Multilayer upright full-automatic dish washing machine

A fully automatic and dishwasher technology, applied in the direction of tableware washing machine/rinsing machine, tableware washing machine/rinsing and rinsing machine parts, tableware washing machine/rinsing machine control, etc., can solve the waste of water resources , Dishwasher cleaning effect is poor, etc., to achieve the effect of even dishes, thorough cleaning, and improved cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

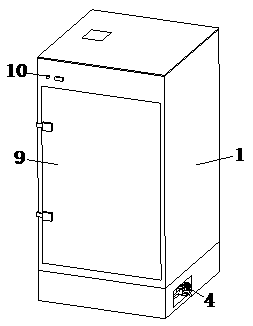

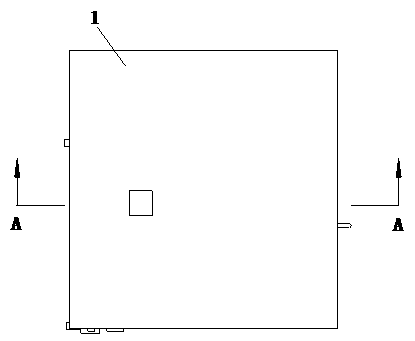

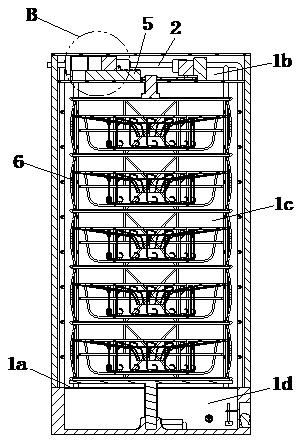

[0037] Combine below Figure 1 to Figure 8 As shown, the embodiment of the present invention provides a multi-layer vertical automatic dishwasher, including a housing 1, a cleaning spray assembly 2, a heating and drying assembly 3, an automatic water inlet and drainage assembly 4, and a dishwashing powder quantitative addition assembly 5 and a dish supporting assembly 6, the inside of the housing 1 is a hollow structure and the housing 1 is provided with two partitions 1a, and the two partitions 1a separate the inner space of the housing 1 into a control chamber 1b, cleaning cavity 1c and pool 1d, the cleaning and spraying assembly 2 is installed in the cleaning cavity 1c, the heating and drying assembly 3 is installed in the pool 1d, the automatic water inlet and drainage assembly 4 is installed in the control cavity 1b and the pool 1d, The dishwashing powder quantitative addition assembly 5 is installed in the control chamber 1b, the dish support assembly 6 is installed in t...

Embodiment 2

[0047] refer to Figure 9As shown, the cleaning spray assembly 2 includes a cleaning water pump 2a, a water main pipe 2b, a water distribution horizontal pipe 2c and four spray pipes 2d, the lower end of the water main pipe 2b is located at the bottom of the pool 1d, and the water pipe The upper end of the water main pipe 2b extends upwards into the control chamber 1b, and the water distribution horizontal pipe 2c is horizontally arranged in the control chamber 1b, and the middle part of the water distribution horizontal pipe 2c communicates with the upper end of the water distribution main pipe 2b. The pipe 2c is provided with four branch pipes 2g, the four spray pipes 2d are rectangularly distributed in the cleaning chamber 1c and the upper ends of the four spray pipes 2d extend into the control chamber 1b, and the four spray pipes The upper ends of 2d are respectively connected with the four branch pipes 2g through hoses one by one. The upper ends of the two spray pipes 2d ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com