Patents

Literature

86results about How to "High linkage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

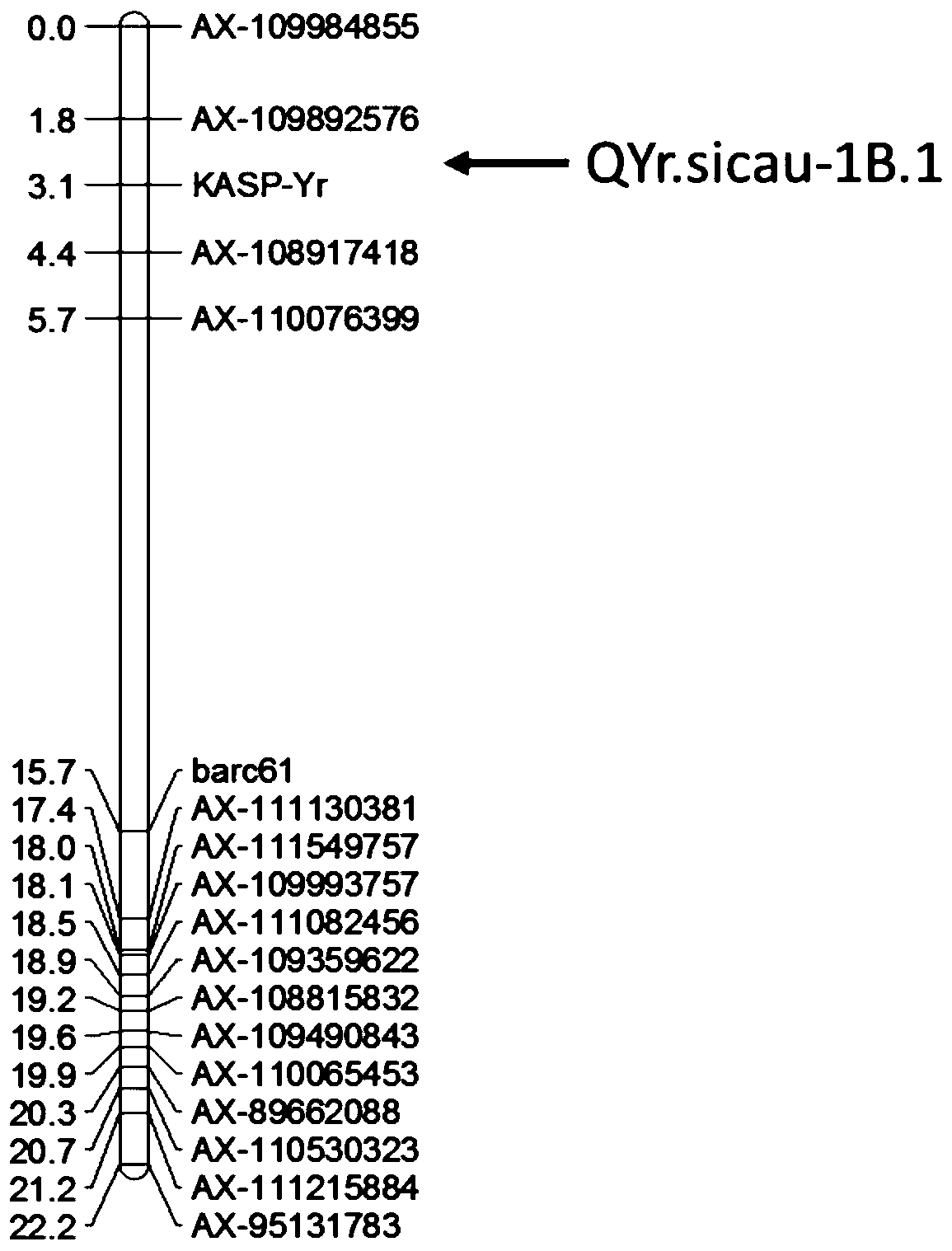

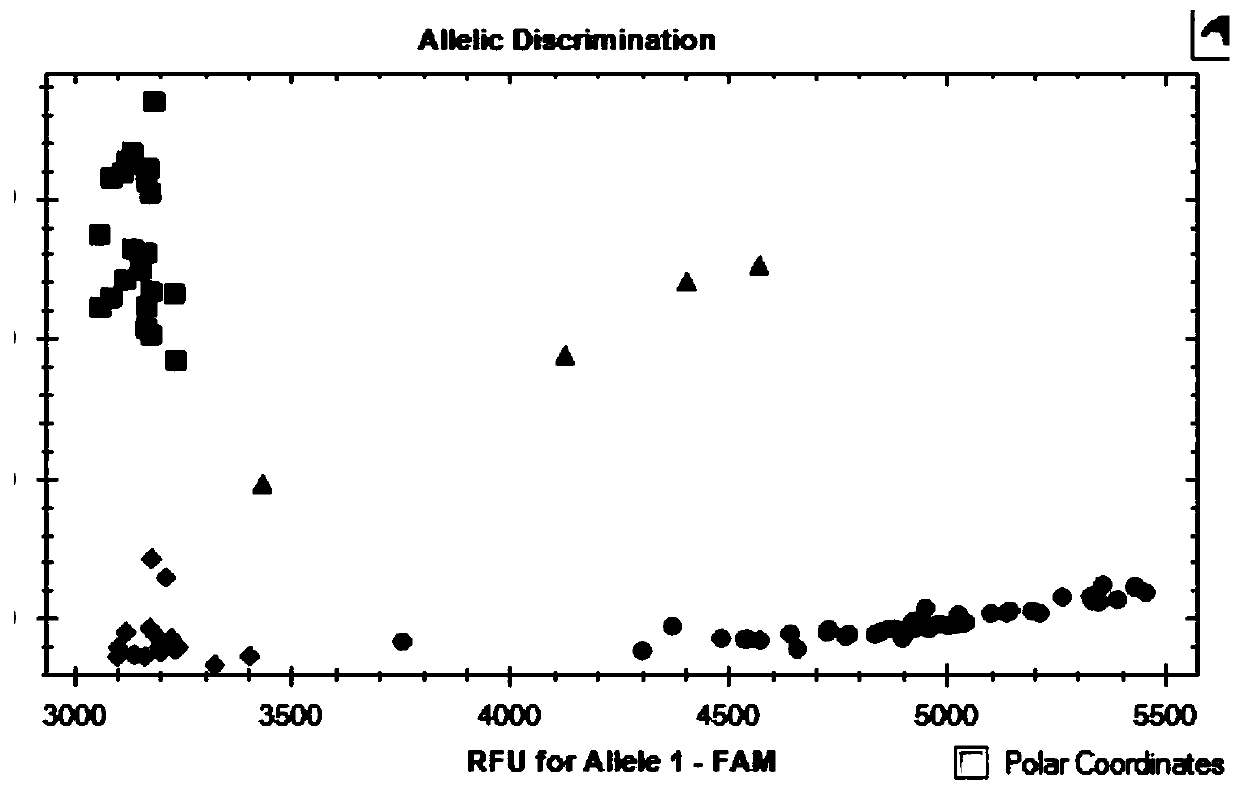

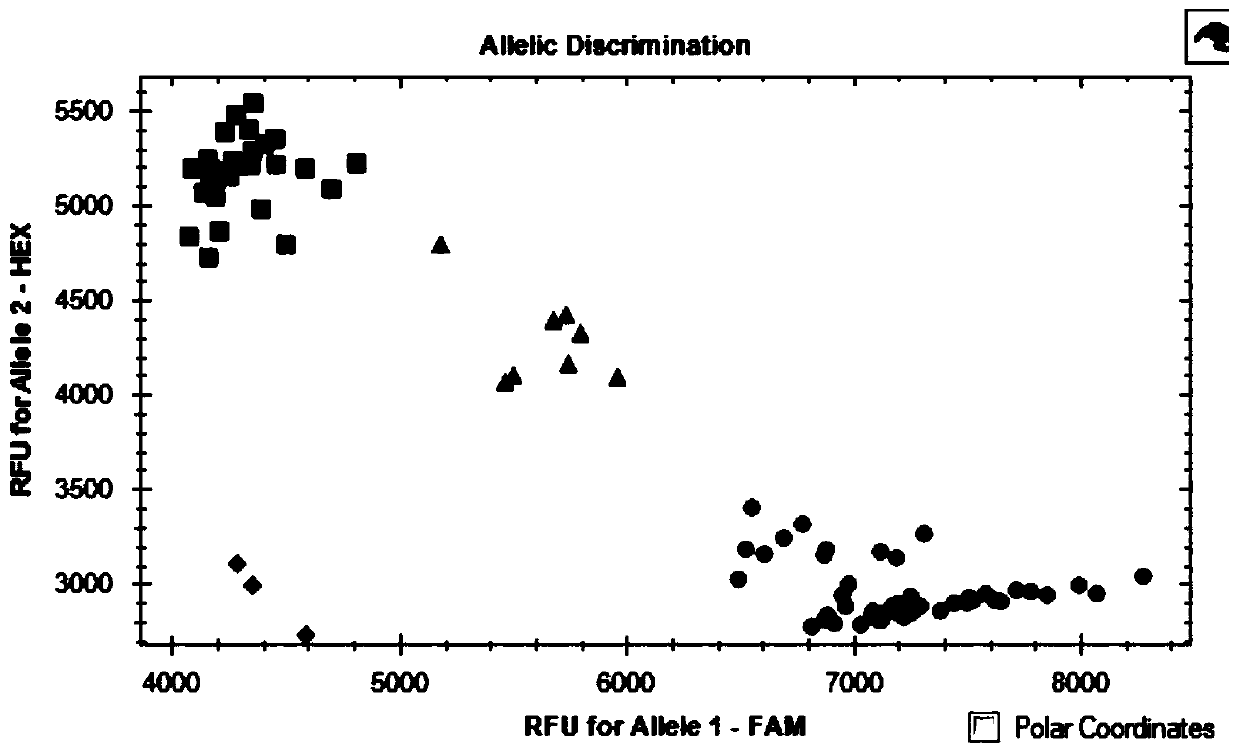

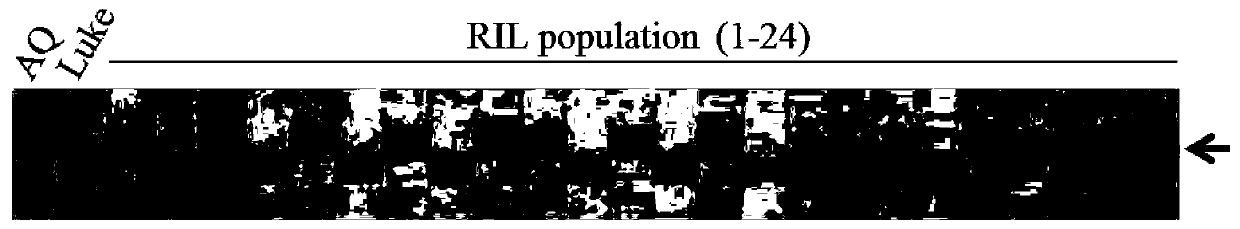

SNP molecular marker linked with wheat stripe rust resistance gene QYr.sicau-1B-1 and application thereof

ActiveCN109706263AQuick filterConvenient Assisted BreedingMicrobiological testing/measurementDNA/RNA fragmentationAgricultural scienceMolecular breeding

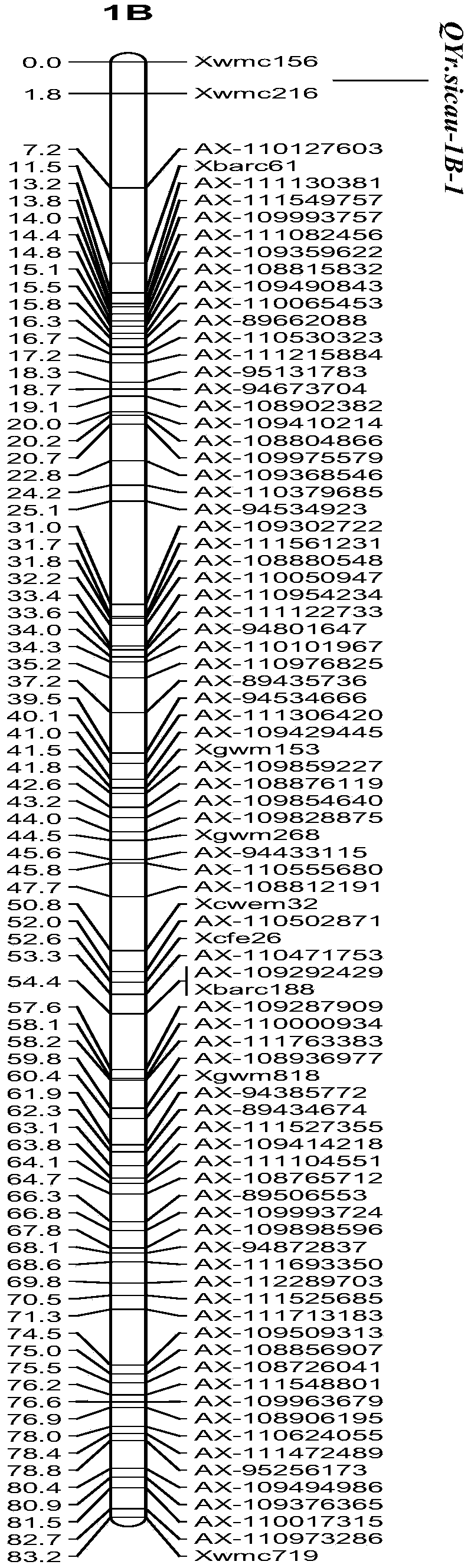

The invention belongs to the technical field of molecular breeding, and provides an SNP molecular marker linked with a wheat stripe rust resistance gene QYr.sicau-1B.1 and application thereof. The SNPmolecular marker is KASP-Yr, which can be obtained by amplifying a primer having a nucleotide sequence as shown in SEQ ID NO.1-3. Detection analysis indicates that the molecular marker can be used for accurately tracking wheat stripe rust resistant QTL QYr.sicau-1B.1 and predicting the stripe rust resistance characteristics of wheat, so that molecular designed breeding can be performance conveniently. The invention further discloses a method for identifying the molecular marker linked with wheat stripe rust resistance QTL QYr.sicau-1B.1. By utilizing the method, the stripe rust resistance prediction accuracy can be reinforced to quickly screen wheat variety or strain with stripe rust resistance for breeding, the breeding process for high-yield variety of wheat can be greatly accelerated.

Owner:SICHUAN AGRI UNIV

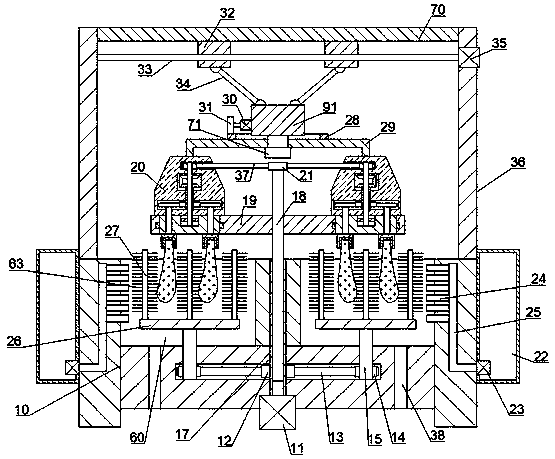

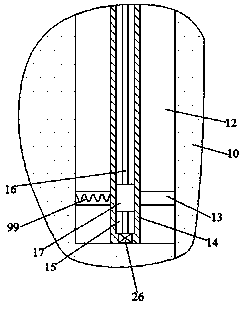

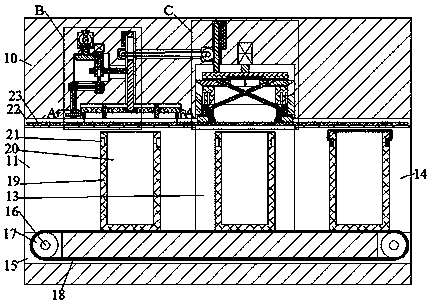

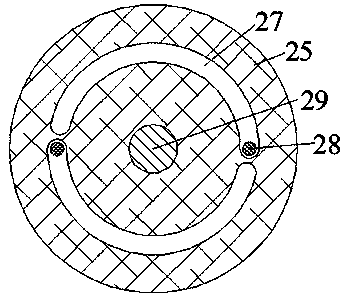

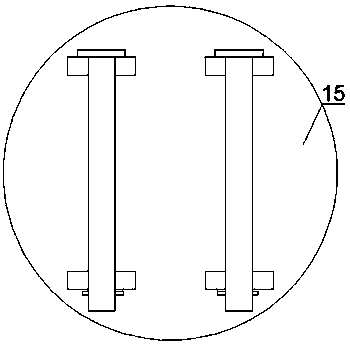

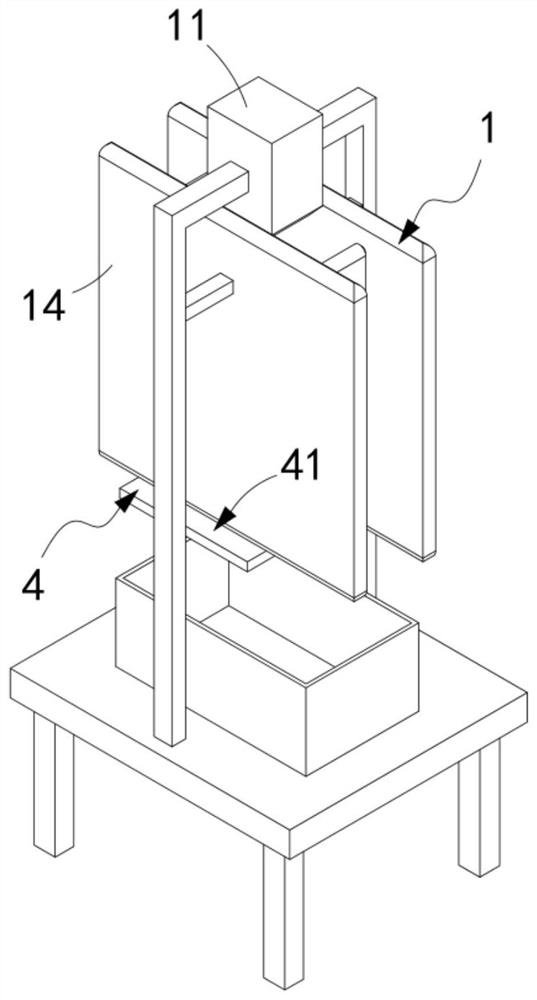

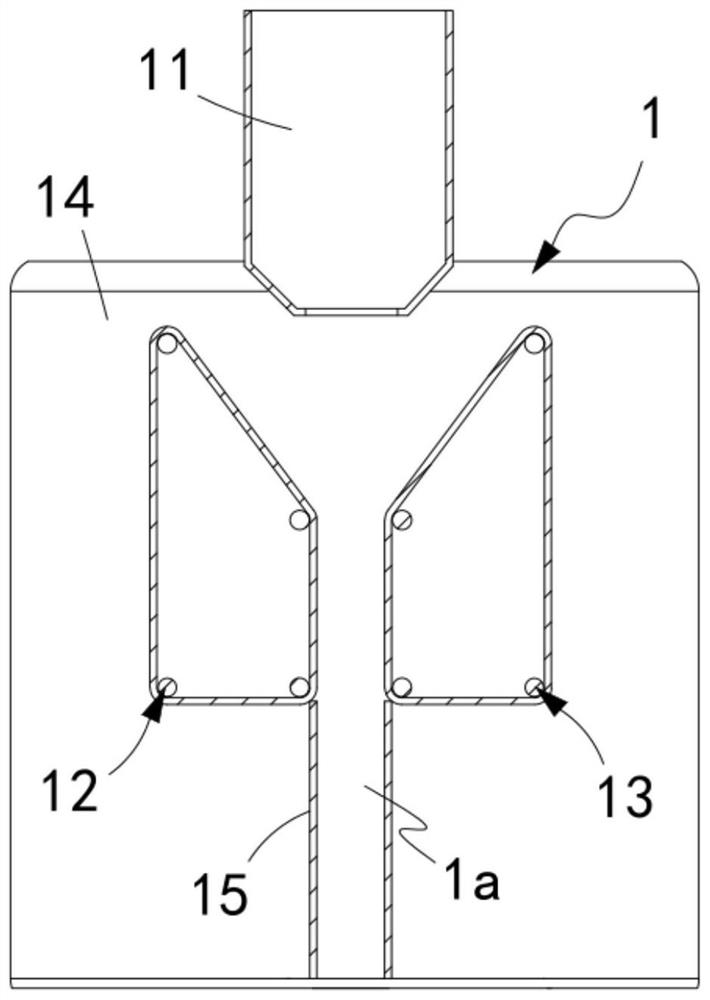

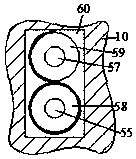

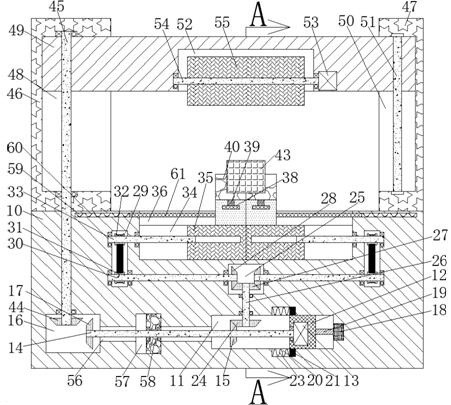

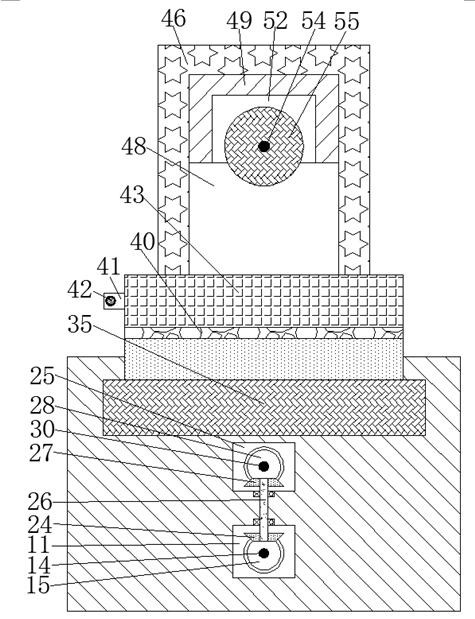

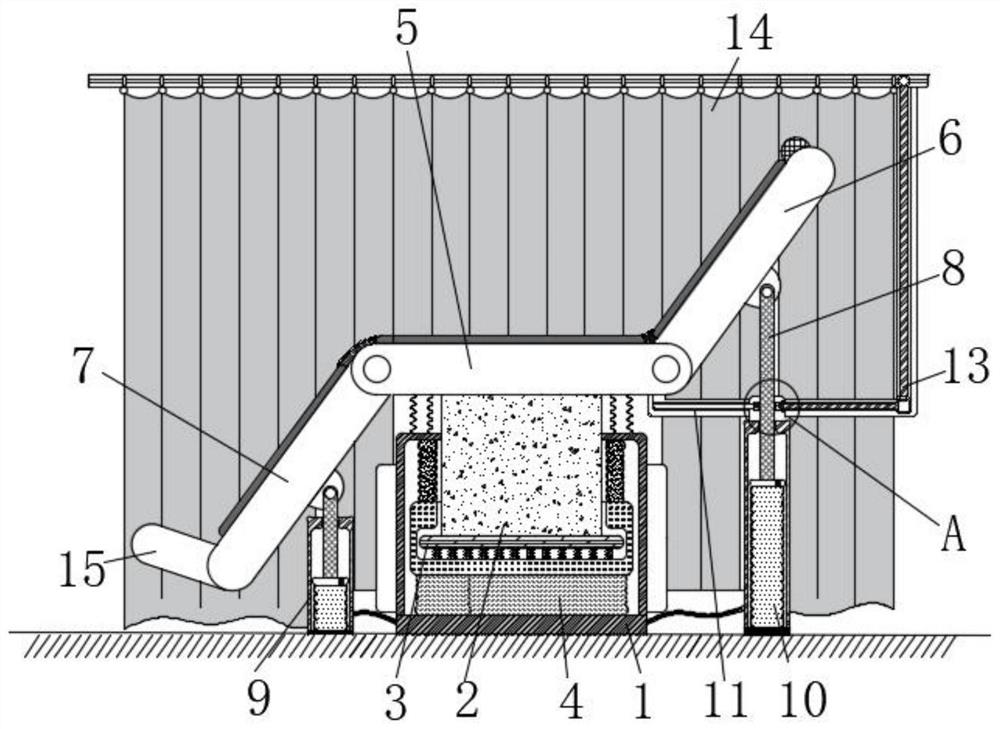

Fan blade cleaning device made of novel carbon fiber materials

ActiveCN111420918AHigh linkageImprove linkage and improve cleaning effectCleaning using toolsCleaning using liquidsFiberCarbon fibers

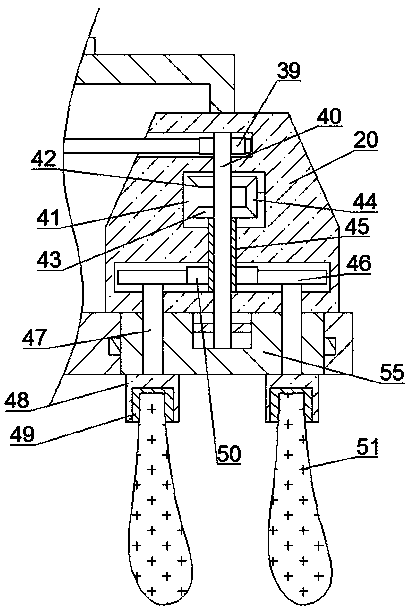

The invention discloses a fan blade cleaning device made of novel carbon fiber materials. The fan blade cleaning device made of the novel carbon fiber materials comprises a base, two cleaning cavitieswhich are symmetrical left and right are formed in the base, openings of the two cleaning cavities are designed to face upwards, rotating discs are rotationally arranged in the two cleaning cavitiescorrespondingly, three cleaning shafts which are evenly distributed are fixedly arranged on the top faces of the rotating discs, and brushes are fixedly arranged on peripheries of cleaning shafts correspondingly. According to the fan blade cleaning device made of the novel carbon fiber materials, a plurality of blades can be clamped through sliding of a plurality of clamping blocks, the fact thatcleaning the plurality of blades at the same time can be carried out is realized, the cleaning number is greatly increased; when the blades rotate, the blades can be driven by the rotating discs to carry out revolution with a driven shaft as the circle center, and the brushes are driven by the rotating discs to rotate, so that the cleaning speed is greatly increased; and meanwhile, the structure is relatively simple, transmission components are all very common components, the cost is low, and popularization is convenient.

Owner:江苏韩塑新材料有限公司

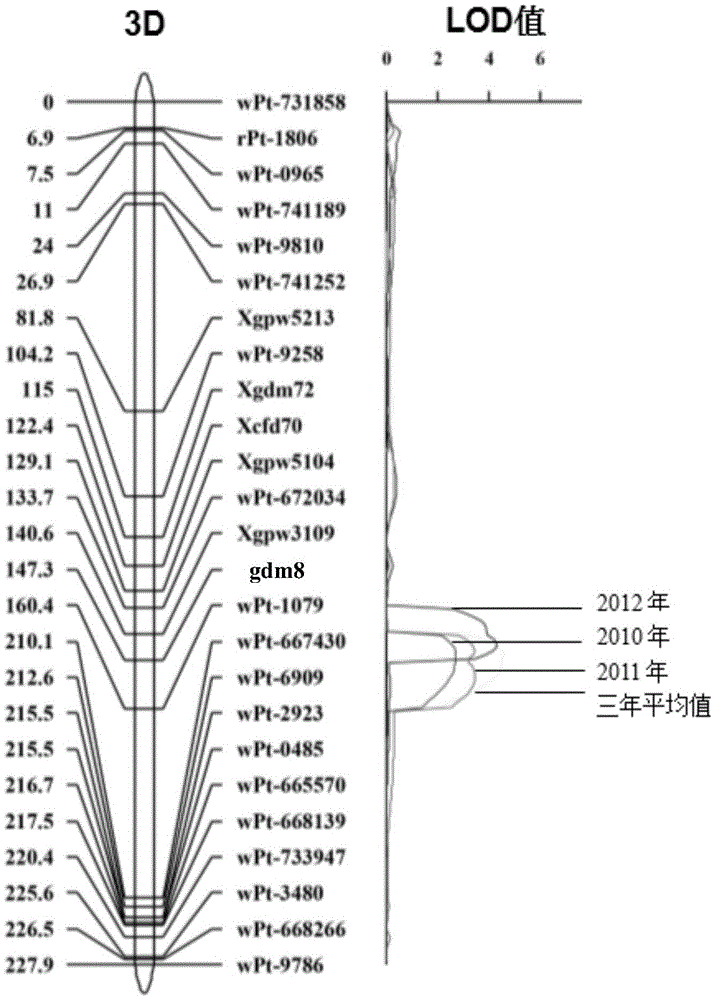

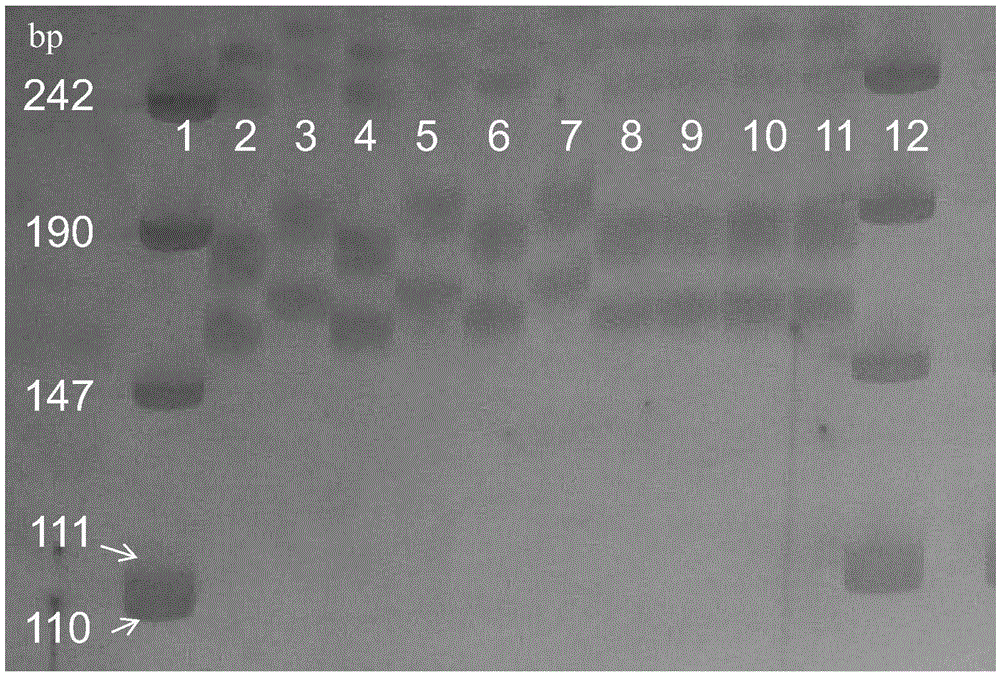

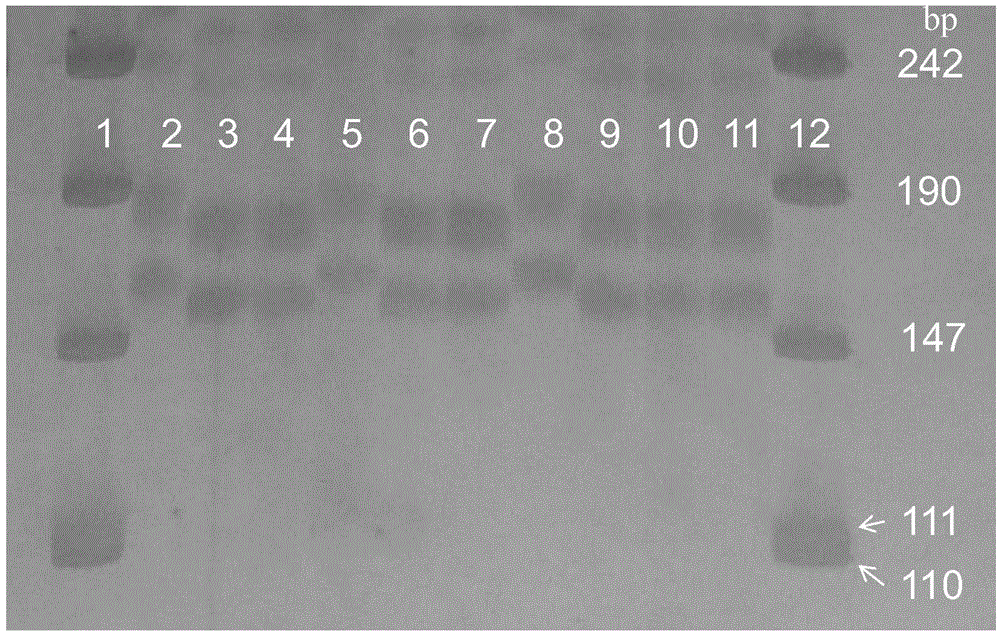

SSR molecular marker linked with wheat spikelet number QTL and application of SSR molecular marker

InactiveCN105525008AConvenient Assisted BreedingHigh linkageMicrobiological testing/measurementDNA/RNA fragmentationTriticeaeAgricultural science

The invention provides an SSR molecular marker linked with wheat spikelet number QTL and application of the SSR molecular marker. The molecular marker gdm8 linked with the wheat spikelet number, disclosed by the invention, locates on a wheat 3D chromosome, and the molecular marker is a flanking marker (co-dominant marker) of spikelet number QTL QSns.sau.3D on the long arm of the wheat 3D chromosome, with high linkage degree. The marker can be used for detecting the spikelet number QTL on the wheat 3D chromosome and for rapidly screening out plants having the site, so that molecular assisted selection for the high production of wheat can be conveniently performed. The molecular marker gdm8 provided by the invention, which is closely linked with the spikelet number QTL QSns.sau.3D on the wheat 3D, is applicable to wheat spikelet number character mapping, so that the plants with less spikelet are discarded during breeding; therefore, the molecular marker can improve the working efficiency of breeding and provide a basis for researches on the wheat spikelet number gene.

Owner:SICHUAN AGRI UNIV

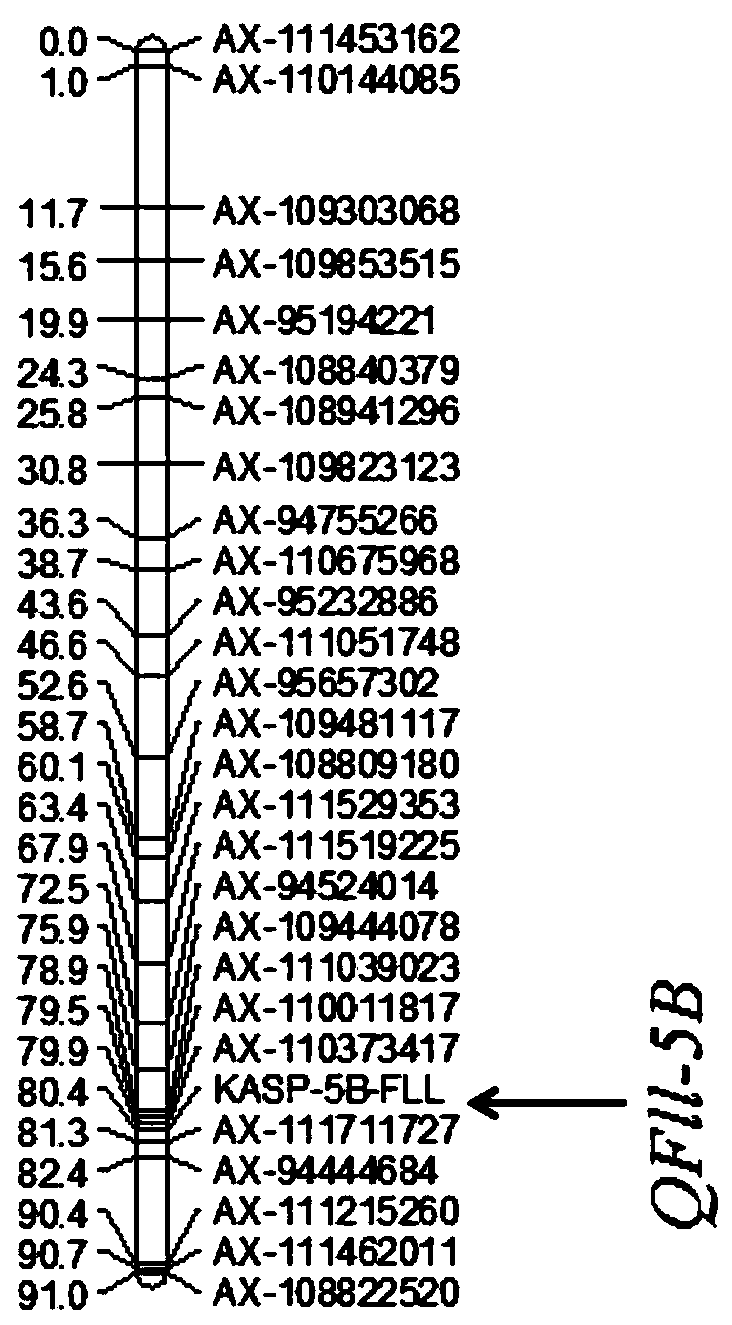

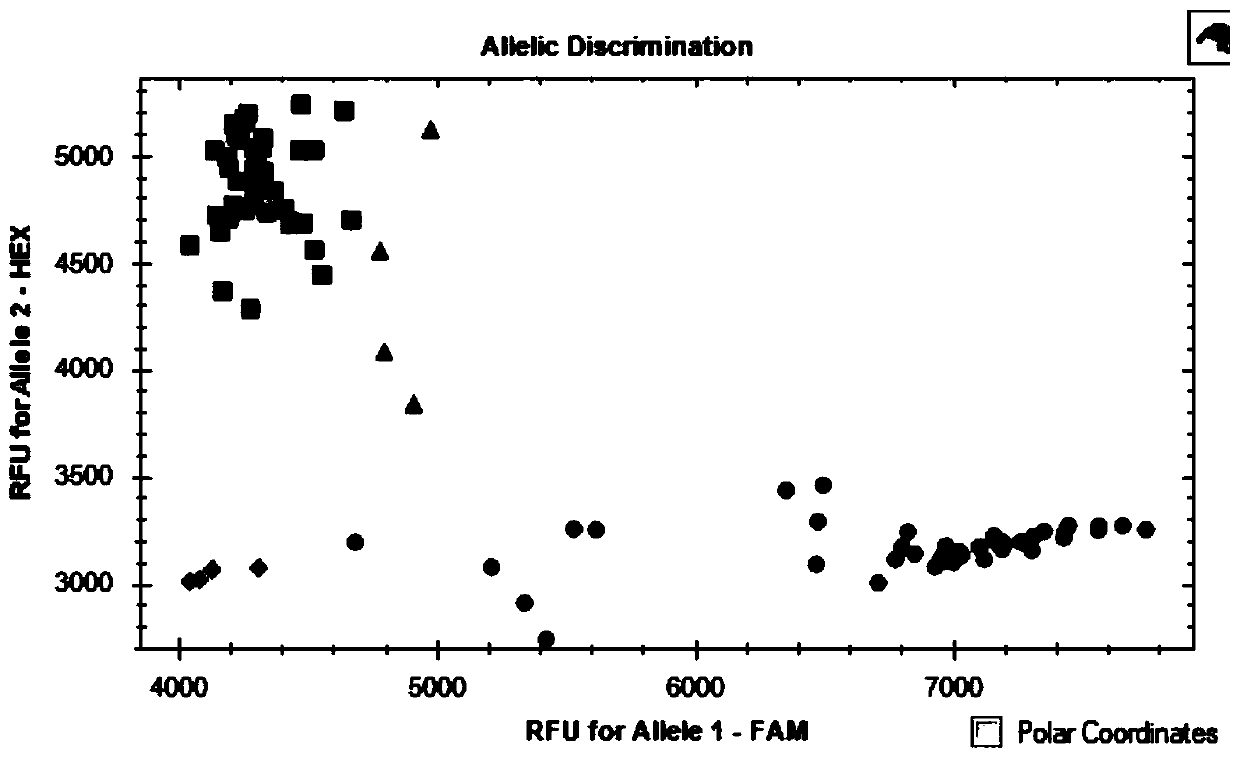

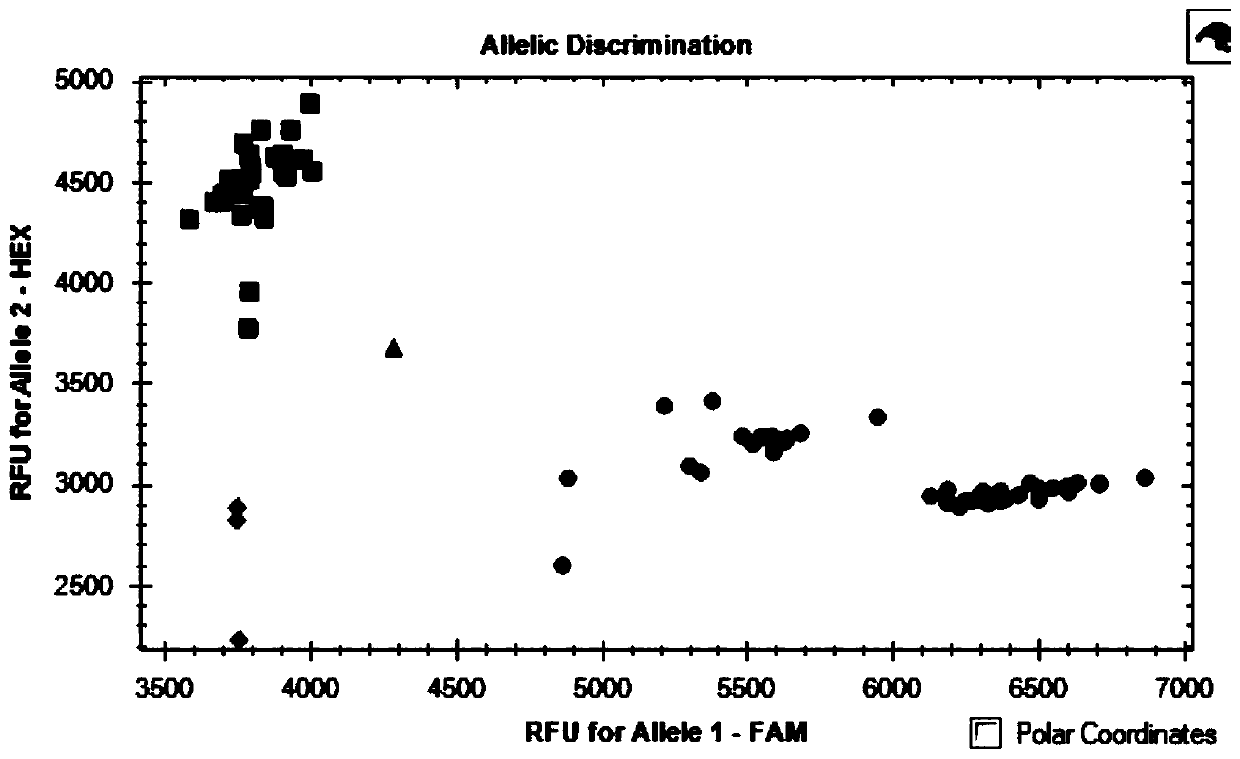

Triticum aestivum L. flag leaf length quantitative trait locus (QTL) linked molecular marker and application thereof

ActiveCN110499387AHigh linkageImprove use valueMicrobiological testing/measurementAngiosperms/flowering plantsBiotechnologyLong arm

The invention relates to the field of triticum aestivum L. molecular breeding, and particularly discloses a triticum aestivum L. flag leaf length quantitative trait locus (QTL) linked molecular markerand application thereof. The single nucleotide polymorphism (SNP) molecular marker linked with triticum aestivum L. flag leaf length QTL QFll-5B is provided and located on a 5B chromosome long arm ofa RefSeqv1.0 genome edition, and is the 51st of a sequence shown in SEQ ID NO.31, polymorphism is C / T, and the SNP molecular marker can be obtained by amplification of a primer shown in a nucleotidesequence such as SEQ ID NO.1-3. The SNP molecular marker can accurately trace the triticum aestivum L. flag leaf length QTL QFll-5B, and predict the flag leaf length characteristics of triticum aestivum L., and molecular design breeding is convenient. The invention further discloses a method for identifying the molecular marker. The prediction accuracy of the flag leaf length can be enhanced by using the method, so that varieties or strains of the triticum aestivum L. with increased the flag leaf length are conveniently and rapidly screened for breeding, and the breeding progress of the varieties of the triticum aestivum L. with a high yield can be greatly accelerated.

Owner:SICHUAN AGRI UNIV

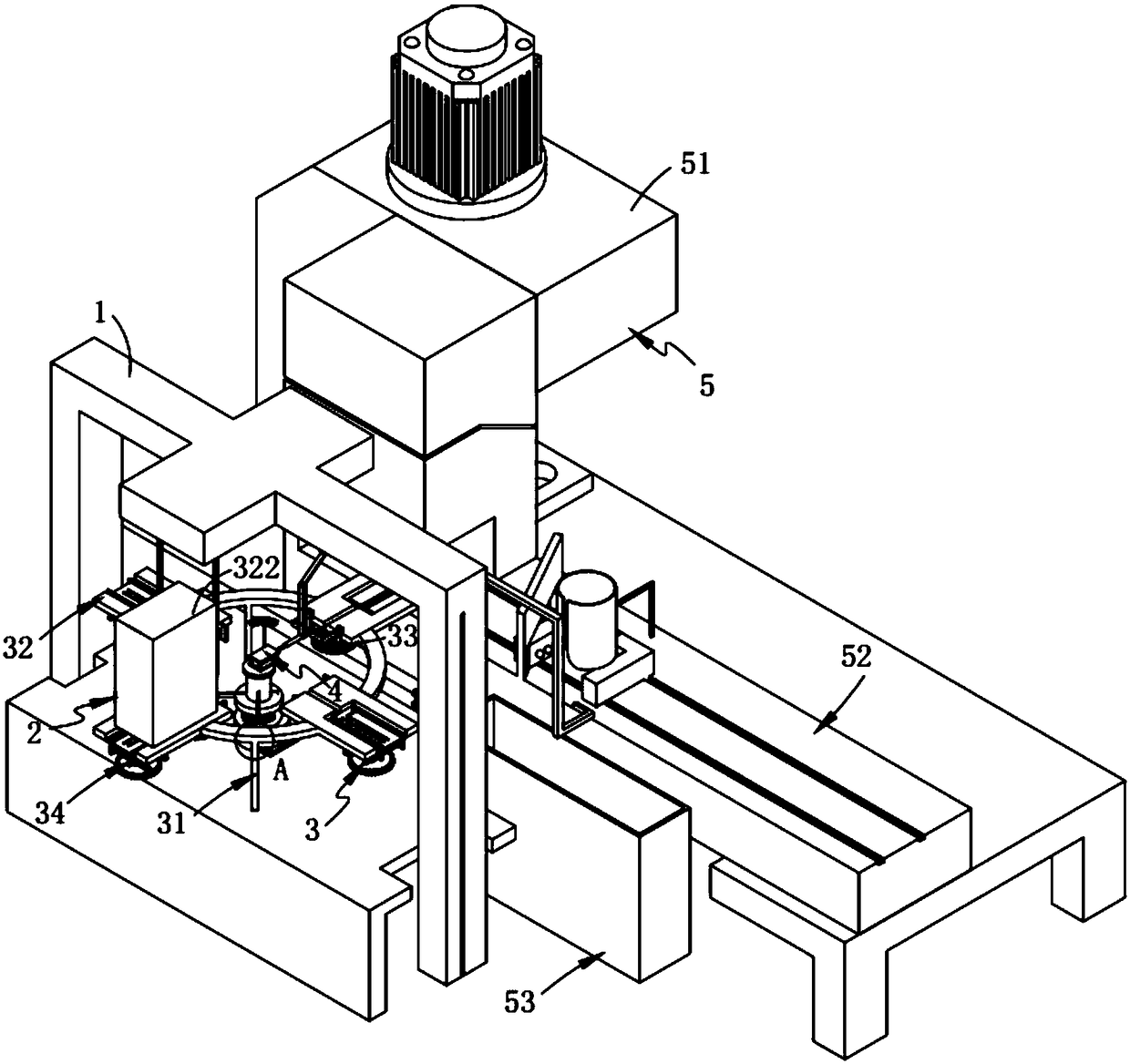

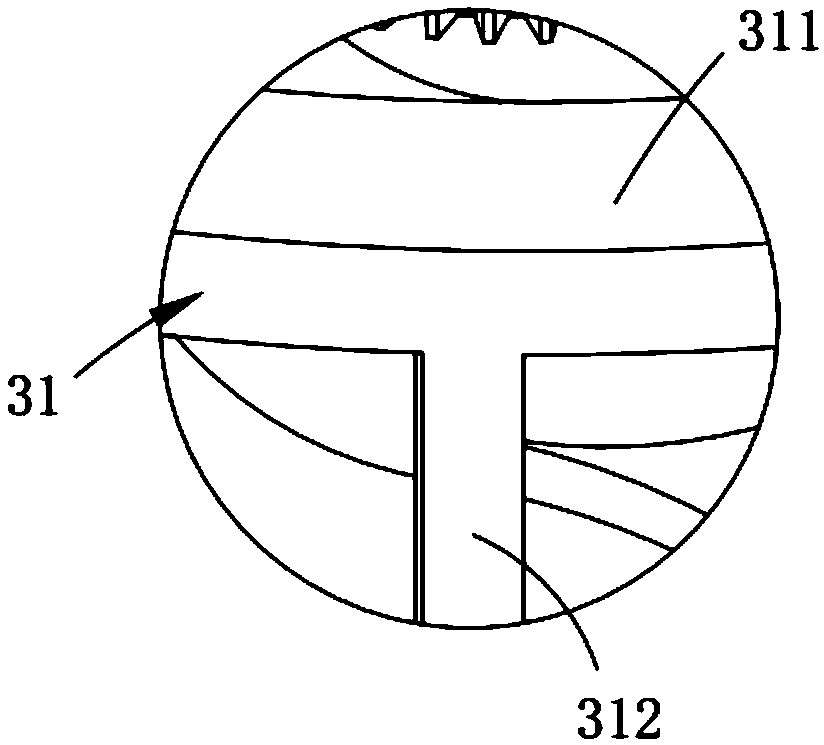

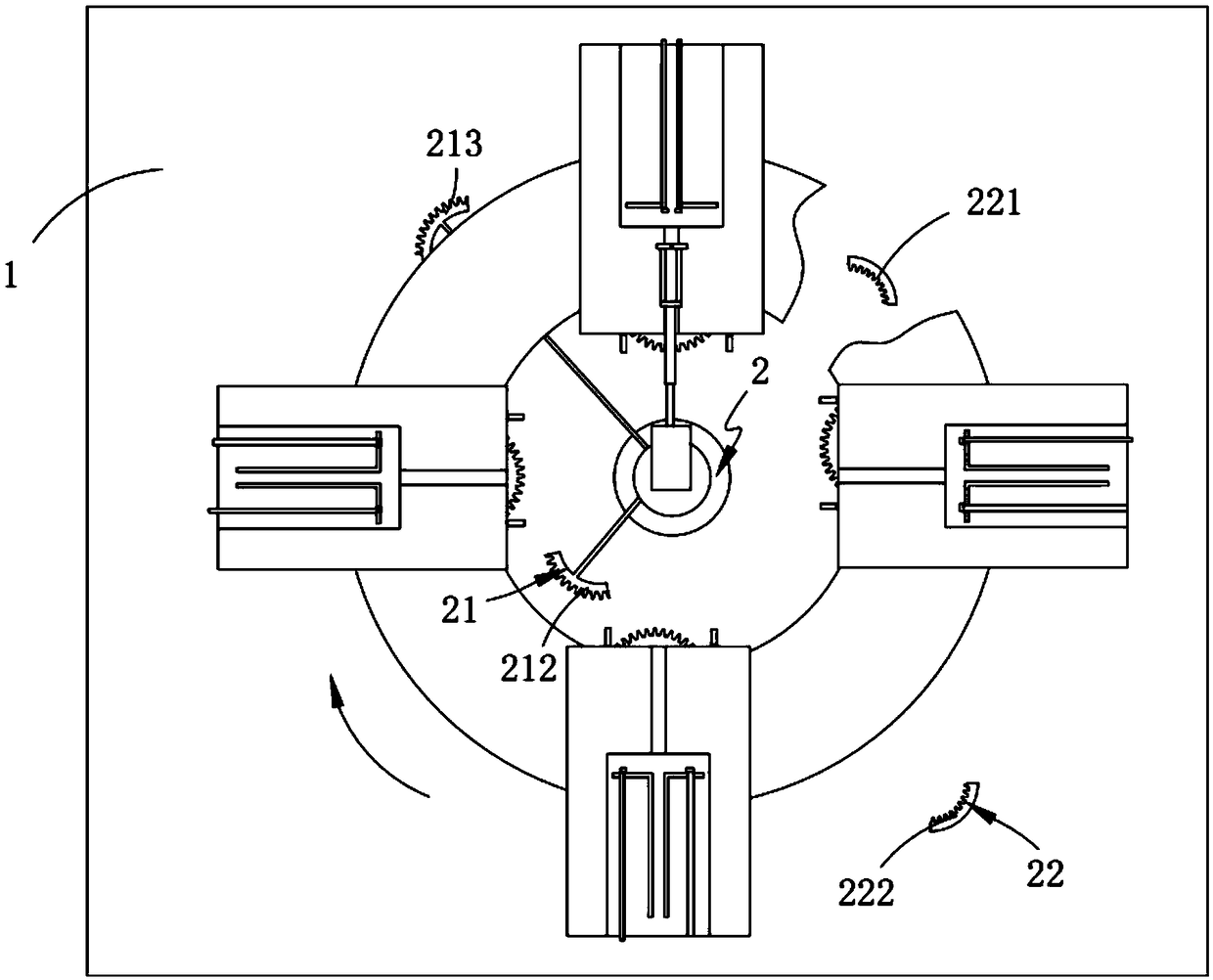

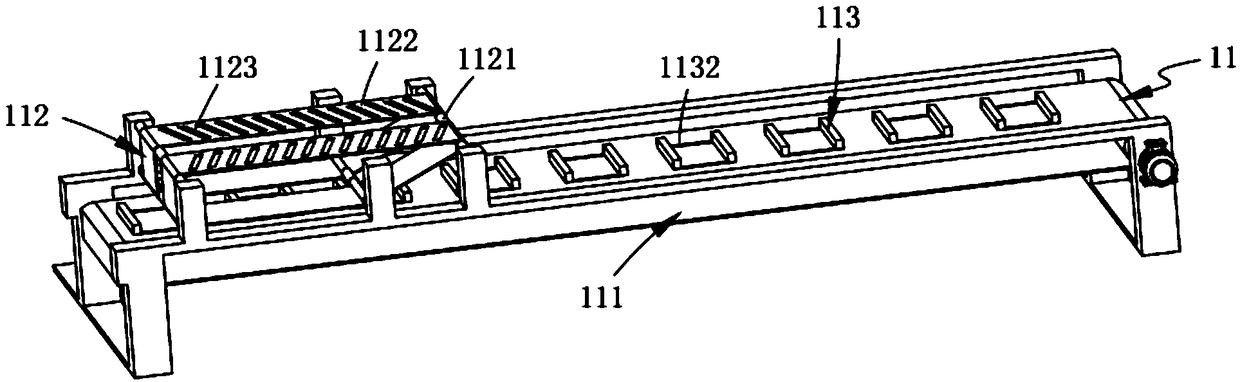

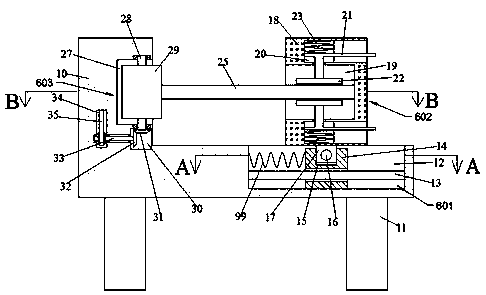

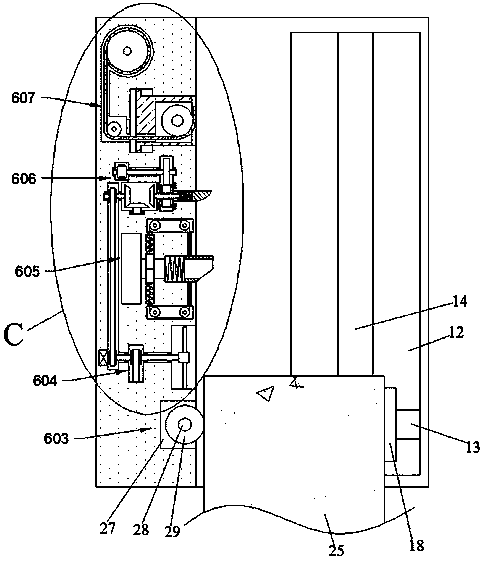

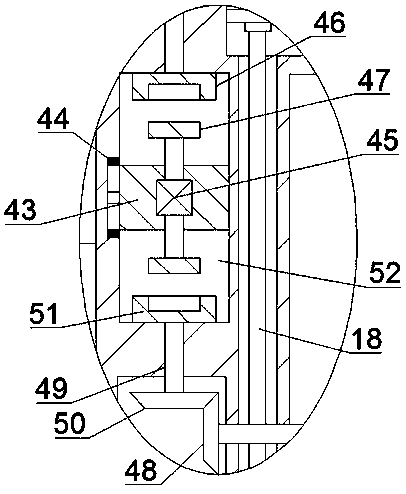

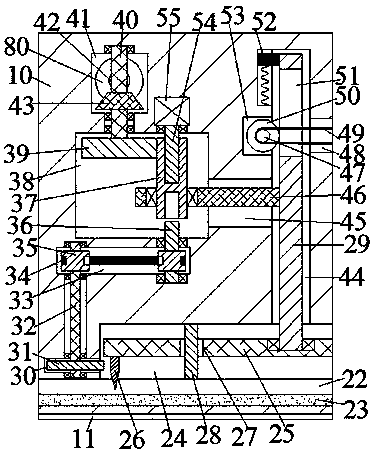

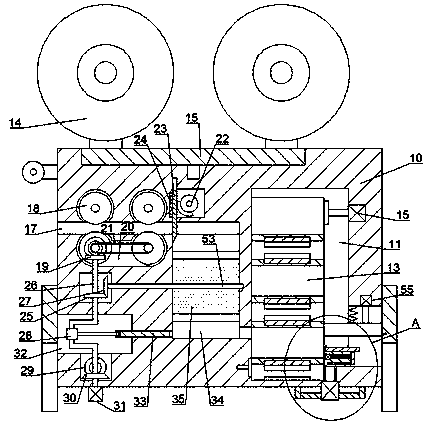

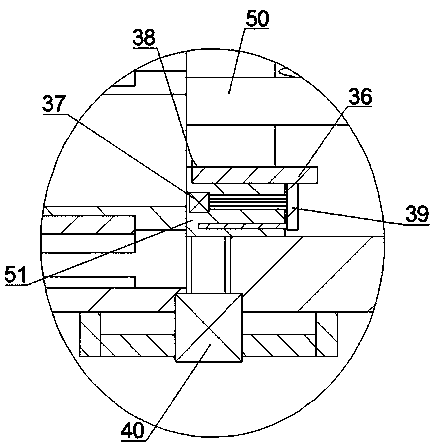

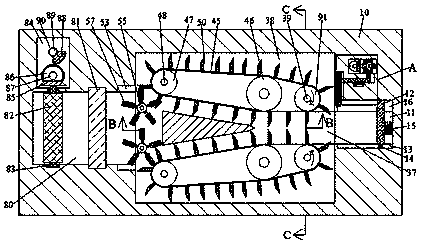

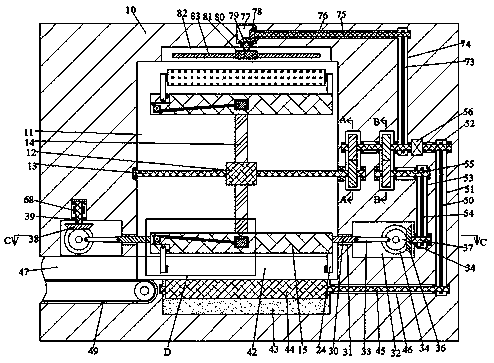

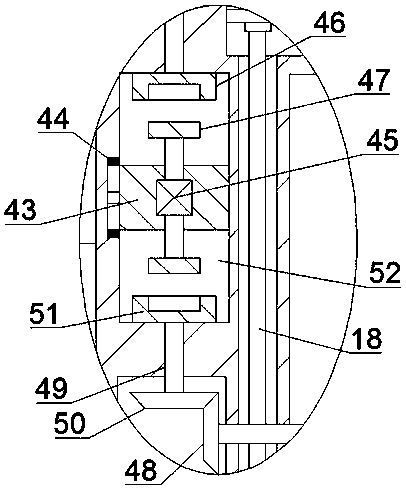

E-shaped inductance automatic processing device

ActiveCN109273252AAchieve a straightening effectImprove continuityInductances/transformers/magnets manufactureInductancePositioning system

The invention relates to an E-shaped inductance automatic processing device, comprising a frame; An adjusting mechanism fixedly arranged on the rack; A clamping mechanism comprising a turnover assembly fixedly arranged on the turnover assembly and provided with four groups of feeding assemblies in a circumferential array, a first positioning assembly fixedly arranged at the bottom of the feeding assembly and positioned at the front end of the feeding assembly, and a second positioning assembly fixedly arranged at the rear end of the feeding assembly; A smoothing mechanism fixedly arranged on the tightening assembly and cooperated with the second positioning assembly to drive; And a coil conveying mechanism, wherein the coil conveying mechanism comprises a wire pressing machine arranged atthe output end of the smoothing mechanism, an uplink assembly arranged at one side of the wire pressing machine and perpendicular to the output end of the smoothing mechanism, and a discharge assemblyarranged at the output end of the transmission assembly; The invention solves the technical problems that the wires are uneven in bending and different in shape when the wires are connected, and thewires still need to be manually straightened after the wires are connected.

Owner:阜阳汇中芯自动化技术有限公司

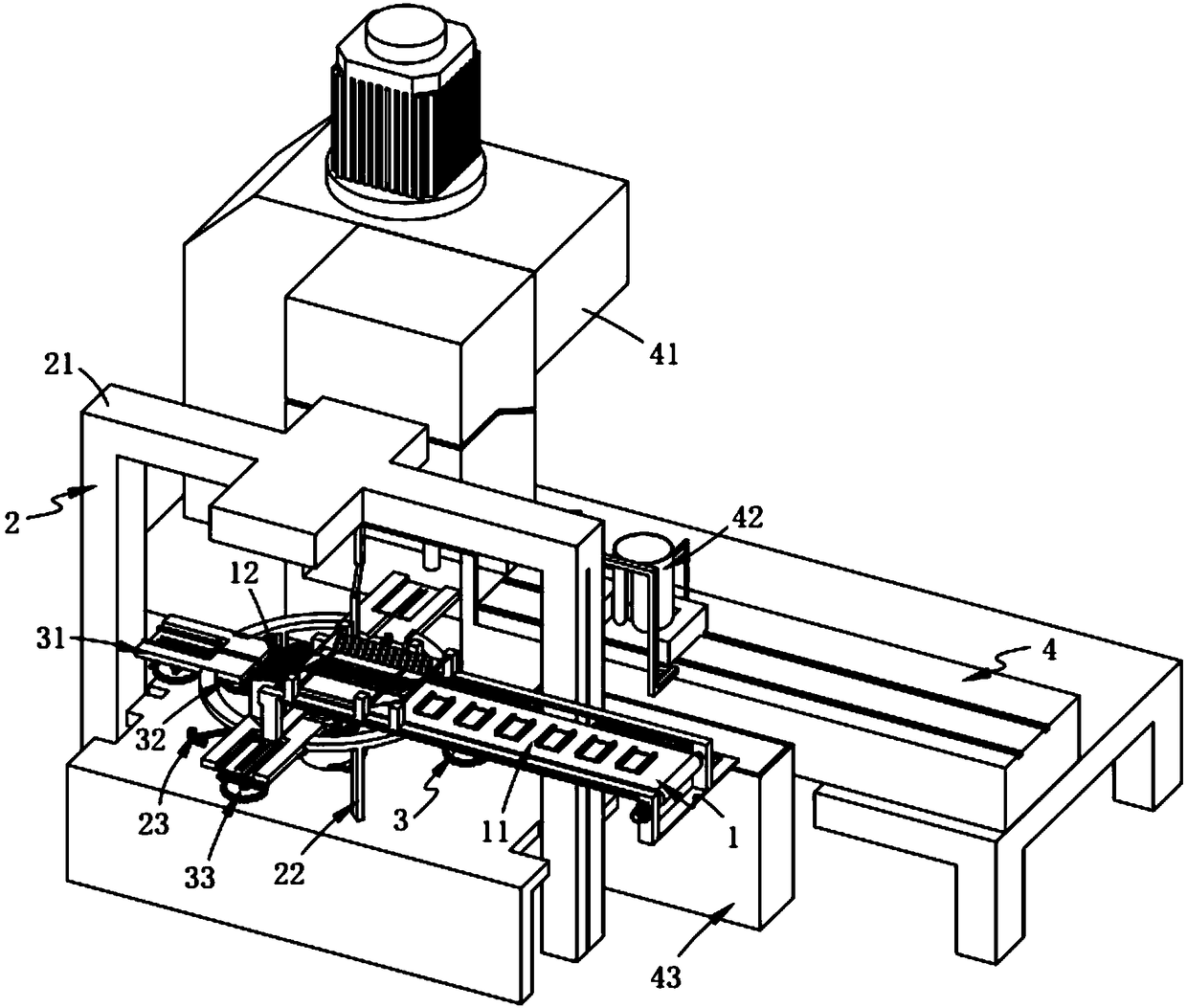

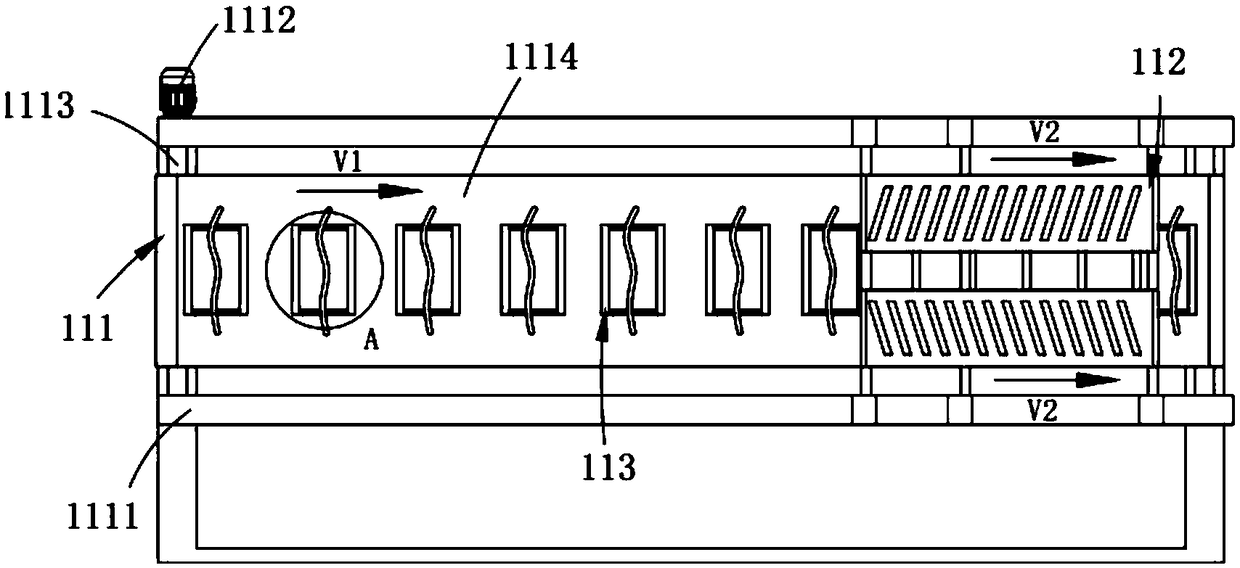

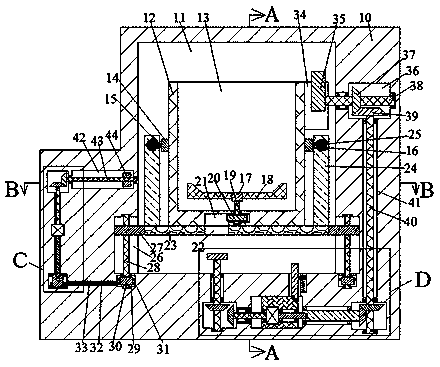

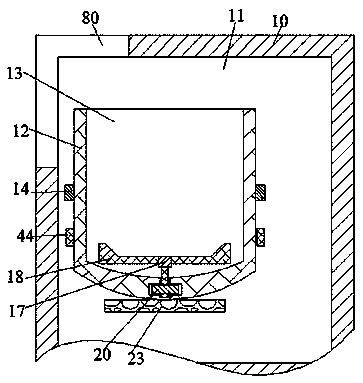

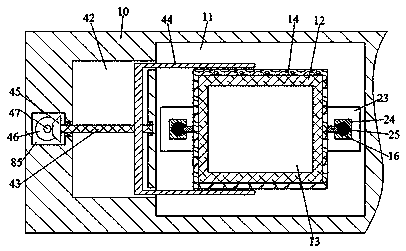

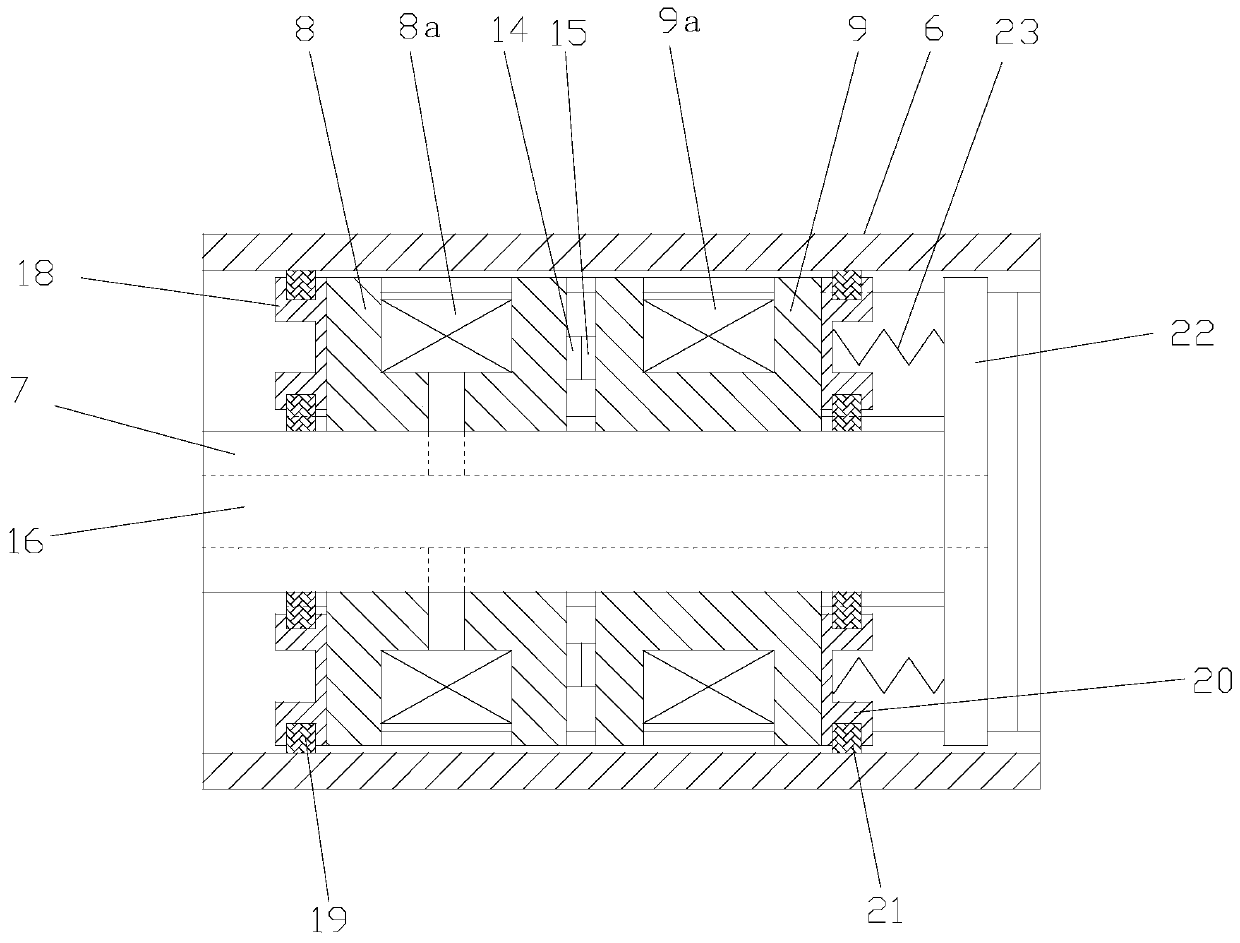

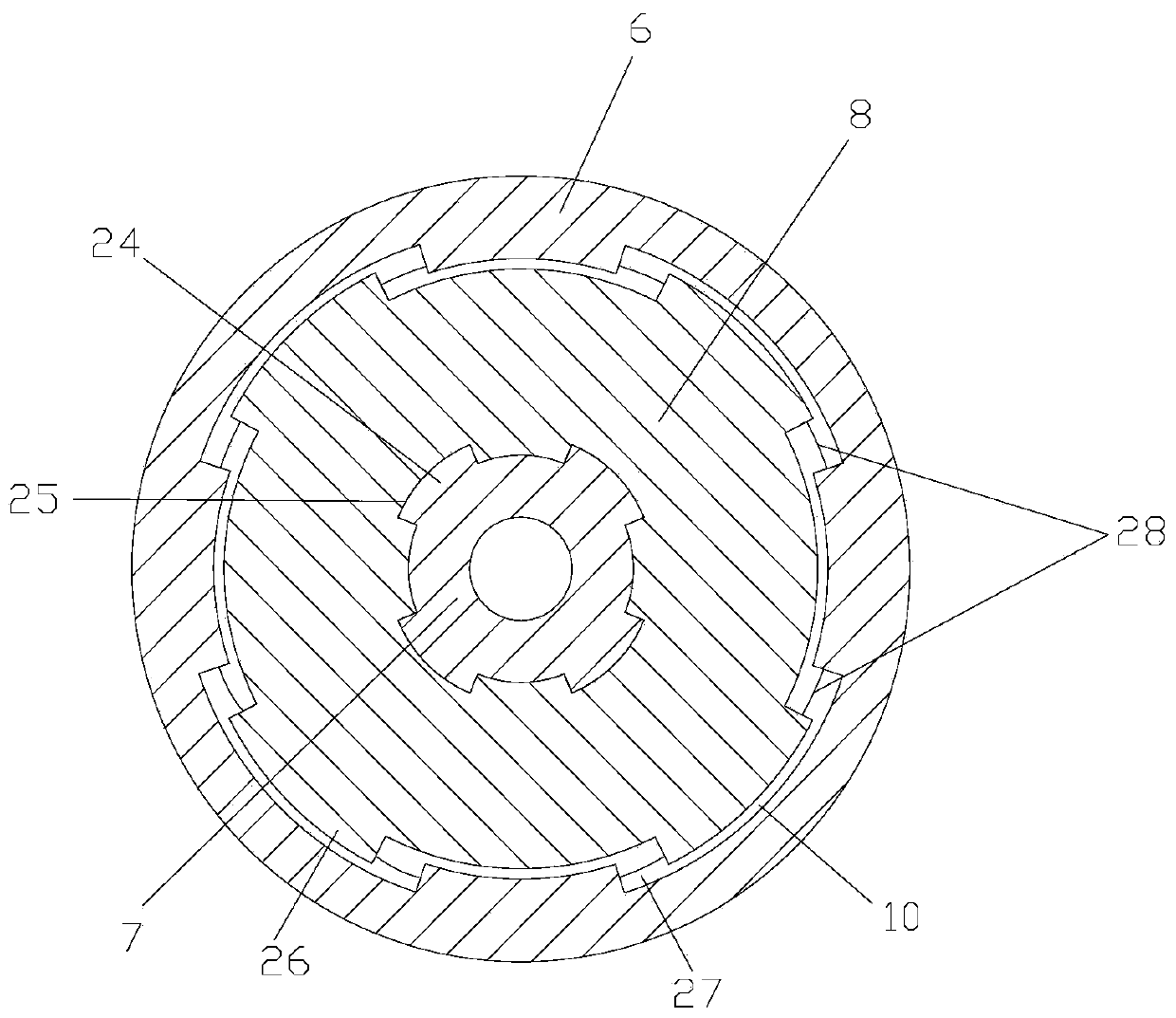

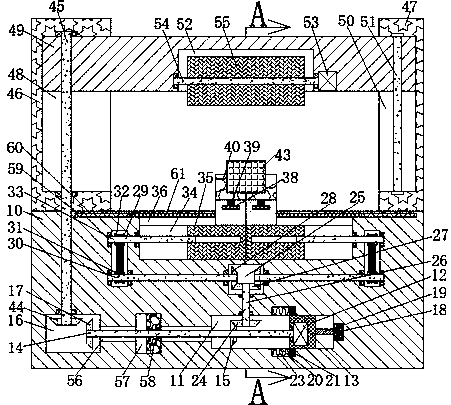

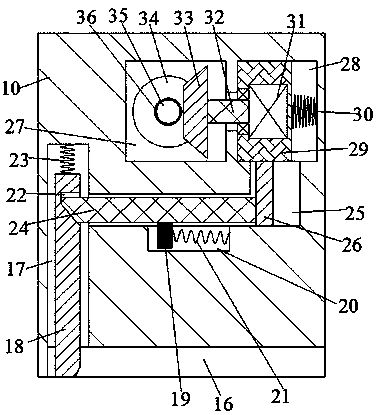

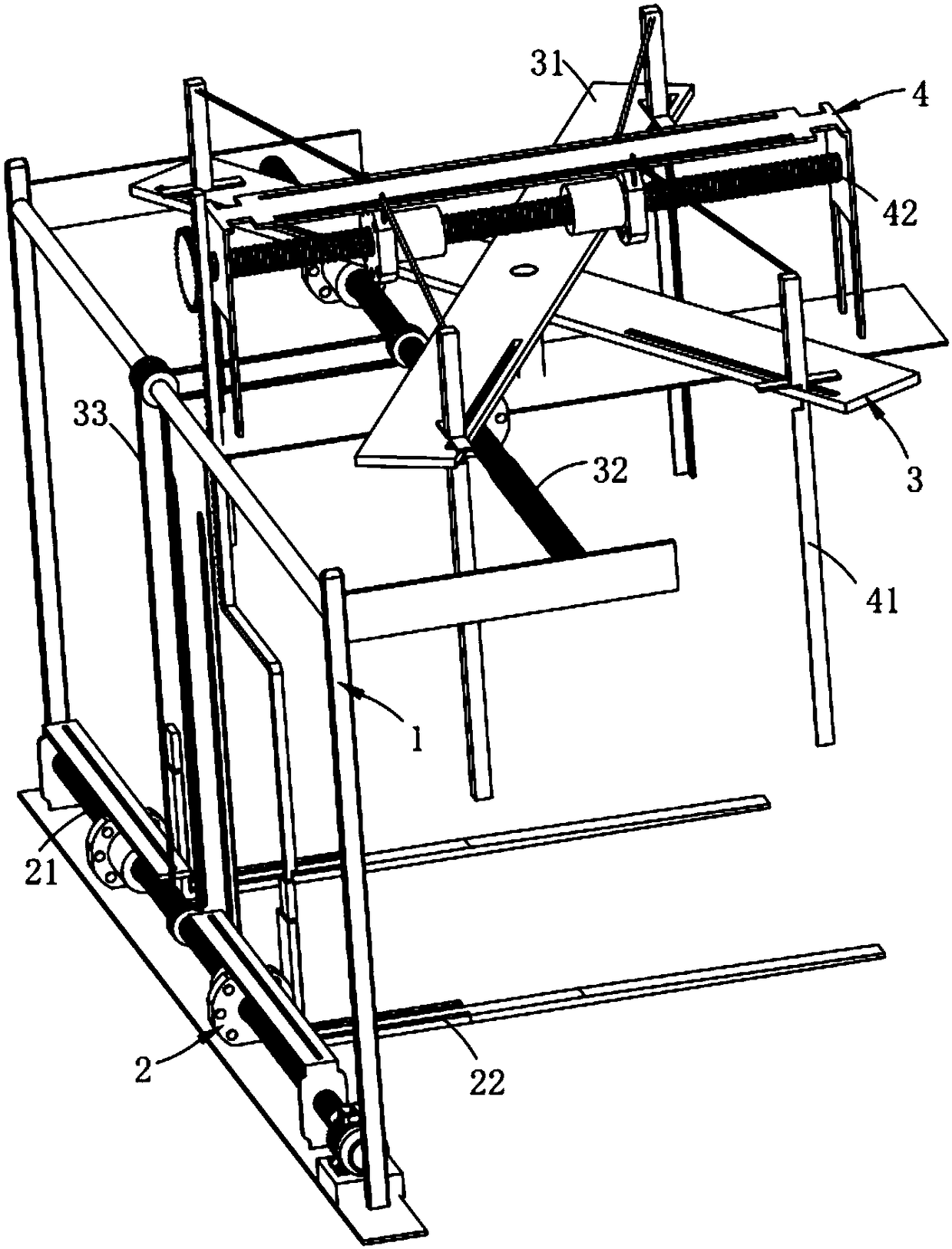

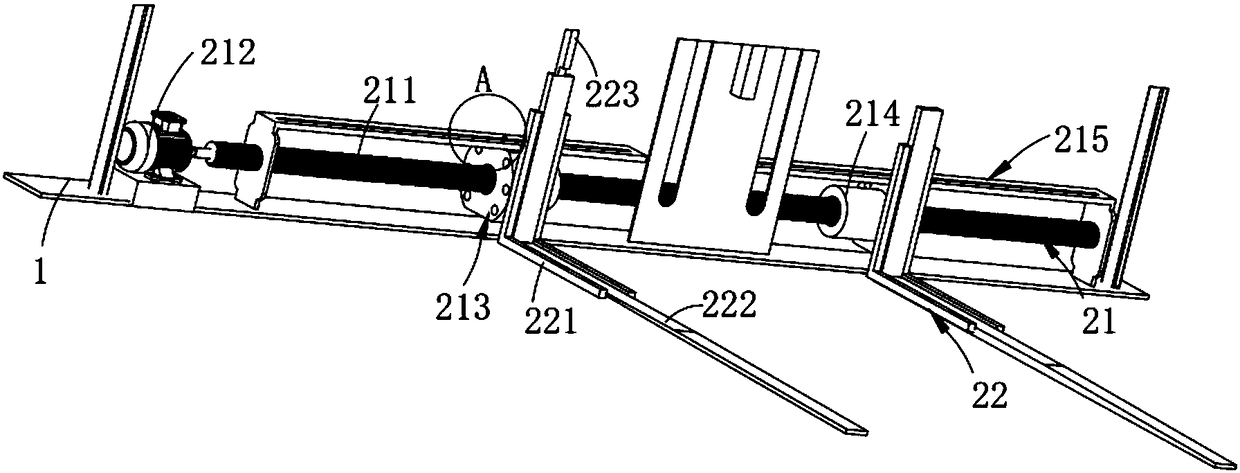

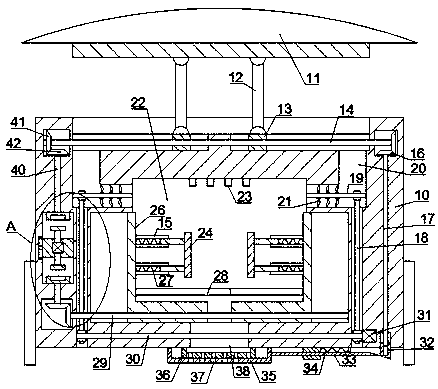

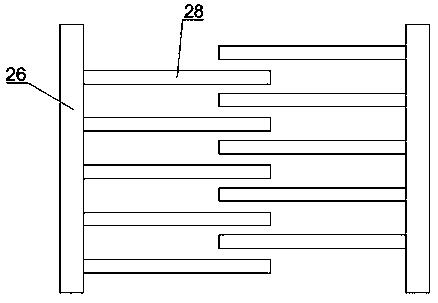

Electromagnetic clutch coil automatic assembly system for compressor

ActiveCN109360730AImprove product qualityIncrease productivityCoils manufacturePressure wireElectromagnetic clutch

The invention relates to an electromagnetic clutch coil automatic assembly system for a compressor. The system comprises a first level flattening mechanism, a turnover mechanism, a secondary level flattening mechanism and a wiring mechanism, and the first level flattening mechanism comprises a compressing straightening assembly and a wire outlet assembly at an output end of the compressing straightening assembly; the turnover mechanism comprises a frame for mounting the compressing straightening assembly, switching assemblies disposed on the frame and a driving mechanism mounted on the frame;the second level flattening mechanism circumferentially displaying on the plurality of groups of switching assemblies includes a receiving assembly mounted on the switching assemblies, a first bandingassembly arranged slidably below the receiving assembly and a second banding assembly located behind the first banding assembly, and the first banding assembly and the second banding assembly are both in cooperative drive with the drive mechanism; the wiring mechanism includes a pressure wire machine, a coil upper assembly and a reset assembly; the system solves the technical problem that a wireis twisted and pinched when the wire works, and a wire head cannot be accurately placed under the pressure wire machine every time under the automatic conveying.

Owner:赵娟

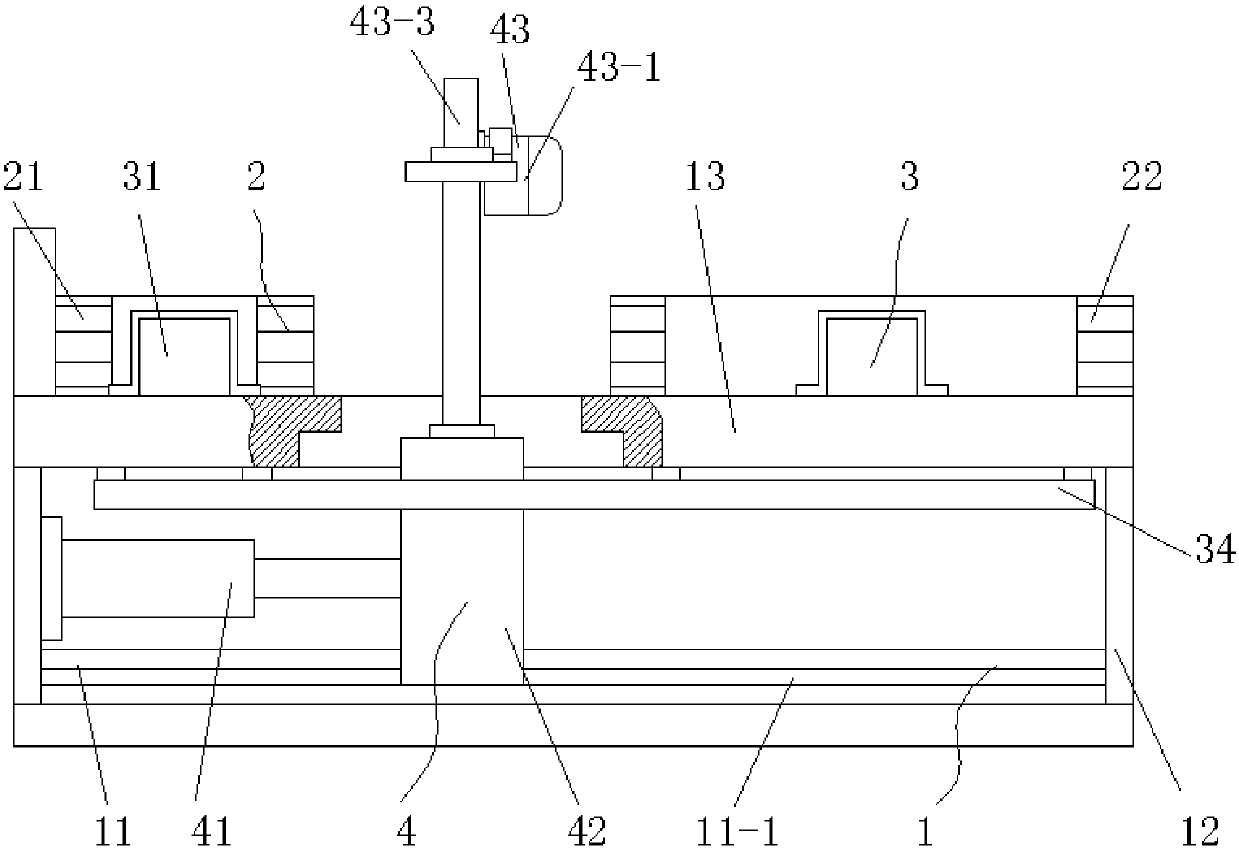

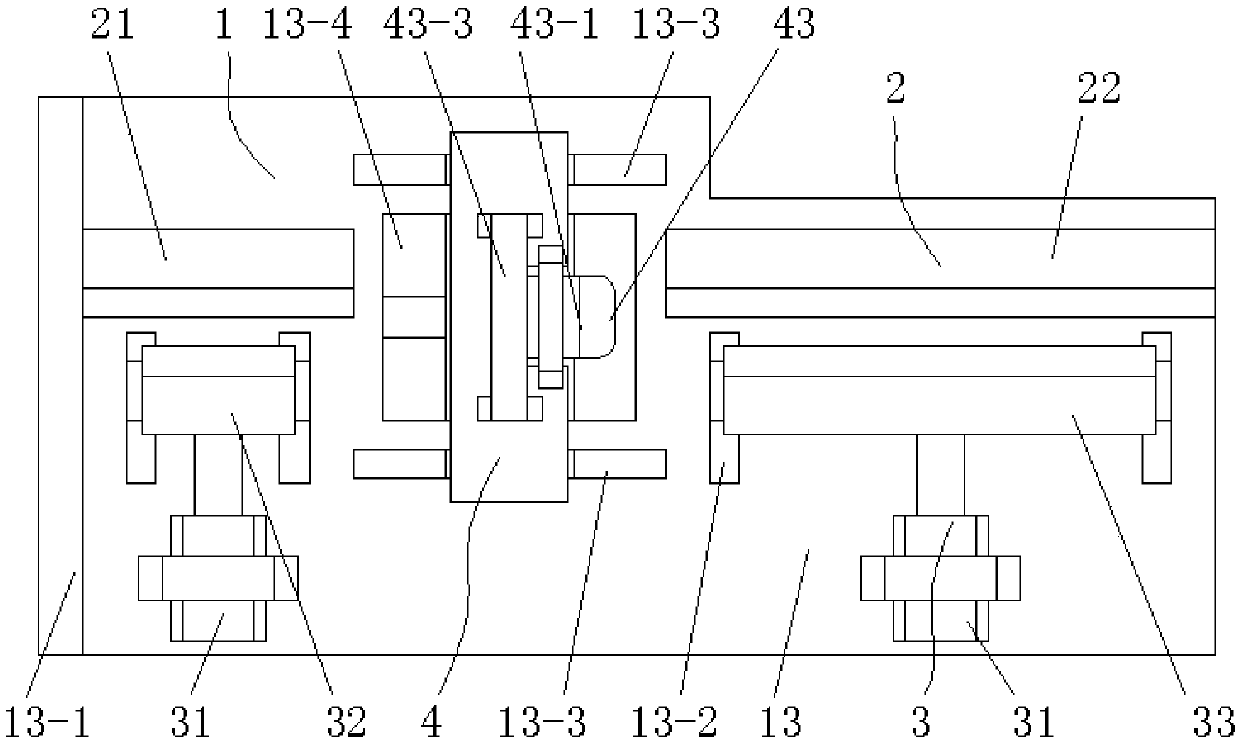

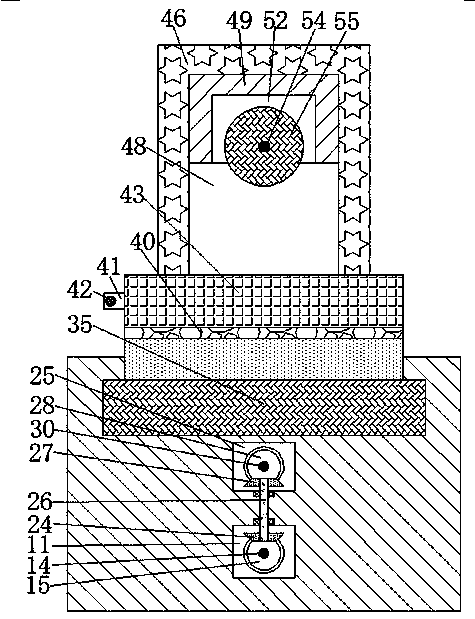

Fixed-distance automatic cutting device of metal corrugated pipe

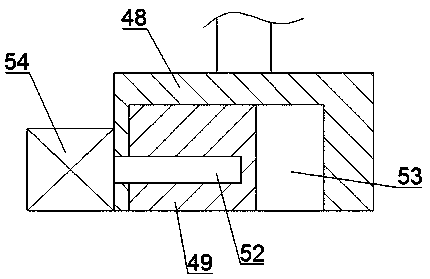

InactiveCN107900436ARealization of fixed-distance automatic cuttingEasy to placeWork clamping meansTube shearing machinesPush and pullPush pull

The invention discloses a fixed-distance automatic cutting device of a metal corrugated pipe, and relates to the technical field of metal corrugated pipe machining equipment. The fixed-distance automatic cutting device comprises a machine frame, a fixing clamping block, a movable clamping mechanism and an adjustable cutting mechanism. The machine frame comprises a bottom plate, two supporting plates and a cutting platform, wherein the fixing clamping block consists of a first fixing clamping block and a second fixing clamping block which are fixedly arranged on a cutting platform. The movableclamping mechanism comprises push-pull small air cylinders, a first movable clamping block, a second movable clamping block and a linkage rod. The adjustable cutting mechanism consists of a push-and-pull large air cylinder, a double-rod air cylinder and a cutting component. According to the fixed-distance automatic cutting device of the metal corrugated pipe, the fixed-distance automatic cutting of the metal corrugated pipe can be realized, the waste of pipe cutting is avoided, and meanwhile, the cutting efficiency is greatly improved.

Owner:MAANSHAN FEIDA BELLOWS MFG CO LTD

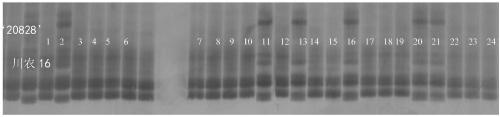

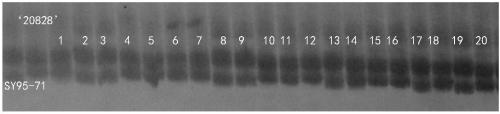

Wheat stripe rust-resistant gene QYr.sicau-1B-1 SSR molecular marker and application

InactiveCN109321671AConvenient Assisted BreedingHigh linkageMicrobiological testing/measurementDNA/RNA fragmentationBiotechnologyResistant genes

The invention provides a wheat stripe rust-resistant gene QYr.sicau-1B-1 SSR molecular marker and application. The invention provides a codominant molecular marker Xwmc156 which is located on the wheat 1B chromosome and linkaged with the wheat stripe rust-resistant gene. The molecular marker Xwmc156 is tightly linkaged with the stripe rust-resistant QTL QYr. Sicau-1B-1 on wheat 1B, and can be usedfor positioning the character of the wheat strip rust, accordingly the plants highly sensitive to the stripe rust are eliminated in the breeding process, and the breeding working efficiency is improved. The molecular marker can also be used for detecting the stripe rust-resistant QTL on the wheat 1B chromosome, rapidly screens out the plants with the locus, accordingly can conveniently conduct molecular assistant breeding of high stripe rust-resistant wheat, and has good application prospects.

Owner:SICHUAN AGRI UNIV

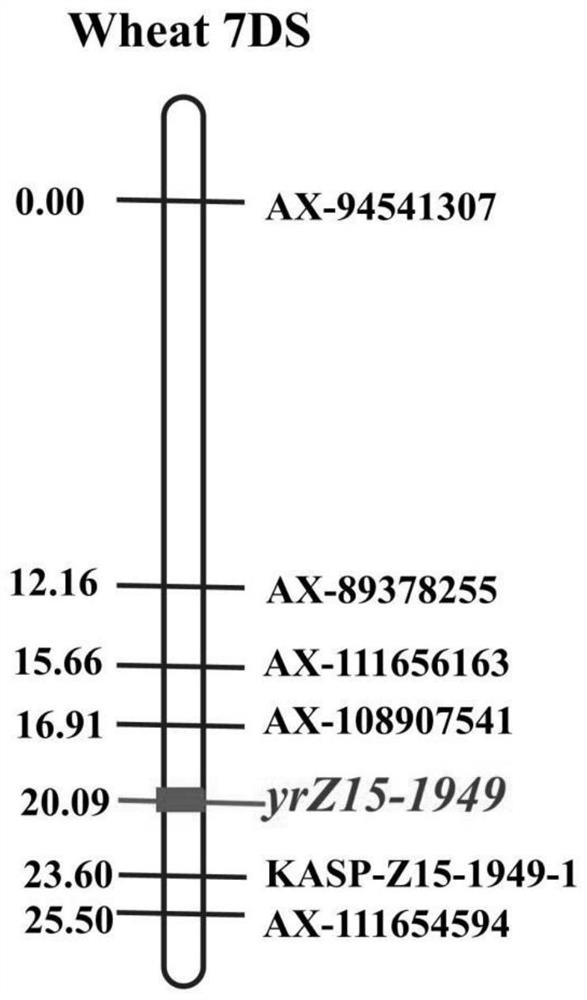

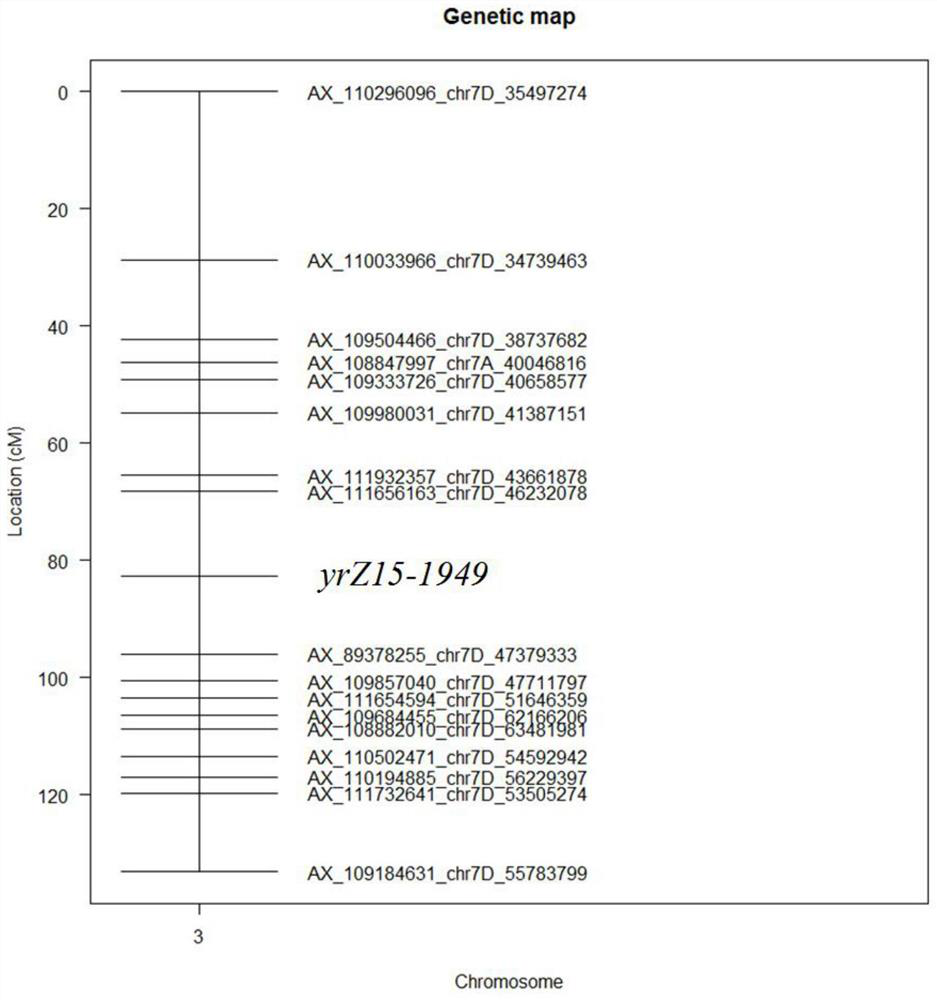

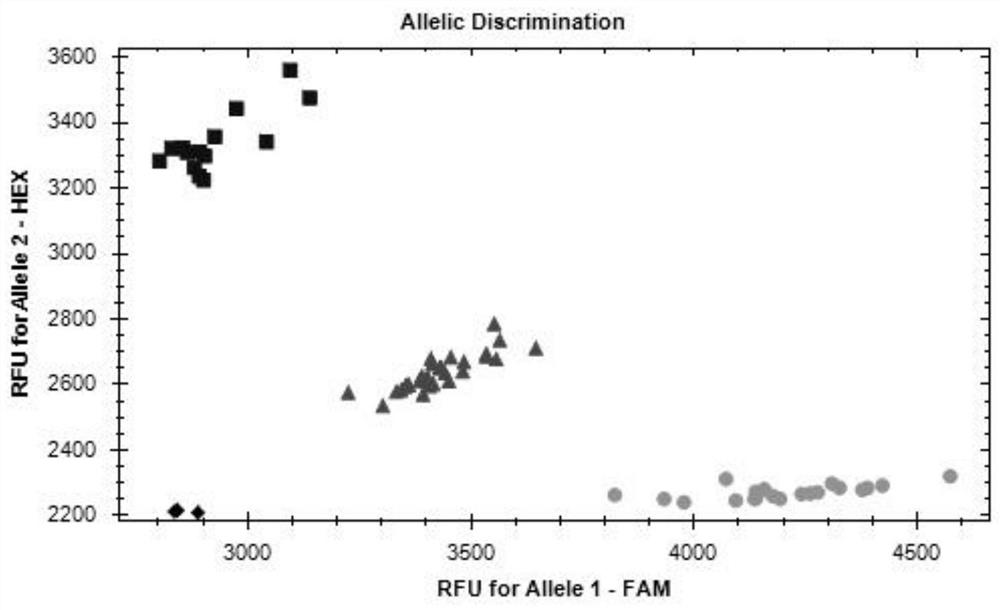

Wheat stripe rust resistance gene yrZ15-1949 as well as molecular marker and application thereof

ActiveCN112430606AAdding new sources of resistance to stripe rustIncreased stripe rust resistanceMicrobiological testing/measurementPlant peptidesMolecular biologyBiotechnology

The invention discloses a wheat stripe rust resistance gene yrZ15-1949 as well as a molecular marker and application thereof. The wheat stripe rust resistance gene yrZ15-1949 is located on a wheat 7Dchromosome short arm, and the physical position of the gene yrZ15-1949 in a RefSeqv1.0 genome version is 43.66 Mb to 46.51 Mb. The SNP site of the molecular marker is located in a yrZ15-1949 interval,the polymorphism is A / G, and the molecular marker can accurately track the wheat stripe rust resistance gene yrZ15-1949. The invention further discloses a primer group for identifying the wheat stripe rust resistance gene yrZ15-1949, the primer group provided by the invention can be used for rapidly screening out a wheat variety or strain with the wheat stripe rust resistance gene yrZ15-1949 forbreeding, and the breeding process of a wheat disease-resistant variety can be greatly accelerated.

Owner:SICHUAN AGRI UNIV

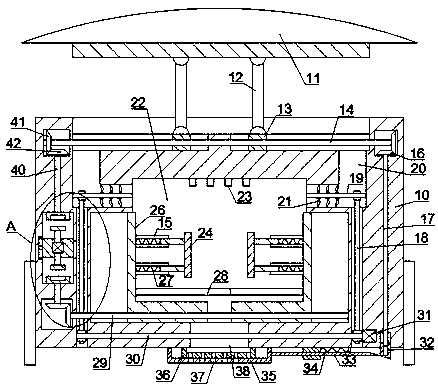

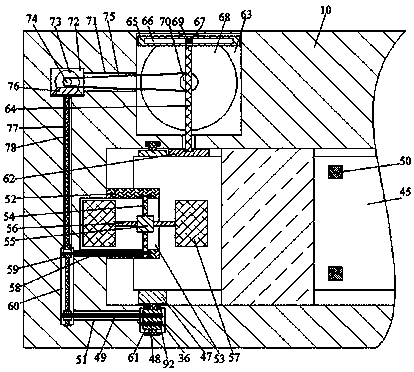

Furniture board automatic guide-in side seal device

ActiveCN110509393AStrong edge bandingImprove adhesionOther plywood/veneer working apparatusGrinding drivesEngineeringGrinding wheel

The invention discloses a furniture board automatic guide-in side seal device. The device comprises a machine body, four supporting columns are fixedly arranged on the lower end face of the machine body, a guide-in cavity is formed in the machine body, a guide-in device is arranged in the guide-in cavity, a clamping device is arranged on the upper side of the guide-in device, a board is clamped inthe clamping device, a grinding device is arranged on the left side of the guide-in cavity, the grinding device comprises a grinding wheel, and a wind power device is arranged on the rear side of thegrinding device. Through the effect of the guide-in device and the clamping device, the board can be driven to carry out conveying of side seal operation, the board is subjected to side grinding, chipping removal, side seal glue coating and side seal strip attaching in sequence, board side seal is finished, start and stop of the device avoid waste of the materials used by side seal through boardmoving control, and board side seal stability is achieved.

Owner:山东朝泰实业有限公司

Special installation box for electric switch control cabinet

ActiveCN110797777AAvoid shakingAffect normal workSubstation/switching arrangement cooling/ventilationEngineeringStructural engineering

Owner:湖北腾诚能源设备有限公司

Black root korean ginseng and its preparing method

InactiveCN1857704AHas a strong effectRegulatory effect on immune functionPlant ingredientsKorean ginsengMedicine

The present invention provides a black root Korean ginseng and its preparation process. The black root Korean ginseng has saponin content obviously higher than other red ginseng products. The preparation process of the black root Korean ginseng includes adding astragalus root 20%, root of straight ladybell 20%, acanthopanax bark 20%, ophiopogon root 17%, tuckahoe 16% and dry ginger 7% into solvent; heating and concentrating to obtain concentrated solution; soaking red ginseng in the concentrated solution, and repeated steaming and drying for nine times.

Owner:崔成釿

Special chemical equipment for papermaking

InactiveCN109289604ADeployment is convenient and simpleEvenly deployedRotary stirring mixersTransportation and packagingBiochemical engineeringPapermaking

The invention discloses special chemical equipment for papermaking. The equipment comprises a machine body, inside which a cavity is arranged. The rear side of the cavity is communicated with the outside space and equipped with a trough. A preparation tank having arc-shaped bottom is arranged in the cavity. An abutting plate is fixedly arranged at the upper side of the right end face of the preparation tank. The lower side of the abutting plate is fixed with an annular fixing ring at the outer periphery of the preparation tank. A preparation cavity with the opening facing upwards is arranged inside the preparation tank. A supporting block is arranged inside the preparation cavity. The equipment of the invention has a simple structure and is convenient to operate. The preparation tank is raised through a lifting device to facilitate discharging and reclaiming. With the arrangement of a cam for extrusion and rotation of the preparation tank, the preparation tank is inclined, and the feeding and reclaiming are convenient and the operation is simple. In addition, through rotation of a stirring plate, raw materials are uniformly blended. With the arraignment of a U-shaped rod, stabilityof the preparation tank during the stirring and rotating process is ensured. The equipment has a compact structure, has high linkage, and is energy-saving, environmentally friendly and highly-efficient.

Owner:林焱

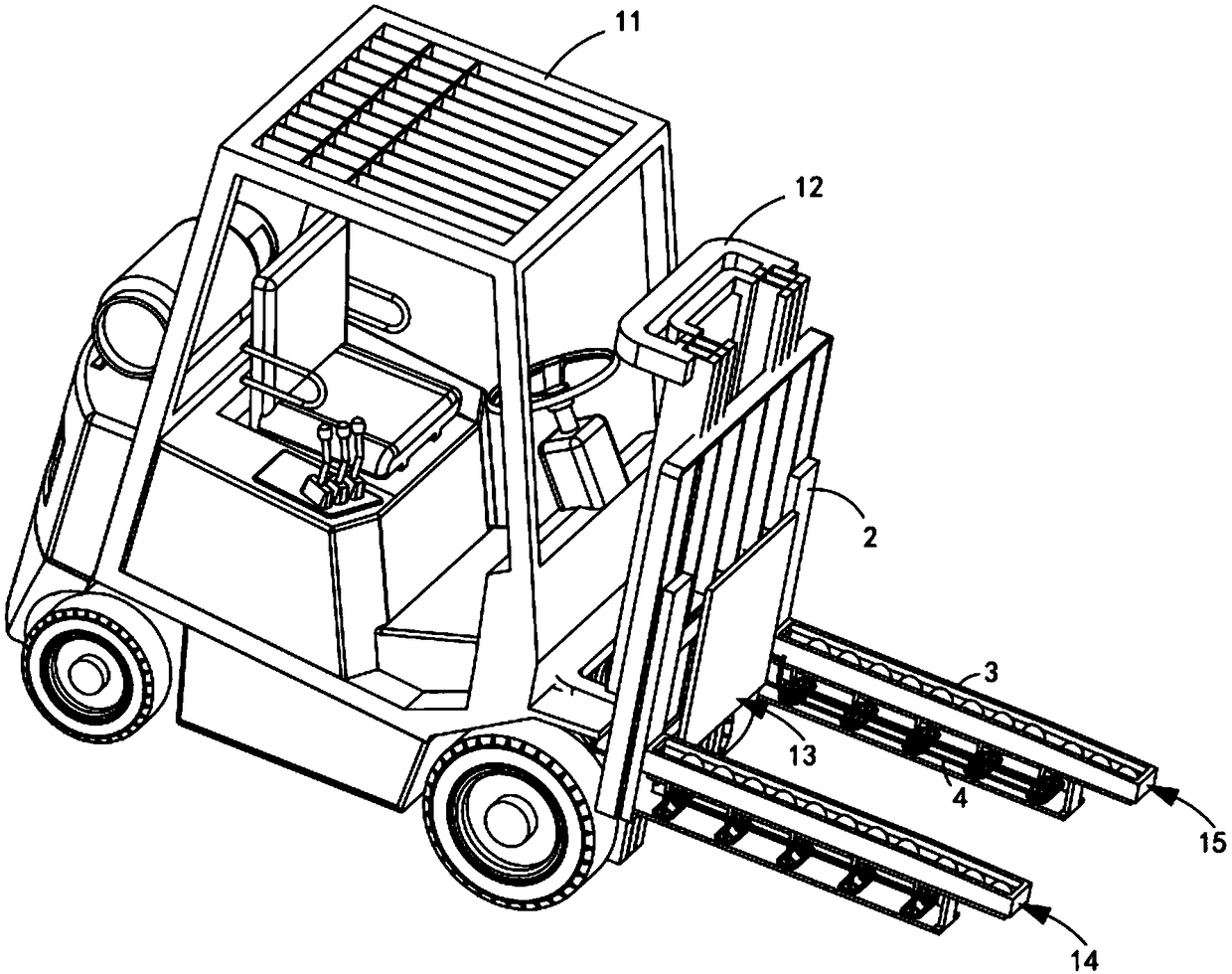

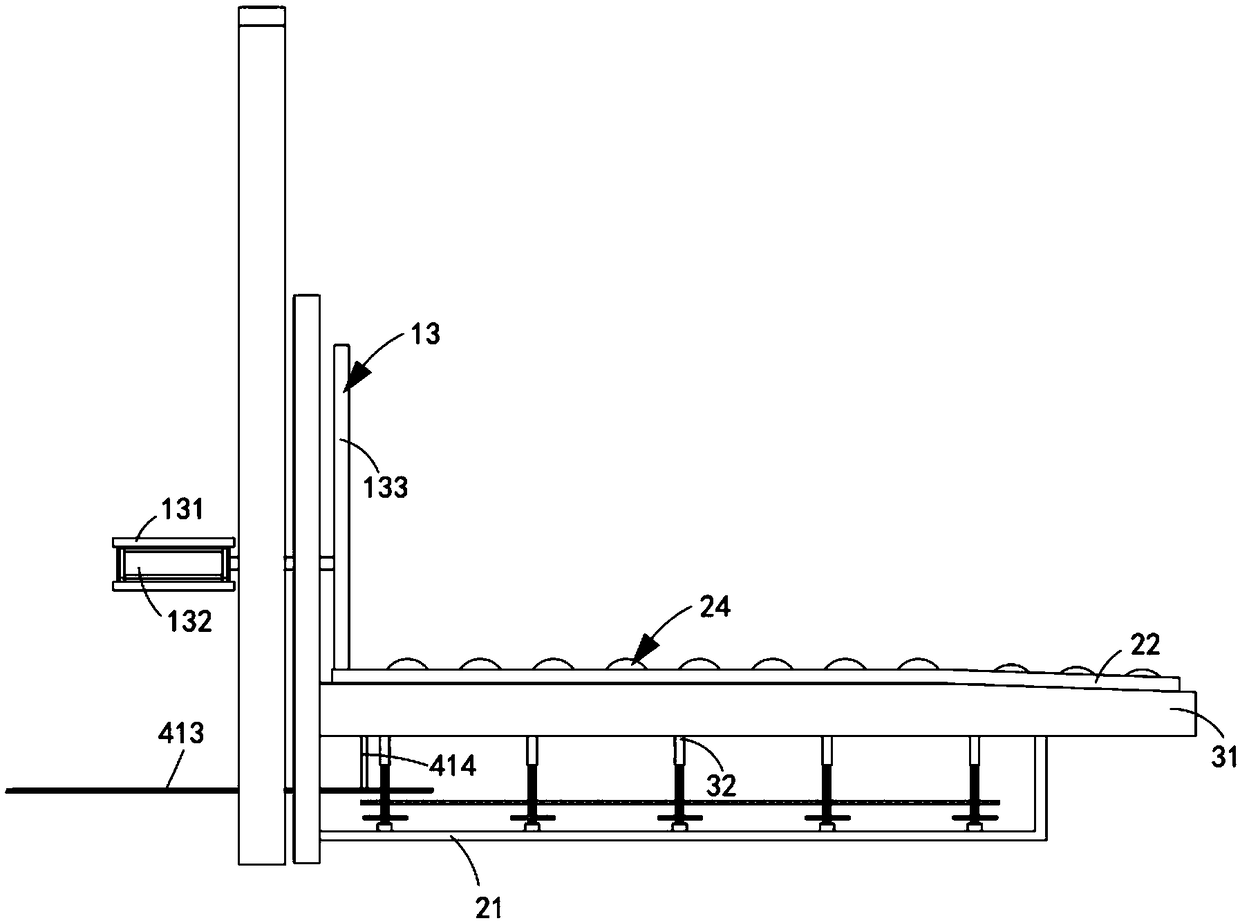

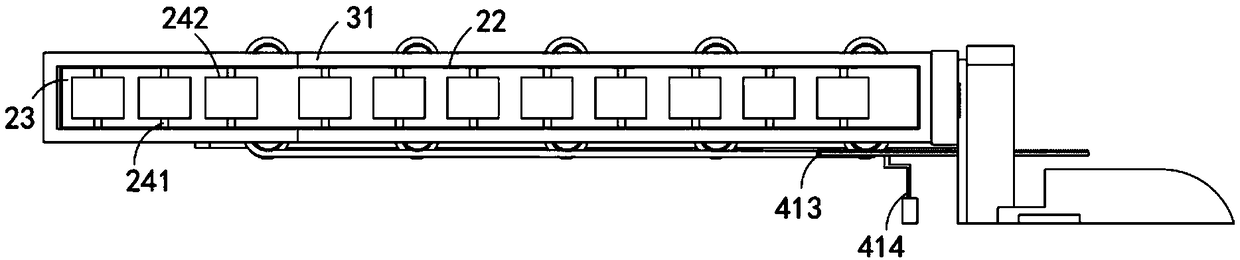

Forward movement type automatic material pushing forklift

ActiveCN108689338AAccurate placementSo as not to damageLifting devicesMechanical engineeringEngineering

Owner:ZHEJIANG SHANGJIA MACHINERY

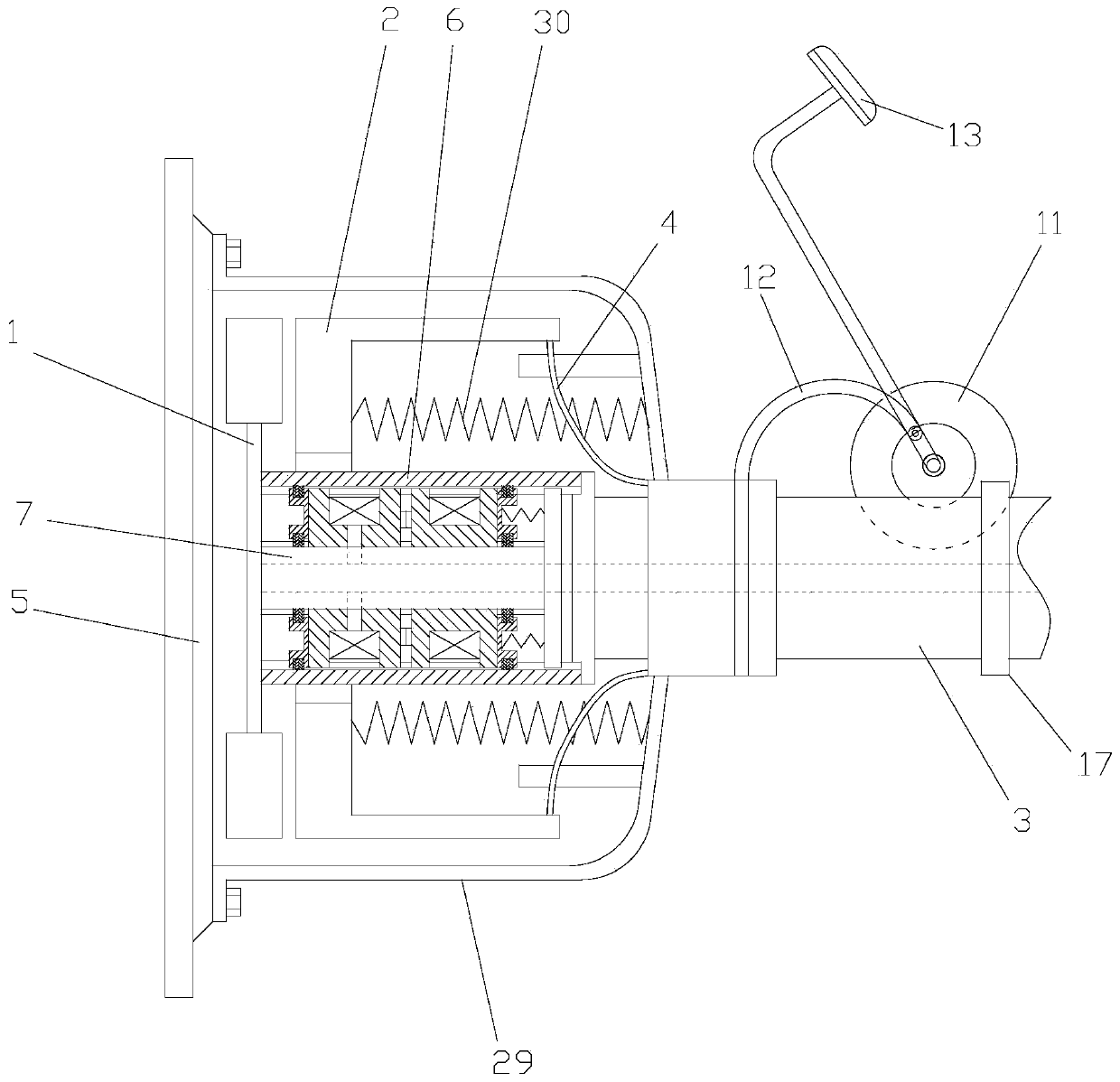

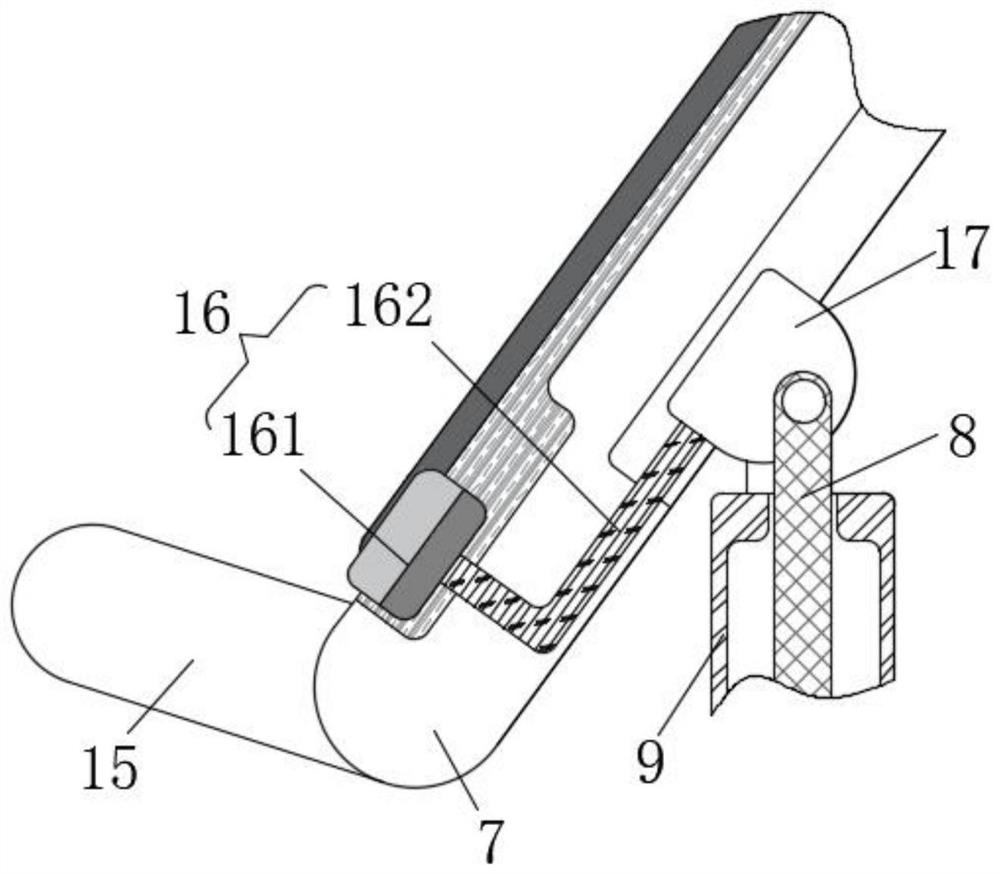

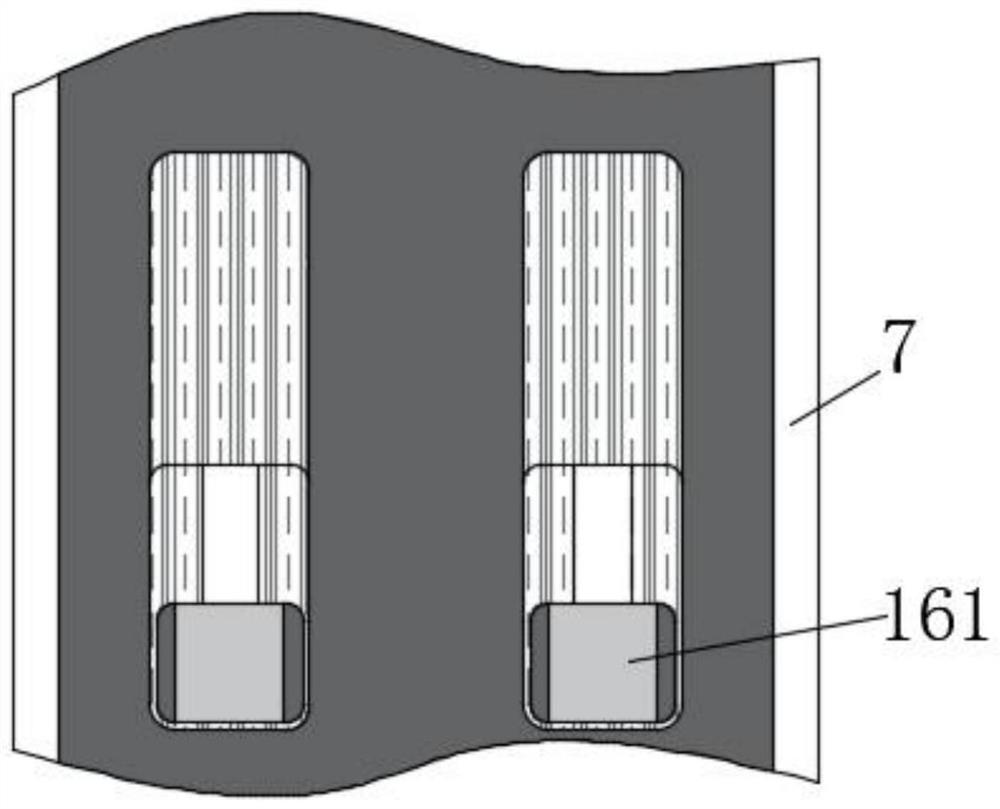

Controllable automobile clutch based on magnetorheology

PendingCN109737153AAdjustable binding forceReduce operator fatigueNon-rotating vibration suppressionElectrically actuated clutchesEngineeringDrive motor

The invention discloses a controllable automobile clutch based on magnetorheology. The controllable automobile clutch comprises a driven plate, a pressure plate, a transmission input shaft, a diaphragm spring connected with the pressure plate and a pushing device for pushing the diaphragm spring; the driven disk is in transmission connection with the transmission input shaft through a magnetorheological damper; the magnetorheological damper comprises a sleeve, a rotating shaft, a coil drum I and a coil drum II; the pushing device comprises a driving motor and a transmission mechanism for transmitting driving force of the driving motor to a diaphragm spring, a motor switch of the driving motor is arranged on the coil drum 1 and the coil drum II, and when the coil drum II moves towards the coil drum I to a set value, the motor switch is started. The controllable automobile clutch can adjust the magnitude of the magnetic field by changing the magnitude of the current, damping parameters are changed, the vibration damping control is achieved, and the control fatigue of a driver can be reduced.

Owner:CHONGQING VOCATIONAL INST OF ENG

Package cover sealing equipment

ActiveCN109823998AReduce consumptionSave human effortFlanged caps applicationHollow articlesMechanical engineeringEnergy consumption

The invention discloses package cover sealing equipment. The package cover sealing equipment comprises a cover sealing machine; a conveying cavity opened to the left side is formed in the cover sealing machine; a cover production device is arranged on the upper side of the conveying cavity, and is used for directly producing sealing covers of packages; a cover sealing cavity communicates to the right side of the conveying cavity; and a cover sealing device is arranged on the upper side of the cover sealing cavity. The package cover sealing equipment is compact in structure and convenient to operate, controls rotation of a conveying belt and independent work of the cover production device through a power device, is high in linkage performance, and saves the electric energy consumption; secondly, when the cover sealing device works, the power device switches the power through a linkage device to drive the cover production device to work, so that the cover production and the cover sealingare performed at the same time, and independent cover production equipment, a package cover transportation device and the labor and machinery energy consumption in the transportation process are saved; and through continuous shearing of package covers and sealing molding in the cover sealing procedure, the sealing process is simple and efficient.

Owner:SHANDONG HUANQIU TINPLATE CAN MAKING

High-thermal-conductivity aluminum alloy

ActiveCN110091243AIngenious and reasonable structureEasy to operateGrinding carriagesPolishing machinesDrive shaftAlloy

The invention discloses a high-thermal-conductivity aluminum alloy. The high-thermal-conductivity aluminum alloy comprises a workbench and a power cavity arranged in the workbench, a sliding block isconnected in the power cavity in a sliding fit mode, a limiting device is connected to the sliding block, a moving motor is fixedly arranged in the sliding block, a transmission shaft extending leftwards is fixedly arranged on an output shaft of the moving motor, a first steering bevel gear is fixedly arranged on the transmission shaft, a clamping device is connected with the upper end of the first steering bevel gear in a meshed mode, a fixing mechanism is fixedly arranged on the clamping device, a gear connecting cavity is formed in the left end wall of the power cavity, and a second steering bevel gear is fixedly arranged at the left end of the transmission shaft. The automatic polishing equipment is more reasonable and ingenious in integral structure, the operation is convenient, the efficiency of machining the high-heat-conduction aluminum alloy is high, the function that a lifting and polishing device clamps a fixing mechanism can be realized by a single driving motor, the use safety is high, and the high-thermal-conductivity aluminum alloy has high use and popularization value.

Owner:江苏凯乐金属科技有限公司

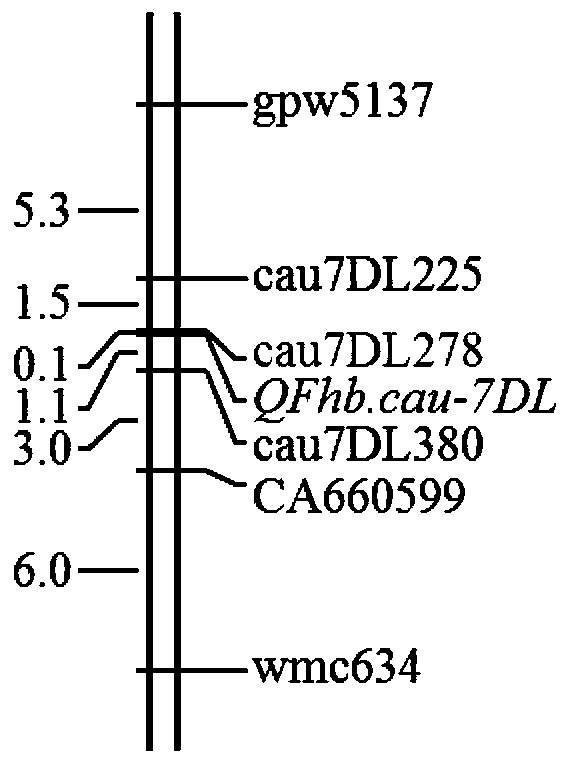

DNA marker closely linked to wheat 7DL chromosome scab-resistant gene and application thereof

ActiveCN110878300AHigh linkageImprove breeding efficiencyMicrobiological testing/measurementICT adaptationBiotechnologyResistant genes

The invention discloses a DNA marker closely linked to a wheat 7DL chromosome scab-resistant gene and an application thereof. The invention provides a molecular marker cau7DL278 located on a 7DL chromosome and linked to wheat scab resistance. The marker is a marker closely linked to scab resistance QTL QFhb. cau-7DL on the wheat 7DL chromosome, and is a codominant marker with high linkage degree (genetic distance is 0.1 cM). The molecular marker provided by the invention has the characteristics of rapidity, accuracy and high efficiency, and can be used to detect the scab resistance QTL QFhb. cau-7DL on the wheat 7DL chromosome and rapidly and accurately screen plants with the locus, thus improving breeding efficiency, laying a theoretical foundation for breeding wheat varieties with high scab resistance and providing molecular marker-assisted selection methods.

Owner:CHINA AGRI UNIV

Conductive wire insulation outer layer peeling and cutting device

InactiveCN110943356AHigh linkageAvoid high costLine/current collector detailsElectrically conductiveCircular cavity

The invention discloses stripping and cutting equipment for an insulating outer layer of a conductive wire. Main machine body, a circular cavity is formed in the main machine body; a circular cavity is rotationally formed in the circular cavity; grooves which are uniformly distributed are formed in the periphery of the cylinder; a feeding cavity is formed in the left side of the circular cavity; the upper side and the lower side of the feeding cavity are each provided with two sets of rolling wheels. The device can work through the power motor; the rolling wheel drives the wire to enter the cylinder; the motor drives the cylinder to rotate and drives the cutter to move up and down to cut off the wire, the whole process is extremely high in linkage, the problems of high cost and large matching error caused by driving of a plurality of motors are avoided. Meanwhile, after the wire is cut off, the insulating outer layer of the wire can be peeled off through sliding of the sliding plate, and multiple purposes of one machine are achieved.

Owner:东阳宗添电子科技有限公司

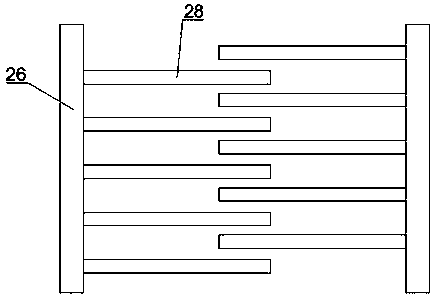

Straw bag knitting machine

InactiveCN108908576AImprove distributionImprove uniformityCane mechanical workingAutomationLinkage concept

The invention discloses a straw bag knitting machine. The machine comprises a machine body, a material cavity which is provided with a forward opening and used for placing straw or rice straw is formed in the machine body, a push plate is arranged in the material cavity in a sliding manner, the right end face of the push plate is fixedly provided with a telescopic spring with the right end fixedlyconnected with the right end wall of the material cavity, a guide sliding groove with a downward opening is formed in the lower side of the material cavity in a communication manner, the lower end face of the push plate is fixedly provided with a guide sliding block with the lower end extending into the guide sliding groove, the upper side of the material cavity is provided with a push groove with a downward opening in a communication manner, the upper end of the push plate extends into the push groove, a sudden stop safety device is arranged on the upper side of the push groove, and a conveying cavity is formed in the left side of the material cavity in a communication manner. The knitting machine is high in whole device linkage, energy-saving, environment-friendly, high in automation degree, and capable of reducing manual participation and manufacturing cost, and through a material lacking sudden stop device, straw bags are complete, well-balanced and flat.

Owner:何纪全

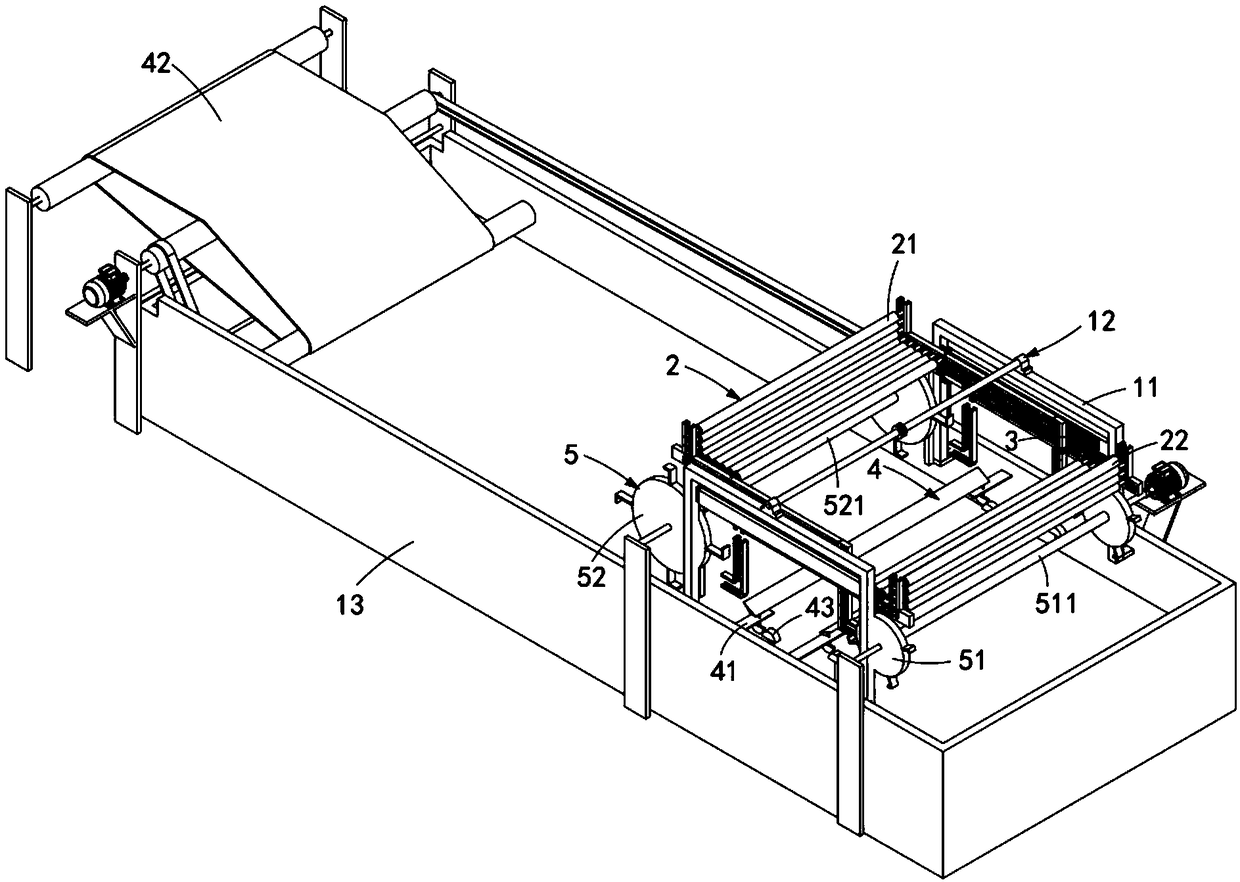

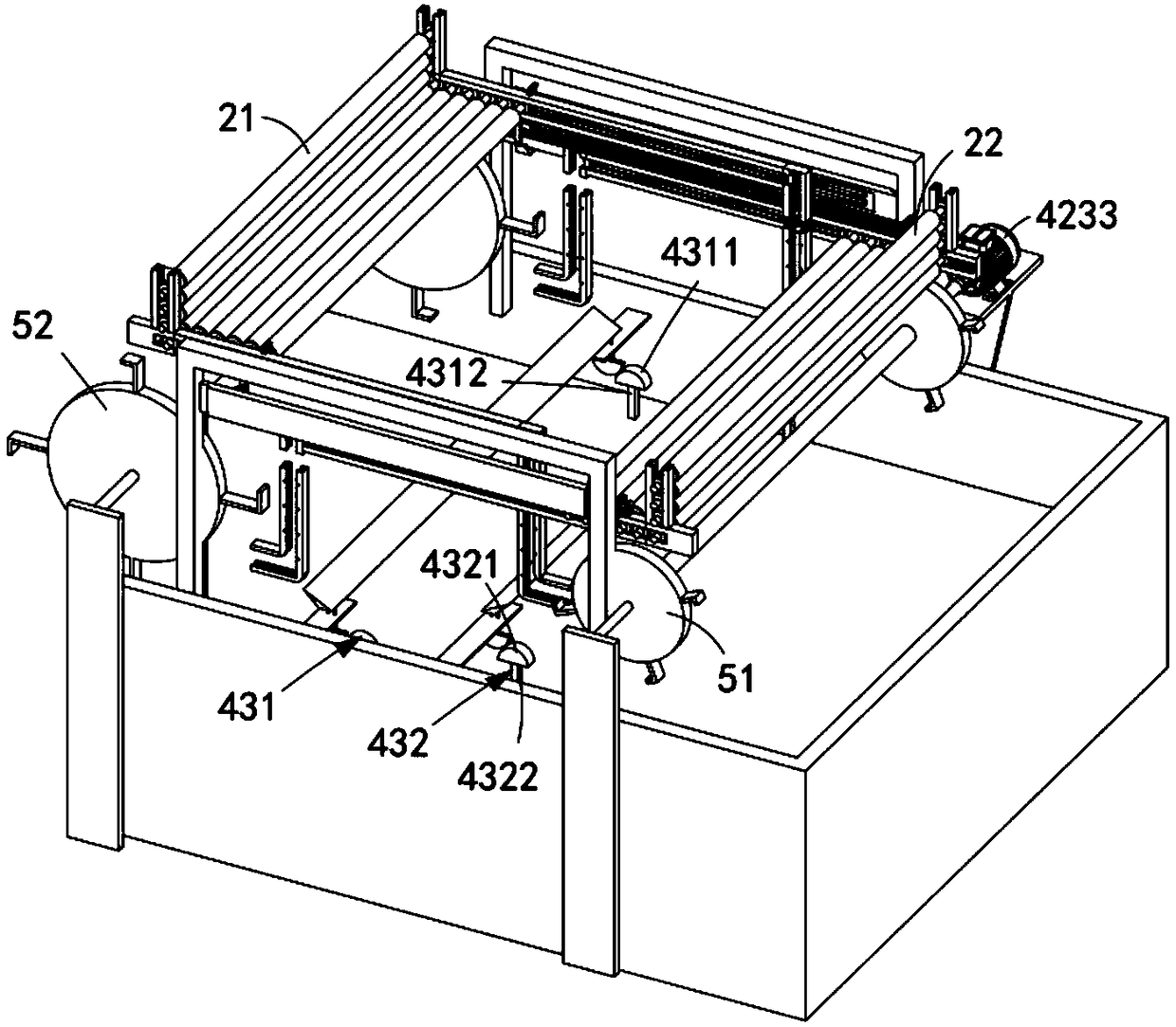

Bean vermicelli cooking device with slitting function

ActiveCN109176624AHigh linkageHigh degree of automationMetal working apparatusFood scienceEngineeringMechanical engineering

The invention relates to a bean vermicelli cooking device with a slitting function. The device comprises a bean starch sheet conveying belt which is erected on the top of a rack, a boiling tank is arranged on the bottom of the bean starch sheet conveying belt, the rack is arranged in the boiling tank, and the rack comprises a material supporting mechanism, driving mechanisms, a shearing mechanismand circular mechanisms. The material supporting mechanism is fixedly arranged below the bean starch sheet conveying belt and arranged on the rack, the material supporting mechanism is used for supporting the bean starch sheet conveying belt to vertically output bean starch sheets and enabling the bean starch sheets to be output in an S shape, and the material supporting mechanism comprises a first paving assembly and a second paving assembly. The driving mechanisms are symmetrically arranged below the bean starch sheet conveying belt and are arranged between the first paving assembly and thesecond paving assembly; the shearing mechanism is arranged below the driving mechanisms and comprises a sheet forming assembly, a conveying-out assembly and a control assembly; and the circular mechanisms are located on the two sides of the shearing assembly, are rotatably arranged on the rack and each comprise a first returning assembly and a second returning assembly. The device solves the technical problems that the shearing structure is complex, and after shearing is finished, the bean starch sheets cannot be transmitted out in time.

Owner:赵长春

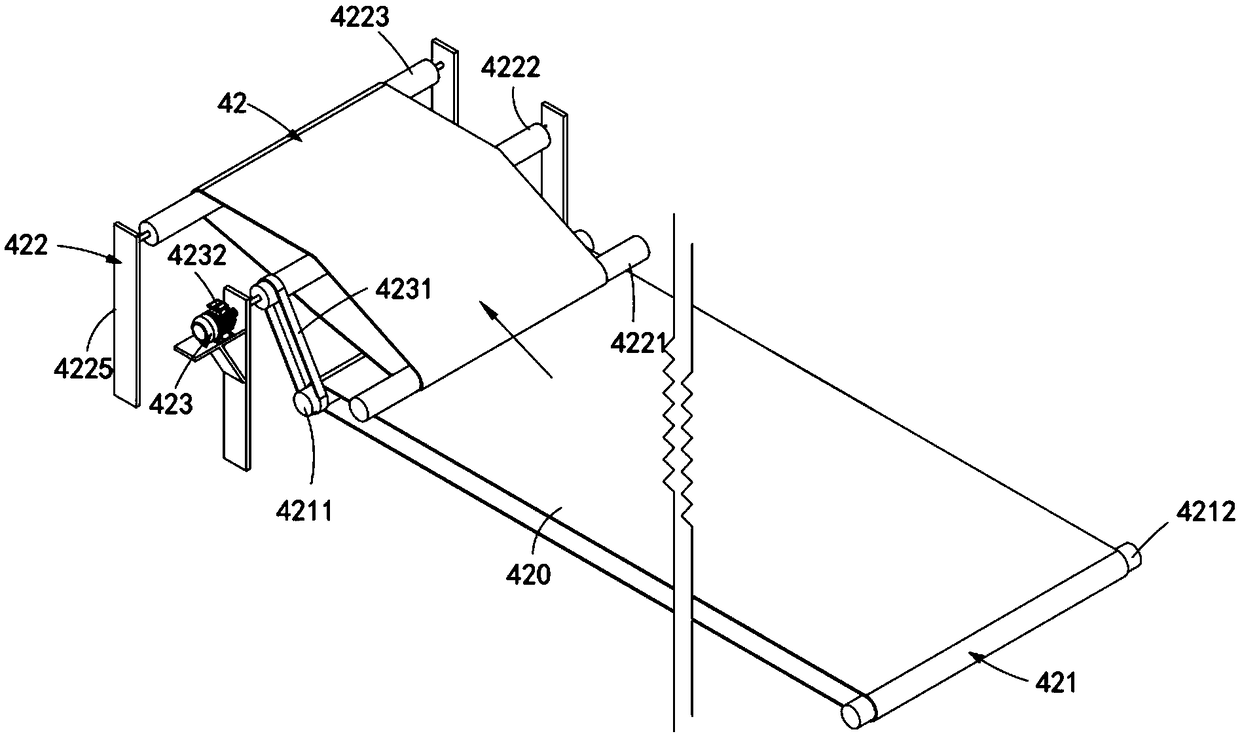

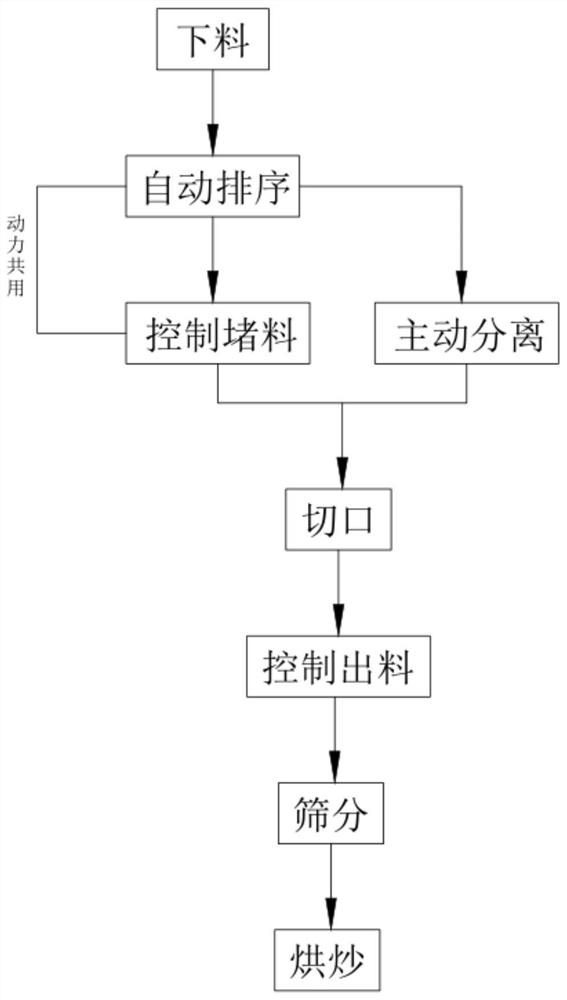

Processing technology of stir-fried pumpkin seeds convenient to shell

The present invention relates to a processing technology of stir-fried pumpkin seeds convenient to shell. The processing technology comprises the following steps: step one, feeding; step two, automatic sequencing; step three, controlling material blocking; step four, active separation, wherein in synchronization with the step three, a material blocking assembly drives a transmission assembly to synchronously transmit, the transmission transmission assembly drives a supporting rod to move, and inserting assemblies move towards gaps between two adjacent pumpkin seeds and realize separation of the integrally bonded pumpkin seeds in the moving process; step five, cutting, wherein a translation process of the inserting assemblies drives an opening mechanism to synchronously move to complete anautomatic cutting operation of middle parts of the pumpkin seeds; step six, discharging controlling; step seven, screening; and step eight, baking and frying. The processing technology solves technical problems that partial pumpkin seeds are adhered together under adhesion of the pulp and not separated thoroughly due to incomplete cleaning, and the targeted single cutting operation of the pumpkinseeds cannot be realized during the cutting operation.

Owner:阜阳运筹生产力促进中心有限公司

Novel wood protective agent and application method thereof

InactiveCN109203153AProtection processing efficiency improvedReduce consumptionWood treatment detailsCoating impregnationThrough transmissionEngineering

The invention discloses a novel wood protective agent and an application method thereof. A device adopted by the method comprises a machine body. A rotating cavity is arranged in the machine body. A rotating wheel is arranged in the rotating cavity. A rotating shaft with the left end rotationally connected with the left end wall of the rotating cavity is fixedly arranged at the axis of the rotating wheel. The right end of the rotating shaft stretches into a transmission cavity and is fixedly provided with a first gear. The upper end face of the first gear is in engaged connection with a quarter of first irregular teeth. A first rotating shaft with the left end rotationally connected with the left end wall of the first transmission cavity is fixedly arranged at the axis of the first irregular teeth. The structure is simple, and operation is convenient; through four transporting blocks evenly distributed on the rotating wheel, the protective treatment efficiency of wood is improved by four times relative to the treatment efficiency of a single time; and through transmission of the irregular teeth, each operation program of the device works intermittently, the device is more coordinated and is higher in linkage, so that consumption of electric energy is reduced, and environment protection and high efficiency are achieved.

Owner:冯斌斌

A high thermal conductivity aluminum alloy polishing equipment

ActiveCN110091243BSolve the problem of laborious movementEasy to operateGrinding carriagesPolishing machinesDrive shaftElectric machine

The invention discloses a high thermal conductivity aluminum alloy polishing equipment, which comprises a workbench and a power chamber arranged in the workbench, a sliding block is slidably connected to the power chamber, and a limiting device is connected to the slider. A mobile motor is fixed inside the slider, and a transmission shaft extending to the left is fixed on the output shaft of the mobile motor. The first steering bevel gear is fixed on the transmission shaft, and the first steering bevel gear is fixed on the transmission shaft. The upper end is meshed and connected with a clamping device, the clamping device is fixed with a fixing mechanism, the left end wall of the power chamber is provided with a gear connection cavity, and the left end of the transmission shaft is fixed with a second steering bevel gear, The automatic polishing equipment of the present invention is more reasonable and ingenious in overall structure, easy to operate, and has high efficiency in processing aluminum alloys with high thermal conductivity. A single driving motor can realize the function of the clamping and fixing mechanism of the lifting polishing device, and the use safety is high. It has high use and promotion value.

Owner:江苏凯乐金属科技有限公司

Clinical prenatal diagnosis and examination device used for obstetrics department

ActiveCN112618245AImprove stabilityReduce physical exertionOperating chairsOperating tablesPrenatal diagnosisEngineering

The invention provides a clinical prenatal diagnosis and examination device used for the obstetrics department, and belongs to the technical field of prenatal diagnosis and examination devices. The clinical prenatal diagnosis and examination device comprises a base, wherein a basic shaft is spliced on the base in a sliding way; the upper end of the basic shaft is connected with a seat plate; the left side and the right side of the seat plate are independently rotatably connected with a backup plate and a supporting plate; the bottom surface of the backup plate and the bottom surface of the supporting plate are independently movably connected with a driven shaft; the left side and the right side of the base are independently connected with a movable restriction seat opposite to each driven shaft; and each driven shaft is movably spliced in each movable restriction seat. By use of the clinical prenatal diagnosis and examination device used for the obstetrics department, through the supporting plate, the seat plate and the backup plate, a variable bed and chair is formed; by use of the seat plate, the basic shaft drives a conversion air bag, a combination function of a stable self-regulating bag and a tightening component is combined, on the basis of improving stability and safety in a process that a pregnant woman sits and lies, compared with the prior art, the clinical prenatal diagnosis and examination device has a simple structure and small energy consumption, saves energy and is environmentally friendly, meanwhile, the clinical prenatal diagnosis and examination device has high flexibility and correspondingly lowers the mechanical loss of the bed and chair.

Owner:JILIN UNIV FIRST HOSPITAL

Adjustable portal assembly for forklift

PendingCN108569650AAchieve clamping stabilityImprove handlingLifting devicesEngineeringMechanical engineering

The invention relates to an adjustable portal assembly for a forklift. The assembly comprises a rack and also comprises an adjusting mechanism, a scissors fork mechanism and a stabilizing mechanism, wherein the adjusting rack is mounted on the rack and comprises a control assembly a and a lifting assembly fixedly connected to the control assembly a and located on one side of the control assembly a; the scissors fork mechanism is located on one side of the adjusting mechanism and is located above the lifting assembly and comprises a cross assembly synchronously driven together with the liftingassembly, a control assembly b slidably arranged on the cross assembly and located below the cross assembly and a driving assembly, one end of which is connected to the control assembly b while the other end of which is connected to the control assembly a; and the stabilizing mechanism is arranged above the scissors fork mechanism and comprises a tightening assembly slidably arranged on the crossassembly and a control assembly c for controlling the tightening assembly to fold and release. The assembly solves the technical problem that a fork leg cannot be adjusted automatically for carrying cargoes of different specifications and sizes, so that the assembly further achieves the effects of clamping and stabilizing materials of various specifications and in different positions.

Owner:三门华和智能科技有限责任公司

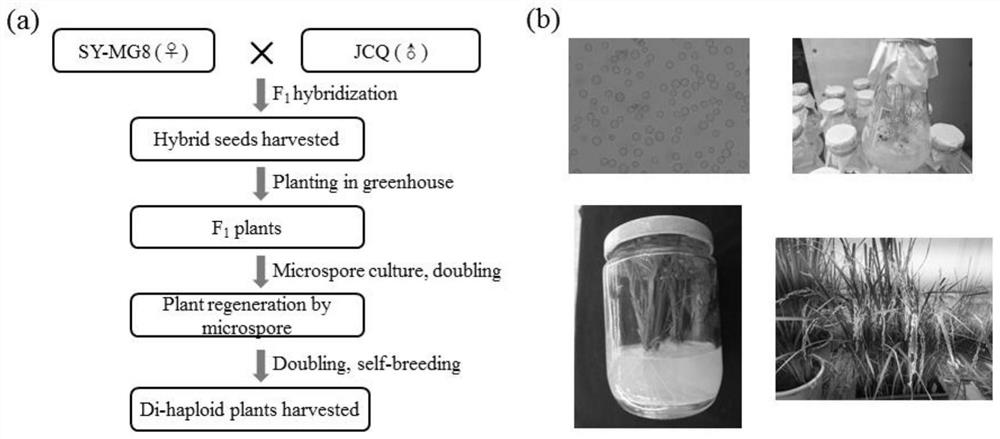

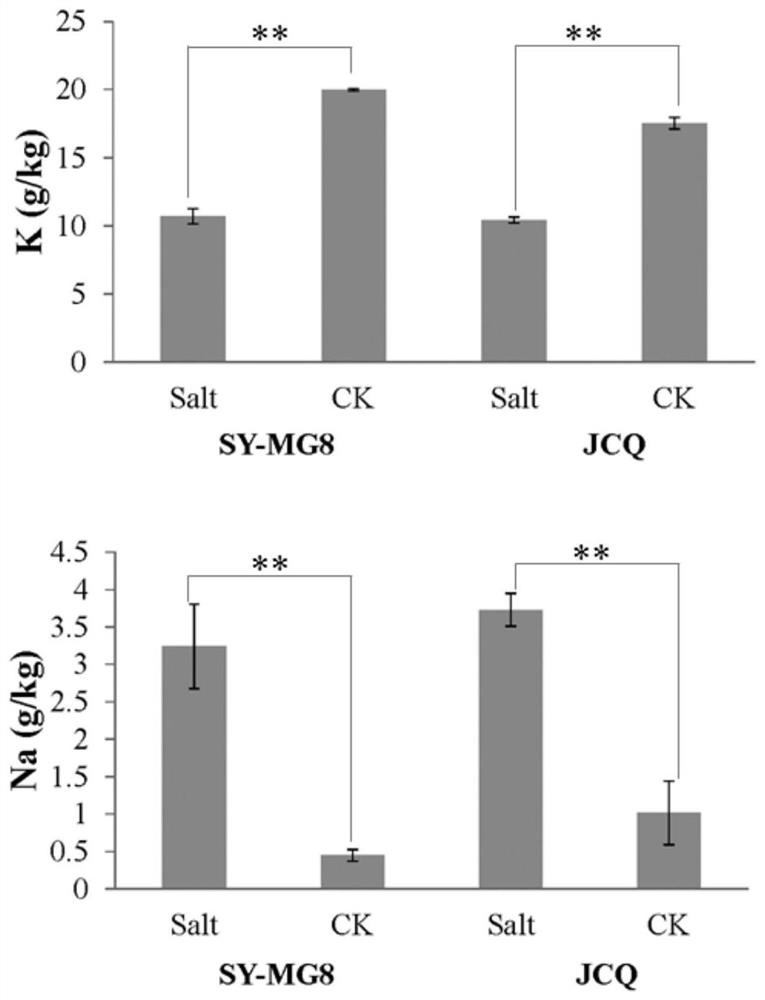

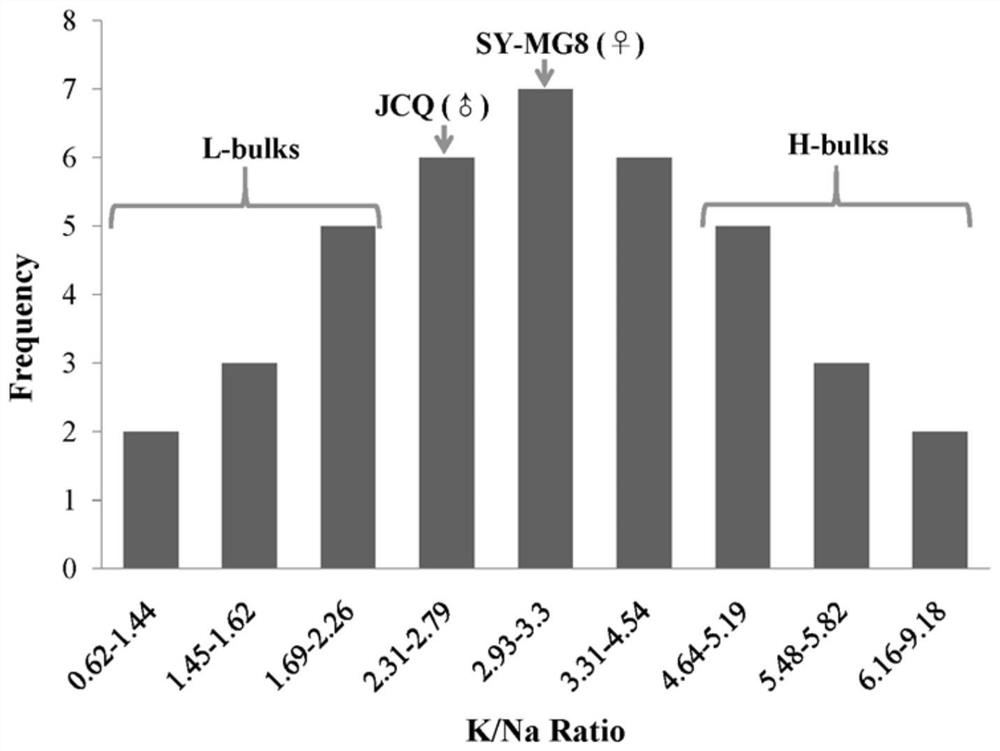

SNP molecular markers linked with rice sodium and potassium ion absorption QTL and application thereof

PendingCN111733278AImprove purposeHigh linkageMicrobiological testing/measurementDNA/RNA fragmentationBiotechnologyMolecular breeding

The invention relates to the field of genetic breeding, and particularly relates to SNP molecular markers linked with rice sodium and potassium ion absorption QTL qK / Na-3-1, primers and application. The SNP molecular markers RS (36172492) and RS (36174628) are located on a Chr3 chromosome short arm of an IRGSP-1.0 genome version, the sequences are shown as SEQ ID NO. 1 and SEQ ID NO. 2, the polymorphisms are (T / G) (G / -), (A / -), and the SNP molecular markers can be obtained by amplifying the primers shown as SEQ ID NO. 3 and SEQ ID NO. 5. The molecular markers can accurately track the rice sodium and potassium ion absorption QTL qK / Na-3-1 and predict the potential salt tolerance characteristic of rice, and then molecular breeding is facilitated. The invention further discloses a method foridentifying the rice sodium and potassium ion absorption QTL qK / Na-3-1 molecular markers. By means of the method, the accuracy of sodium and potassium ion absorption prediction can be enhanced, so that rice varieties or strains with potential enhanced rice salt tolerance are quickly screened out for breeding, and the breeding process of the rice varieties with potential salt tolerance can be greatly accelerated.

Owner:SHANGHAI ACAD OF AGRI SCI

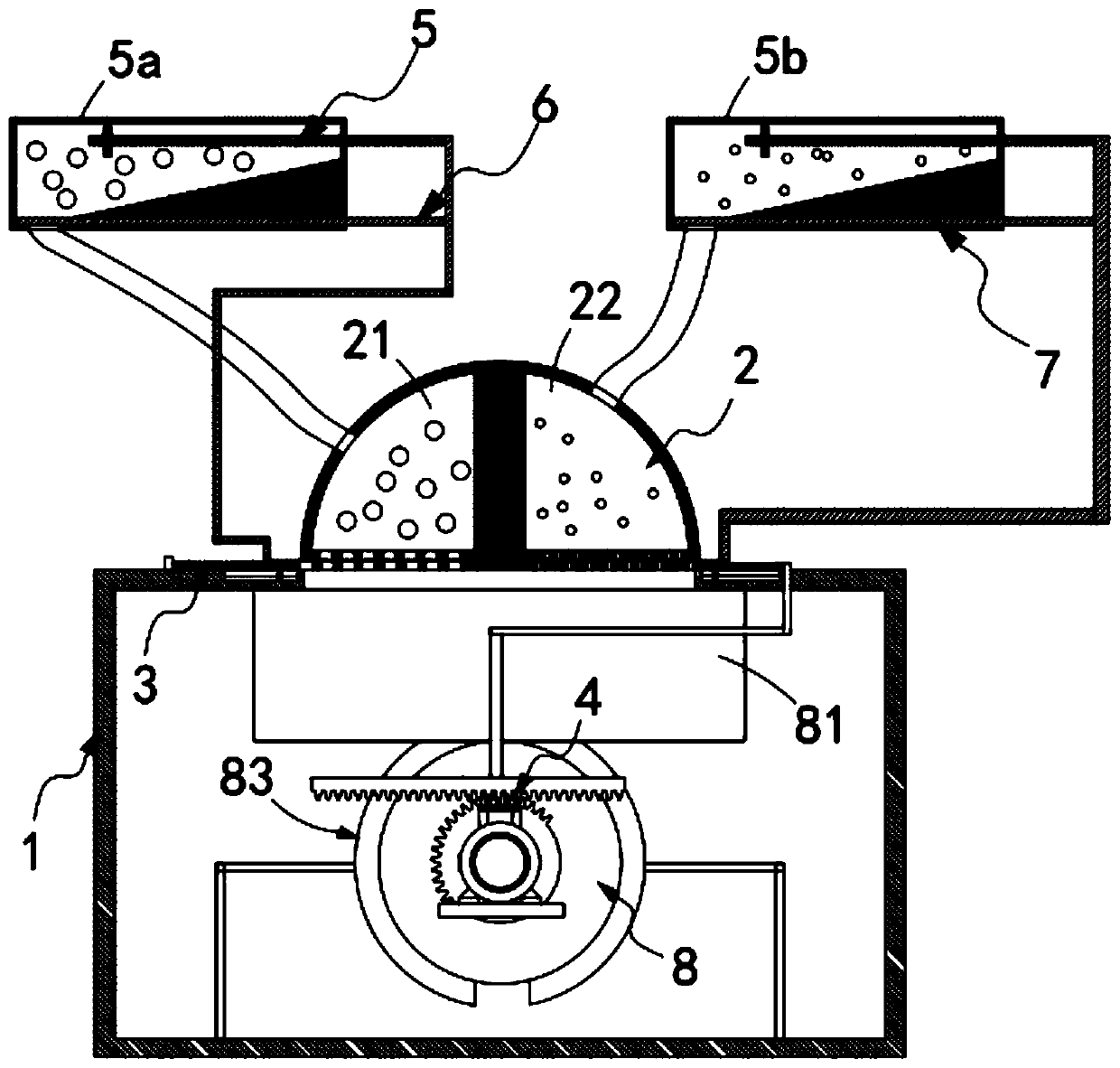

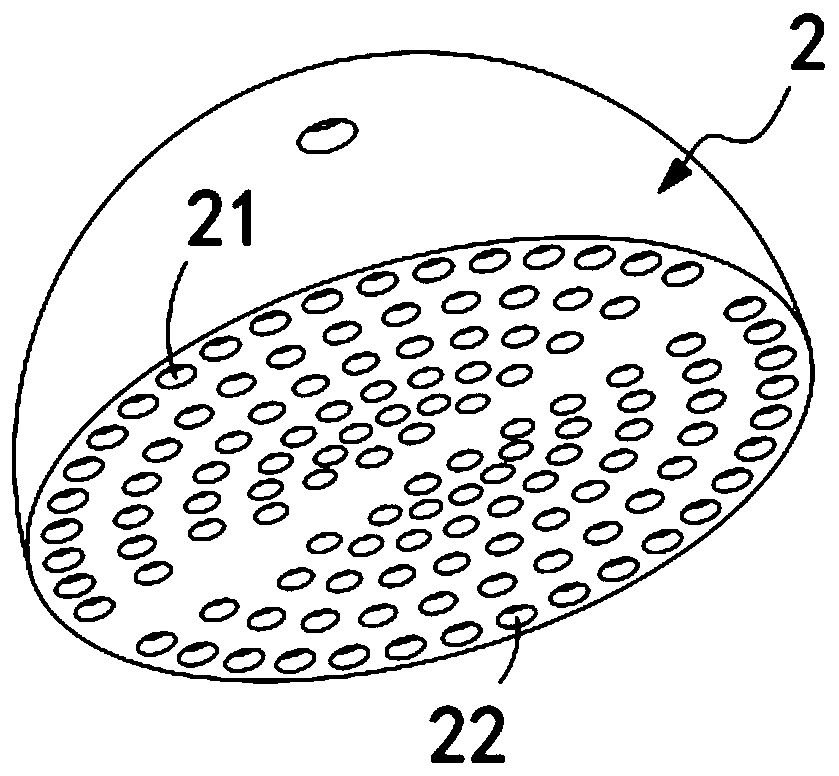

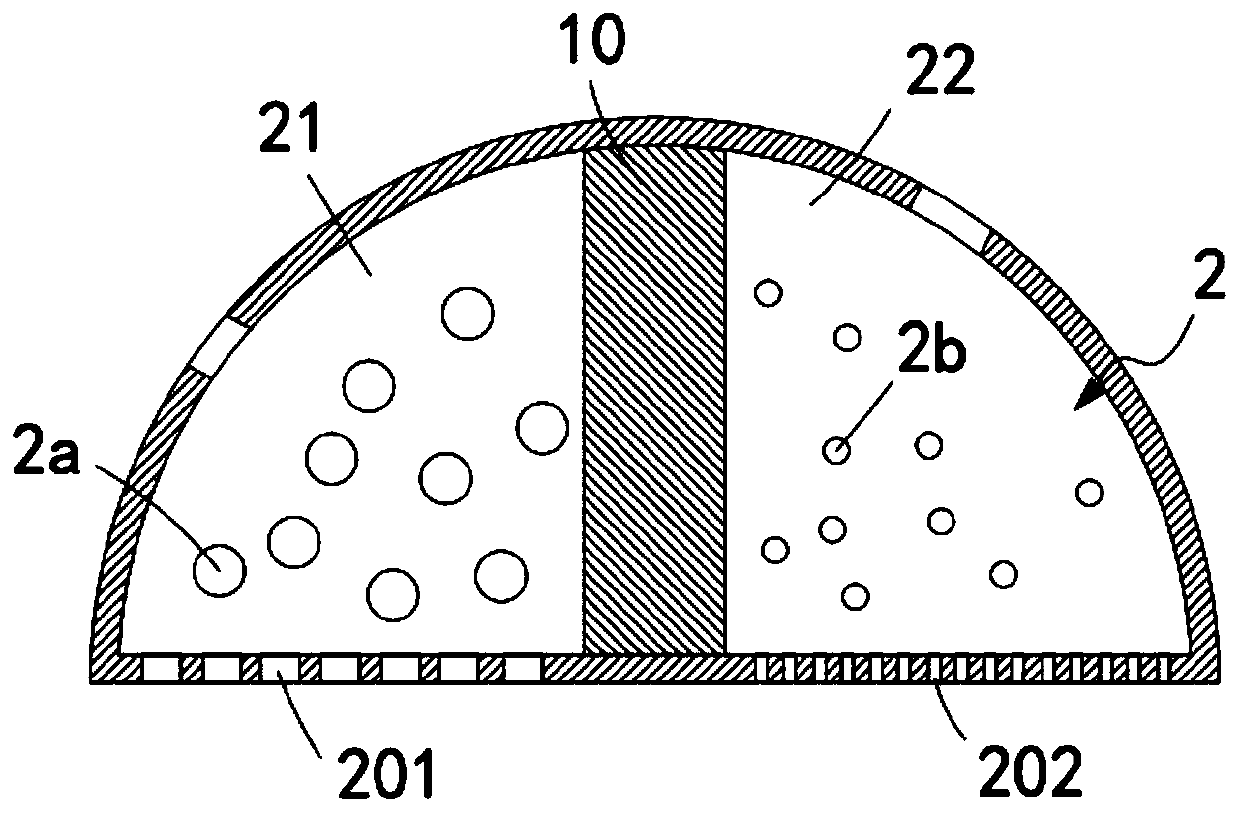

Rain-night reflective bead mixing equipment

InactiveCN111389286ARealize quantitative outputHigh degree of automationTransportation and packagingMixer accessoriesEngineeringMechanical engineering

The invention relates to rain-night reflective bead mixing equipment which comprises a reaction tank, a reflective bead storage box, a discharging assembly, a drive assembly, a supply assembly and a mixing assembly; the discharging assembly is attached to the output end of the reflective bead storage box, and the discharging assembly comprises a rain-night reflective bead mother bead storage spaceand a rain-night reflective sub-bead storage space; the supply assembly comprises a first storage bin and a second storage bin, the first storage bin is communicated with the rain-night reflective bead mother bead storage space of the reflective bead storage box, and a first control assembly is fixedly connected with one end of the discharging assembly and used for controlling discharging of thefirst storage bin; the second storage bin is communicated with the rain-night reflective sub-bead storage space of the reflective bead storage box, and a second control assembly is fixedly connected with the other end of the discharging assembly and used for controlling discharging of the second storage bin; the technical problem that two kinds of beads are different in size, and then accurate proportioning of the two kinds of beads cannot be achieved is solved.

Owner:ZHEJIANG ZHONGXIN NEW MATERIAL CO LTD

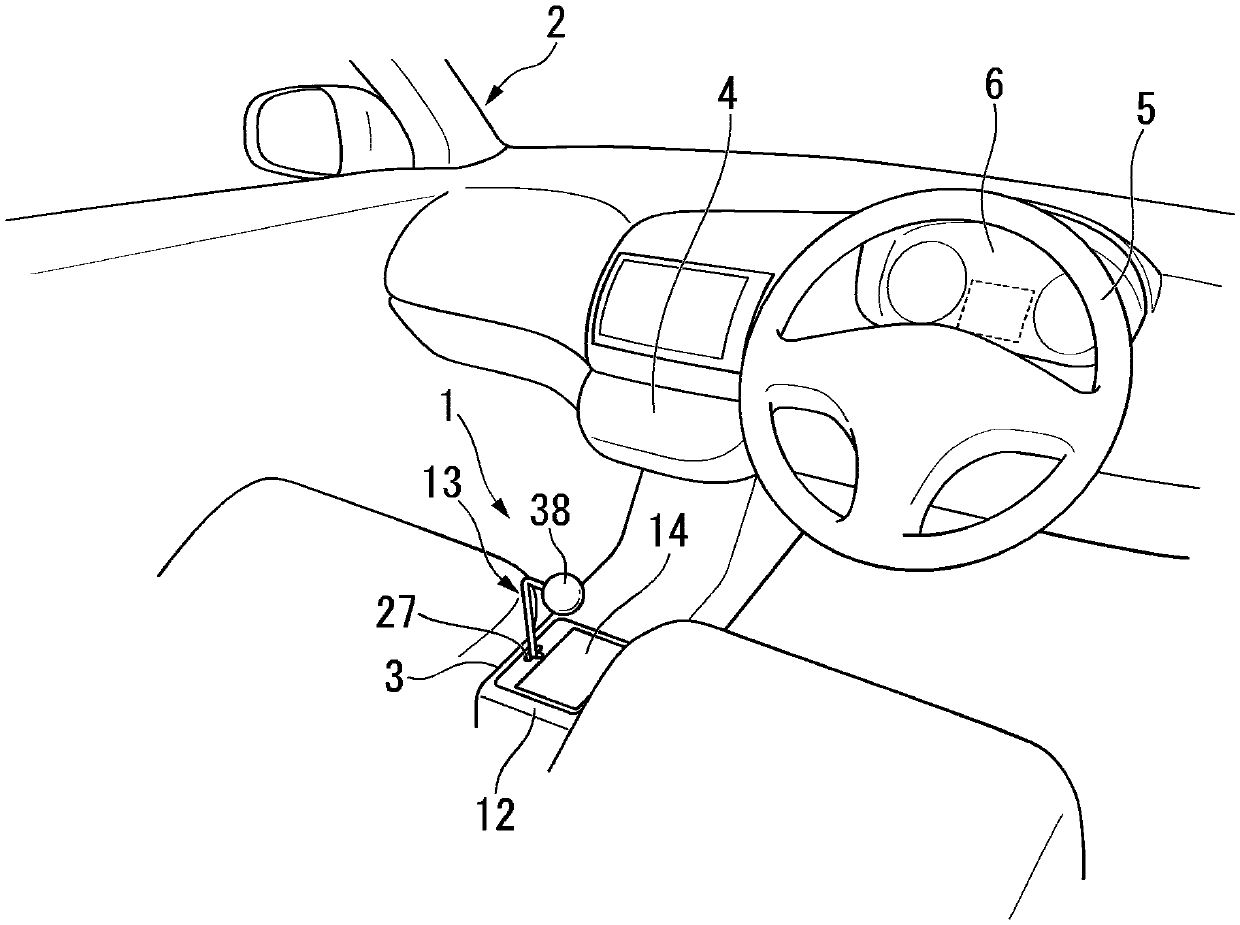

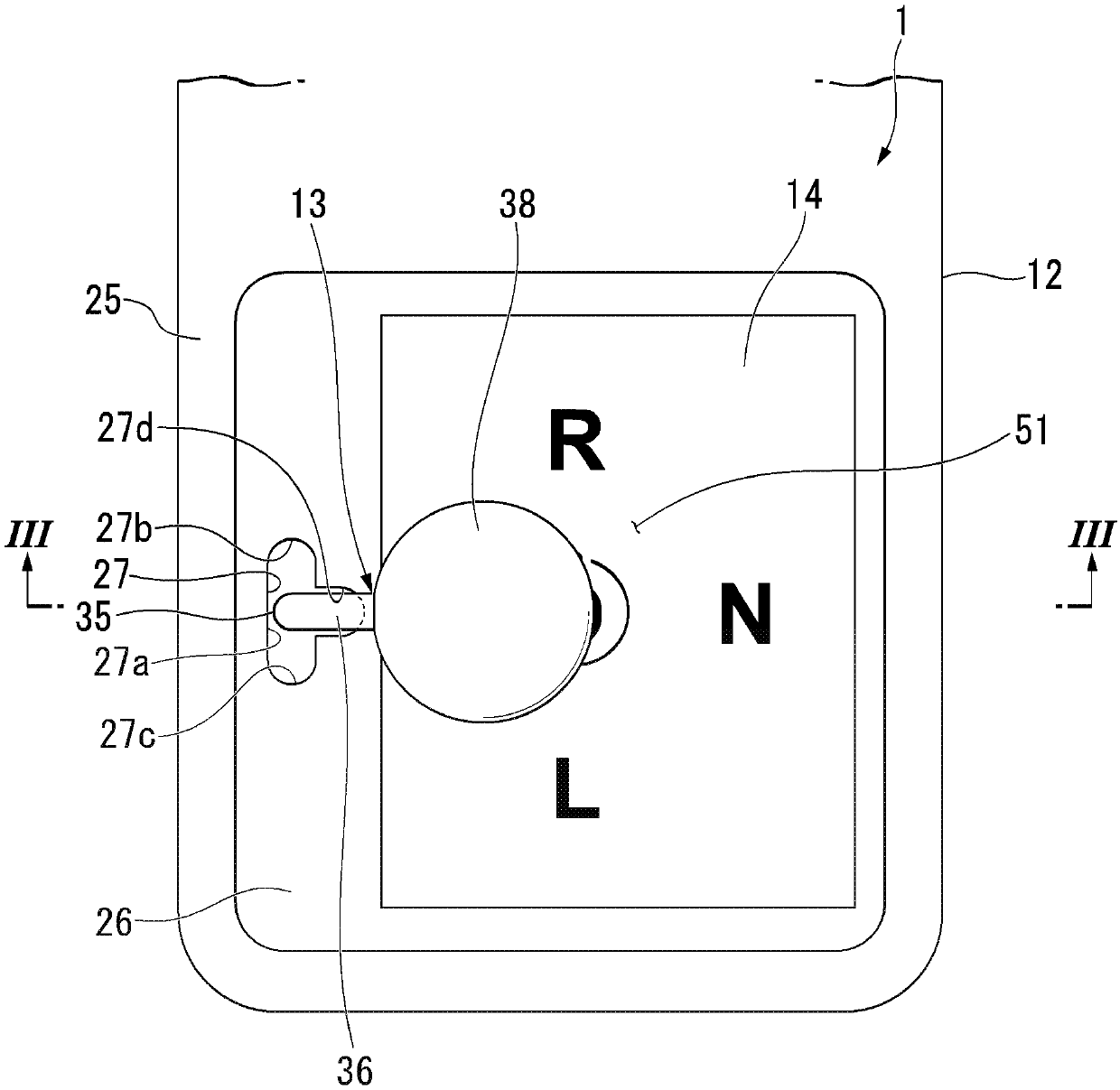

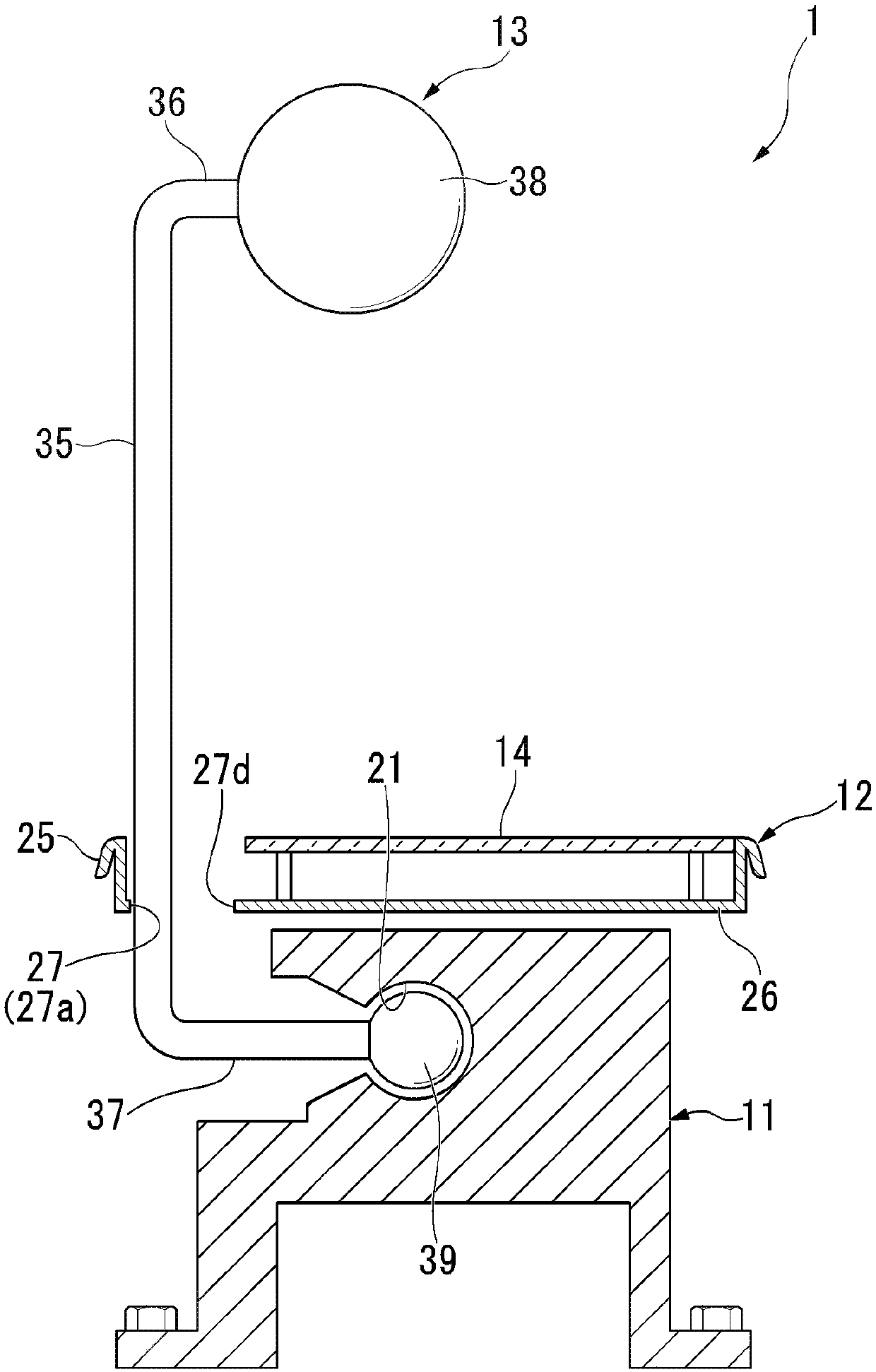

Shifting device

InactiveCN109927548AEasy to operateEasy to masterGearing controlControl devicesAutomatic transmissionOperability

A shifting device capable of improving operability is provided. The shifting device includes a display portion (14) that displays a gear image corresponding to a gear of the automatic transmission, ashift lever (13) that moves from the reference position based on the gear image to select a gear position and is capable of being reset to the reference position in a state where the operating force is released, and a control unit which controls a display mode of the gear image displayed on the display unit (14). The display unit (14) has a selection gear display unit (51a) displaying a gear imageindicating the current gear, a drive system display portion (51b, 51c) and a non-drive system display portion (51d), and the drive system display portion (51b, 51c) and the non-drive system display portion (51d) display a gear image that can be selected by the shift lever (13). The control unit displays only the gear images that can be selected by the shift lever (13) on the drive system displayunits (51b, 51c) and the non-drive system display unit (51d).

Owner:HONDA MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com