Bean vermicelli cooking device with slitting function

A cooking device and vermicelli technology, which is applied in the field of making vermicelli, can solve the problems of complex shearing structure and inability to transmit vermicelli, and achieve the effects of simple structure, high mobility and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

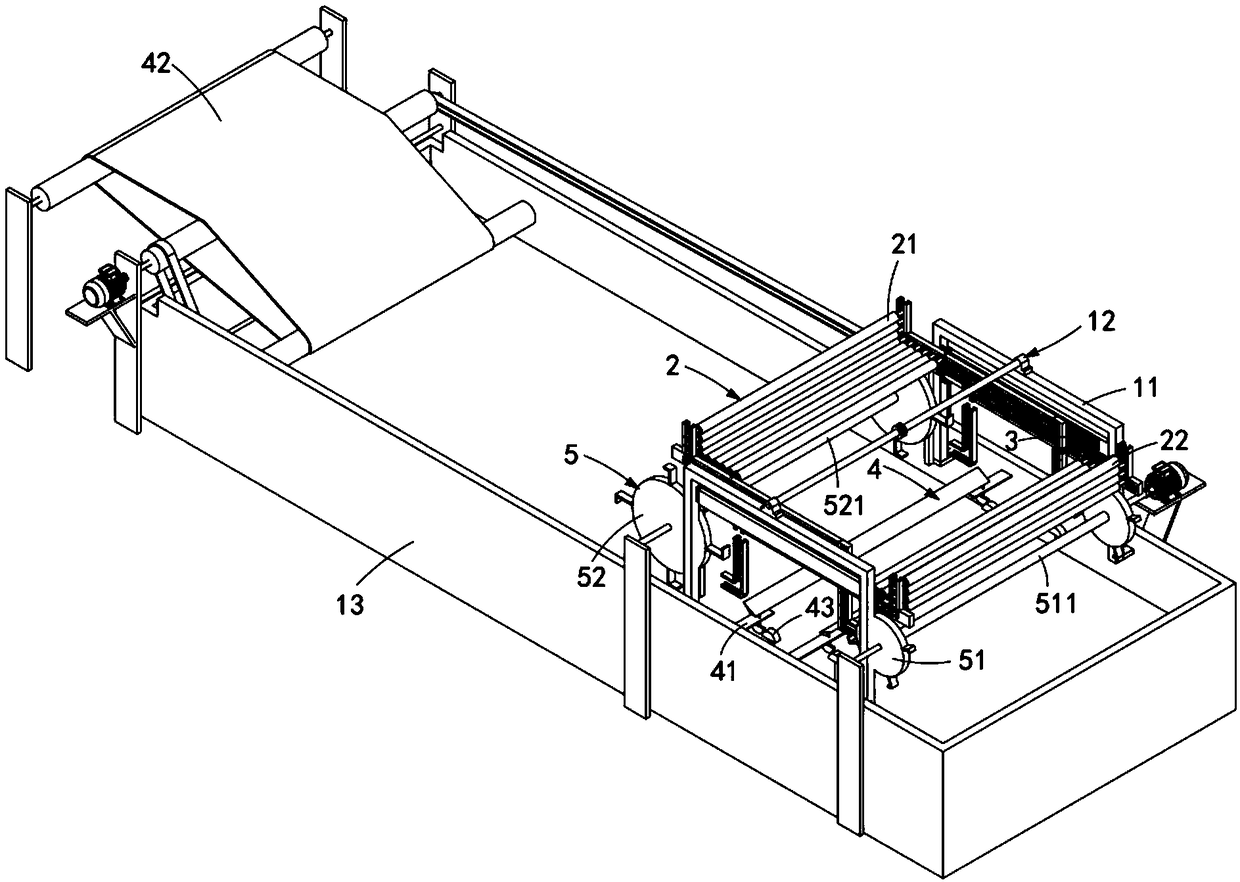

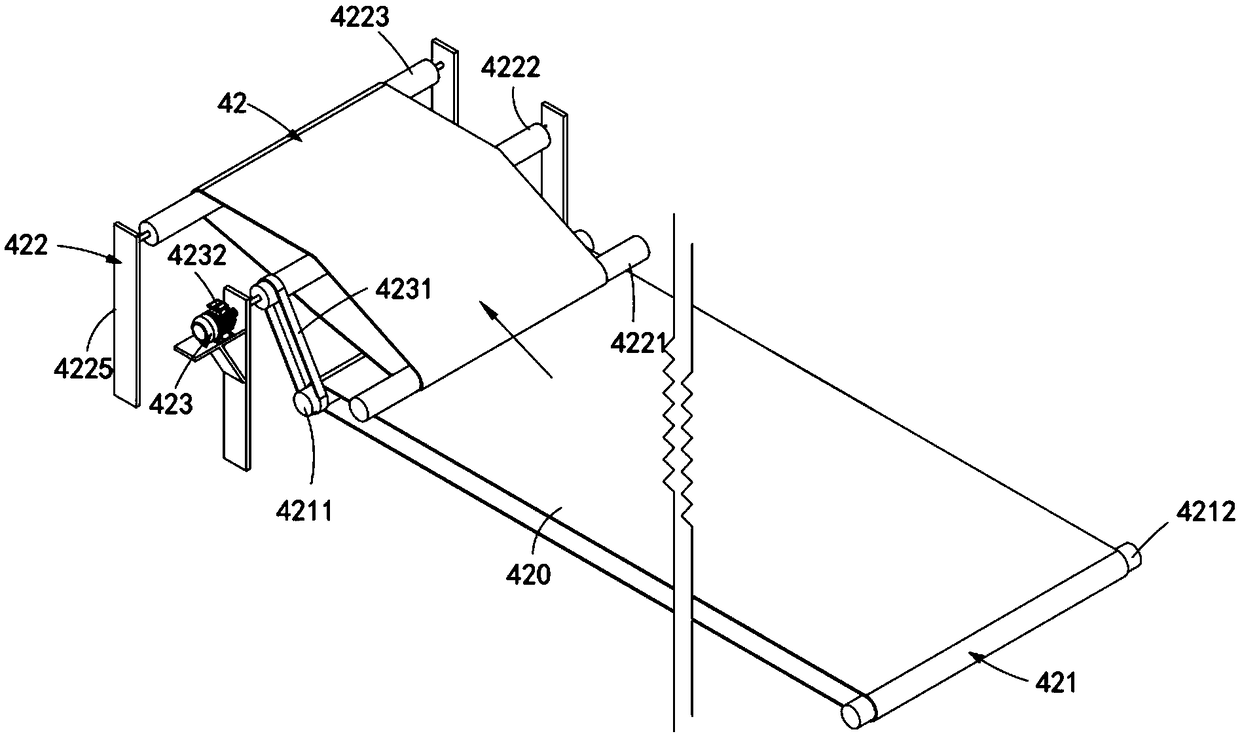

[0069] Such as figure 1 As shown, a vermicelli steaming device with a cutting function includes a vermicelli conveyor belt 12, which is erected on the top of the frame 11, and the bottom is provided with a boiling box 13, and the frame 11 is installed on the boiling box 13 within, including:

[0070] Material-holding mechanism 2, the material-holding mechanism 2 is fixedly arranged below the vermicelli conveyor belt 12 and installed on the frame 11, the material-holding mechanism 2 is used to support the vermicelli that the vermicelli conveyor belt 12 vertically outputs And output it in an S shape, which includes a first paving assembly 21 and a second paving assembly 22 arranged below the first paving assembly 21;

[0071] A driving mechanism 3, the driving mechanism 3 is symmetrically arranged below the powder skin conveyor belt 12, and is arranged between the first material spreading assembly 21 and the second material spreading assembly 22;

[0072] The shearing mechanis...

Embodiment 2

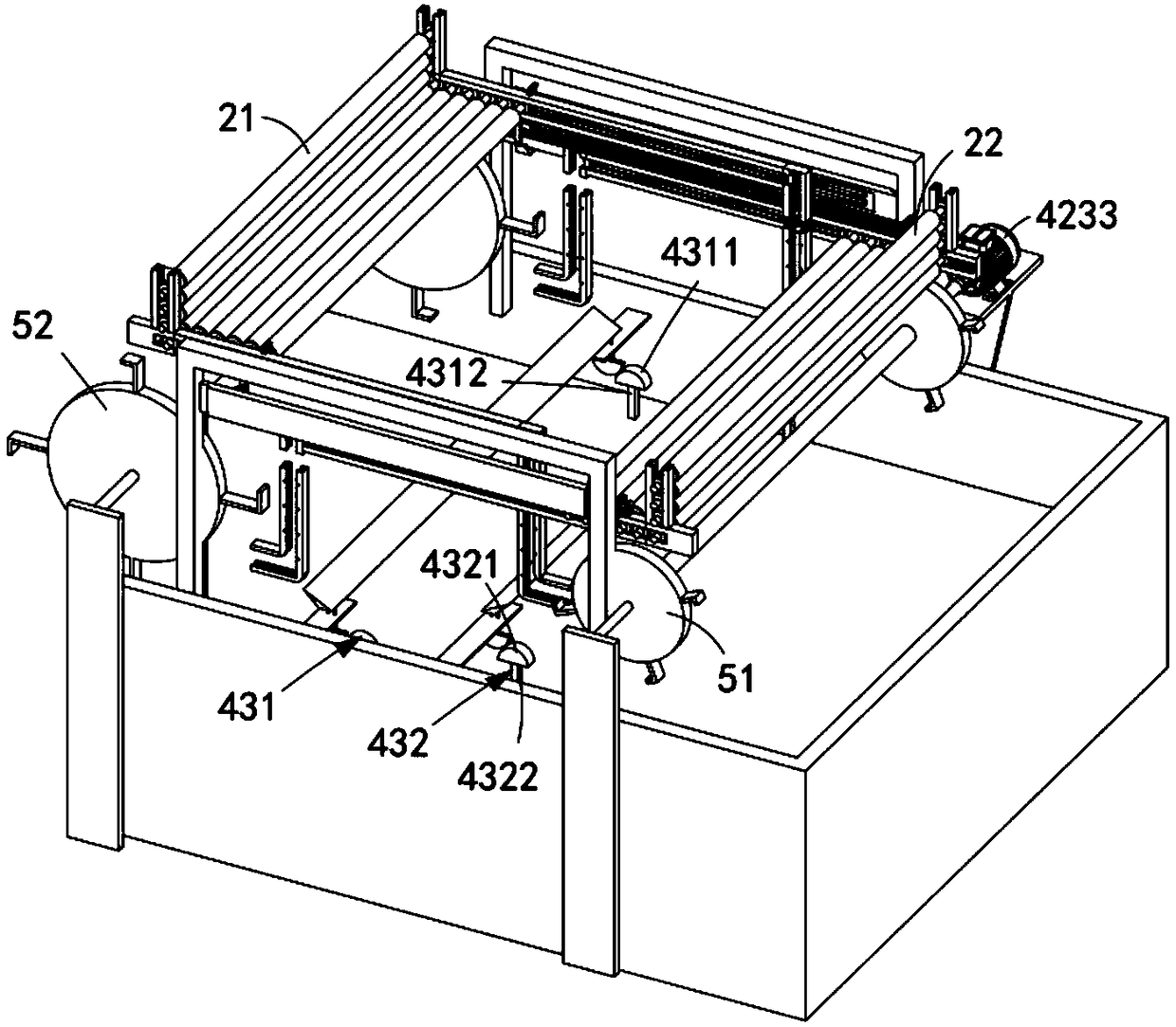

[0121] Such as Figure 6 , Figure 7 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between this embodiment two and embodiment one is:

[0122] Further, the corner size of the intermediate track a4111 and the intermediate track b4121 is A, 90°

[0123] It is worth noting that, by setting 90°<A<180°, on the one hand, the spreading roller a215 and the spreading roller b225 can use the gravitational potential energy to realize automatic falling, and on the other hand, make them have an initial velocity, which can realize parabolic falling The circulation mechanism 5 ensures the stability of the work.

[0124] work process:

[0125] The vermicelli conveyor belt 11 transports the steamed vermicelli, and the vermicelli is vertically ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com