Volume-variable sink-type dish washing machine and assembly method thereof

A sink type and dishwasher technology, which is applied in the direction of tableware washing machine/rinsing machine, tableware washing machine/rinsing and rinsing machine parts, water supply device, etc. Machine use experience, forgetting the second cleaning and other problems, to achieve the effect of ingenious structural design, preventing deformation and damage, and good supporting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

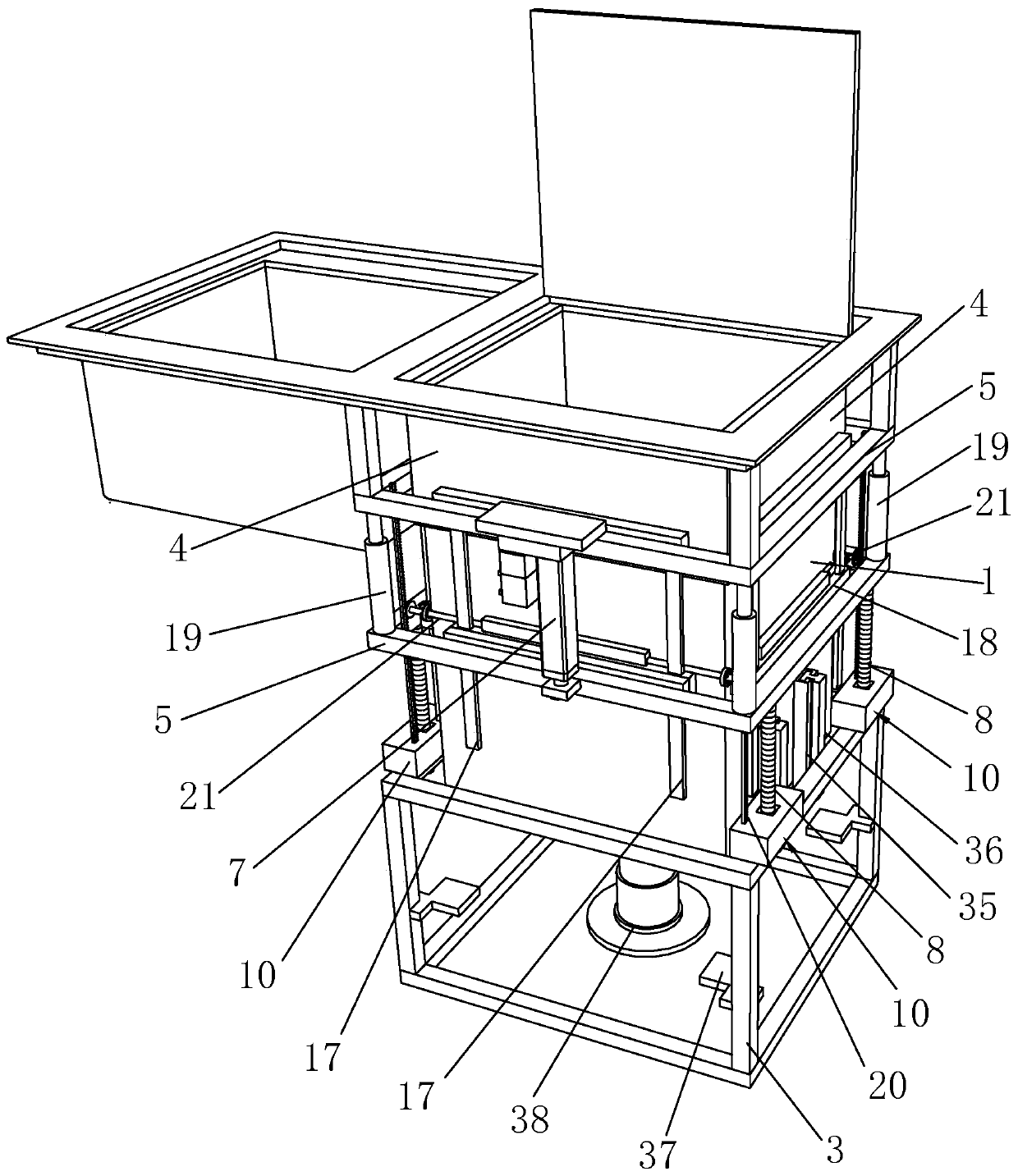

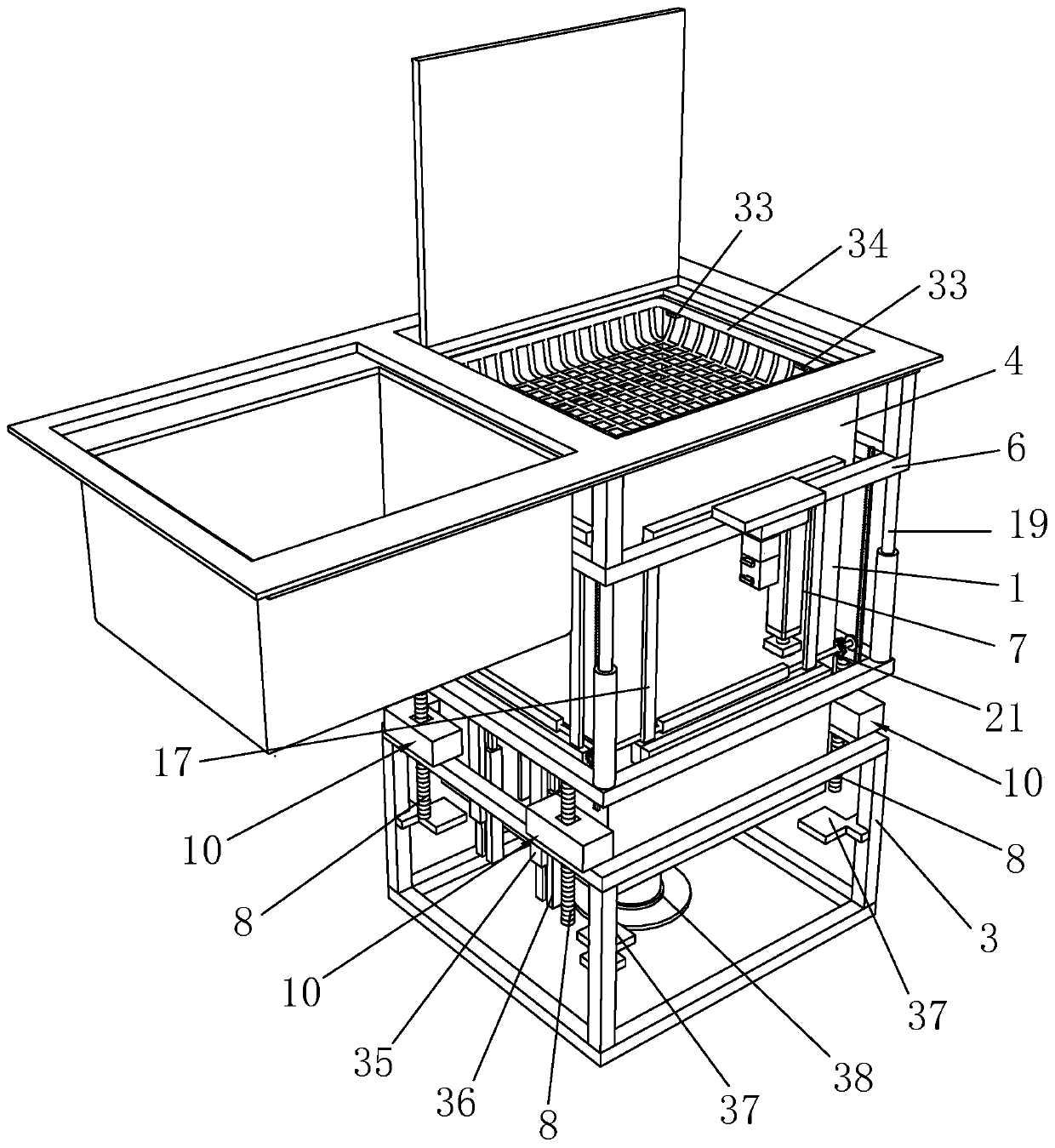

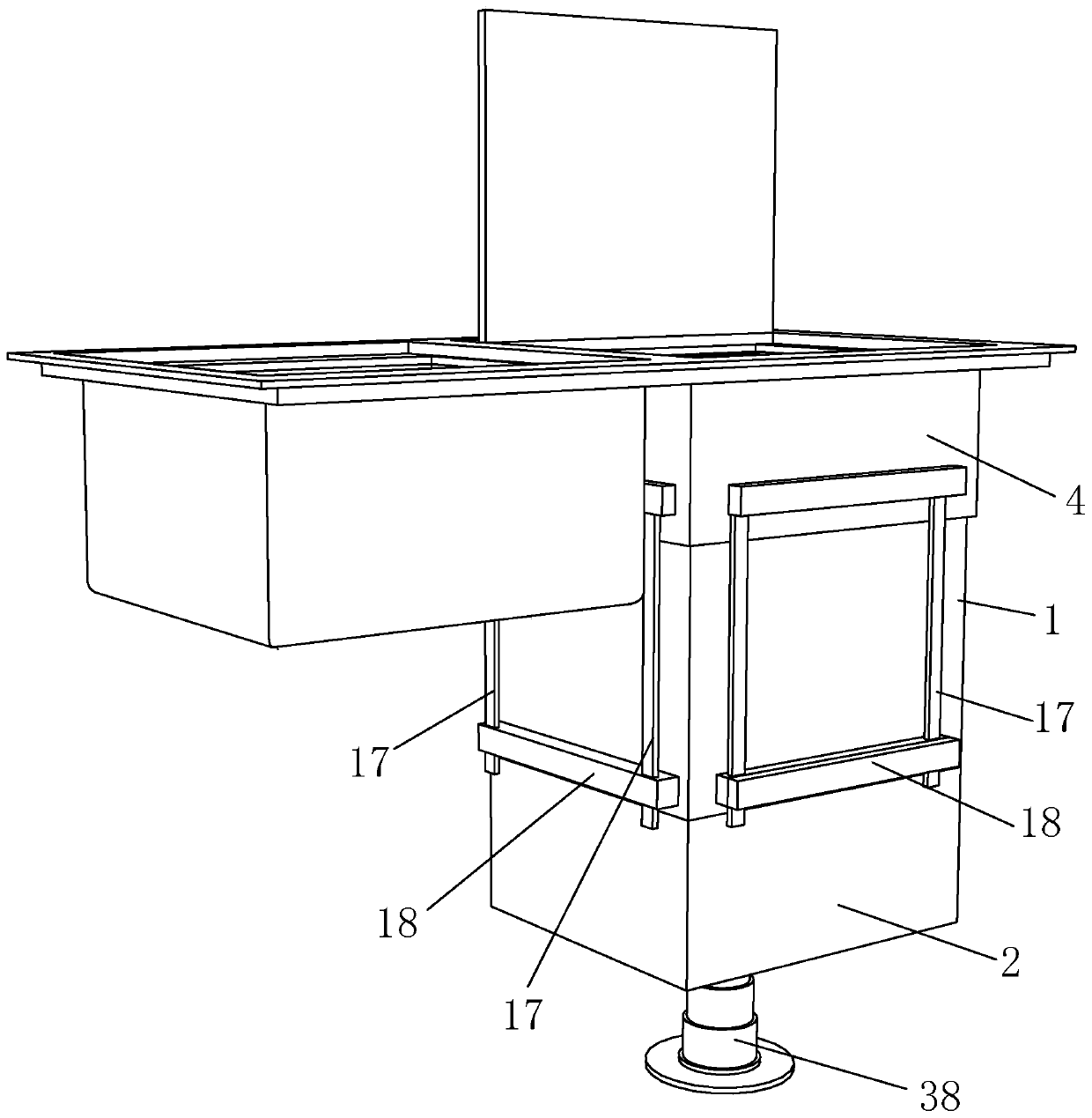

[0034] Such as Figure 1 to Figure 6 As shown, it is a sink type dishwasher with variable volume according to the present invention, which includes a sink 1, a cleaning assembly 2 and a fixed frame 3, the cleaning assembly 2 is connected to the sink 1, the sink 1 is provided with a telescopic plate 4, and the telescopic plate 4 is movably connected with the water tank 1, the water tank 1 is provided with a first fixed frame 5, the telescopic plate 4 is provided with a second fixed frame 6, and an electric push rod 7 is provided between the first fixed frame 5 and the second fixed frame 6, and the electric push rod 7 is arranged between the first fixed frame 5 and the second fixed frame 6. The rod 7 drives the first fixed frame 5 to relatively move below the second fixed frame 6 . The relative movement between the water tank 1 and the telescopic plate 4 is realized by driving the motor, and the capacity of the water tank 1 is increased, so that more tableware can be accommodate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com