Owner:BEIJING THTD PHARMA TECH JOINT CO LTD

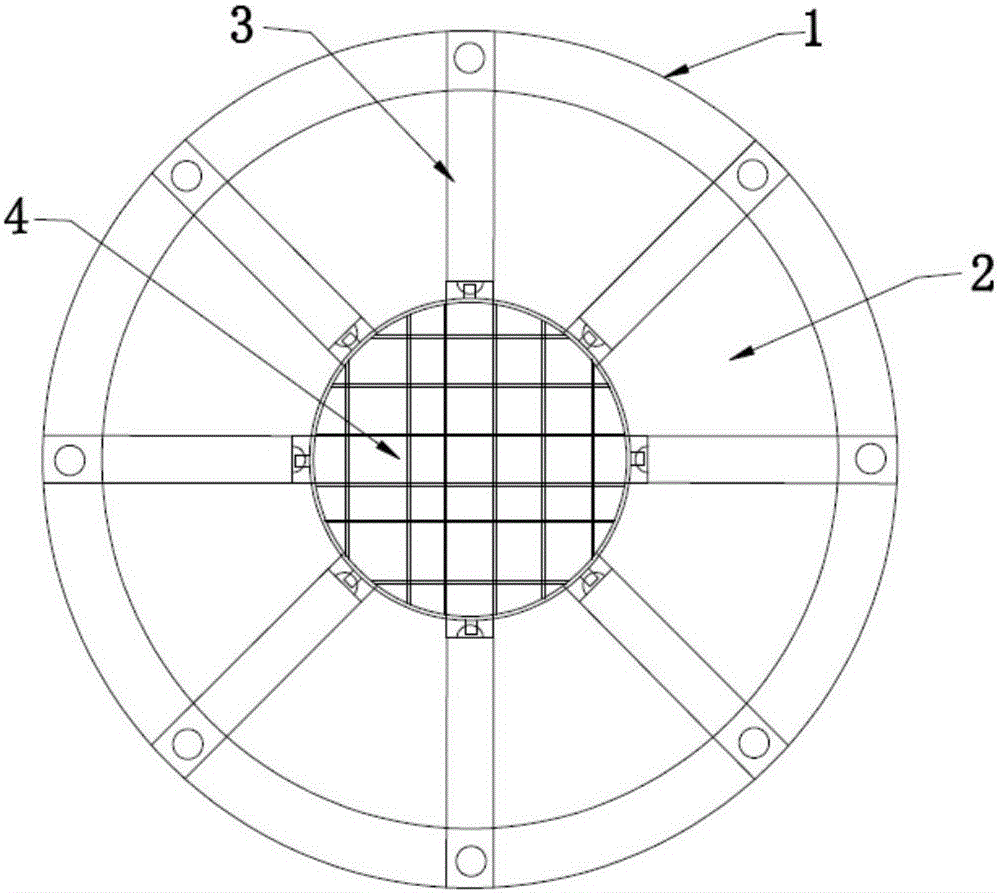

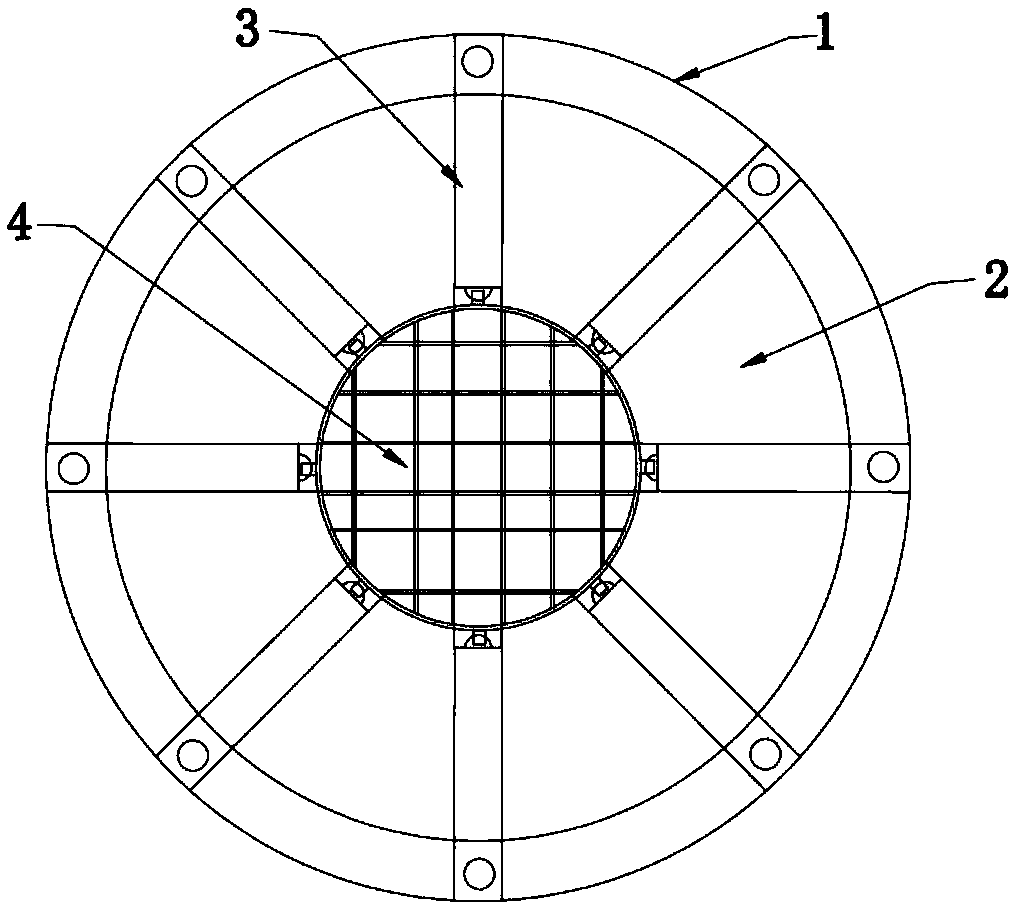

Circular cleaning device for automobile brake pads

ActiveCN109013443BEasy to cleanStable structureCleaning using toolsCleaning using liquidsElectric machineryWater resources

The invention discloses a circulating cleaning device for automobile brake pads, comprising a cleaning cylinder cover, a cleaning cylinder body, a lifting plate, a driving sprocket, an outer cleaning roller, an inner cleaning roller, an assembly rod and a cleaning seat. It is installed on the top of the cleaning cylinder. An electric cylinder is installed in the middle of the top of the cleaning cylinder cover. The electric cylinder is connected to the piston rod. The bottom end of the piston rod is connected to the lifting plate. There is a drive sprocket; the brake pads that can be placed in each layer are distributed above the assembly gasket in a circumferential direction, and the total number of cleaning car brake pads is multiplied by the number of stackable layers. The cleaning roller rotates at the same time to clean the outside and inside of the car brake pads, and the water spray holes and jet holes spray water, which is convenient for cleaning the car brake pads. After cleaning, the water circulates and saves water resources.

Owner:青岛日森机电有限公司

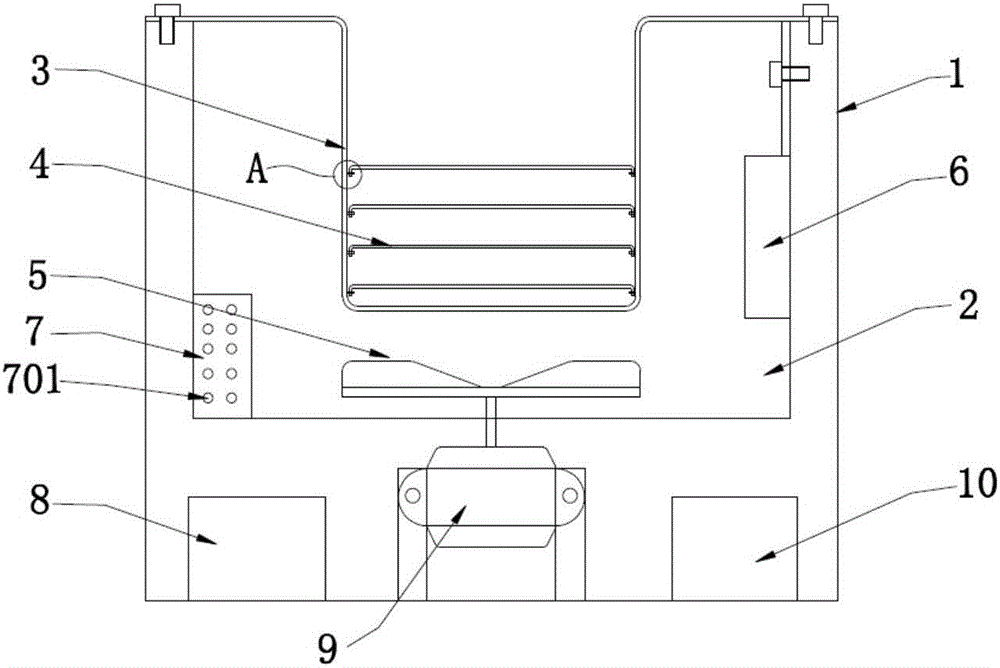

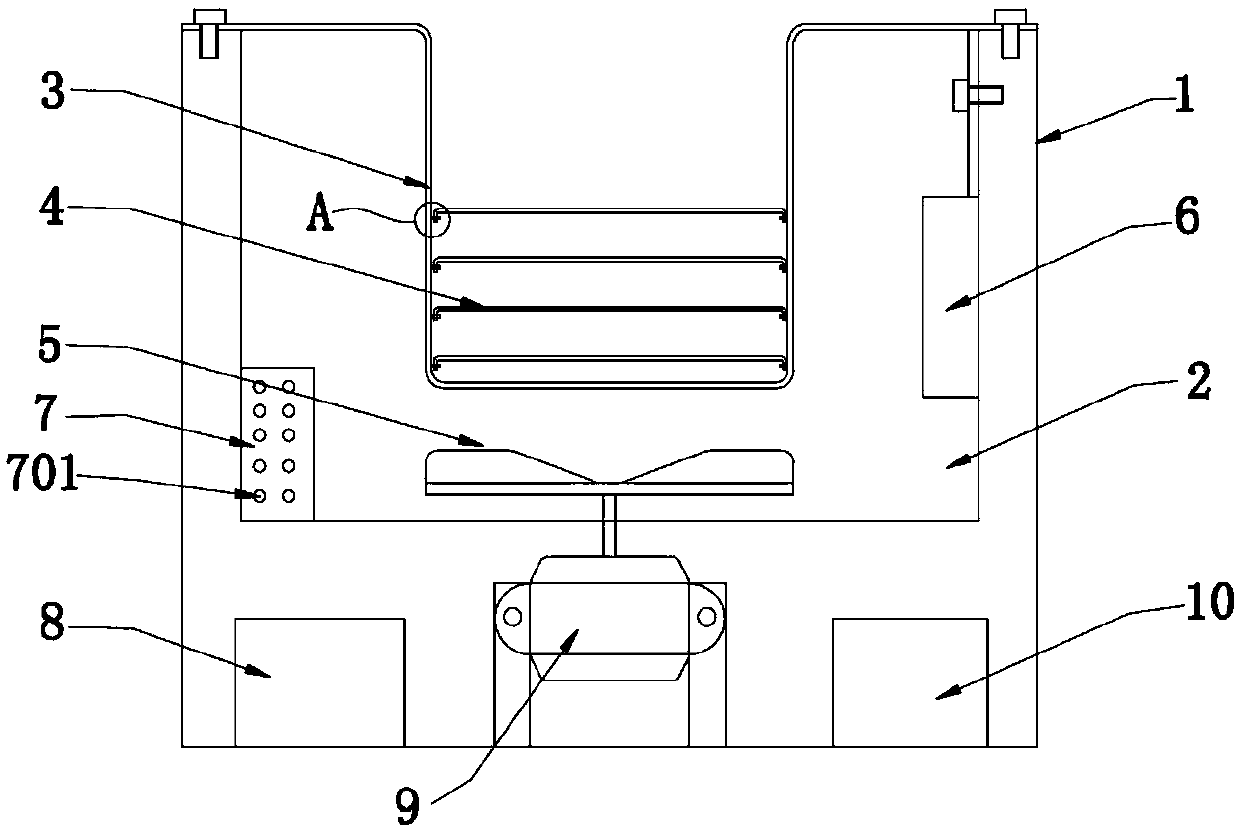

TF card cleaning device and cleaning method thereof

ActiveCN106424004AStrong penetrating powerReduce densityCleaning using liquidsUltrasonic generatorCoal

The invention provides a TF card cleaning device and a cleaning method thereof. The TF card cleaning device comprises a shell and a water tank arranged in the shell. A support and layered carrying plates are arranged in the water tank. The layered carrying plates are fixed and suspended in the central area of the water tank through the support. A plurality of through holes are formed in the layered carrying plates. Products are placed on the layered carrying plates. A stirring device is arranged in the center of the bottom of the water tank. An ultrasonic generator and an active coal containing box arranged at the bottom of the water tank are arranged in the water tank. The ultrasonic generator is arranged on the inner wall of the water tank. The height of the ultrasonic generator is equal to the vertical height of the layered carrying plates. The TF card cleaning method comprises the step that TF cards are placed into a card containing soft bag of the TF card cleaning device. By adopting the TF card cleaning device and the cleaning method thereof. The cleanliness degree of cleaned TF cards is high, the number of cleaned TF cards is large, consumed water is less, cost is low, and the cleaning efficiency of products is effectively improved.

Owner:高普达(广东)芯片有限公司

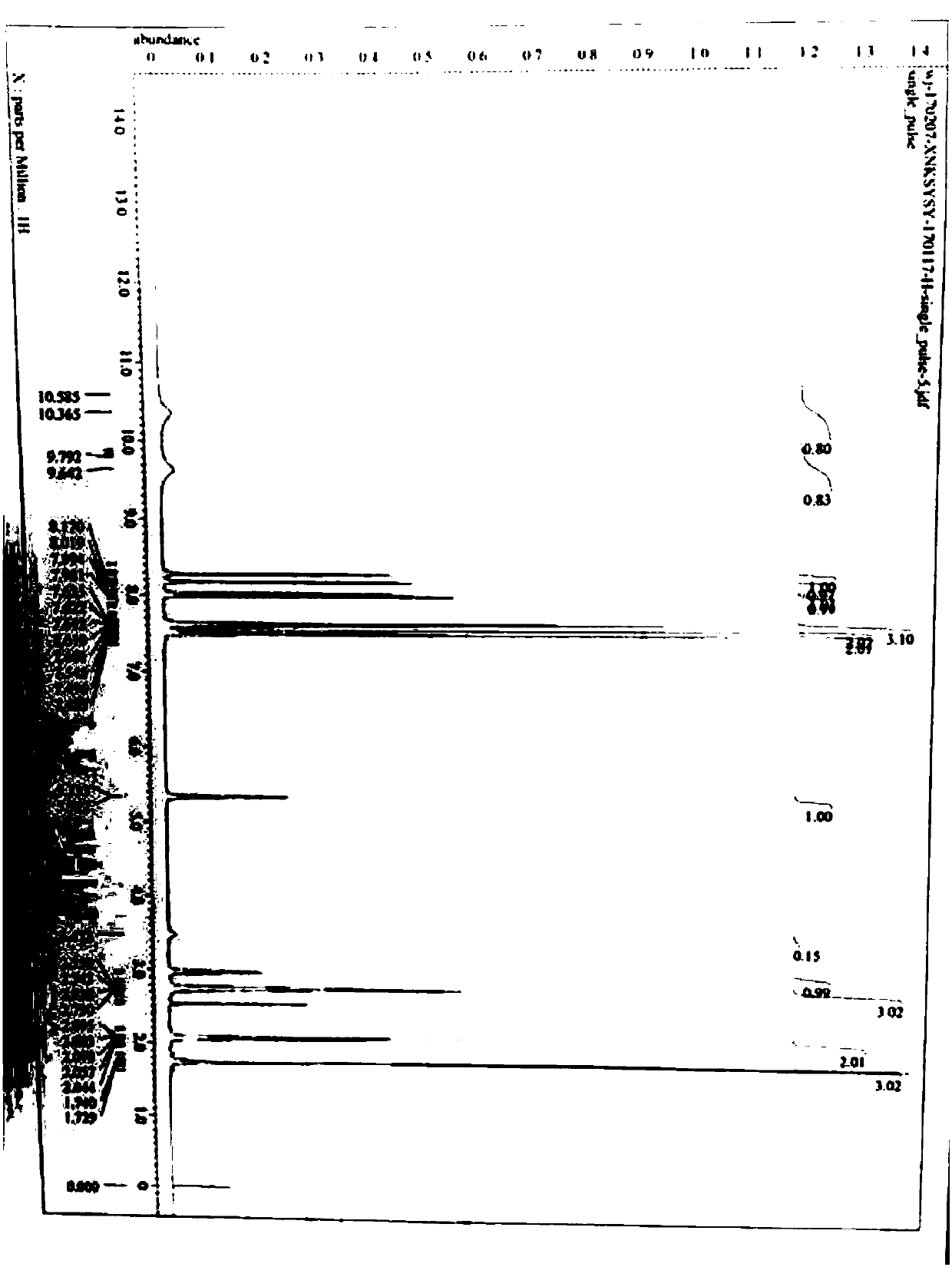

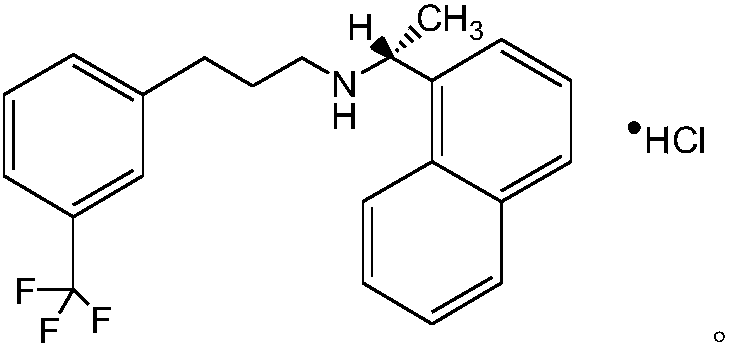

Cinacalcet hydrochloride preparation method

InactiveCN109928881AEasy to operateSimple processAmino compound purification/separationOrganic compound preparationPropanolChemical reaction

The invention provides a cinacalcet hydrochloride preparation method, wherein the cinacalcet hydrochloride finished product is obtained by using 3-(3-trifluoromethylphenyl)propanol and (R)-(+)-1-(1-naphthyl)ethylamine as starting raw materials through two-step chemical reaction, one-step salt formation and two-step purification. According to the present invention, the method has characteristics ofsimple process, easily-available raw materials, economy and environmental protection, easily achieves industrialization, and can promote the economic and technological development of cinacalcet hydrochloride bulk drugs.

Owner:ZHEJIANG WAN SHENG PHARMA CO LTD

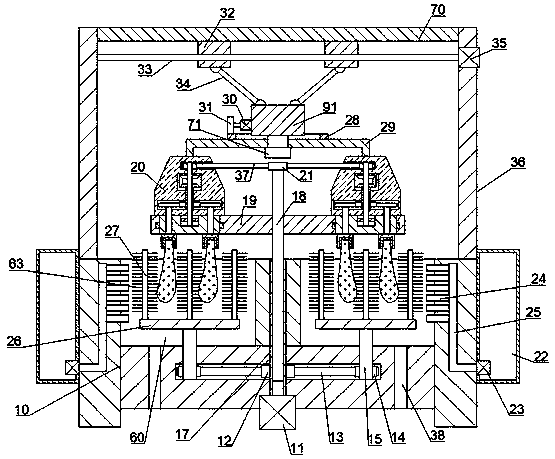

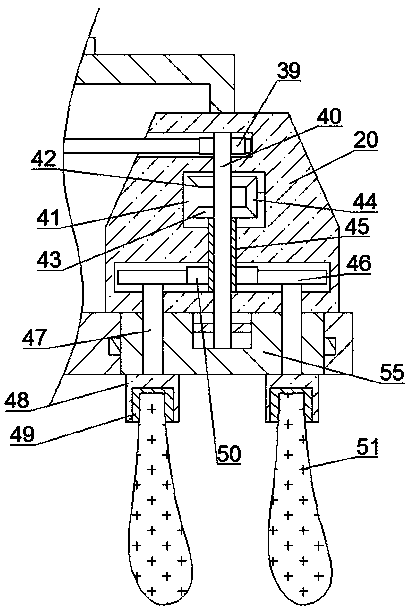

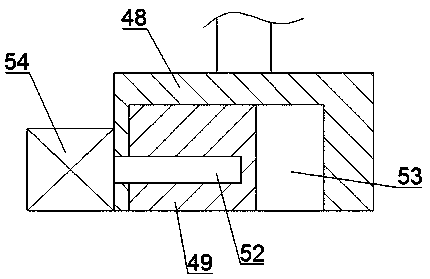

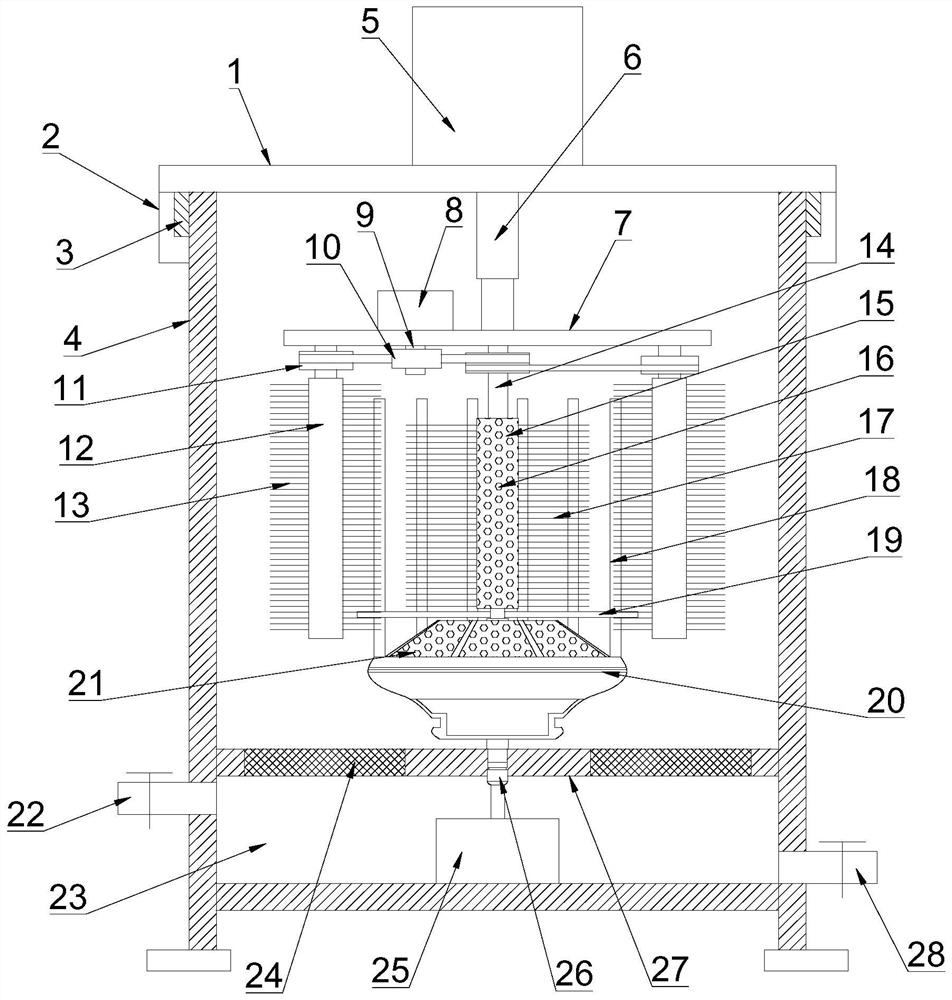

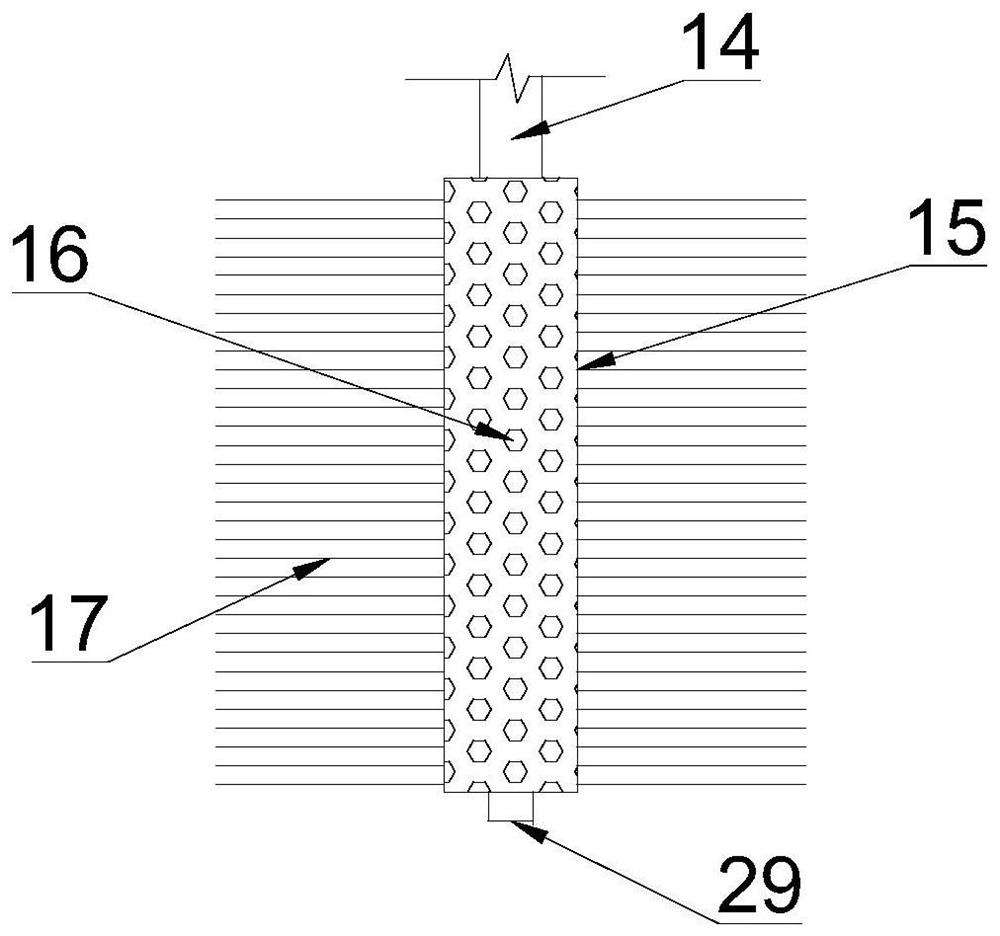

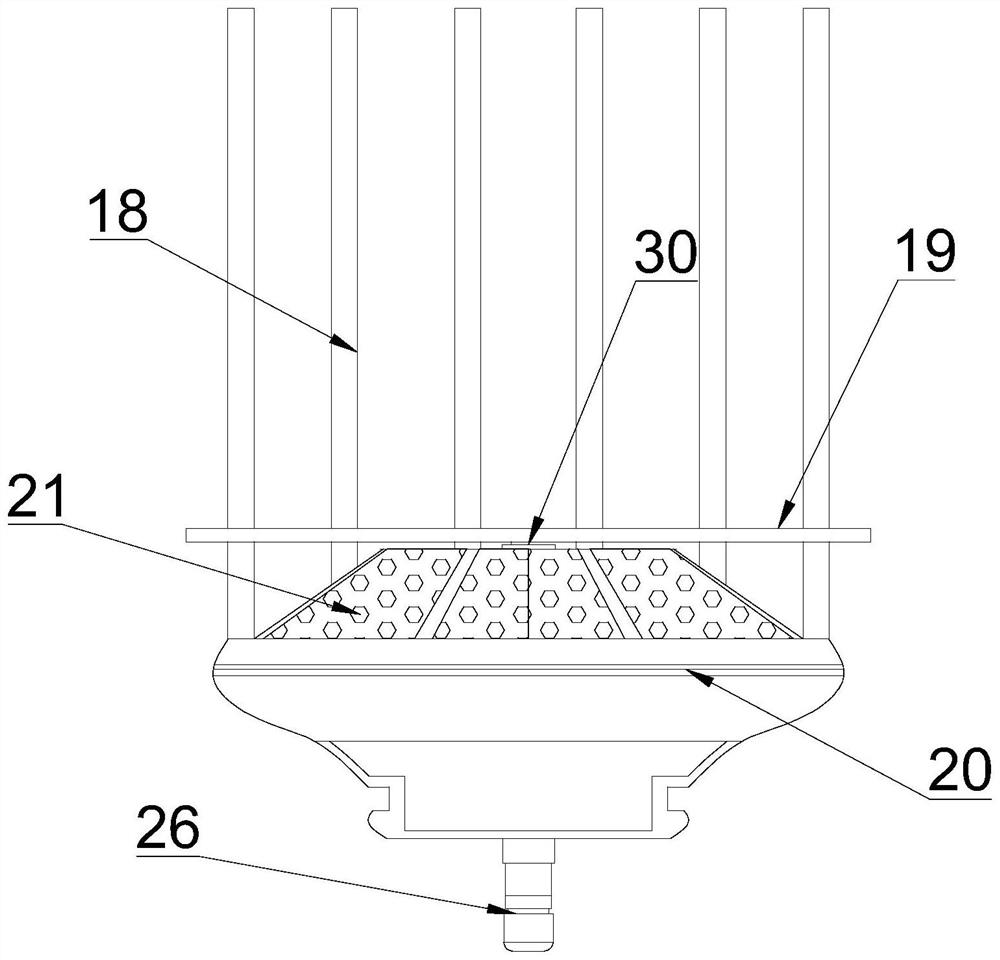

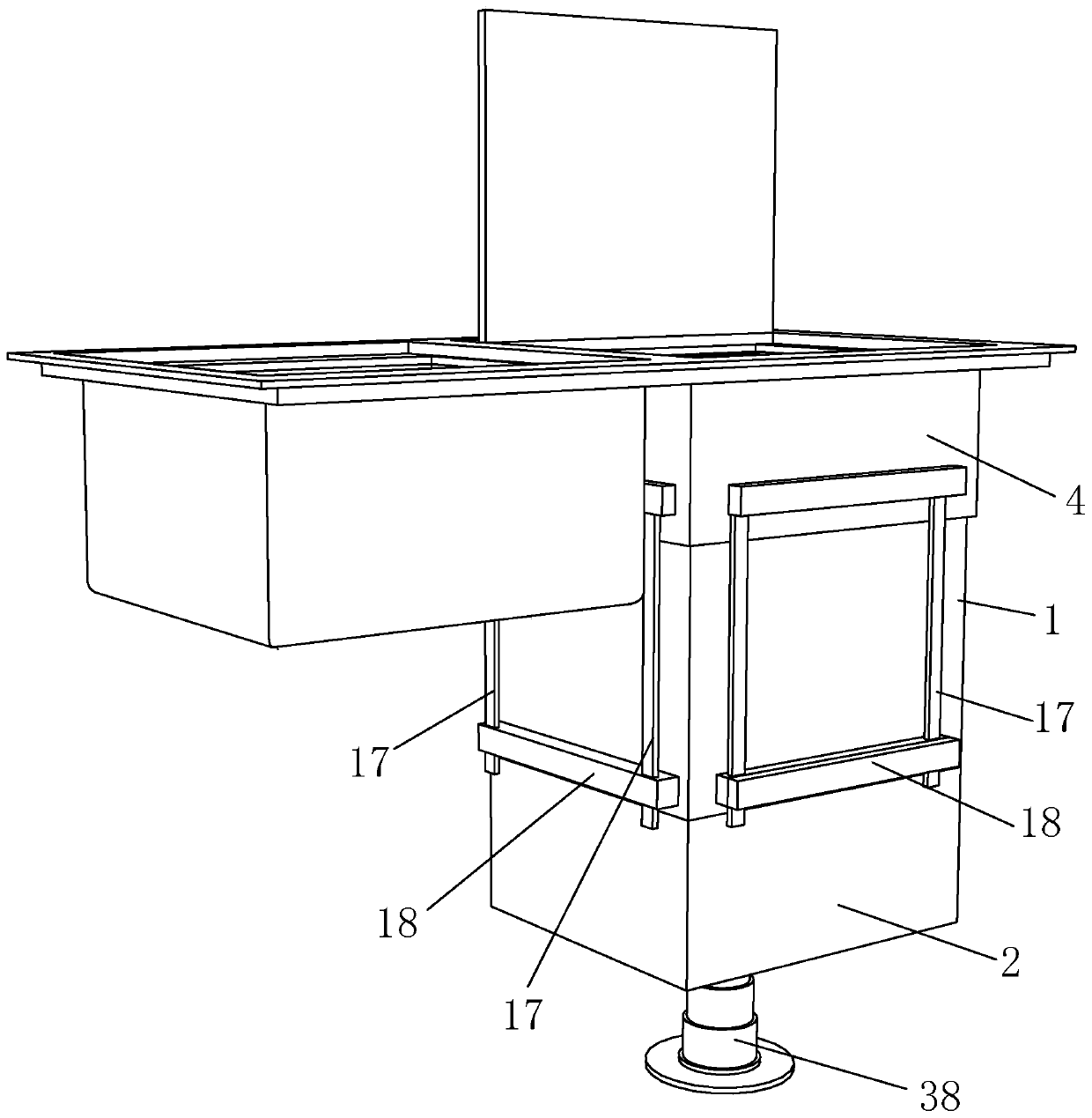

A fan blade cleaning device made of new carbon fiber material

ActiveCN111420918BHigh linkageIncrease the number of washesCleaning using toolsCleaning using liquidsFiberCarbon fibers

The invention discloses a fan blade cleaning device made of novel carbon fiber material, which comprises a base, and two left and right symmetrical cleaning chambers are opened in the base, the openings of the two cleaning chambers are designed to face upwards, and the two cleaning chambers are designed to face upwards. A turntable is installed in the cleaning chamber, and three evenly distributed cleaning shafts are fixed on the top surface of the turntable, and brushes are fixed on the outer circumference of the cleaning shafts. The present invention can slide through multiple clamping blocks. Multiple blades are clamped to realize simultaneous cleaning of multiple blades, which greatly increases the number of cleaning, and while the blades are rotating, the rotating disk will drive the blades to revolve around the driven shaft as the center of the circle, and the brush is also on the rotating disk. Driven to rotate, the cleaning speed is greatly improved. Meanwhile, the structure of the present invention is relatively simple, and the transmission parts are all very common parts, which are low in cost and easy to popularize.

Owner:江苏韩塑新材料有限公司

Preparation method for N-vinyl caprolactam capable of recycling raw materials

The invention relates to a preparation method for N-vinyl caprolactam capable of recycling raw materials, wherein the method for preparing high-purity N-vinyl caprolactam can save cost, is high in productivity and efficiency, is eco-friendly, and is suitable for large-scale industrialized production by the steps of synthesis, rectification, simple distillation and recovery.

Owner:BEIJING THTD PHARMA TECH JOINT CO LTD

Textile material and preparation method thereof

InactiveCN106521933ALess investmentQuick resultsBiochemical treatment with wool-protecting/anti-moth agentsCross-linkDistilled water

The invention provides a preparation method for a functional hygienic antibacterial material. The method comprises the following steps: diluting a 12-18 nanometer silver ion agent in concentration of 600-900ppm by 10-12 times with distilled water or purified water, thereby acquiring a nanometer silver solution; soaking a cotton textile material after being cleaned into the nanometer silver solution and cross-linking for 32-38min; after cross-linking, taking out the cotton textile material from the solution, dewatering and drying, thereby acquiring the functional hygienic antibacterial material. According to the invention, the suitable anionic concentration, grain size and cross-linking time are selected, so that the washing times can be obviously increased. A nanometer antibacterial cotton textile product prepared from the textile material can maintain excellent antibacterial sterilizing effect after the nanometer antibacterial cotton textile product is washed for at least 100 times (one washing counting process is as follows: washing with washing powder or rubbing with soap, and then rinsing with clean water, spin-drying and airing).

Owner:WUXI MINGSHENG TEXTILE MACHINERY

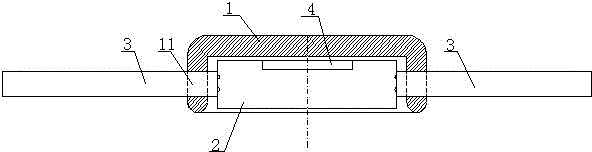

High-strength high-temperature-resistant washing-resistant UHF laundry label capable of application for multiple times

InactiveCN104156755AIncrease the number of washesFix damageRecord carriers used with machinesAntenna substrateEngineering

The invention discloses a laundry label and especially relates to a high-strength high-temperature-resistant washing-resistant UHF laundry label capable of application for multiple times. A spring antenna (3) and a chip (4) are mutually connected and are packaged on an antenna substrate (2) through an epoxy sealant, the antenna substrate (2) is installed in a polyphenylene sulfide housing (1), the polyphenylene sulfide housing (1) is packaged through the epoxy sealant, the polyphenylene sulfide housing (1) is provided with a groove hole (11) for the spring antenna (3) to extend out therefrom, the spring antenna (3) is used for transceiving read-write signals, and the antenna substrate (2) is used for ensuring secure connection between the spring antenna (3) and the chip (4) and amplifying received signals and sent signals. According to the invention, by use of the UHF laundry label, the problem is solved that a washing article is not damaged yet a laundry label is already damaged in the prior art, and the requirement of a hospital environment and a hotel environment for washing and distance reading of the UHF laundry label is completely satisfied.

Owner:上海永力信息科技股份有限公司

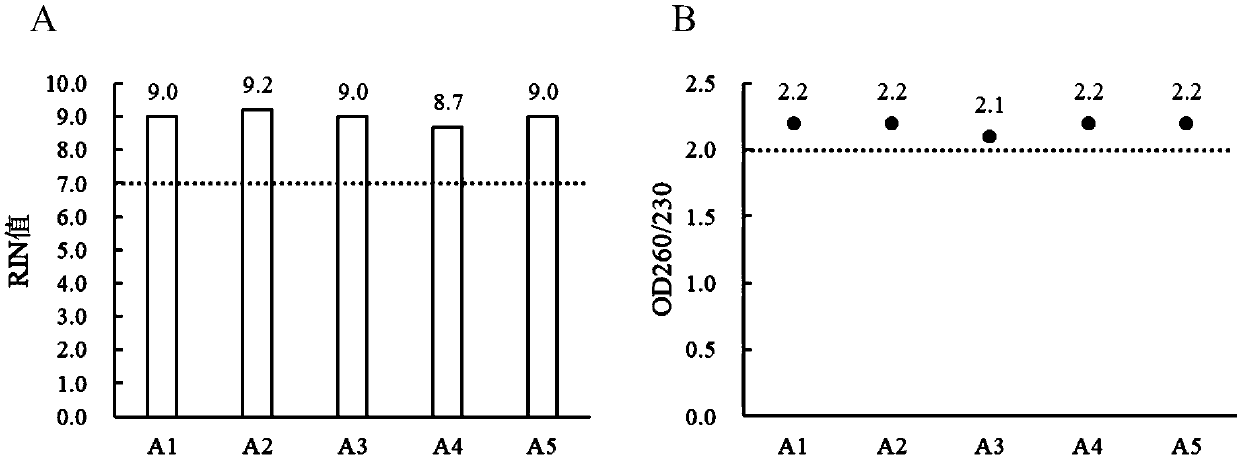

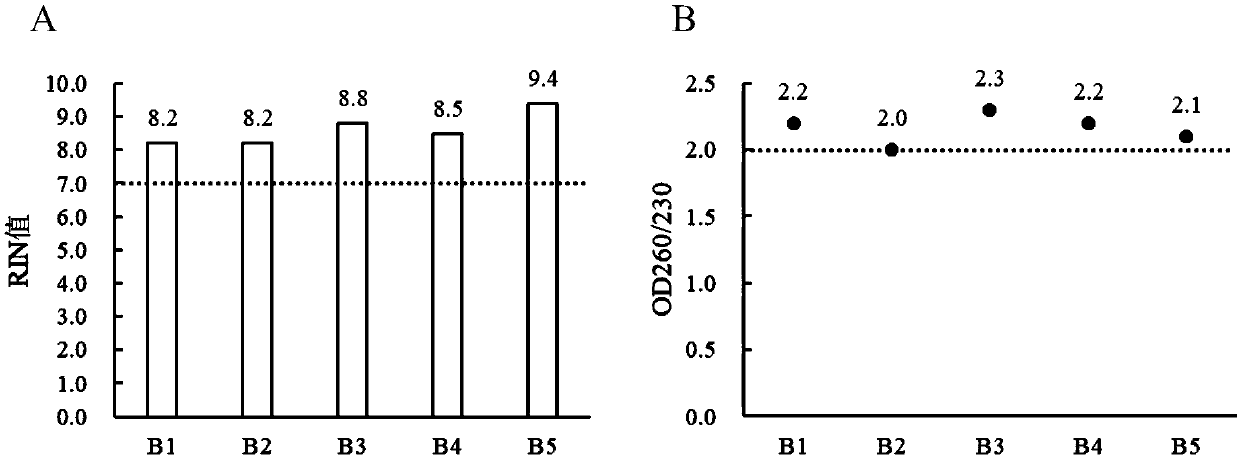

Long-term storage and RNA extraction method of whole blood sample

The invention discloses a long-term storage and RNA (ribonucleic acid) extraction method of a whole blood sample, which comprises the steps of immediately mixing acquired fresh whole blood with 5-15 times of volume of a TRIzol reagent, storing a whole blood-TRIzol mixed system in a refrigerator at -80 DEG C after homogenization, after storage for a period of time, extracting total RNA from the stored whole blood-TRIzol mixed system. The method achieves direct long-term storage of the human whole blood after the homogenization with no need for plasma separation or red blood cell lysis, and whole blood subpackage, and high-quality total RNA with very high purity and integrity is extracted.

Owner:PEKING UNIV

Method for washing pseudo-boehmite

InactiveCN109626404AIncrease the number of washesImprove washing efficiencyAluminium oxides/hydroxidesBoehmiteLiquid storage tank

The invention discloses a method for washing pseudo-boehmite. The method comprises the following steps of primary washing, wherein after aged pseudo-boehmite slurry is filtered, filter residues are discharged into a primary water washing tank, and the filter residues and secondary filtrate sent by a secondary washing liquid storage tank are mixed and washed; secondary washing, wherein filtering iscarried out again, the primary filtrate flows into a primary washing liquid storage tank, the primary filter residues are discharged into a secondary water washing tank, and the primary filter residues and fourth-time filtrate sent by a fourth-time washing liquid storage tank are mixed and washed; tertiary washing, wherein filtering is carried out again, the secondary filtrate flows into the secondary water washing tank and then is pumped into the primary water washing tank, the secondary filter residues are discharged into a tertiary water washing tank, and the secondary filter residues andhot water in a hot water tank are mixed and washed; fourth-time washing, wherein filtering is carried out again, the tertiary filtrate flows into the tertiary water washing tank, tertiary filter residues are discharged into a fourth-time water washing tank, and the tertiary filter residues and the hot water of the hot water tank are mixed and washed; filtering-out, wherein filtering is carried outagain, the fourth-time filtrate flows into the fourth-time washing liquid storage tank and is pumped into the secondary water washing tank, and the fourth-time filter residues are qualified filter residues. The washing frequency is increased, the washing efficiency is improved, but the water consumption is greatly reduced.

Owner:YUNNAN WENSHAN ALUMINUM

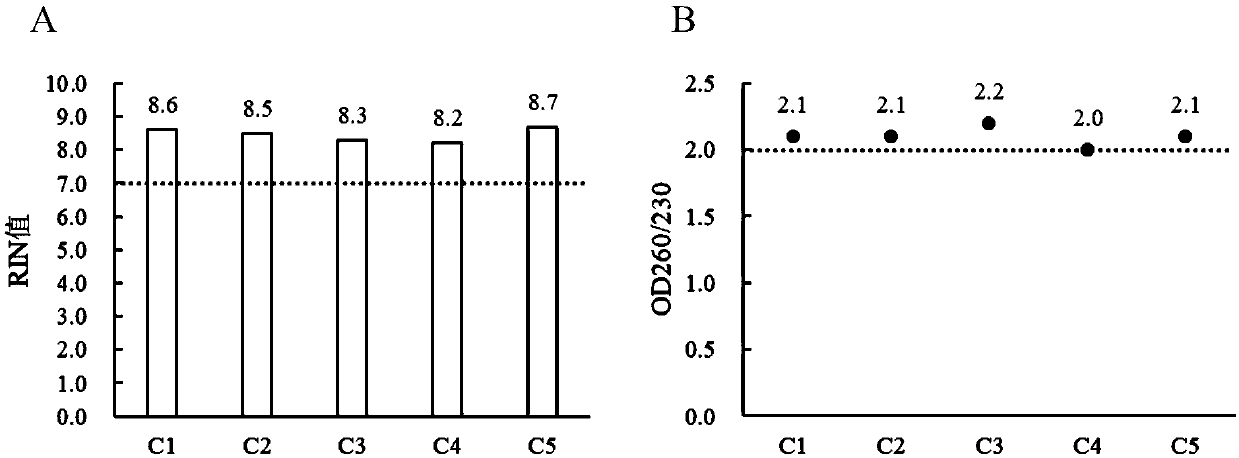

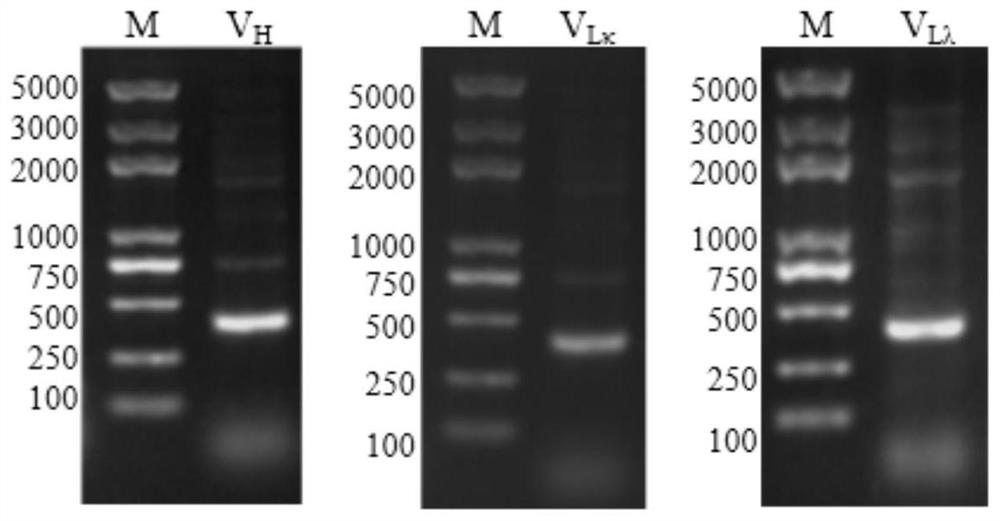

Swine anti-PDCoV-N protein scFv and expression vector, construction method and application thereof

ActiveCN113527477AReduce gene lossIncrease the number of washesLibrary screeningImmunoglobulins against virusesHeavy chainNucleotide sequencing

The invention belongs to the field of molecular biology, and relates to a porcine anti-PDCoV-N protein scFv, in particular to a porcine anti-PDCoV-N protein scFv as well as an expression vector, a construction method and application of the porcine anti-PDCoV-N protein scFv. The scFv of the porcine anti-PDCoV-N protein has an amino acid sequence as shown in SEQ ID No.2; the scFv comprises a heavy chain variable region VH and a light chain variable region VL, the nucleotide sequence of the heavy chain variable region VH is as shown in SEQ ID NO.3, and the nucleotide sequence of the light chain variable region VL is as shown in SEQ ID NO.4. The specific scFv-25 screened and expressed by the invention not only can be used for developing PDCoV diagnosis and treatment reagents, but also can provide help for further research of an N protein mechanism.

Owner:HENAN AGRICULTURAL UNIVERSITY

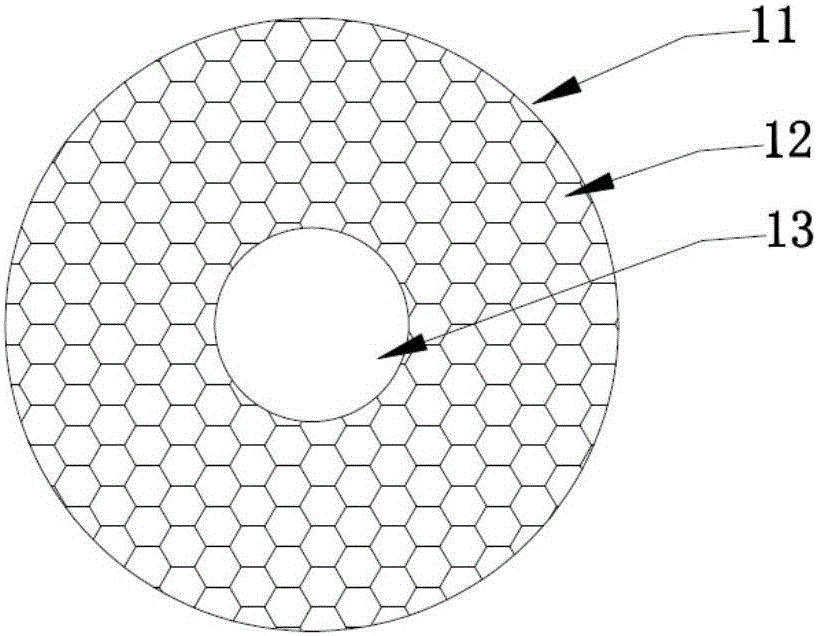

Melt-blow molding process of fiber pillow

PendingCN112064201AAchieve washing resistanceIncrease the number of washesPillowsNon-woven fabricsMelt blowingCombing

The invention discloses a melt-blow molding process of a fiber pillow. The melt-blow molding process of the fiber pillow comprises the following steps of mixing raw material fibers as required for opening, stirring and processing; uniformly feeding to a carding machine through a feeder; combing, feeding to a material box for material preparation and secondary stirring; and carrying out high-temperature and high-pressure cotton spraying to generate a honeycomb coagulated state. According to the melt-blow molding process of a fiber pillow, based on the melt-blow technology, various fibers are mixed and stirred and then finely combed for high-temperature and high-pressure melt-blow molding, so that the fiber pillow achieves a washable function, does not cluster and does not break cotton afterbeing washed, and a user with hidrosis and vigorous oily secretion can properly increase the washing times in the later use process of the fiber pillow, thereby achieving the cleaning and health effects.

Owner:南通芯逸坊家居科技有限公司

A kind of cleaning method of sapphire touch panel

ActiveCN103639141BLess componentsIncrease the number of washesCleaning using liquidsEmulsionBiochemical engineering

The invention provides an optical-grade sapphire touch panel cleaning method. According to the method, saponification and emulsion can be produced to stains and grease on product surfaces through alkaline cleaners so as to clean products, and the workpiece surface cleanliness is controlled. By cleaning through the alkaline liquid, damage to equipment can be minimized, and the product surface quality request can be met. A plurality of sapphire sheets can be dried simultaneously, and the number of the sapphire sheets dried simultaneously can reach 40 sheets to 100 sheets, and the cleaning efficiency is greatly improved.

Owner:ZHEJIANG SHANGCHENG SCI&TECH

Volume-variable sink-type dish washing machine and assembly method thereof

PendingCN111096719APlay a supporting roleAvoid deformation damageTableware washing/rinsing machine detailsDomestic plumbingProcess engineeringWater leak

The invention relates to a volume-variable sink-type dish washing machine, which comprises a water tank, a cleaning assembly and a fixed frame body, the cleaning assembly is connected with the water tank, the water tank is provided with a telescopic plate, the telescopic plate is movably connected with the water tank, the water tank is provided with a first fixed frame, the telescopic plate is provided with a second fixed frame, and an electric push rod is arranged between the first fixed frame and the second fixed frame; the method comprises six steps of a, equipment inspection, b, positioning of the fixed frame and the water tank, c, fixing of the water tank, d, fixing of the fixed frame nd connection of the sliding structure, e, installation of the telescopic sleeve, and f, overall detection. The volume of the cleaning cavity can be increased, the number of tableware cleaned at a time is increased, use of the dish-washing machine is facilitated, and the cleaning efficiency is improved; according to the method, the mounting effect and mounting precision of the sink-type dish washing machine are improved, the mounting efficiency of the sink-type dish washing machine is improved, mounting is convenient, meanwhile, the sliding effect between the sink and the telescopic plate can be improved, and water leakage is avoided.

Owner:浙江蓝炬星电器有限公司

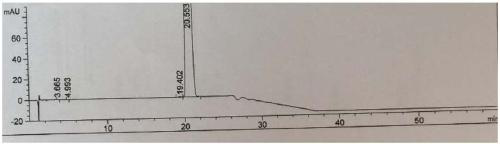

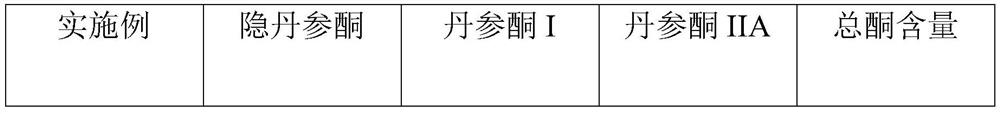

A kind of active ingredient of Tibetan danshen tanshinone and its extraction method and application

InactiveCN108191947BEffective separation and purificationEasy to operateOrganic active ingredientsNervous disorderSalvia miltiorrhizaAlcohol ethyl

The invention discloses an active ingredient of Tibetan salvia tanshinone and its extraction method and application. The extraction method comprises the following steps: drying and crushing Tibetan salvia miltiorrhiza, then soaking in water, and adding 6-8 times the amount of 60-60 90% ethanol, ultrasonic extraction for 60-90min, extraction 1-2 times; Concentrate the ultrasonic extract, then extract with ethyl acetate, collect the extract, concentrate under reduced pressure to obtain a fat-soluble extract, and then extract the extract Dissolved to the corresponding concentration, separated and purified by medium-pressure preparative chromatography. The method of the invention is simple to operate, can effectively separate and purify target components, greatly improves its purity and extraction efficiency, and can fully exert its medicinal value.

Owner:CHENGDU UNIV

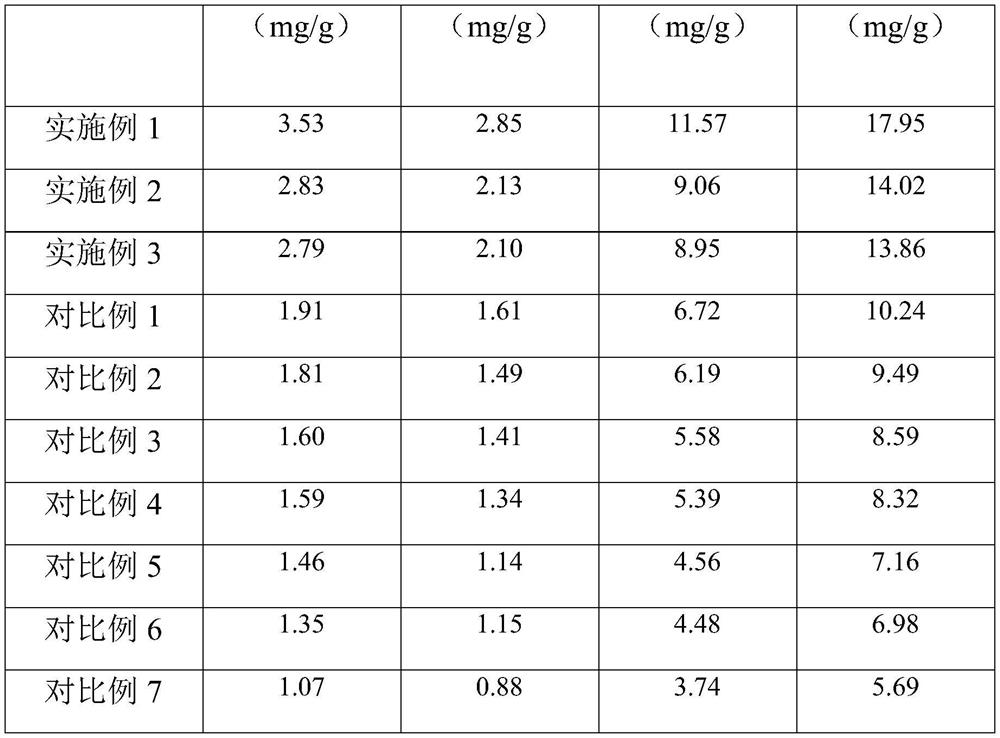

A kind of medical composite material and its manufacturing process

ActiveCN111038038BPrevent penetrationImprove the protective effectSynthetic resin layered productsMedical devicesPolyesterPolyethylene terephthalate glycol

The invention relates to a medical composite material and its manufacturing process. The medical composite material is composed of polyethylene terephthalate fiber, carbon ion filament fiber, polyurethane film and auxiliary materials. The manufacturing process includes the manufacture of polyester filament fibers; the manufacture of conductive silk fibers; weaving polyester filament fibers and conductive silk fibers into textile materials with antistatic functions; the manufacture of antibacterial films; and the manufacture of medical composite materials. The medical composite material manufactured by the invention has a high degree of waterproof, anti-penetration, and anti-bacteria functions, completely eliminates the penetration of patient blood, body fluids, flushing fluids, and other pollutants, and realizes two-way protection functions; at the same time, it has good moisture permeability. Function.

Owner:SHANDONG JUNTAI MEDICAL PROTECTIVE EQUIP TECH CO LTD

Human cardiac troponin I aptamer, screening method and application

InactiveCN102703455BHigh affinityStrong specificityMicrobiological testing/measurementAnimals/human peptidesNucleotideCardiac muscle

The invention relates to a human cardiac troponin I aptamer which has a nucleotide sequence in a sequence table SEQ ID No.1 or a nucleotide sequence in a sequence table SEQ ID No.2 or a nucleotide sequence in a sequence table SEQ ID No.3 or a nucleotide sequence in a sequence table SEQ ID No.4. The human cardiac troponin I (cardiac troponin I) aptamer is high in affinity combined with a cTn I and strong in specificity, improves cardiac troponin I application of diagnosis on early detection and clinical myocardial damage or sensitivity for separating and purifying the cardiac troponin I.

Owner:TIANJIN UNIV OF SCI & TECH

A kind of card washing equipment and cleaning method of TF card

The invention provides a TF card cleaning device and a cleaning method thereof. The TF card cleaning device comprises a shell and a water tank arranged in the shell. A support and layered carrying plates are arranged in the water tank. The layered carrying plates are fixed and suspended in the central area of the water tank through the support. A plurality of through holes are formed in the layered carrying plates. Products are placed on the layered carrying plates. A stirring device is arranged in the center of the bottom of the water tank. An ultrasonic generator and an active coal containing box arranged at the bottom of the water tank are arranged in the water tank. The ultrasonic generator is arranged on the inner wall of the water tank. The height of the ultrasonic generator is equal to the vertical height of the layered carrying plates. The TF card cleaning method comprises the step that TF cards are placed into a card containing soft bag of the TF card cleaning device. By adopting the TF card cleaning device and the cleaning method thereof. The cleanliness degree of cleaned TF cards is high, the number of cleaned TF cards is large, consumed water is less, cost is low, and the cleaning efficiency of products is effectively improved.

Owner:深圳市劲升迪龙科技发展有限公司

Method for recording number of using times of cotton fabrics

ActiveCN103789986AGood soaping fastnessIncrease the number of washesTextiles and paperLaundry apparatusYarnDisperse dye

The invention discloses a method for recording the number of the using times of cotton fabrics. The method includes the following steps that polyester yarn is dyed to be black and white yarn with disperse dyes; white polyester 75d polyester fibers are used as warps, black polyester 50d polyester fibers are used as wefts, yarn-dyed jacquard labels are woven through the large jacquard weaving technology, and marks are woven on the labels; the labels are sewn on some corners of the cotton fabrics; every time the cotton fabrics are washed, the marks on the labels are smeared with oily liquid by using an oil pen. According to the method for recording the number of the using times of cotton fabrics, the yarn is woven into the yarn-dyed jacquard labels through the large jacquard weaving technology, various marks are woven on the labels, the labels have good soaping fastness, the number of washable times can be up to 300 to 500, the service life of the labels is longer than that of the cotton fabrics, and the cotton fabrics can be used and maintained correspondingly according to the number of Arabic numerals or squares which are smeared off the labels.

Owner:NANTONG SIDEFU TEXTILE DECORATION

High-in-oil breakdown strength insulation paper for extra-high voltage transformer and manufacturing method thereof

PendingCN113445350AImprove evennessAvoid damagePulp properties modificationPulp beating methodsProcess engineeringIndustrial engineering

The invention relates to a high-in-oil breakdown strength insulation paper for an extra-high voltage transformer and a manufacturing method thereof, the insulation paper adopts electronic grade natural color sulfate needlebush insulation pulp as a raw material, the pulp is subjected to purification treatment to prepare double-layer pulp with different beating degrees, a small amount of dispersing agent is added into the pulp, and then a double-cylinder paper machine is adopted for compounding and papermaking to form raw paper, and finally, super calendering is performed so as to obtain the raw paper. The breakdown strength in oil of the insulating paper manufactured by adopting the method is improved by 66% compared with that of insulating paper manufactured by adopting single-layer paper making, and is improved by 45% compared with that of insulating paper manufactured by adopting double-layer paper making with the same beating degree.

Owner:CHINA NAT PULP & PAPER RES INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com