Density-adjustable multilayer periodic structure

A periodic structure and density technology, applied in the direction of layered products, rubber layered products, synthetic resin layered products, etc., can solve the problems of elastic wave inability to propagate, shape wave attenuation, etc., to achieve standardized production, convenient production, and targeted strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

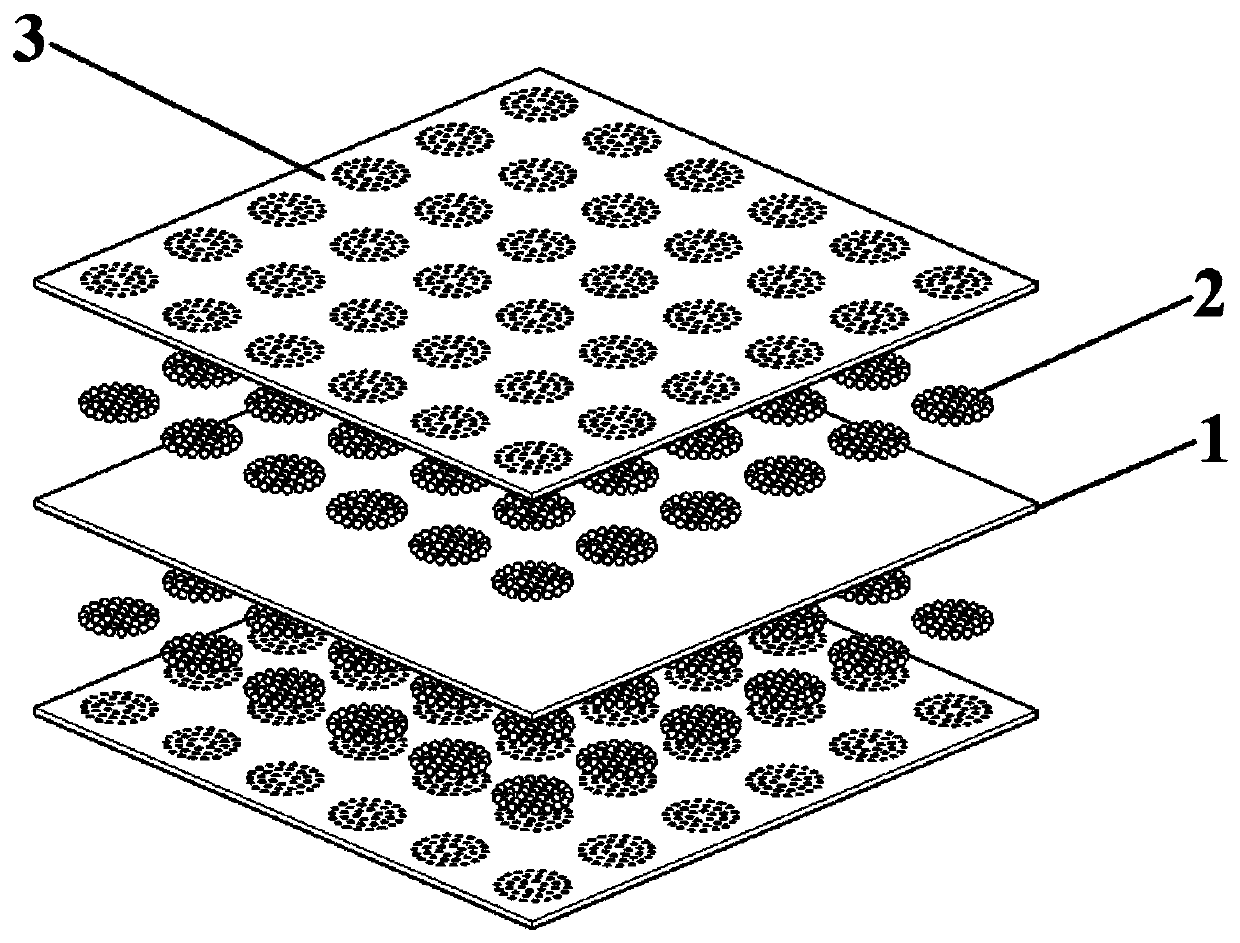

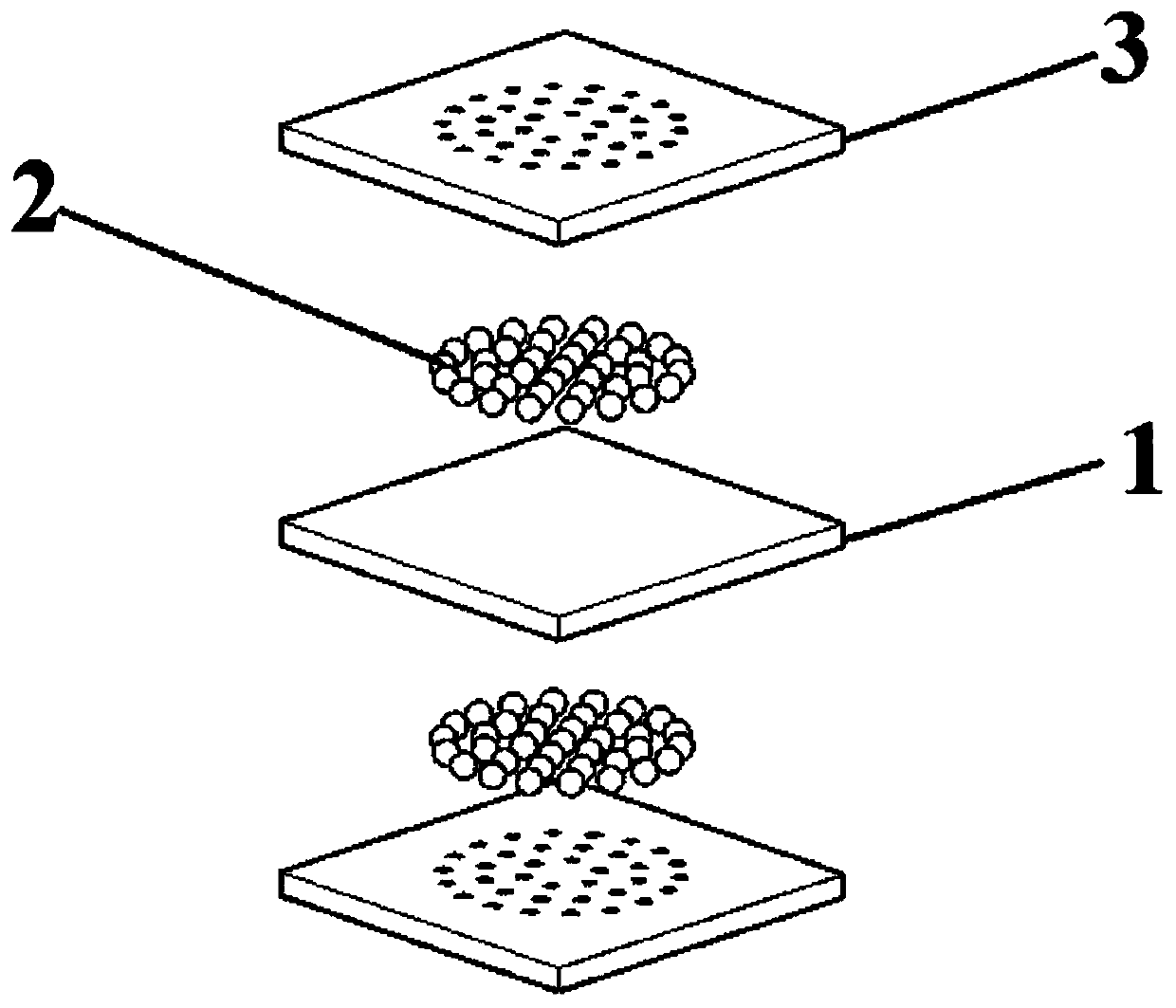

[0030] Such as figure 1 , 2 , 3, and 7, this embodiment is a multilayer periodic structure with adjustable density. The hard small blocks are made of small spheres, which are embedded in the upper and lower outer films or plate substrates. The local parts are evenly arranged in a circle, and the overall arrangement is a circular area such as m rows and n columns. The unit cells are arranged in squares. , the lattice constant is set to a 1 . A film or plate without block is arranged in the middle layer as a substrate, and multi-layer films or plate substrates are connected together by pasting to form a multi-layer periodic structure with adjustable density.

Embodiment 2

[0032] Such as figure 1 , 4 As shown, this embodiment is a multilayer periodic structure with adjustable density. The hard small block adopts a small cuboid, which is embedded in the upper and lower outer films or plate substrates. The parts are evenly arranged in a square, and the overall arrangement is a square area such as m rows and n columns. The unit cells are arranged in squares. The lattice constant is set to a 1 . A film or plate without block is arranged in the middle layer as a substrate, and multi-layer films or plate substrates are connected together by pasting to form a multi-layer periodic structure with adjustable density.

Embodiment 3

[0034] Such as figure 1 , 5 As shown, this embodiment is a multilayer periodic structure with adjustable density. The upper hard small block adopts small spheres, which are partially arranged in a circle, and a circular area such as m rows and n columns is arranged as a whole. The unit cells are arranged in squares, and the lattice constant is set to a 1 , embedded on the upper film or plate substrate; the lower hard small block is a small cuboid, which is arranged in a square partly, and a square area such as m rows and n columns is arranged as a whole, and the unit cells are arranged in squares. The lattice constant is set to a 2 , embedded in the film or plate substrate on the underside. A film or plate without block is arranged in the middle layer as a substrate, and multi-layer films or plate substrates are connected together by pasting to form a multi-layer periodic structure with adjustable density.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com