Forward movement type automatic material pushing forklift

A material fork, automatic technology, applied in the direction of lifting device, etc., can solve problems such as damage and wear of goods, and achieve the effect of accelerating sliding speed, improving utilization rate and easy control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

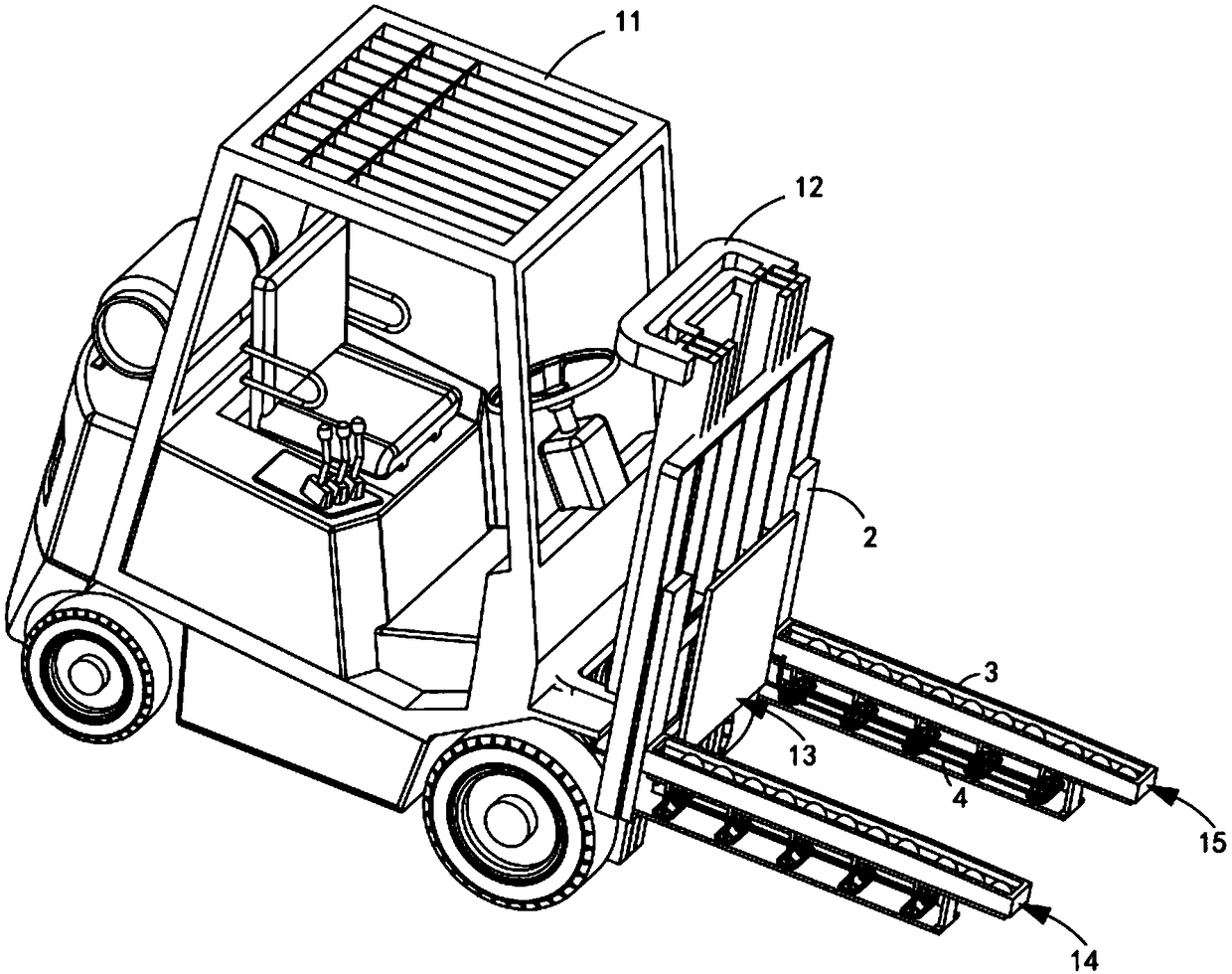

[0067] like figure 1 As shown, a forward-moving automatic pusher forklift includes a forklift 11, a mounting frame 12 arranged in front of the forklift, and also includes:

[0068] A horizontal push mechanism 13, the horizontal push mechanism 13 is installed on the mounting frame 12;

[0069] A lifting mechanism a14, the lifting mechanism a14 is arranged on the mounting frame 12 and is located on one side of the horizontal pushing mechanism 13; and

[0070] a lifting mechanism b15, the lifting mechanism b15 is arranged symmetrically with the lifting mechanism a14;

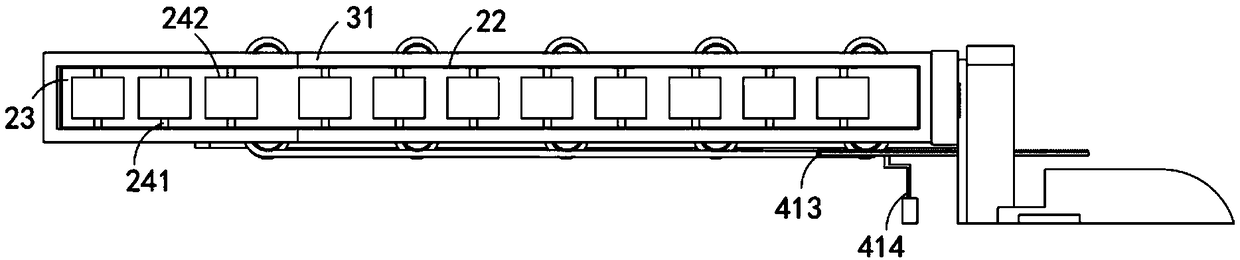

[0071] Both the lifting mechanism a14 and the lifting mechanism b15 include a support assembly 2 fixedly arranged on the mounting frame 12, a control assembly 3 slidably arranged on the support assembly 2, and a control assembly 3 arranged on the control assembly 3 and used The drive assembly 4 is used to cooperate with the control assembly 3 to move longitudinally. Under the cooperation of the relative transmiss...

Embodiment 2

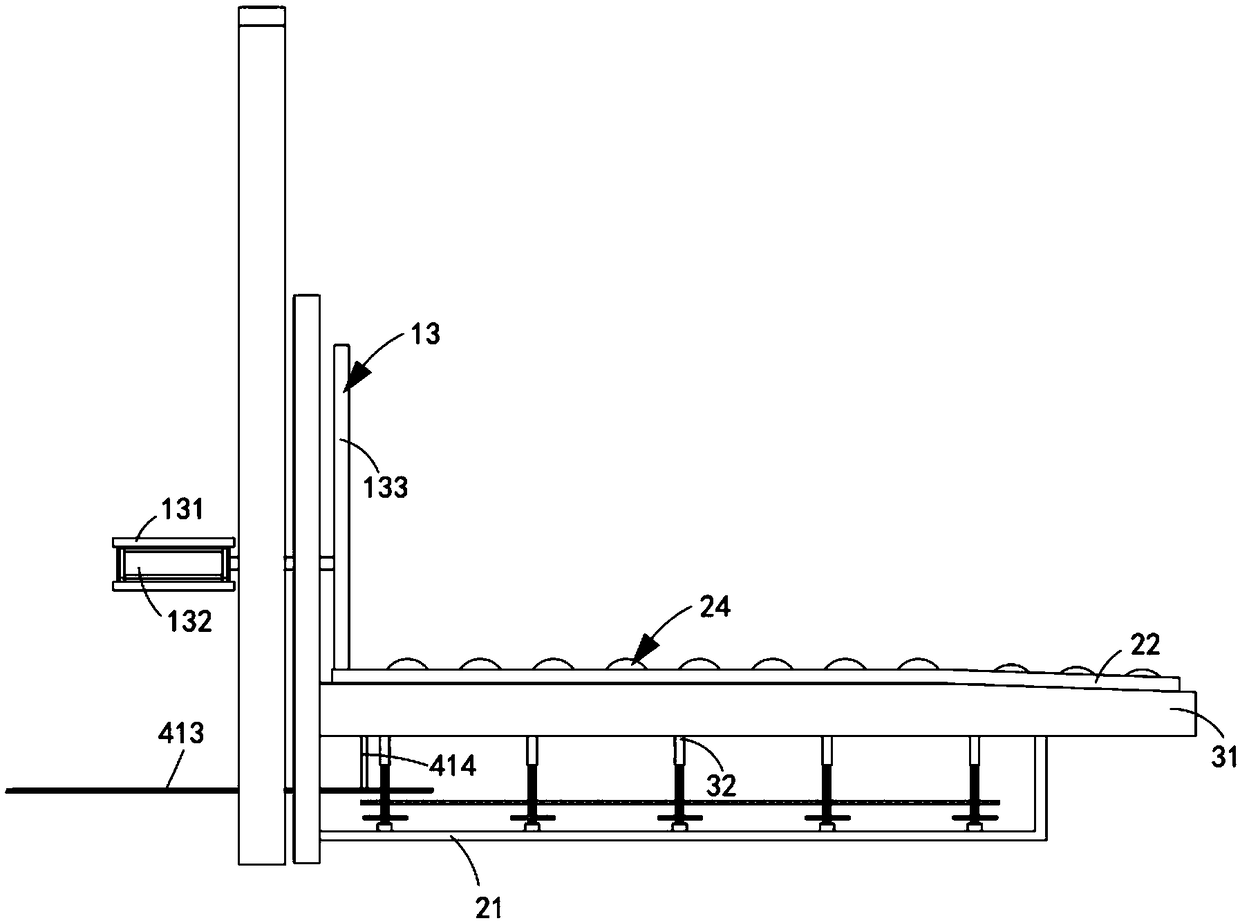

[0114] like figure 2 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between this embodiment two and embodiment one is:

[0115] Further, the rear part of the port 23 of the fixed bin 22 is arranged obliquely downward.

[0116] In the example in this city, the rear part of the bin mouth 23 of the fixed bin 22 is arranged obliquely downward, so that when the material falls to the destination, it plays a guiding role, speeds up the falling speed of the material, and reduces friction.

[0117] work process:

[0118]When the forklift 11 was close to the placement position, the flat push cylinder 132 was started, and the flat push plate 133 moved forward, and the flat push plate 133 began to contact the material. At the same time, the connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com