Display screen processing technology

A processing technology and display screen technology, applied in optics, instruments, nonlinear optics, etc., can solve problems such as troublesome film tearing operations and reduce assembly efficiency of liquid crystal display devices, so as to improve film tearing efficiency, reduce manual operation intensity, and improve The effect of processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

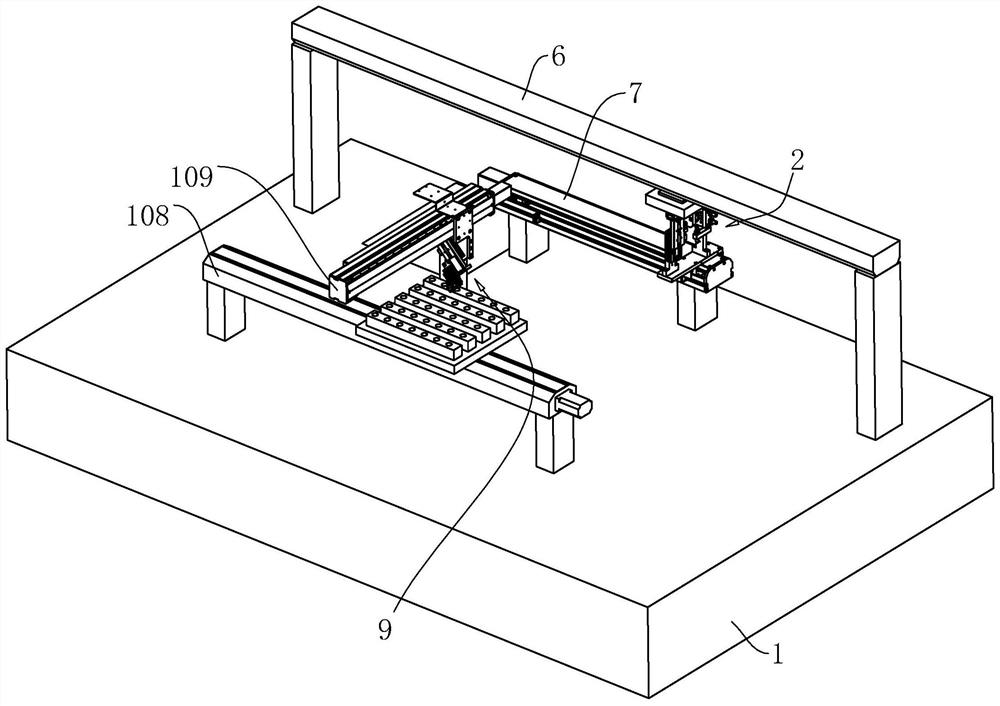

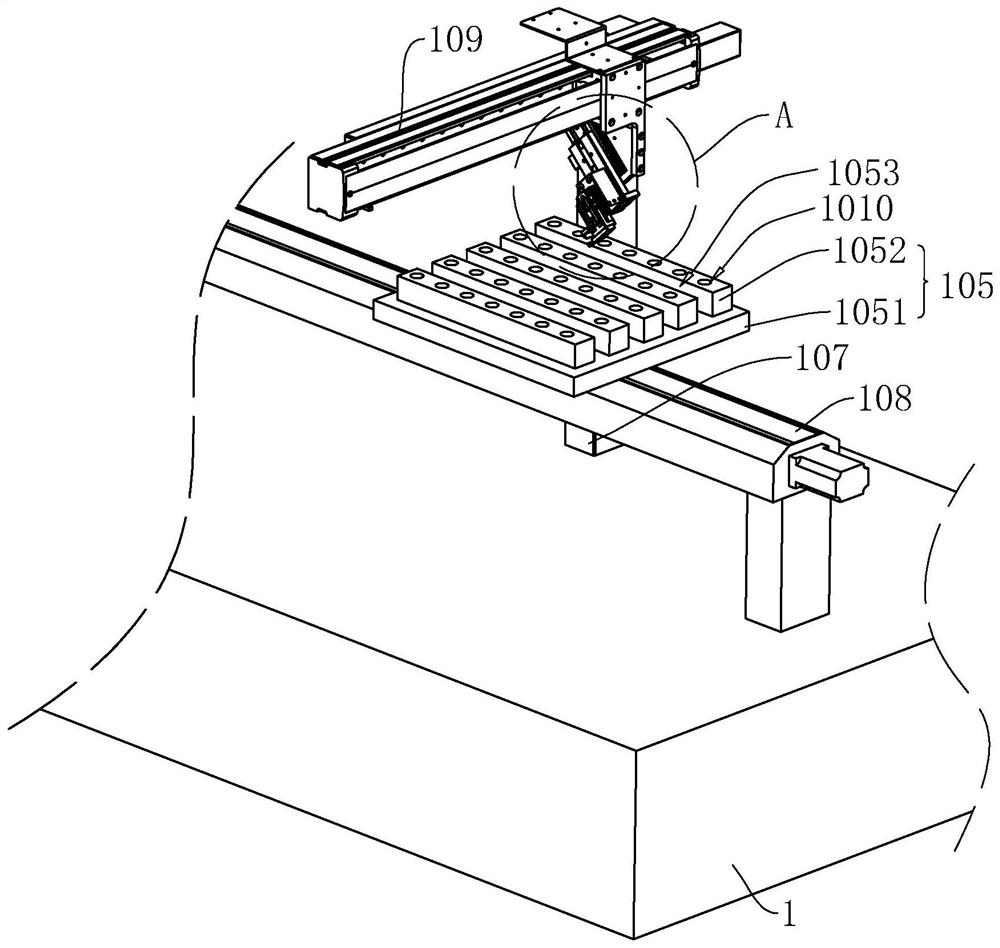

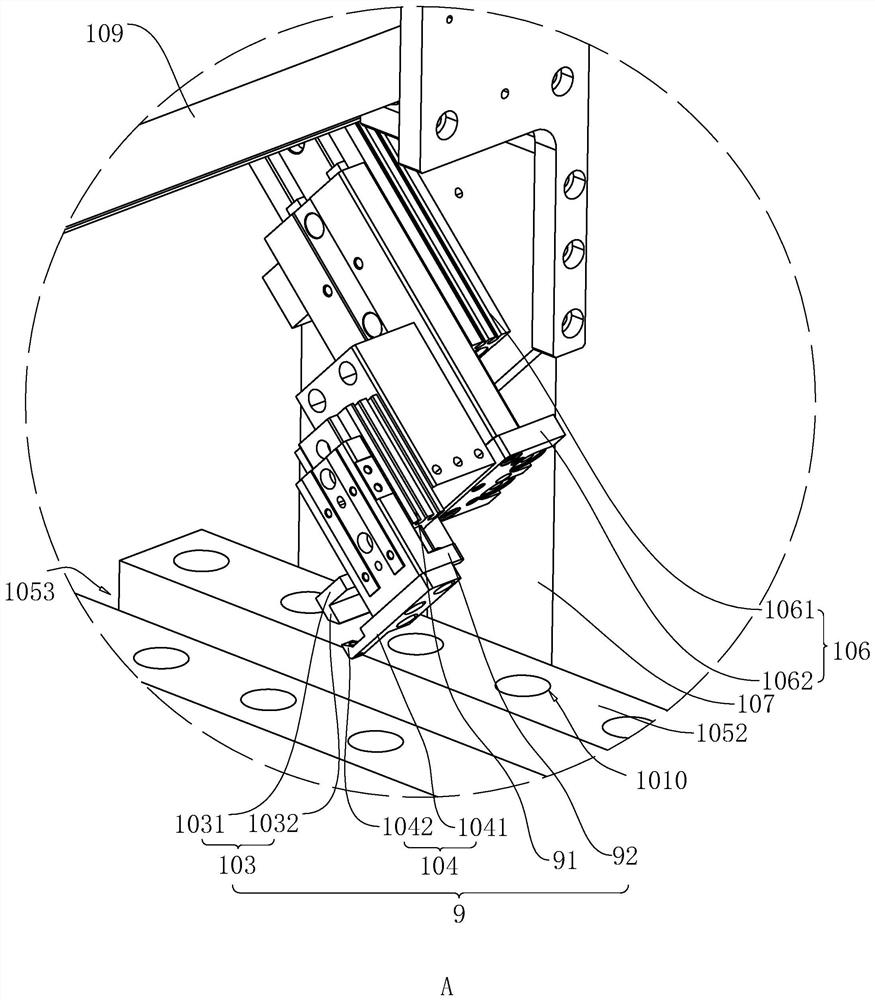

[0045] The following is attached Figure 1-6 The application is described in further detail.

[0046] The embodiment of the application discloses a display screen processing technology. refer to Figure 1-6 , a display processing technology comprising the following steps:

[0047] S1a. Transport the backlight to the first film tearing device, so as to tear off the protective film on the surface of the backlight;

[0048] S1b. Positioning the position of the liquid crystal module;

[0049] S2. The liquid crystal module after positioning is transported to the second film tearing device to tear off the protective film on the surface of the liquid crystal module;

[0050] S3. Transport the liquid crystal module and the backlight to the CCD detection system for positioning;

[0051] S4, then attaching the liquid crystal module to the surface of the backlight source;

[0052] S5. Pressing the liquid crystal module onto the surface of the backlight, so that the liquid crystal m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com