Patents

Literature

41results about How to "Realize slitting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cable stripping tool

ActiveCN102593763ARealize switchingRealize slittingApparatus for removing/armouring cablesKnife bladesElectric cables

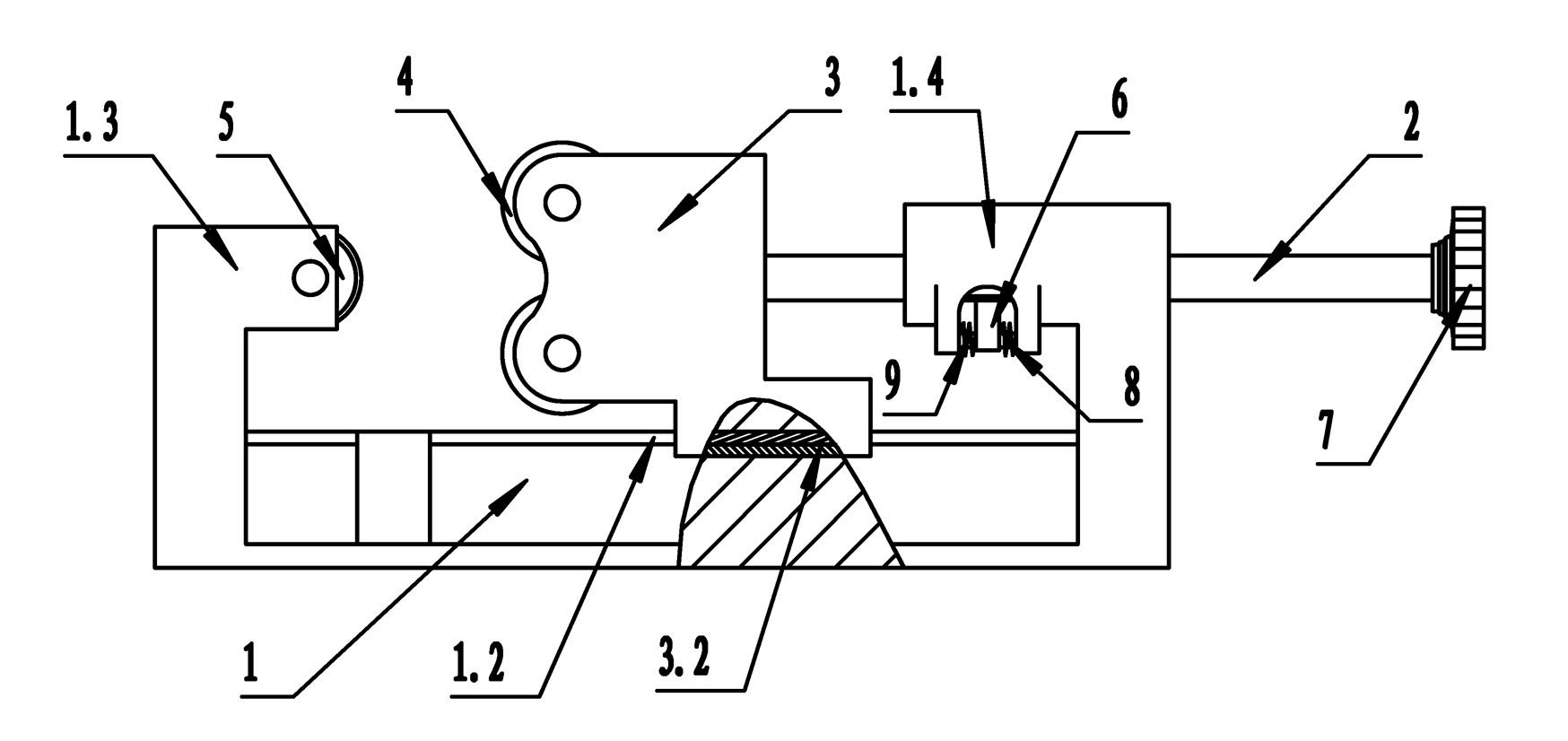

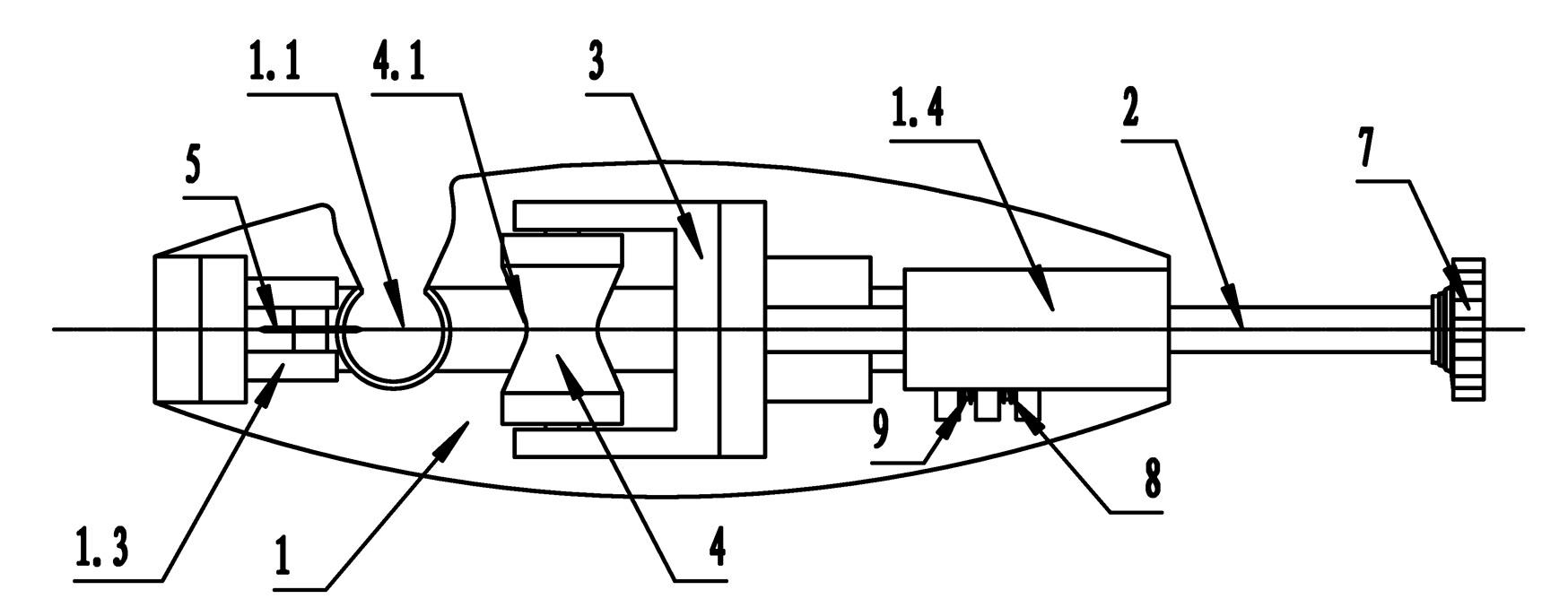

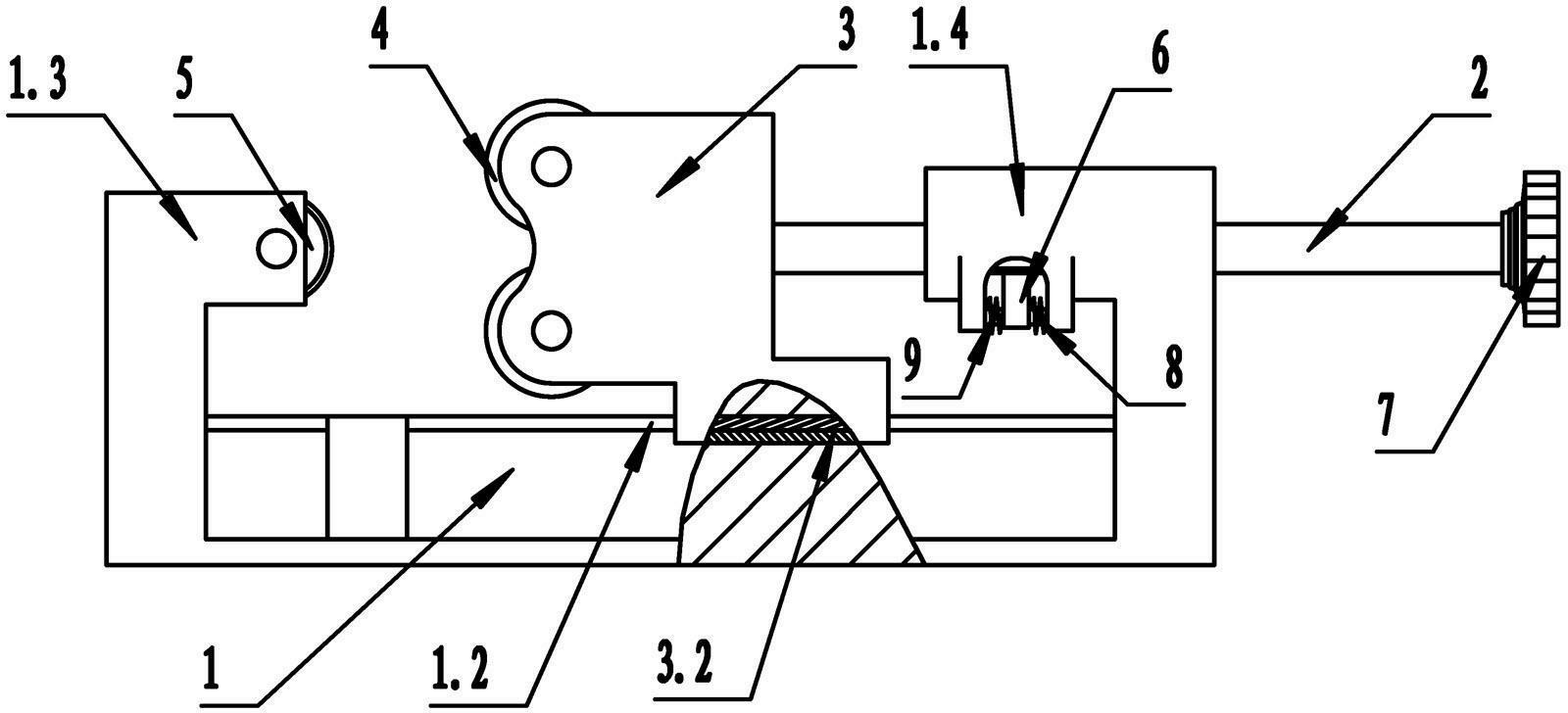

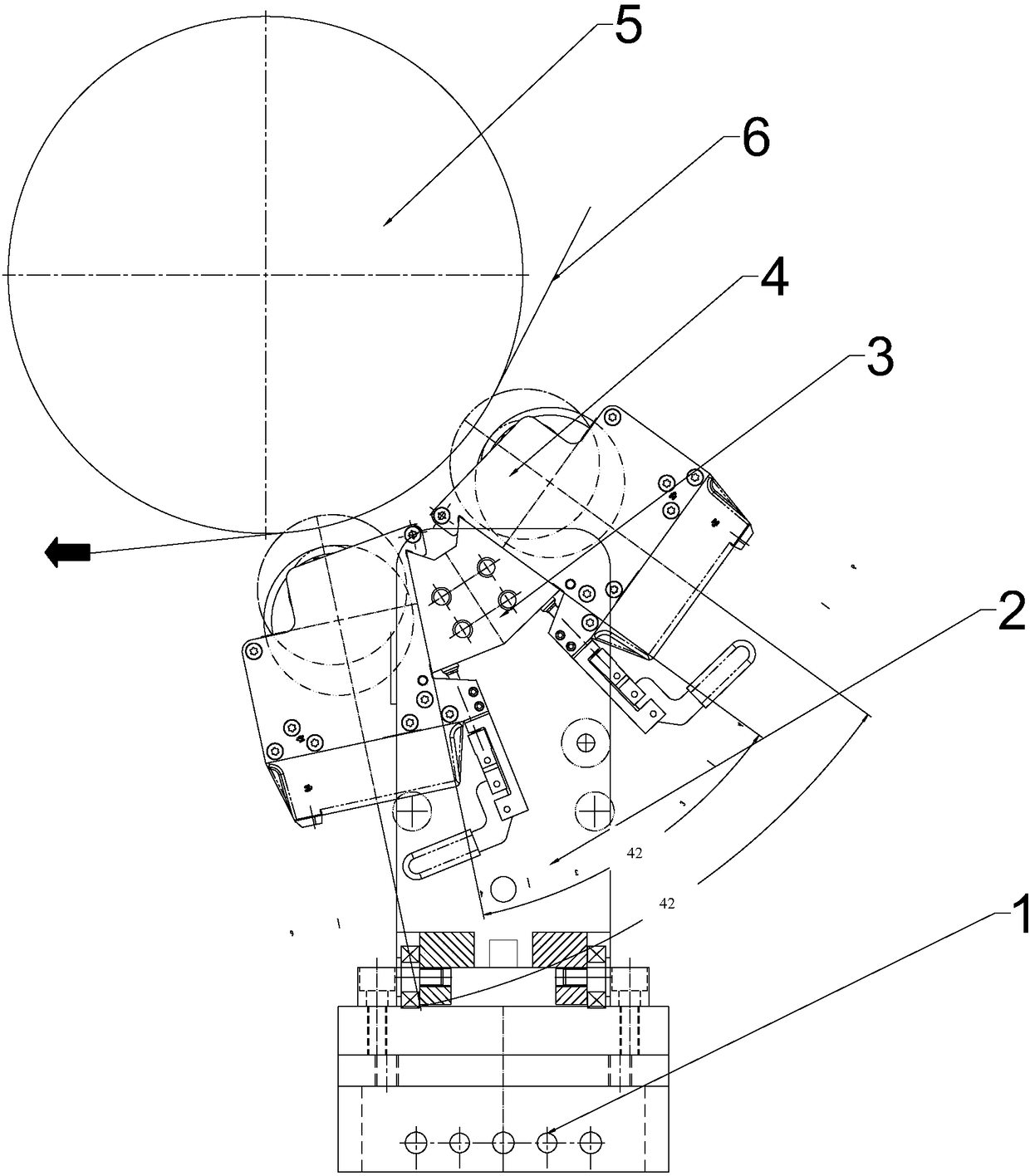

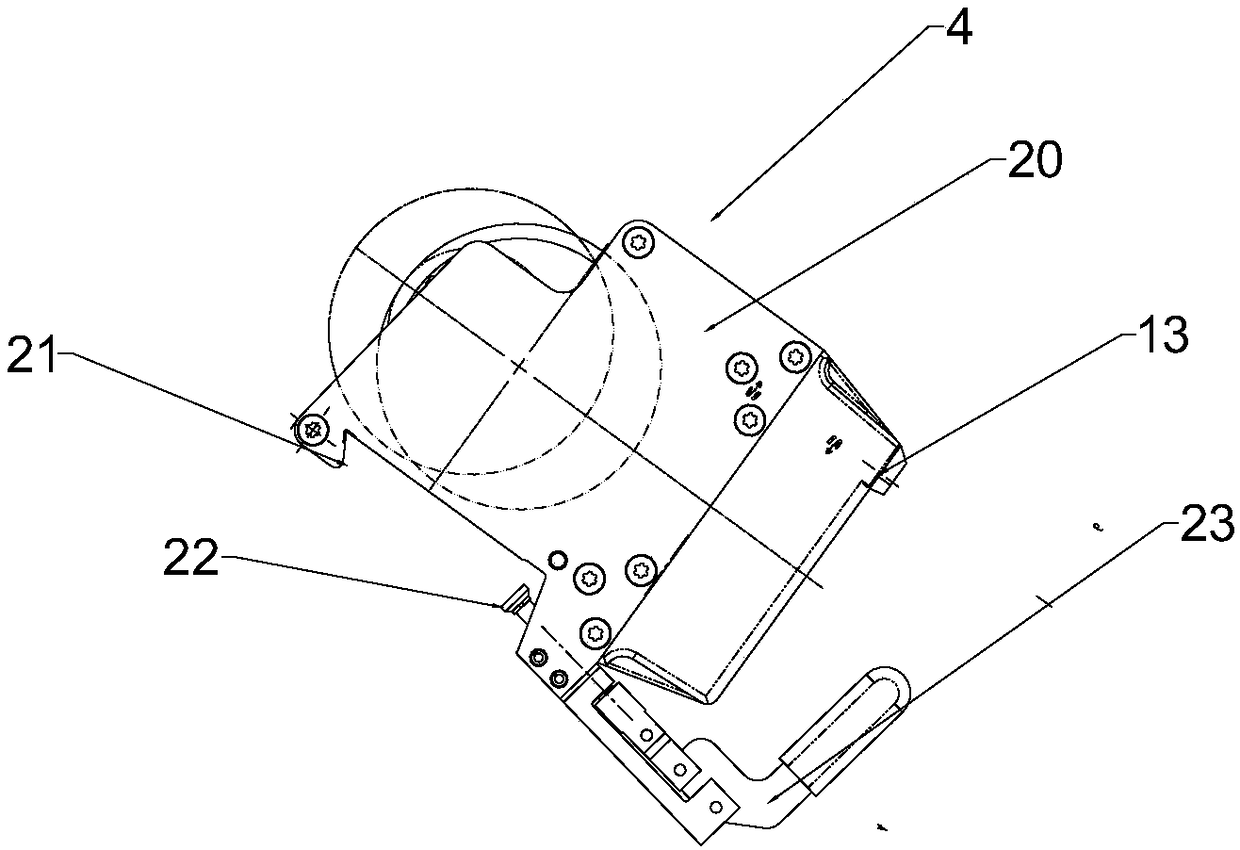

The invention provides a cable stripping tool comprising a bracket (1); a left upper support (1.3) with a U-shaped slot is arranged on the left end of the bracket (1), and a circular cutting blade (5) is also installed on the left end of the bracket (1); a tubular right upper support (1.4) is arranged on the right end of the bracket (1), and a lead screw (2) is also installed on the right end of the bracket (1) via a lead screw nut (6); a guide rail (1.2) is arranged on the middle part of the bracket (1); a pulley installation frame (3) is also arranged by connecting the guide rail (1.2) and the middle part of the bracket (1); a guide slot (3.1) matched with the guide rail (1.2) is arranged at the bottom of the pulley installation frame (3); the right end of the pulley installation frame (3) is connected with a left end shaft of the lead screw (2), and a pair of pulleys (4) are installed on a left end of the pulley installation frame (3); an arc-shaped notch (4.1) is arranged in the middle of the pulleys (4); and a notch (1.1) used for holding a cable is arranged on the bracket (1) at the right lower side of the blade (5). The cable stripping tool disclosed by the invention has the advantages of rapid cable stripping speed, even notches and high security and reliability.

Owner:BINZHOU POWER SUPPLY COMPANY OF STATE GRID SHANDONG ELECTRIC POWER

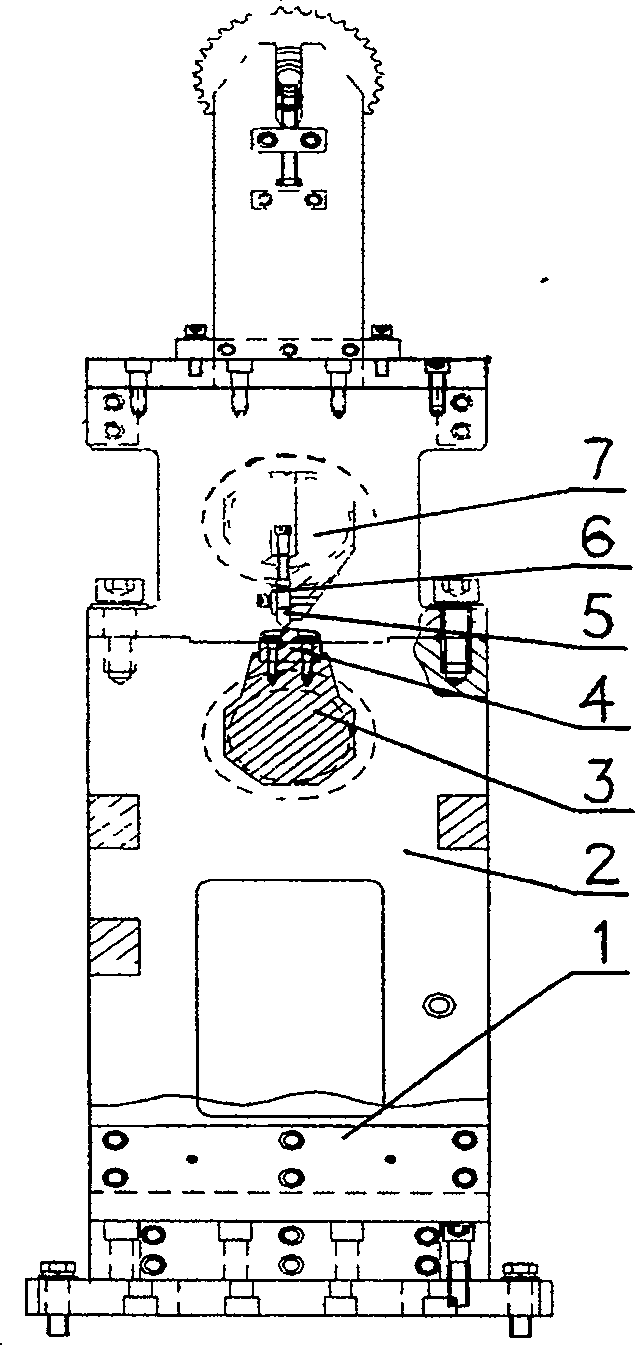

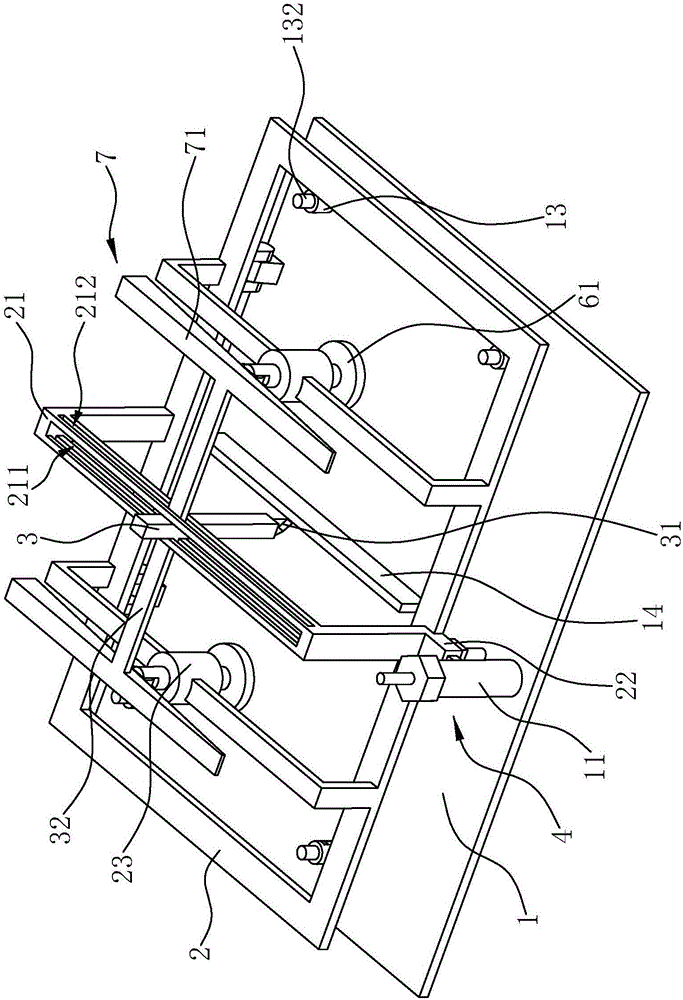

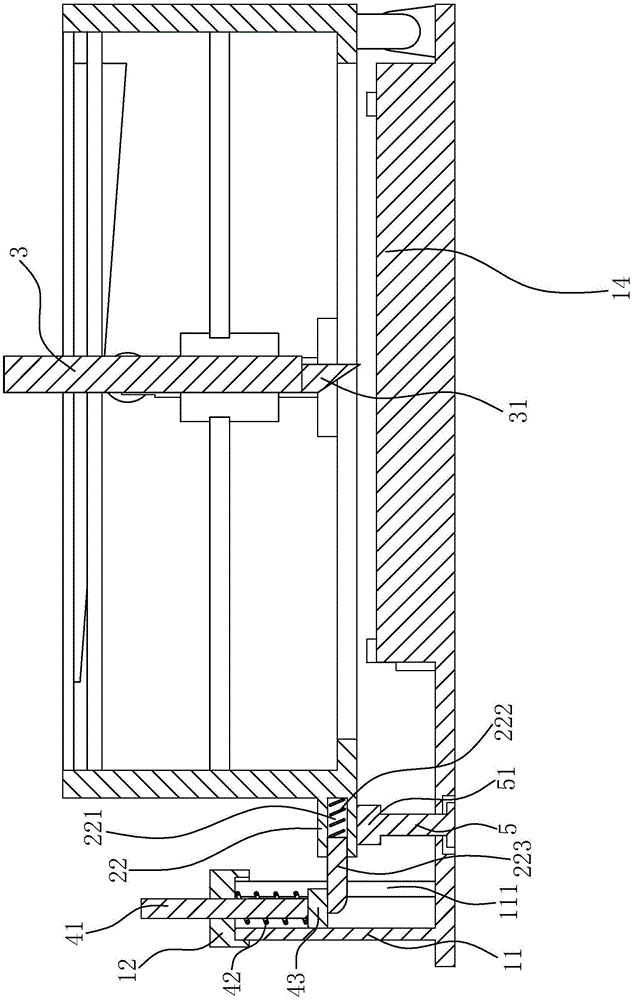

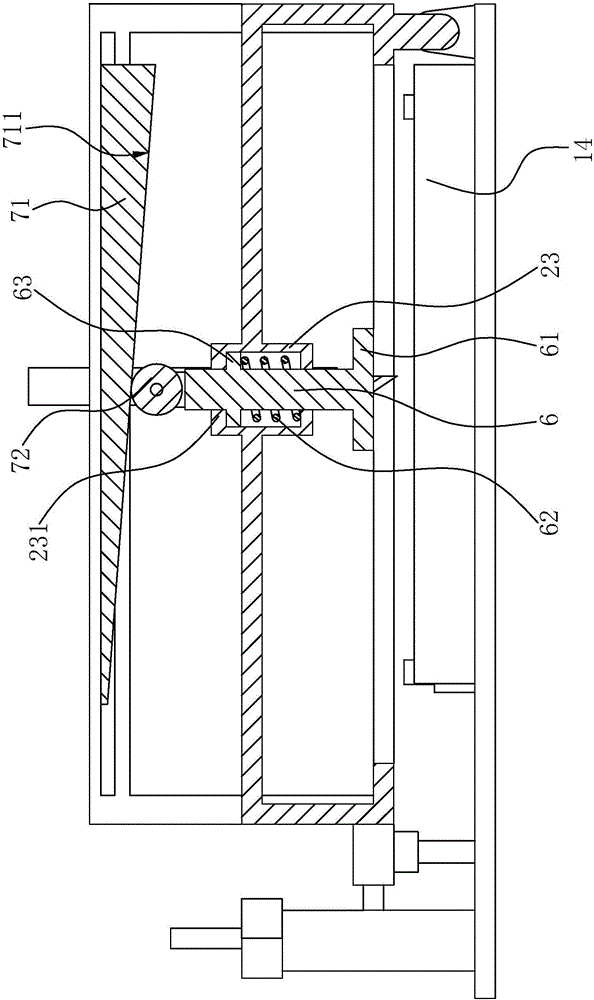

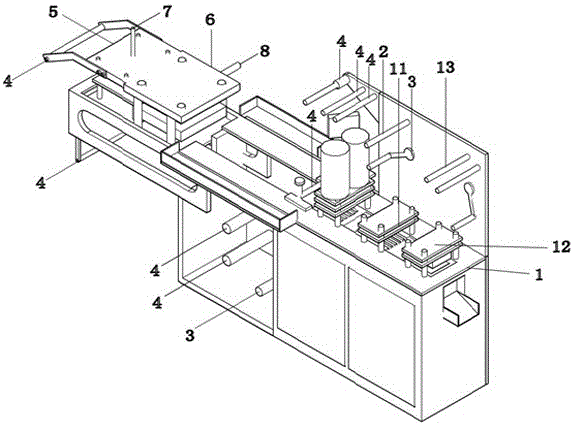

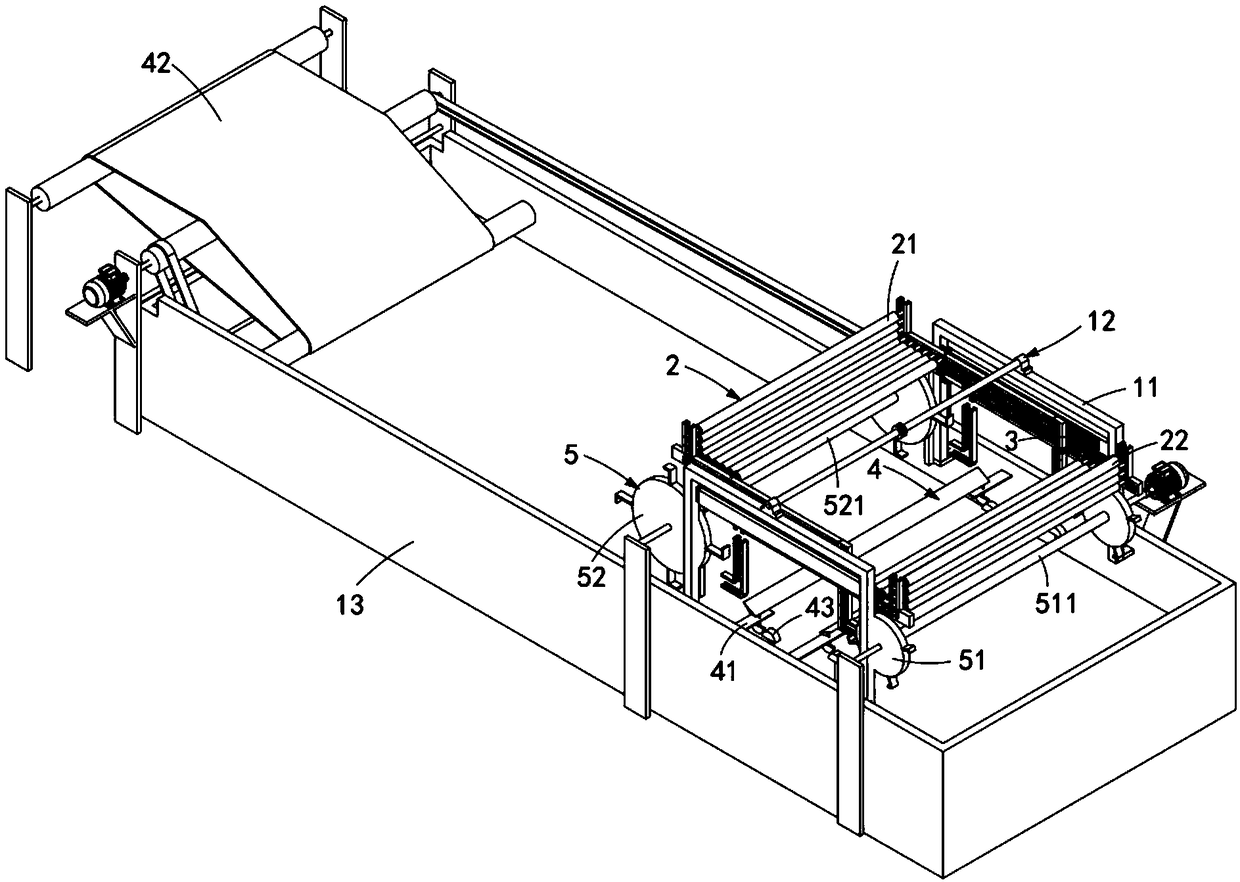

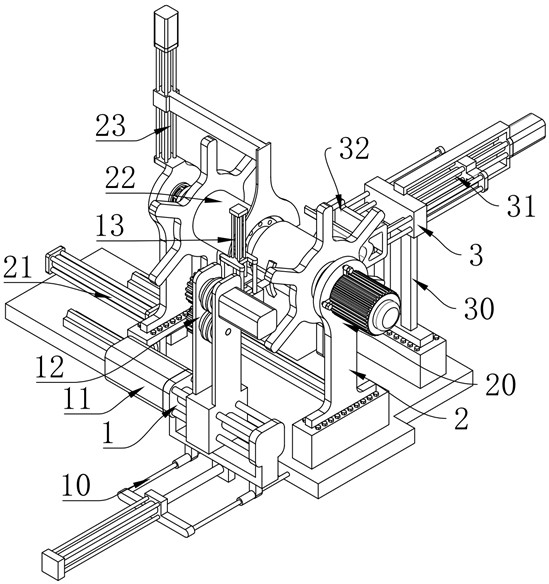

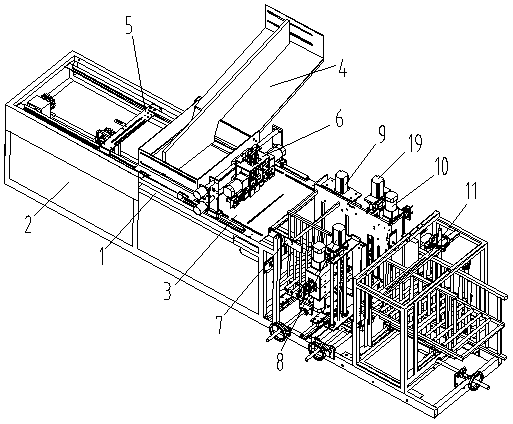

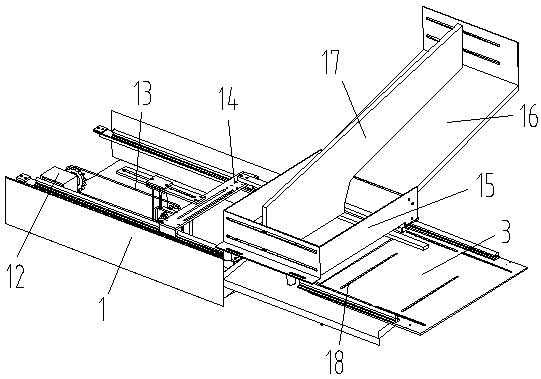

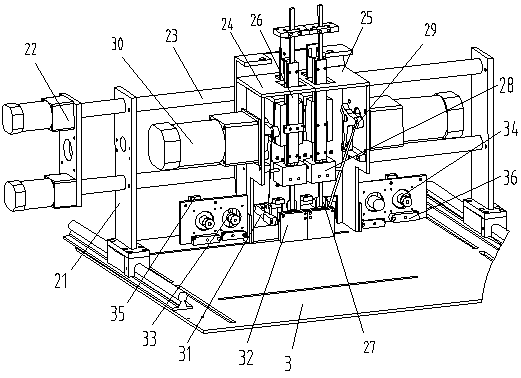

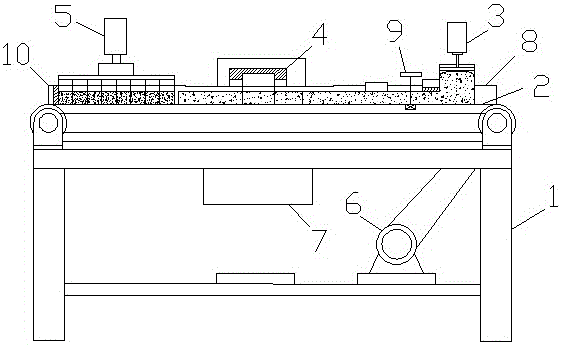

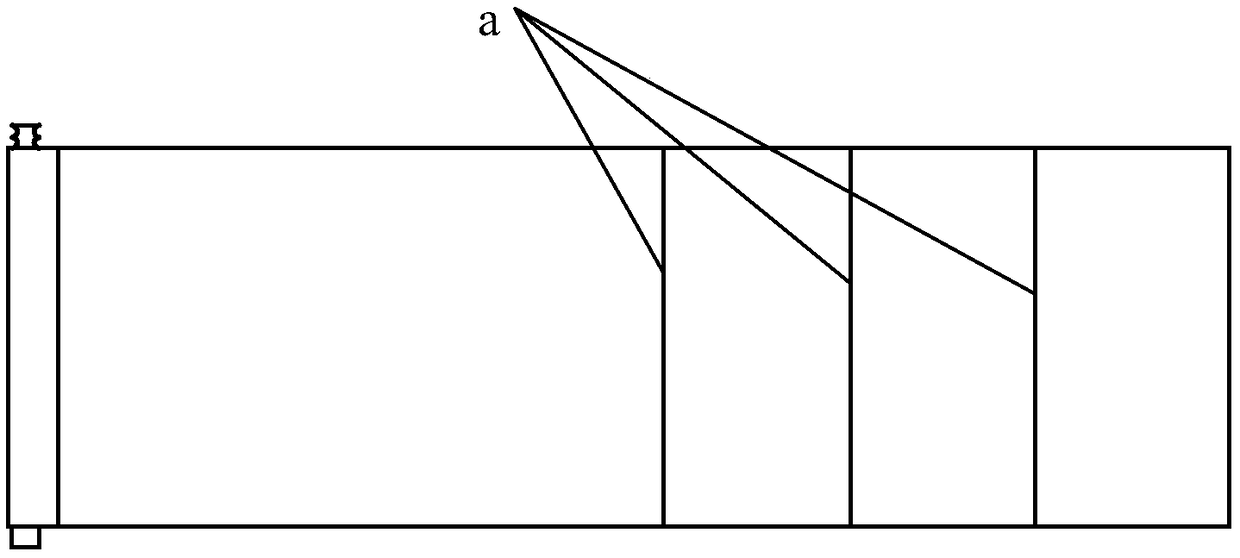

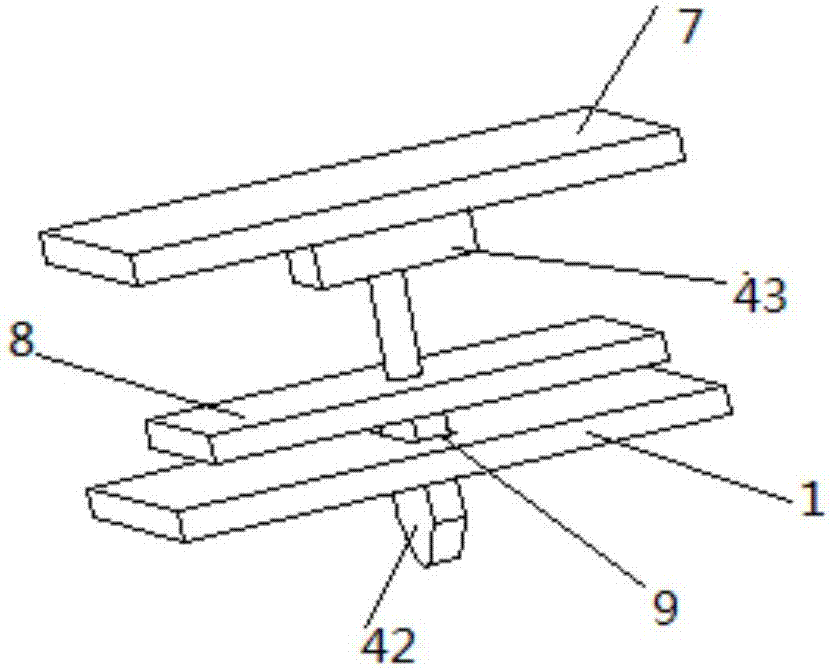

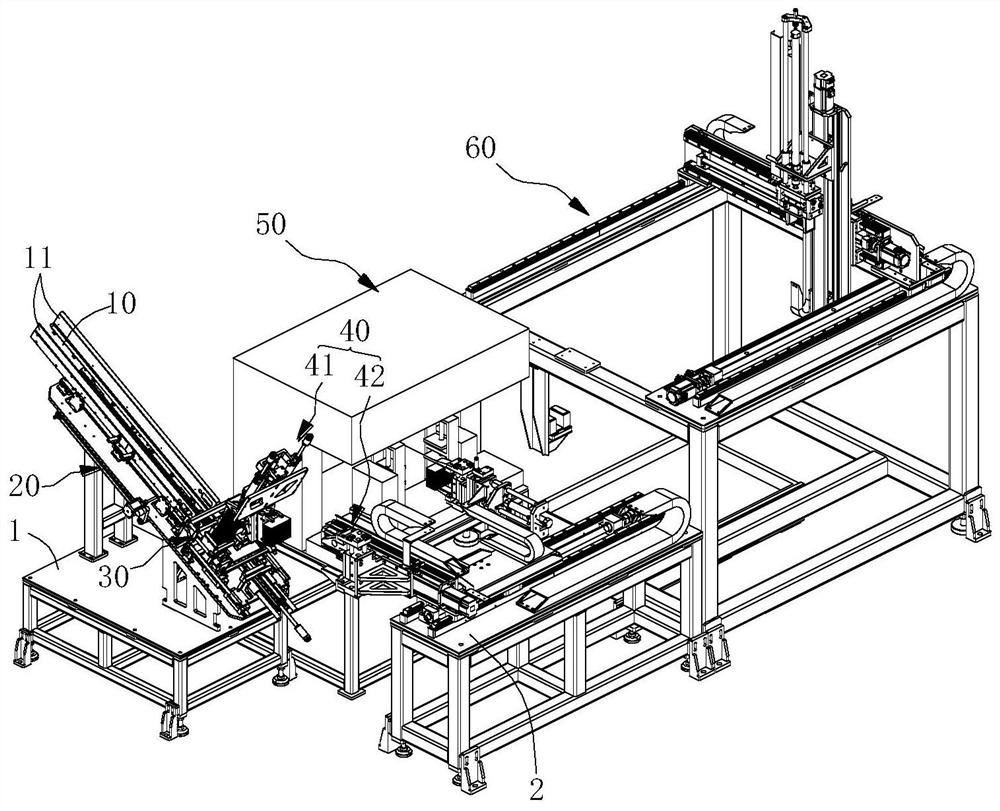

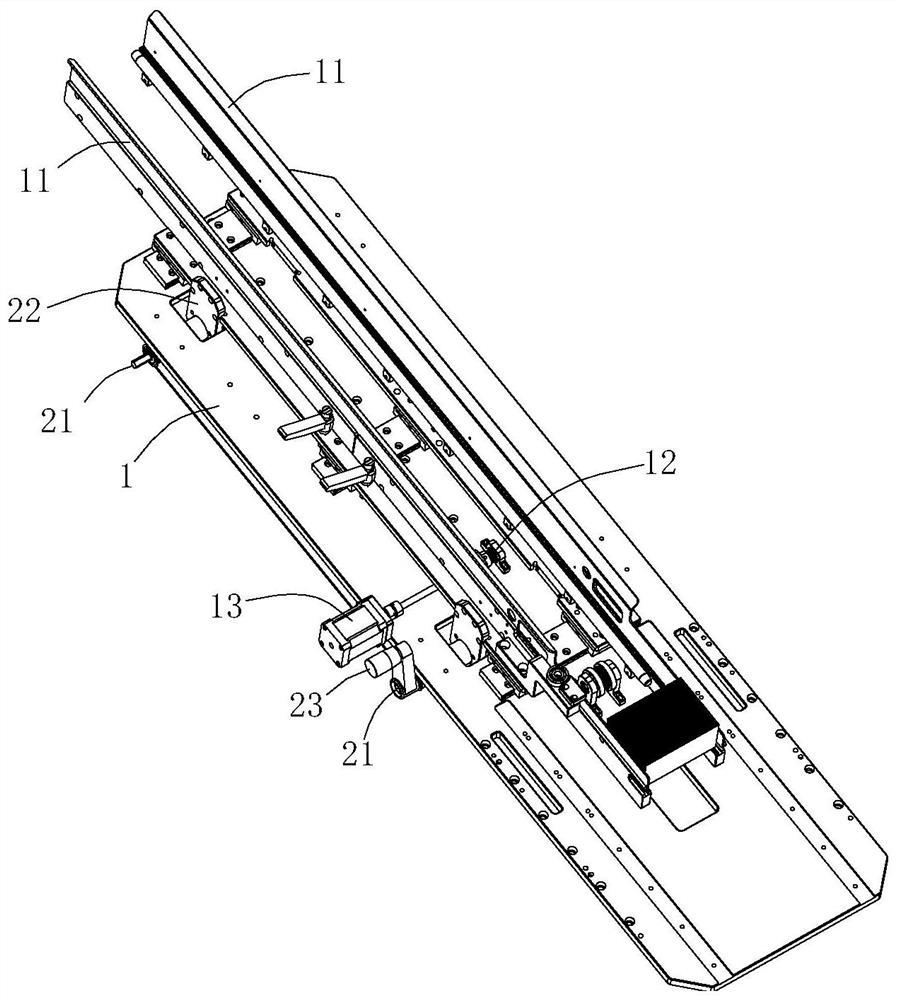

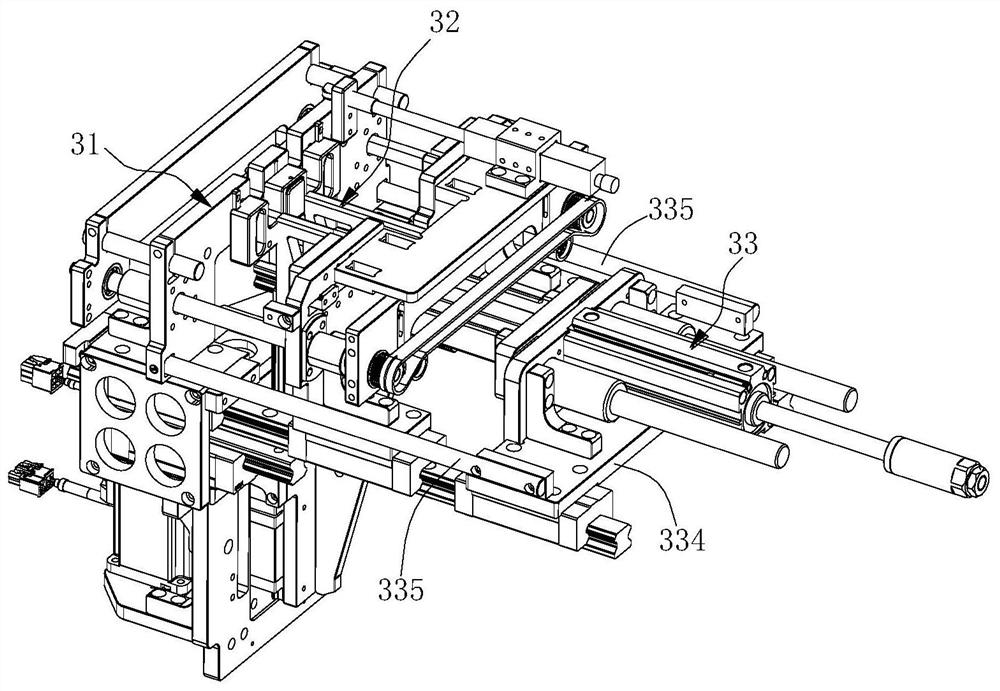

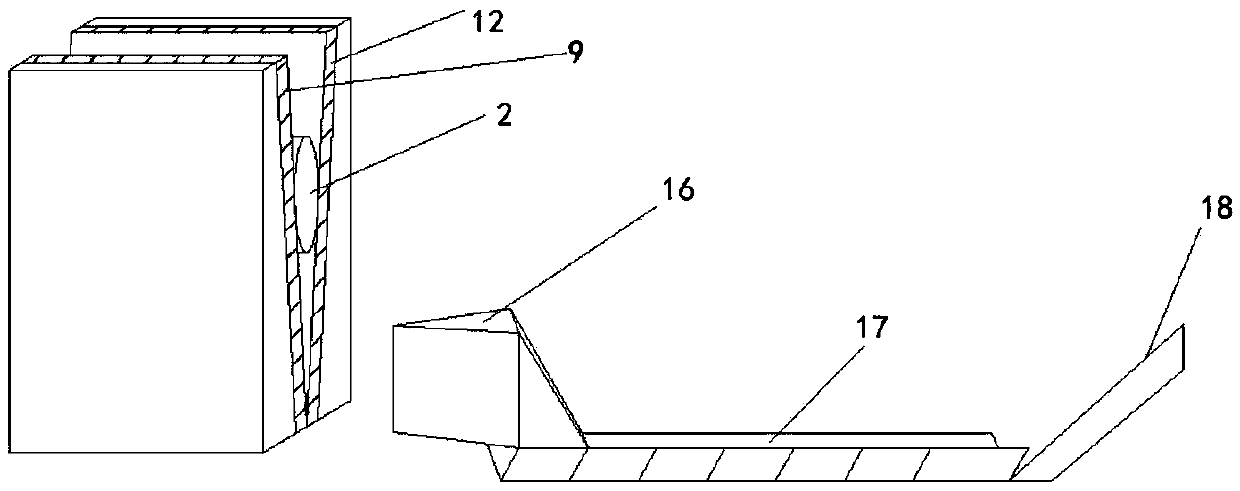

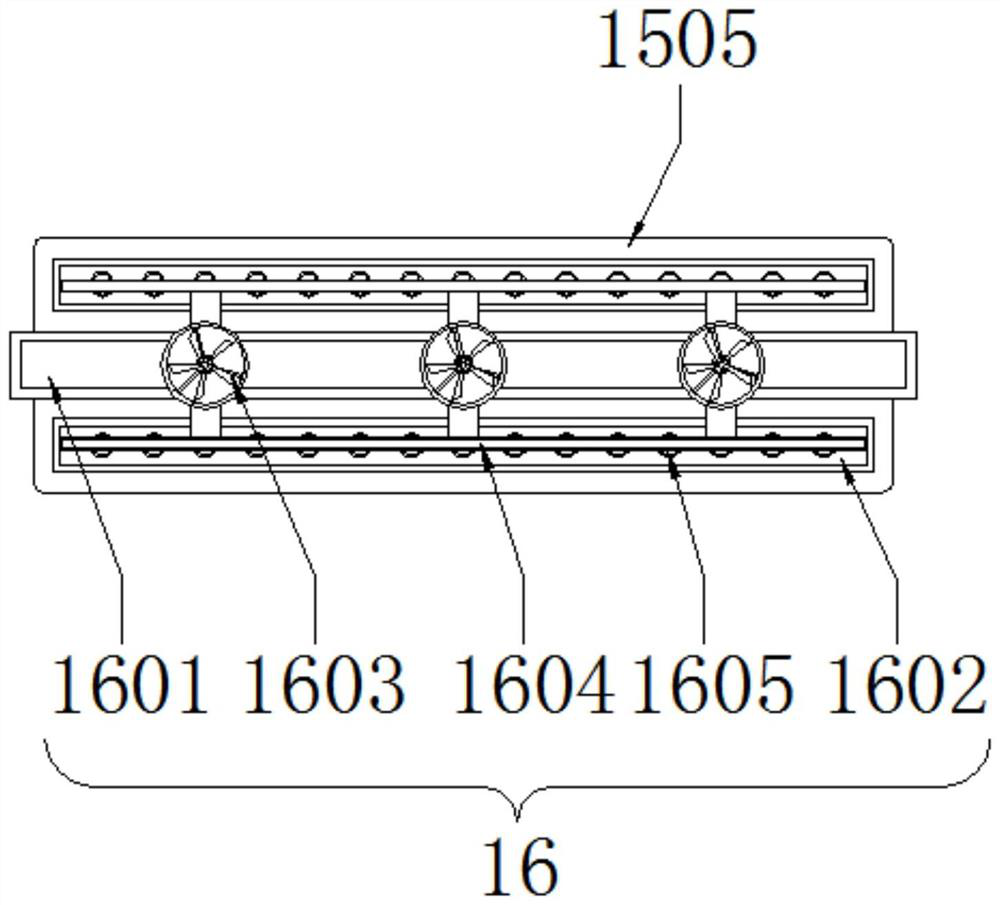

Moso bamboo cutting production line

InactiveCN107803898ARealize slittingRealize de-sectionCane mechanical workingProfiling/shaping machinesProduction lineRaw material

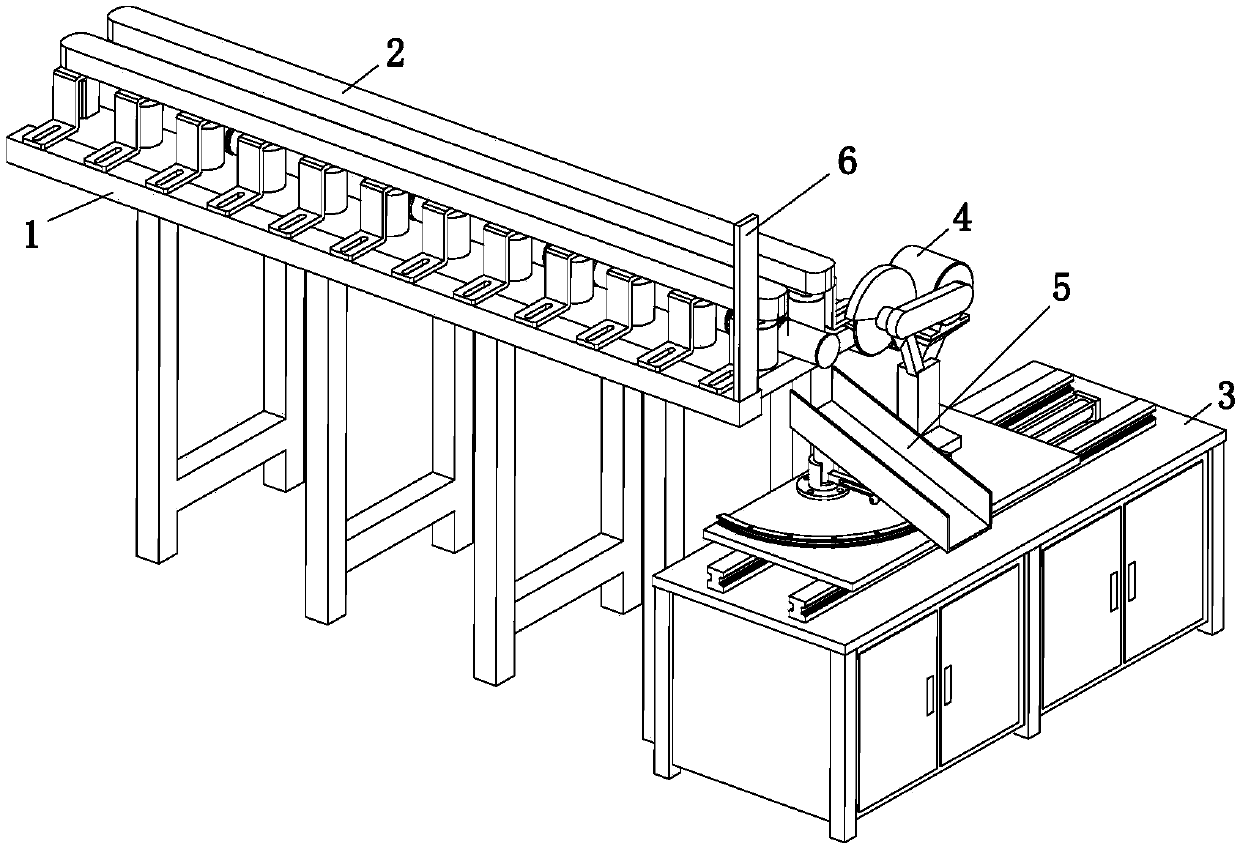

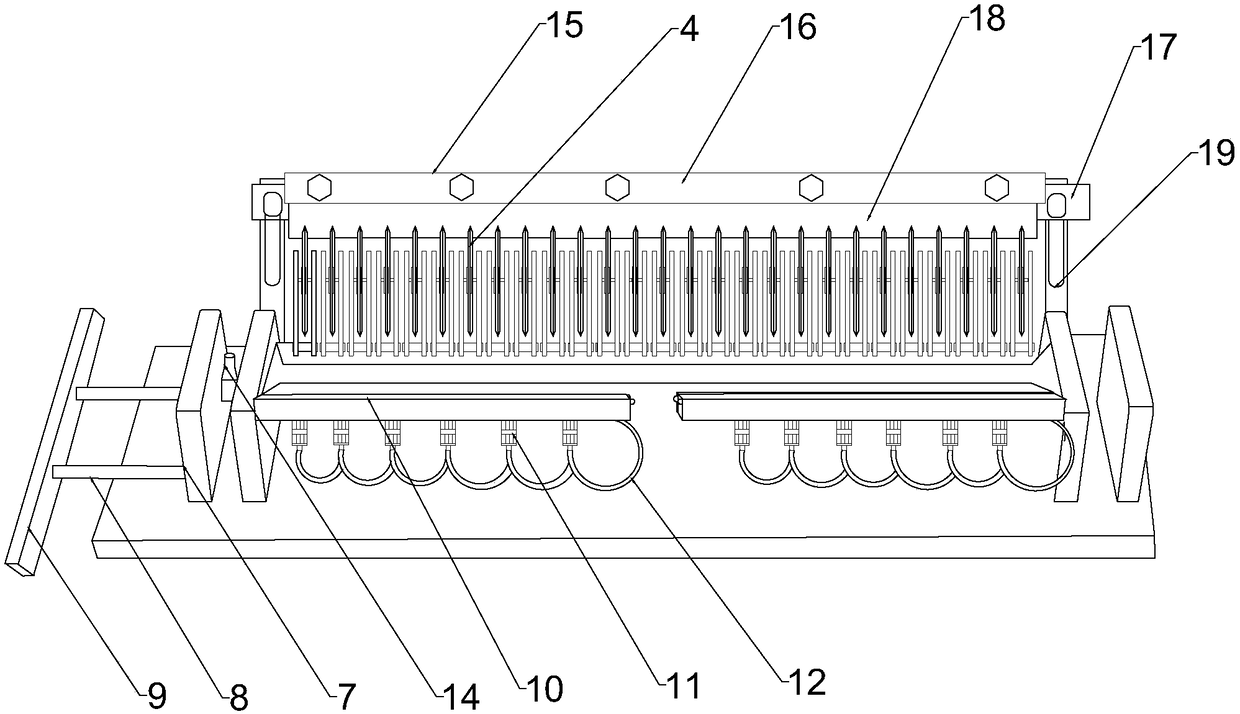

The invention relates to the field of bamboo product production, in particular to a moso bamboo cutting production line. The moso bamboo cutting production line comprises a strip-shaped raw material table, a processor and a control device. A feeding end and a discharging end are arranged at the two ends of the raw material table correspondingly. A pushing device used for pushing moso bamboo to thedischarging end from the feeding end is arranged on the raw material table. A bamboo joint position detecting device is arranged at the position, close to the discharging end, of the raw material table. A cutting table is further arranged on the side close to the discharging end of the raw material table. A cutting machine capable of horizontally moving in the direction perpendicular to the pushing direction of the pushing device is arranged on the cutting table. A separating device moving synchronously with the cutting machine is arranged at the position, located below a cutting knife of thecutting machine, of the cutting table. The moso bamboo cutting production line can achieve automatic bamboo pole slitting and joint removing, and the work efficiency can be greatly improved.

Owner:NINGBO FENGHUA ZHINIU AUTOMATION EQUIP DESIGN CO LTD

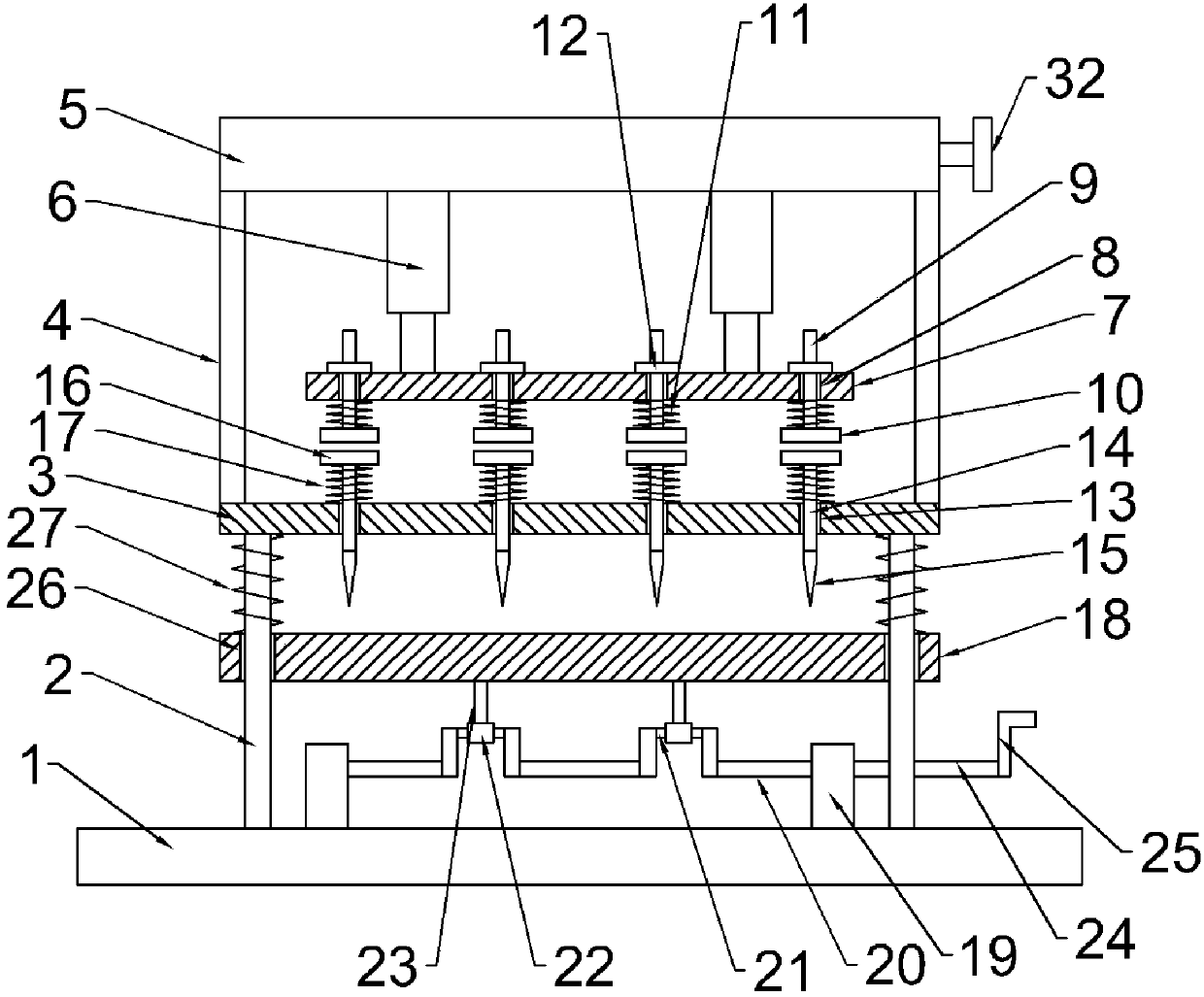

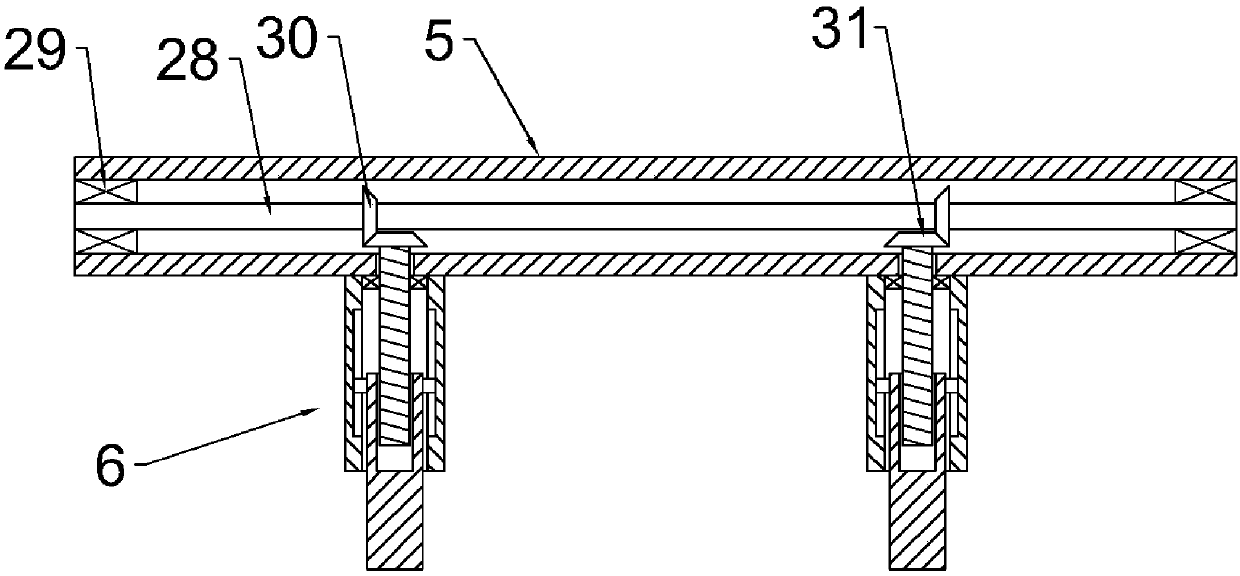

Slitting device for manual steamed bun making

InactiveCN107650174AAdjustable lengthRealize slittingMetal working apparatusArchitectural engineering

The invention discloses a cutting device for handmade steamed buns, which comprises a bottom plate, a support column, a support plate, a support rod, a support cylinder, a telescopic rod, a mounting plate, and a mounting hole. Studs are inserted in the mounting holes, and the studs A pressing block is installed at the lower end, and a first spring is arranged between the pressing block and the mounting plate. Vertical bar, the lower end of the vertical bar is disassembled and installed with a cutter, the top of the vertical bar is installed with a top plate, a second spring is arranged between the top plate and the supporting plate, and a bearing plate is arranged between the supporting plate and the bottom plate. The present invention can change the height position of the cutter through the telescopic rod to realize the slitting of dough with different thicknesses. The first spring can adjust the pre-tightening force of the pressing plate, and the second spring can make the cutter not in use. When it is on the top of the lower section of the support plate, the cutter is only at a lower position when in use, with high safety performance.

Owner:姜伟龙

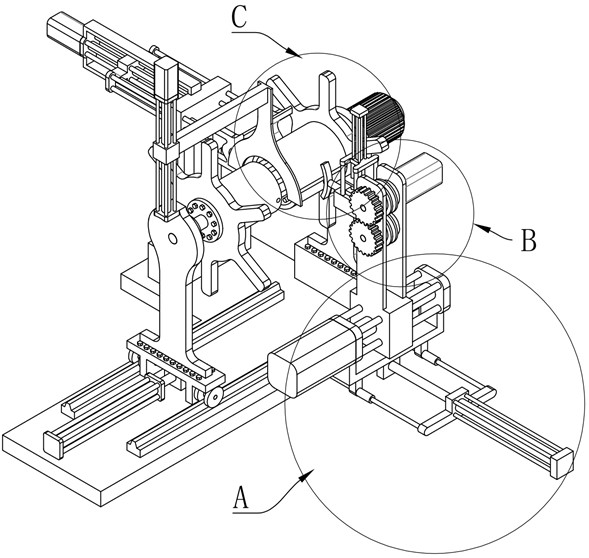

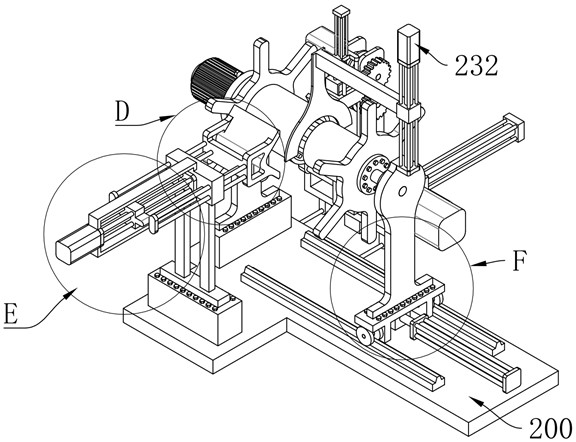

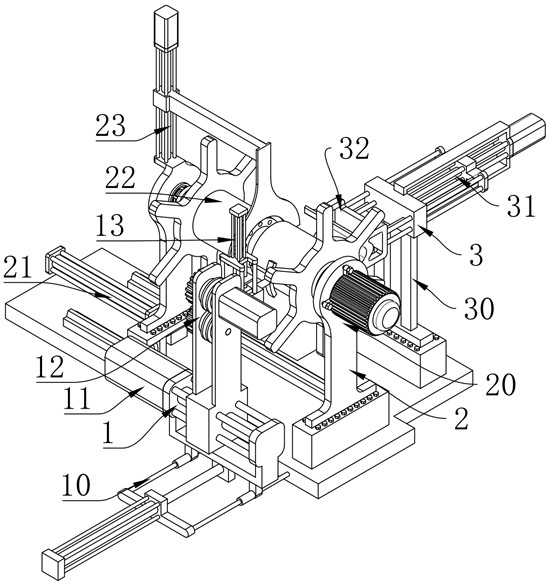

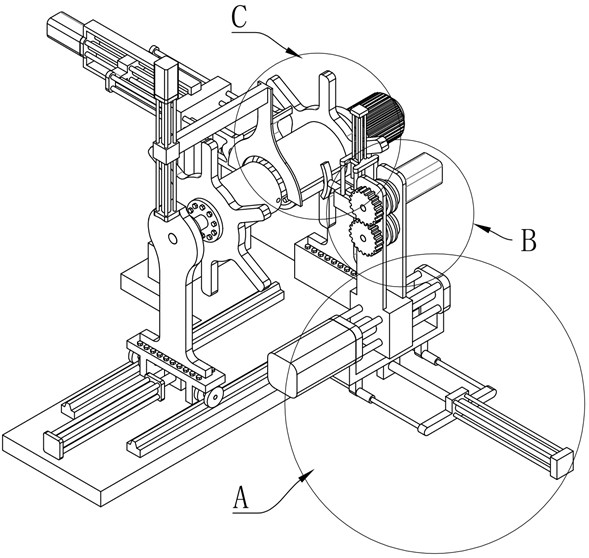

Cutting device for adult incontinence underpants finished product

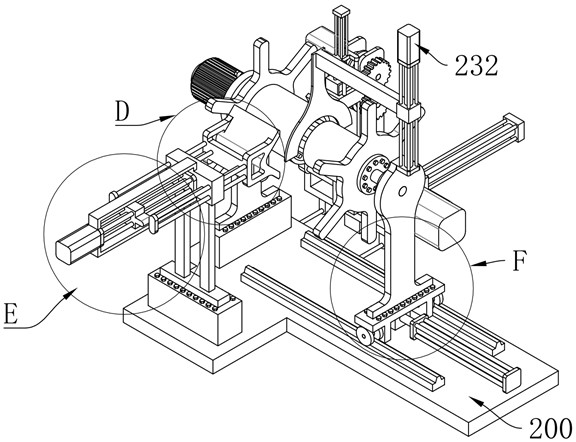

ActiveCN100408284CRealize slittingEnsure precise engagementMetal working apparatusGear wheelEngineering

The invention relates the shutoff device and method used for adult incontinence trouser. Bed plate axes is in axle hole of case plank, bed plate block is fixed on bed palte axes, cutter axes is in axle hole of case plank, blade is fixed on cutter axes and contacted with bed plate block, bed plate axes engages with the cutter axes by gears, and they turn at the same time. The invention has the following advantages: realizing the cut between adult incontinence trouser and finished product; the design of regulating gear insures the precise mesh to avoid the shortage of cutter displacement; the adjustment of cutter phase insures that the cutter cuts on the embossing part.

Owner:ZHEJIANG YONGCHUANG MACHINERY

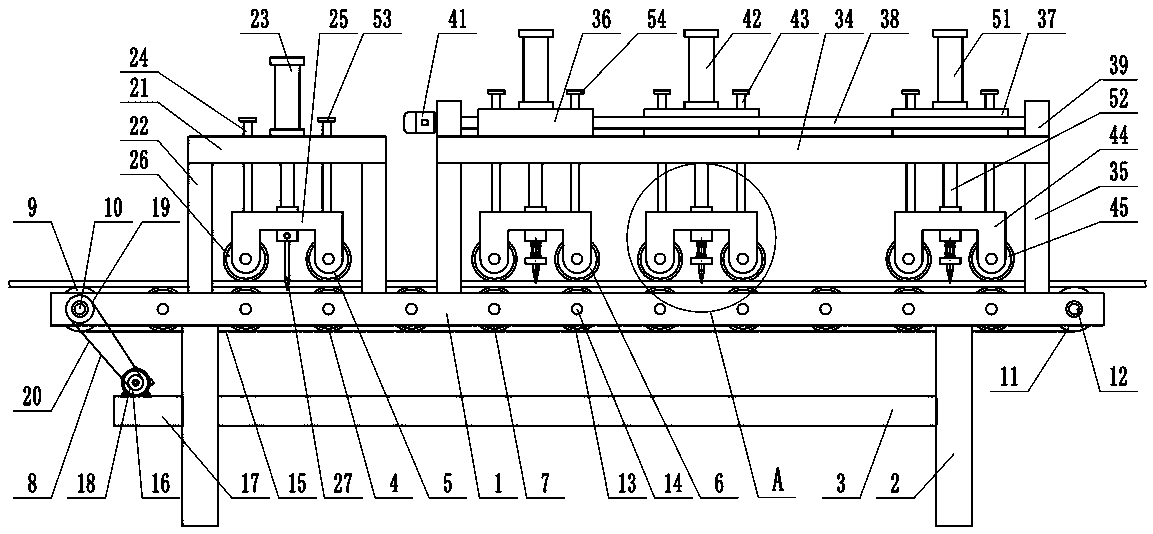

Corrugated board slitting and indenting machine

PendingCN110027247AImprove the support effectCause pressure lossBox making operationsPaper-makingEngineeringMechanical engineering

The invention provides a corrugated board slitting and indenting machine, and belongs to the technical field of corrugated paper box processing. The corrugated board slitting and indenting machine comprises a conveying device, a slitting device and indenting devices, wherein the conveying device comprises a conveying support assembly and a conveying drive assembly; two slitting press rollers of the slitting device can be rotatably arranged on two sides of the lower end of a slitting frame; a slitting tool rest can be arranged on the slitting frame in a front-and-back sliding way; a slitting screw rod is connected with a slitting tool rest screw rod; a slitting cutter is arranged under the slitting tool rest; the more than two indenting mechanisms are arranged in a front-and-back staggeringway; indenting sliding seats of the indenting mechanisms are arranged on indenting sliding guide rods in a left-and-right sliding way; indenting screw rods are connected with indenting sliding seat screw rods; indenting press rollers can be rotatably arranged on two sides of the lower ends of indenting frames; and indenting cutter handles are arranged on indenting tool rests in an up-and down sliding way. According to the corrugated board slitting and indenting machine provided by the invention, corrugated boards can be quickly slit and indented, and an indenting position is adjustable relative to a slitting position.

Owner:浙江东恒控股股份有限公司

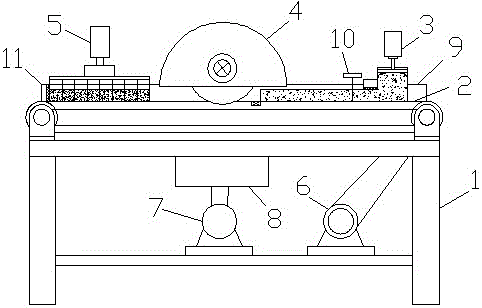

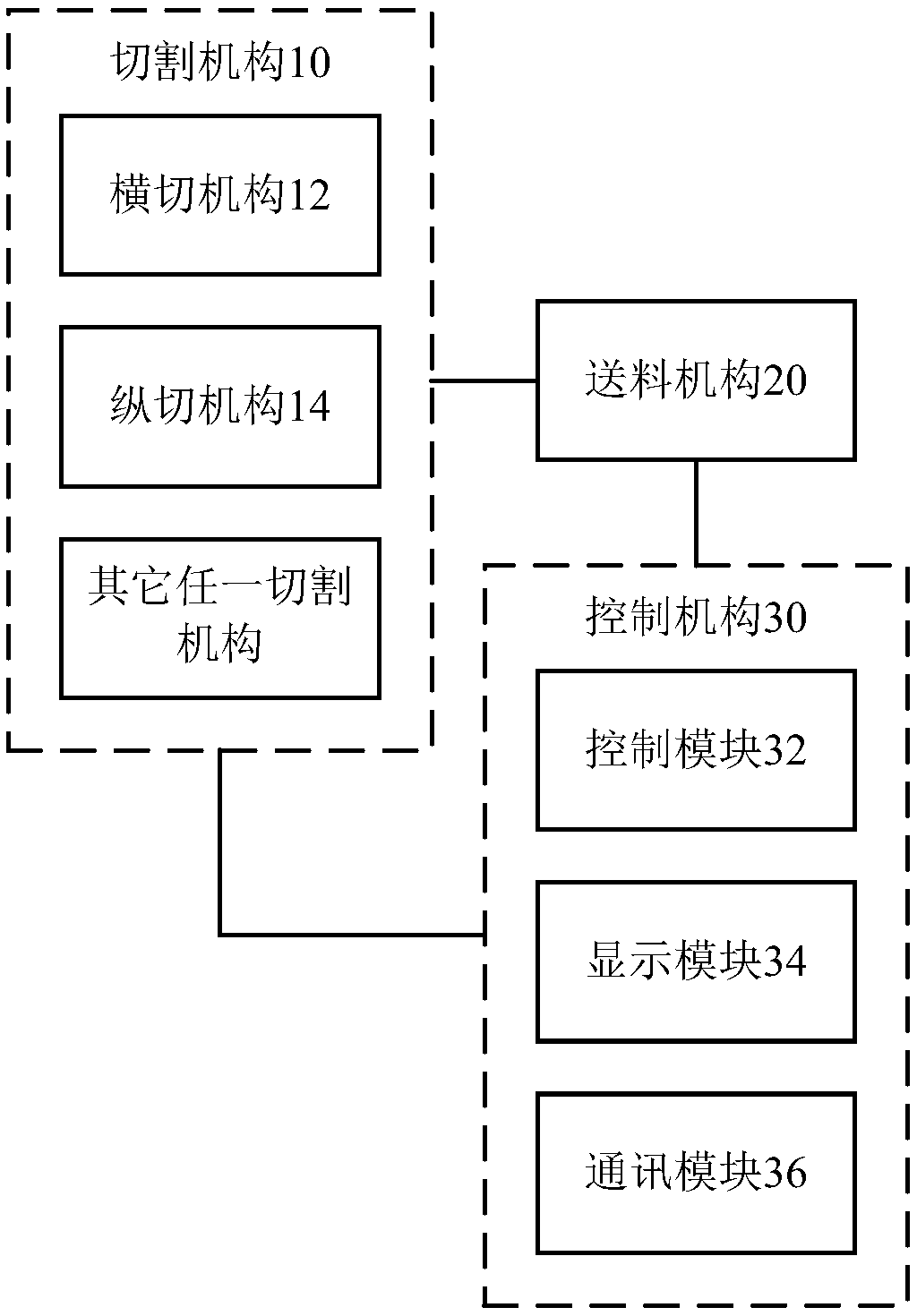

Film roll cutting device and control method thereof

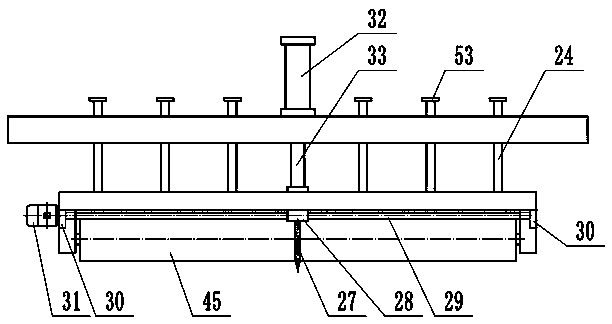

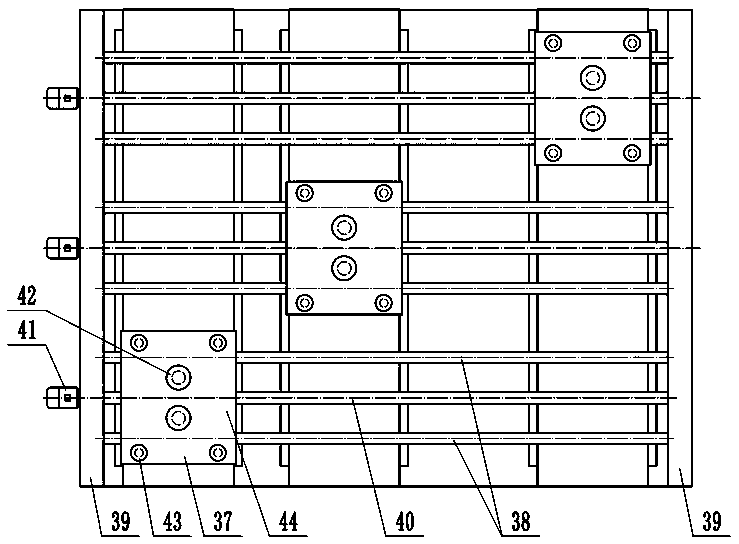

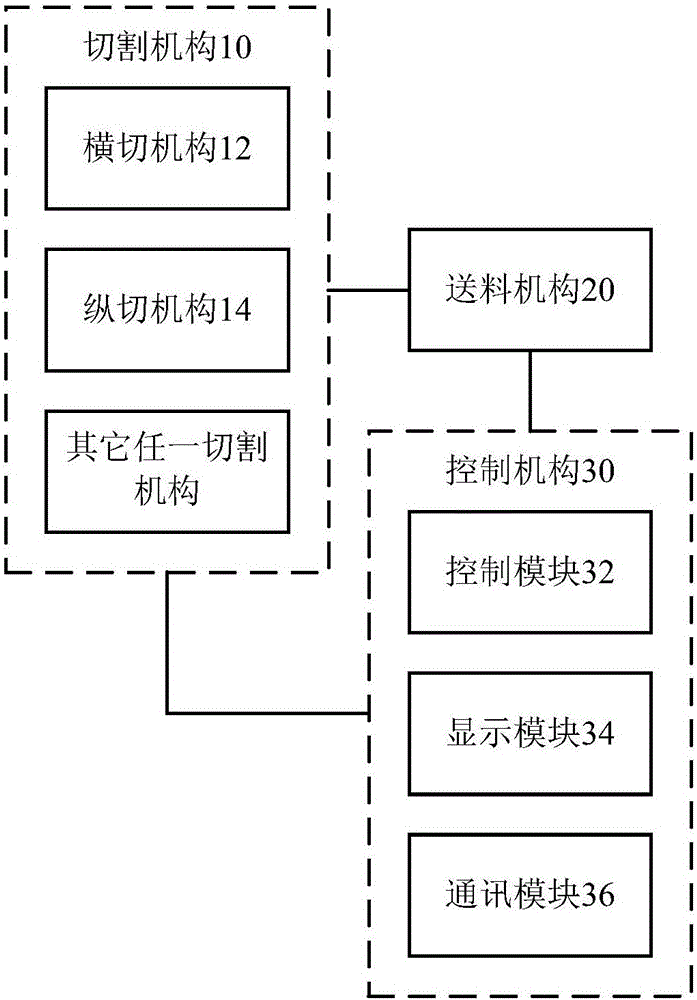

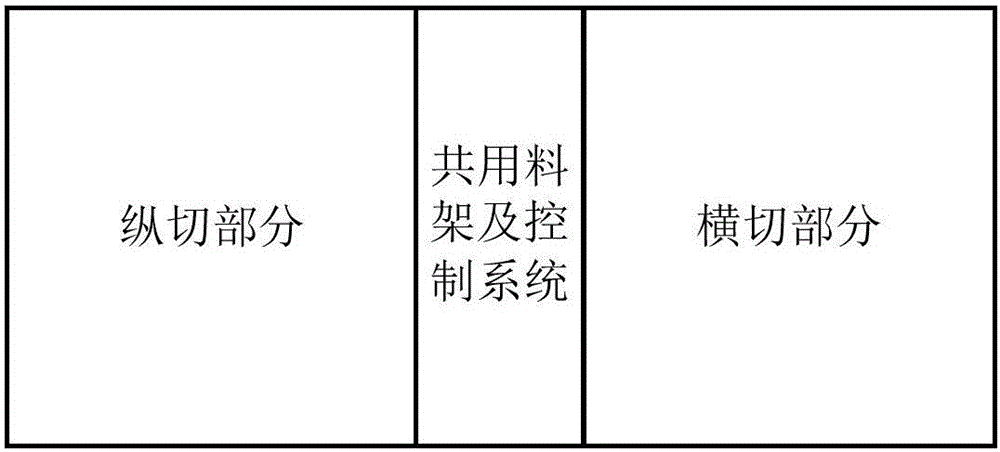

ActiveCN106698054ARealize slittingImprove convenienceFunction indicatorsArticle deliveryEngineeringMechanical engineering

The invention discloses a film roll cutting device and a control method thereof. The film roll cutting device comprises two or more cutting mechanisms, a feed mechanism and a control mechanism. The two or more cutting mechanisms and the feed mechanism are arranged in a matched mode, and the two or more cutting mechanisms are used for cutting a film roll in any of preset two or more kinds of cutting modes. The feed mechanism is used for loading the film roll and conveying the film roll to any cutting mechanism. The control mechanism and the two or more cutting mechanisms as well as the control mechanism and the feed mechanism are arranged in a matched mode, and the control mechanism is used for controlling any cutting mechanism and the feed mechanism to achieve cutting of the film roll in any cutting mode. By adoption of the scheme, the detects that in the prior art, use is inconvenient, the working efficiency is low, and the cost is high can be overcome, and the beneficial effects of convenient use, high working efficiency and low cost are achieved.

Owner:GREE ELECTRIC APPLIANCES INC

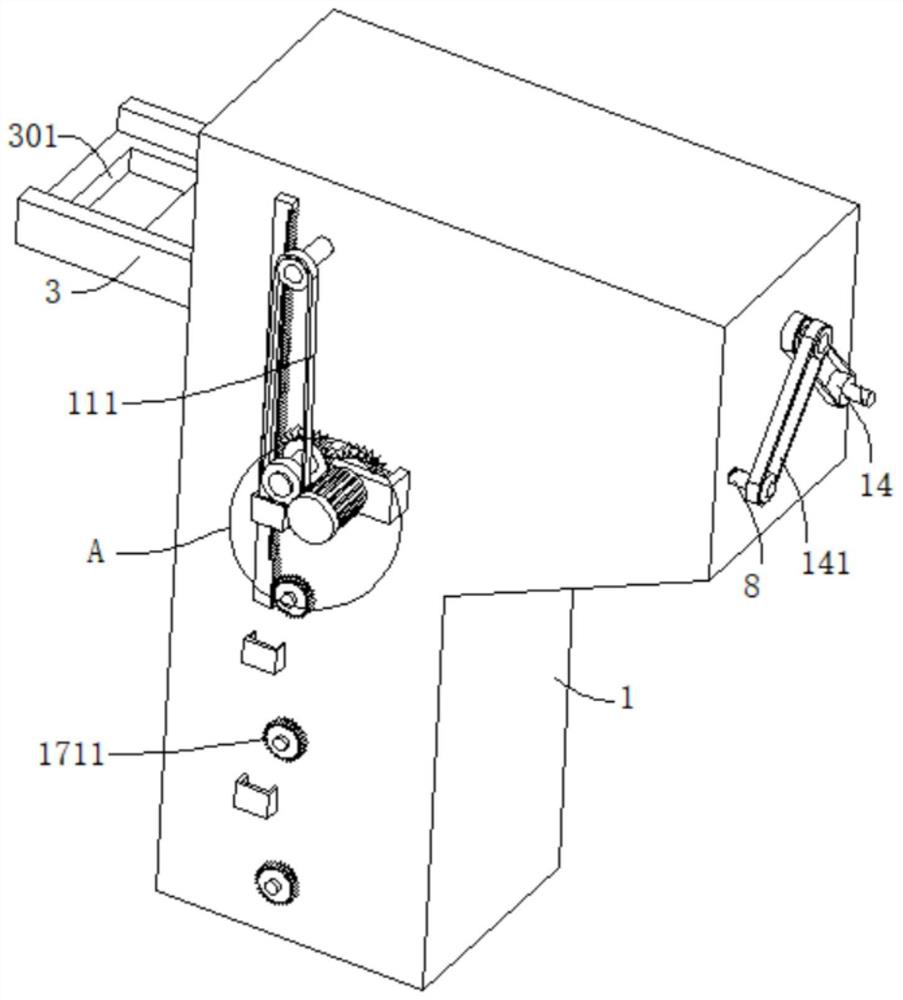

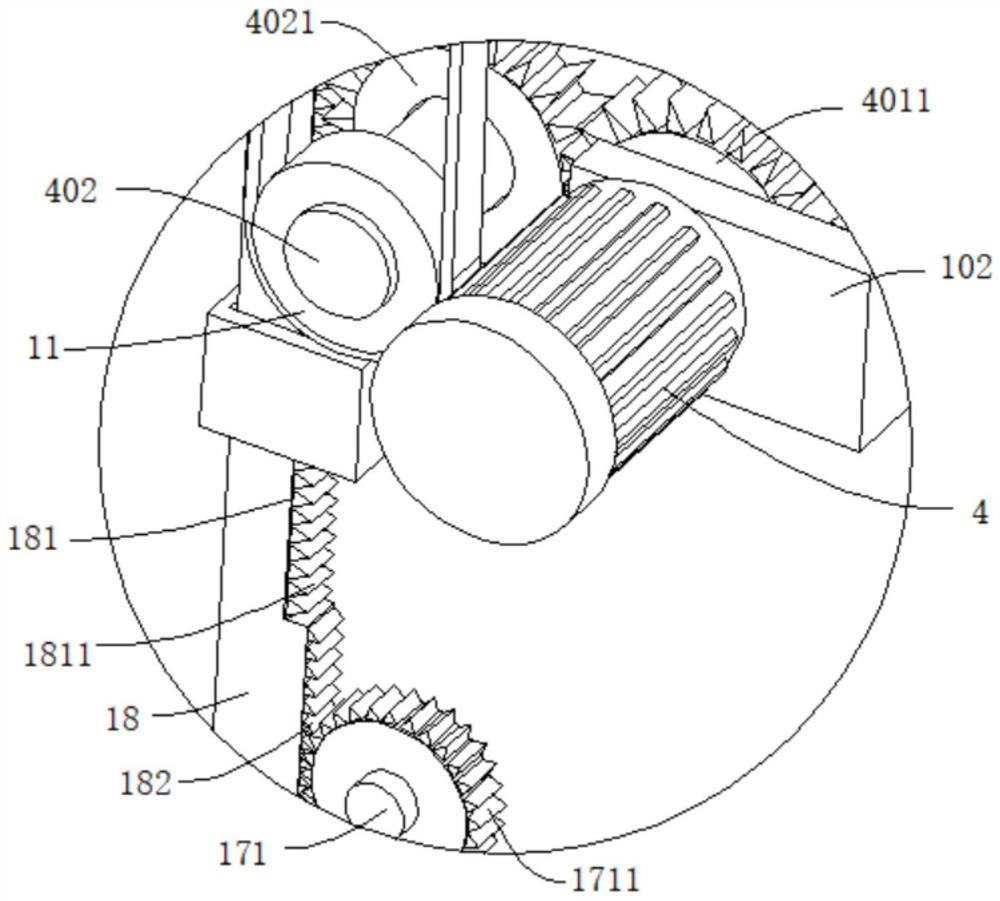

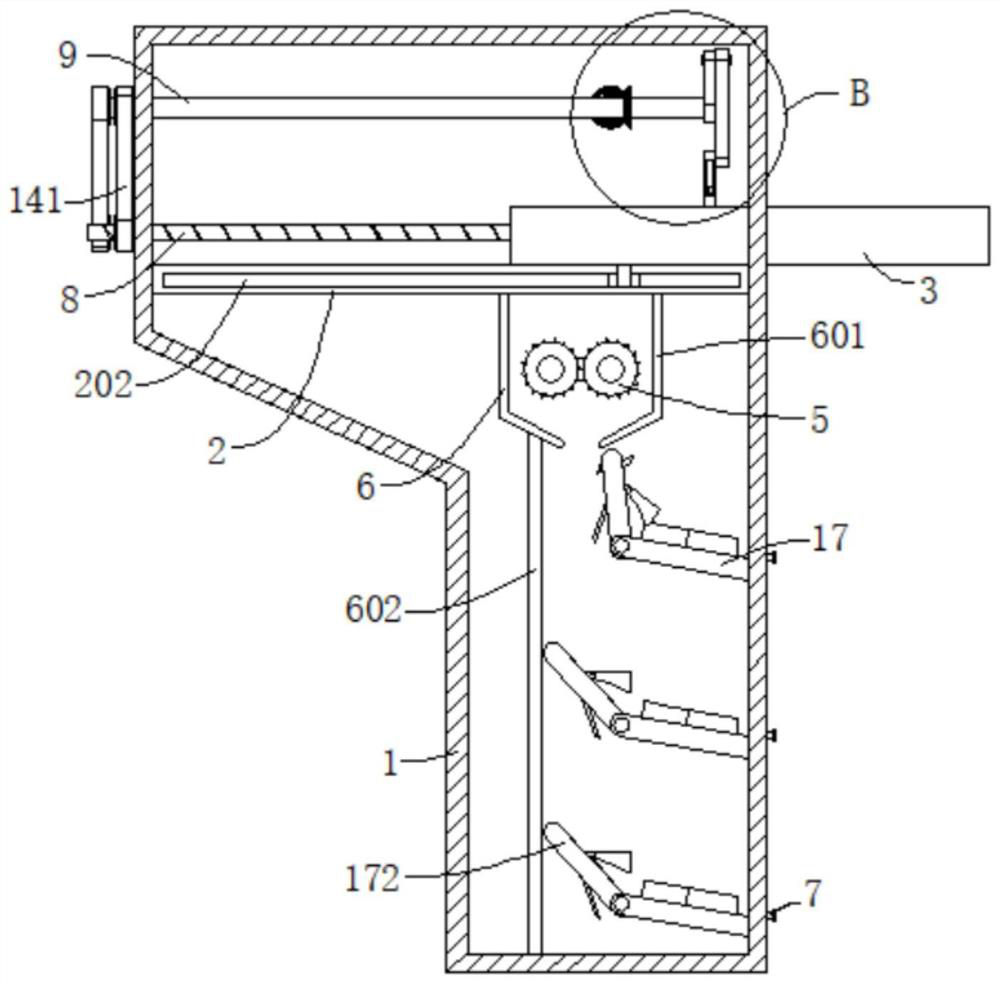

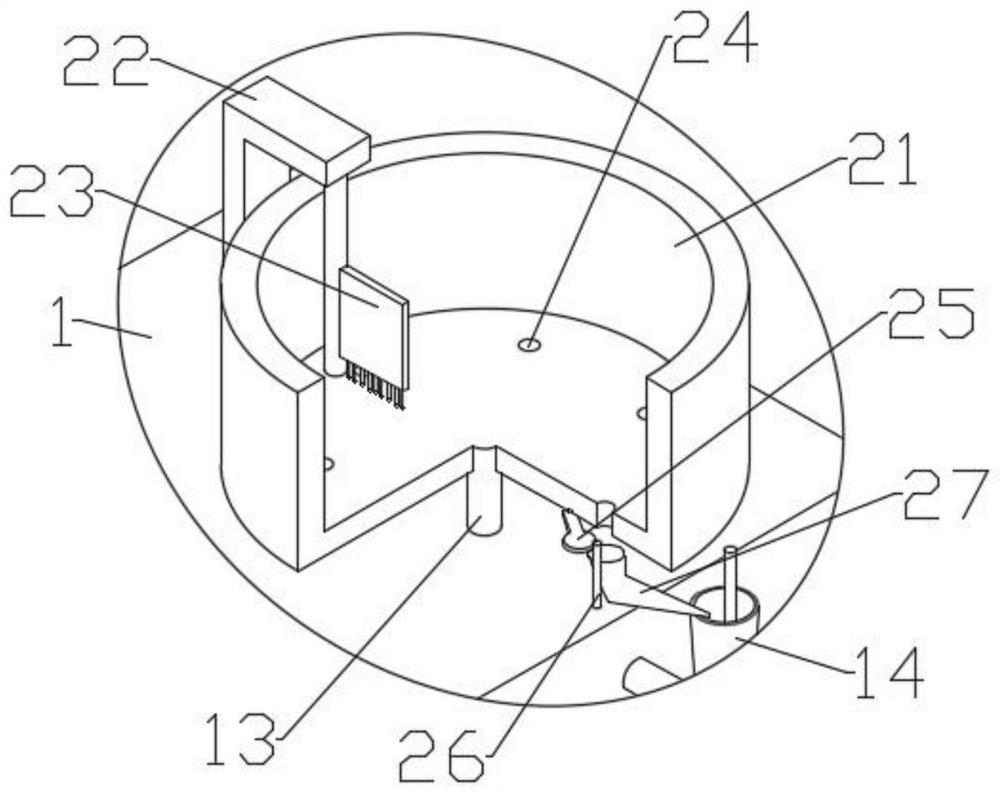

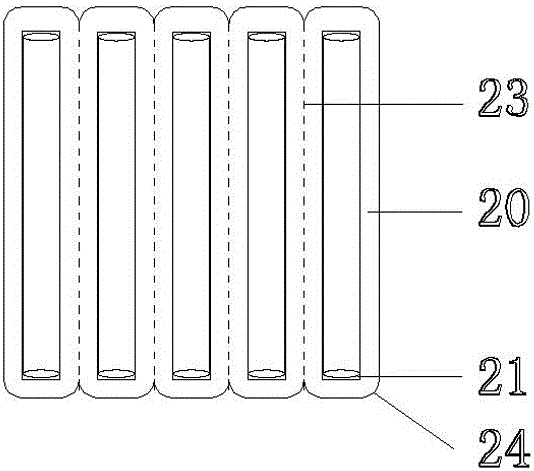

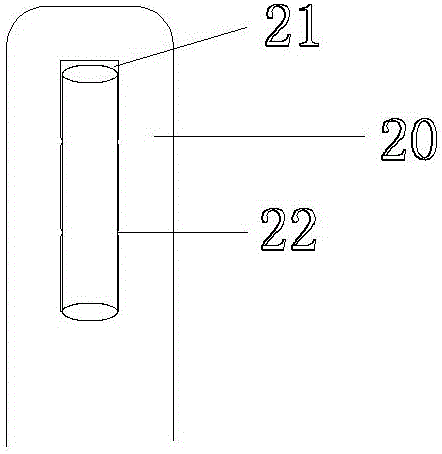

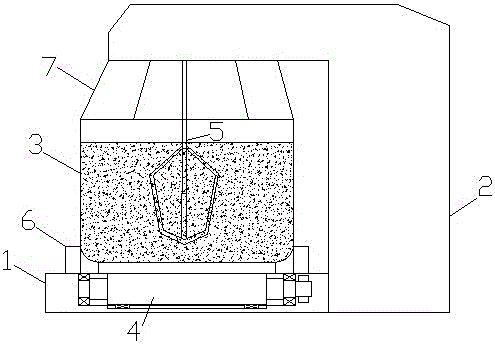

Sample preparation device for food safety detection

ActiveCN112857931AReduce security testing costsReduce manufacturing costPreparing sample for investigationFood safetyGear wheel

The invention discloses a sample preparation device for food safety detection, and belongs to the technical field of food safety detection. The sample preparation device for food safety detection comprises a sample preparation box, the inner wall of the sample preparation box is fixedly connected with a fixing plate, an inlet is formed in the outer wall of the sample preparation box and located above the fixing plate, the inner wall of the sample preparation box is further rotationally connected with a lead screw and a rotating shaft, the outer wall of the lead screw is in threaded connection with a placement plate, and the placement plate is slidably connected to the outer wall of the fixing plate, the outer wall of the rotating shaft is connected with a cutting mechanism, the cutting mechanism is arranged above the placement plate, through holes are formed in the outer wall of the fixing plate, three blanking openings matched with the through holes are formed in the outer wall of the placement plate, the outer wall of the sample preparation box is connected with a supporting seat, the outer wall of the supporting seat is connected with a motor, and the output end of the motor is connected with a first rotating shaft, a first gear is connected to the outer wall of the first rotating shaft; the device is simple in structure, the manufacturing cost of the device is reduced, the food safety detection cost is further reduced, and the actual use requirements can be met.

Owner:深圳信测标准技术服务有限公司

Building tile cutting device

InactiveCN106584682ARealize slittingEasy to operateStone-like material working toolsArchitectural engineeringBuilding construction

The invention provides a building tile cutting device and belongs to the technical field of construction equipment. The building tile cutting device solves the problem that the existing building tile cutting quality is poor. The building tile cutting device comprises a bottom plate and a swing frame. Buffer columns are arranged on the bottom plate. The swing frame is hinged to the bottom plate. A guide rail is fixedly connected to the swing frame and slidably connected with a tool bar. A tool bit is fixedly connected to the lower end of the tool bar. A pressing piece is arranged on the bottom plate. An abutting protruding edge is arranged on the bottom plate. The tool bit is located over the abutting protruding edge. Two guide sleeves are fixedly connected to the swing frame. A pressing rod is slidably arranged in each guide sleeve in a penetrating manner. A pressing disc is fixedly connected to the lower end of each pressing rod. Each transmission piece is arranged between the tool bar and the corresponding pressing rod. By the adoption of the building tile cutting device, the building tiles can be cut off quickly, and operation is convenient and fast.

Owner:ZHEJIANG OCEAN UNIV

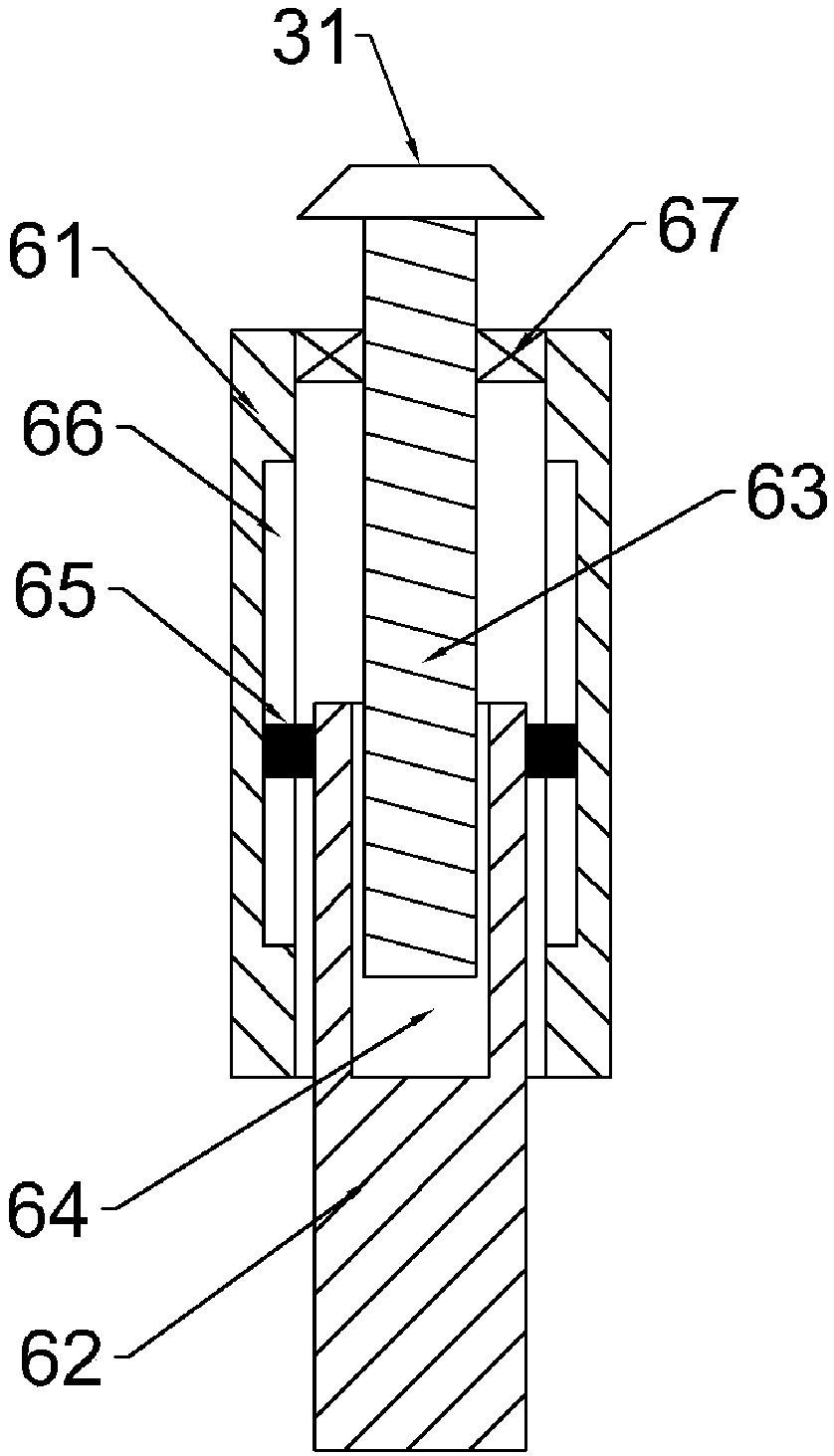

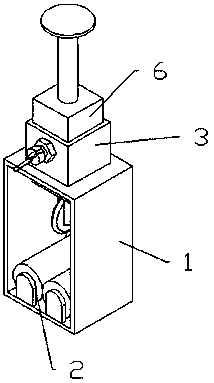

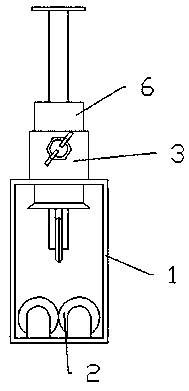

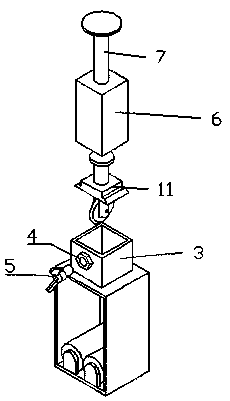

Thread stripper

PendingCN109193481ANot easy to slide outRealize slittingApparatus for removing/armouring cablesEngineeringScrew thread

A thread stripper includes a support frame, roller, guide groove, Retaining nut, Fastening pin, guide pillar, Push rod, rectangular bayonet, cylindrical groove, stripping body, wherein the support frame is of a rectangular structure, at that bottom of the inn wall of the supporting frame are arranged two rotating rollers of the same size, the two rollers are axially parallel and the outer walls are tangent, a guide groove of a rectangular structure is vertically arranged on the top of the support frame, the guide groove penetrates the top surface of the support frame vertically, a fixing nut is arranged on the outer wall of the guide groove, the fastening pin is threadably connected with the fixing nut, the guide pillar of the rectangular structure is slidably connected with the guide groove vertically, and a push rod in a vertical direction is fixed on the top of the guide pillar. The invention realizes the longitudinal cutting and the ring cutting of the electric wire, changes the single function of the traditional stripping tool, and realizes the dual-purpose function of one device.

Owner:枣庄京弘电力材料股份有限公司

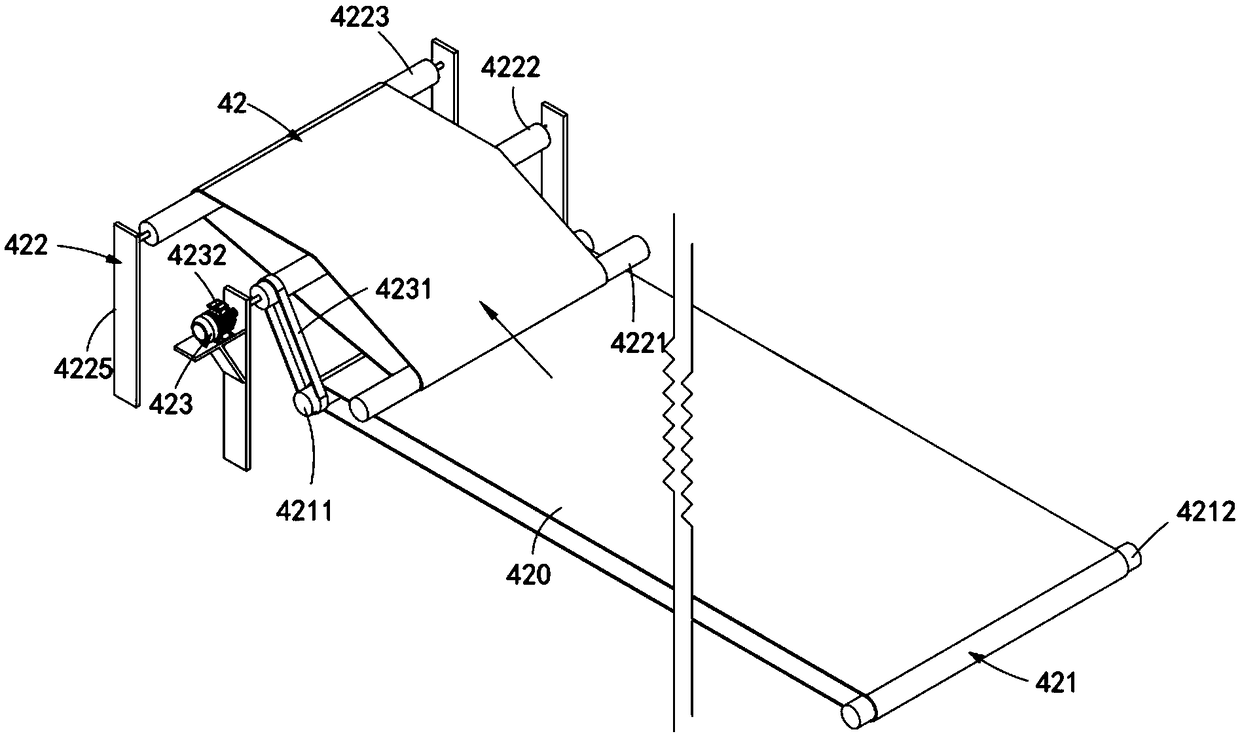

Packaging production method of water-soluble film product

ActiveCN113086259ARealize opening and closingRealize quantitative outputWrapper twisting/gatheringSolid materialSoluble FilmElectric machinery

The invention discloses a packaging production method of a water-soluble film product. The packaging production method comprises the following steps that powder is put into a quantitative discharging mechanism; a driving shaft drives a rotating plate to rotate along a rotating groove through an opening and closing mechanism, so that a pair of electric heating plates conduct opening and closing movement, and after the electric heating plates are attached, a bottom transverse opening and side openings of a packaging bag strip are subjected to heat sealing; a motor drives the driving shaft to rotate to enable the electric heating plates to seal the bottom and the side walls of the packaging bag strip, the quantitative discharging mechanism intermittently and quantitatively puts powder into a hopper, and the hopper guides the powder into the packaging bag strip with the sealed bottom and the sealed side edges; the electric heating plates separate and loosen the packaging bag strip, meanwhile, the driving shaft drives a conveying mechanism to pull the packaging bag strip in a linkage manner, the filled powder moves to the bottoms of the electric heating plates, the electric heating plates are closed again to seal the packaging bag strip at the top of the powder, and the multiple products are continuously and hermetically packaged on the packaging bag strip; and the conveying mechanism conveys and enables the packaged products to enter a cut-off mechanism, and the driving shaft drives the cut-off mechanism to cut off packaging bag strips between the adjacent products in a linkage manner.

Owner:干将新材料有限公司

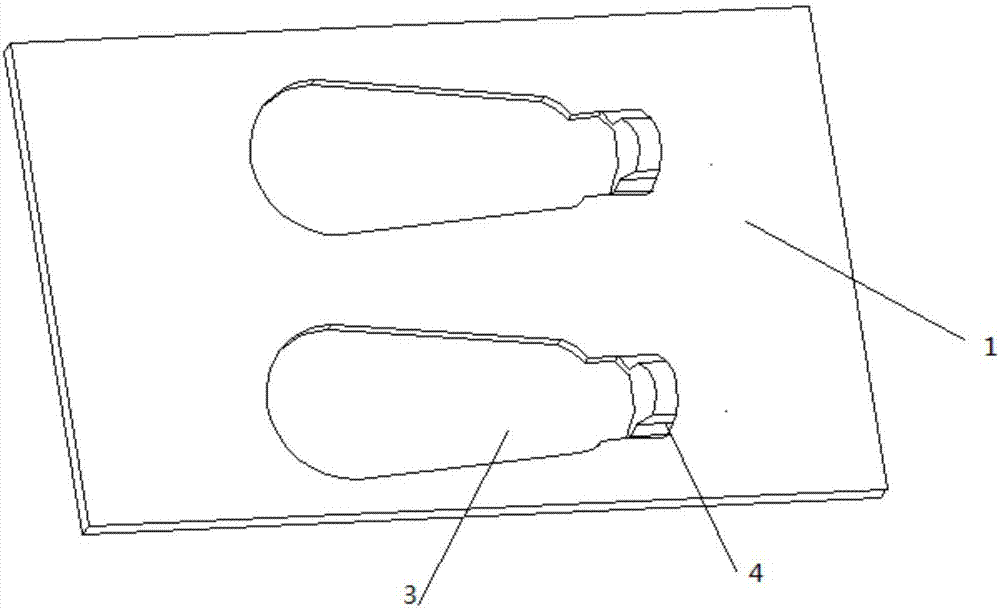

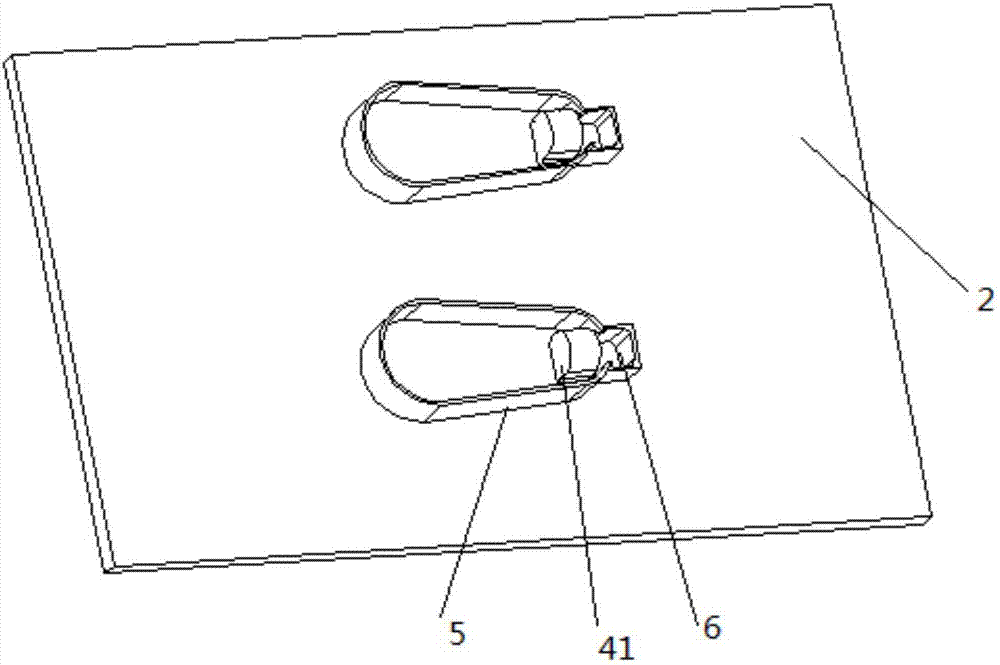

Damp-proof moisture-retention cigarette package structure and production equipment thereof

ActiveCN106697375AAvoid attenuationAvoid elevationPackaging cigaretteControl systemMechanical engineering

The invention provides a damp-proof moisture-retention cigarette package structure and production equipment thereof, relates to the technical field of cigarette package equipment, solves the problem that cigarettes are squeezed under the situation that a conventional cigarette package is adopted, and overcomes the defects that special-purpose production equipment with high integration level does not exist, the amount of required equipment is large, the operation is complicated, and the efficiency is not high. The production equipment specifically comprises a baseplate cutting and winding mechanism, an encapsulation layer printing and coating mechanism, a substrate unwinding and shaping mechanism, an encapsulation layer unwinding and paving mechanism and a package trimming mechanism, wherein the baseplate cutting and winding mechanism comprises a pneumatic device, a pneumatic cutter and a winding shaft; the pneumatic device is used for providing power to control the pneumatic cutter to rise and fall to perform cutting; the winding shaft is controlled by a variable-frequency variable-speed motor; the encapsulation layer printing and coating mechanism comprises a printing plate, a pressing and printing roll, a drying device and a coating roll. The production equipment provided by the invention is high in functional integration level, simple to operate, high in efficiency, high in shaping speed, good in shaping effect, high in cutting precision and high in working efficiency; and a control system is simple and reasonable in structure.

Owner:ENDIAN SCI & TECH DEV OF YUNNAN

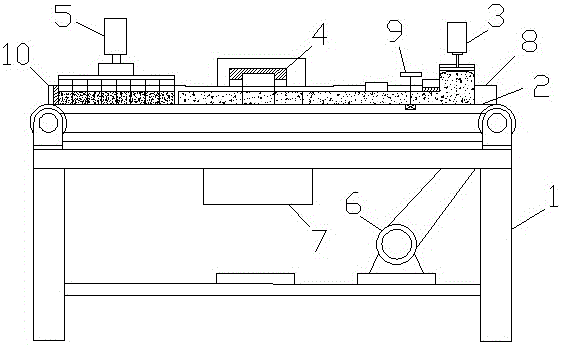

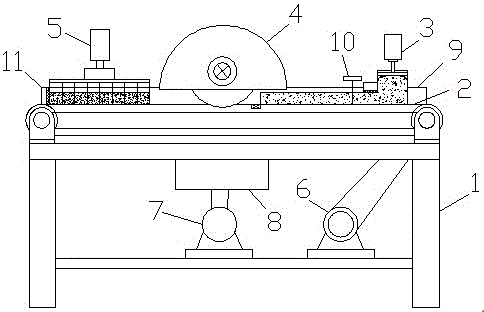

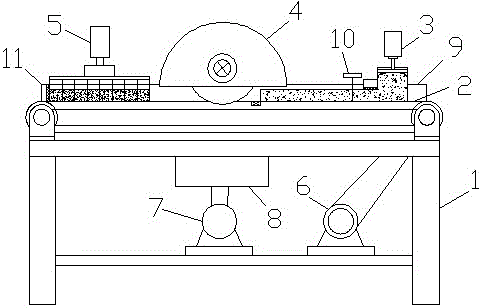

Efficient and safe noodle cutting device

The invention discloses an efficient and safe noodle cutting device. The noodle cutting device comprises an efficient and safe noodle cutting device stander, wherein a worktable is arranged on the stander, a conveying belt is arranged on the worktable, and a noodle pressing mechanism, a longitudinal noodle cutting mechanism and a transverse noodle cutting mechanism are sequentially arranged on the conveying belt along the conveying direction; a power mechanism for driving the conveying belt to work is arranged at the bottom of the stander; the longitudinal noodle cutting mechanism comprises a fixedly arranged longitudinal cutter frame, and a plurality of longitudinal cutters are arranged on the longitudinal cutter frame side by side; and protecting plates are further arranged on two sides of the conveying belt. According to the efficient and safe noodle cutting device, kneaded raw dough is pressed into corresponding shapes by virtue of the noodle pressing mechanism, meanwhile, pressed raw dough blocks are longitudinally cut by virtue of the longitudinal cutters under the action of the noodle pressing mechanism and the conveying belt, are conveyed to the transverse noodle cutting mechanism to be transversely cut and then can be pushed away from the conveying belt manually or by virtue of a push rod, and therefore, the cutting of raw dough blocks of Sachima is realized.

Owner:重庆玖和食品工业有限公司

Bean vermicelli cooking device with slitting function

ActiveCN109176624AHigh linkageHigh degree of automationMetal working apparatusFood scienceEngineeringMechanical engineering

The invention relates to a bean vermicelli cooking device with a slitting function. The device comprises a bean starch sheet conveying belt which is erected on the top of a rack, a boiling tank is arranged on the bottom of the bean starch sheet conveying belt, the rack is arranged in the boiling tank, and the rack comprises a material supporting mechanism, driving mechanisms, a shearing mechanismand circular mechanisms. The material supporting mechanism is fixedly arranged below the bean starch sheet conveying belt and arranged on the rack, the material supporting mechanism is used for supporting the bean starch sheet conveying belt to vertically output bean starch sheets and enabling the bean starch sheets to be output in an S shape, and the material supporting mechanism comprises a first paving assembly and a second paving assembly. The driving mechanisms are symmetrically arranged below the bean starch sheet conveying belt and are arranged between the first paving assembly and thesecond paving assembly; the shearing mechanism is arranged below the driving mechanisms and comprises a sheet forming assembly, a conveying-out assembly and a control assembly; and the circular mechanisms are located on the two sides of the shearing assembly, are rotatably arranged on the rack and each comprise a first returning assembly and a second returning assembly. The device solves the technical problems that the shearing structure is complex, and after shearing is finished, the bean starch sheets cannot be transmitted out in time.

Owner:赵长春

Bilateral protecting type dough-cutting device

The invention discloses a bilateral protecting type dough-cutting device which comprises a dough-cutting device frame, wherein a workbench is arranged on the frame; a conveyor belt is arranged on the workbench; a dough-pressing mechanism, a longitudinal sawing mechanism and a horizontal dough-cutting mechanism are successively arranged above the conveyor belt along a conveying direction; a first power mechanism for driving the conveyor belt to rotate and a second power mechanism for driving the longitudinal sawing mechanism are arranged at the bottom of the frame; and protecting plates are arranged on the two sides of the conveyor belt. According to the invention, the dough-pressing mechanism is utilized to press a mixed dough material into a corresponding shape, then the dough material is conveyed to the longitudinal sawing mechanism for longitudinally cutting through the conveyor belt and conveyed to the horizontal dough-cutting mechanism for horizontally cutting, and the dough after being horizontally cut is pushed away from the conveyor belt through manpower or a push rod, so that the cutting of the dough material of caramel treats is realized.

Owner:重庆玖和食品工业有限公司

A kind of building tile cutting device

InactiveCN106584682BRealize slittingEasy to operateStone-like material working toolsArchitectural engineeringTool wear

Owner:ZHEJIANG OCEAN UNIV

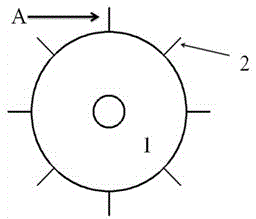

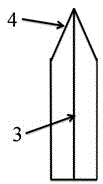

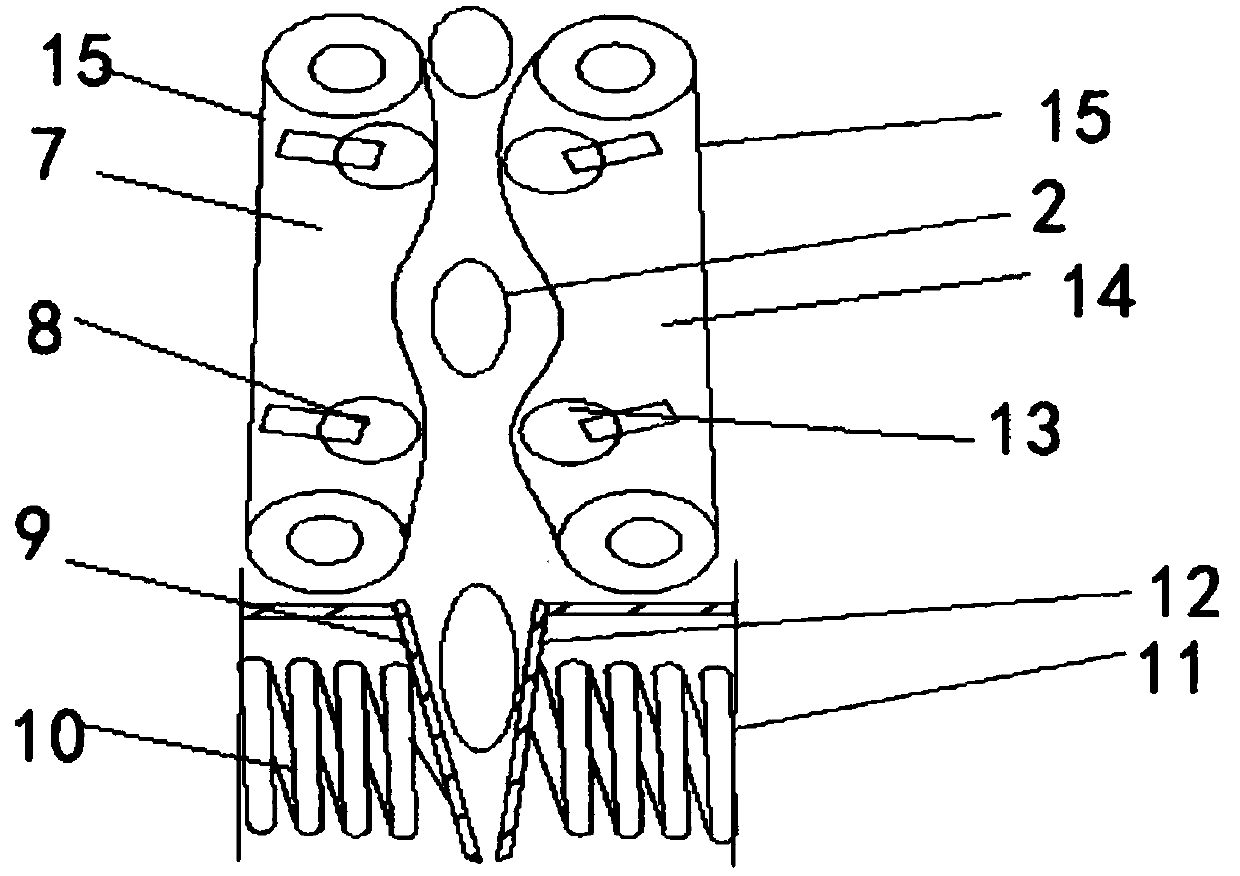

Carding roller used for machining Teflon ultra thin and short fiber

ActiveCN103789853BReduce mechanical performance requirementsRealize slittingFilament/thread formingKnife bladesPolytetrafluoroethylene

The invention discloses a carding roller used for machining Teflon ultra thin and short fiber. A plurality of cutting blades are distributed on the cylindrical surface of the carding roller, the blades are arranged in the whole cylindrical face in the peripheral direction of the carding roller to form m circulations, m is a positive integer larger than or equal to two, in each circulation, the cutting blades are linearly arranged in the axis direction of the carding roller to form 2n rows, n is a positive integer larger than or equal to one, the thickness of the blades is X, the multiple cutting blades are arranged according to the rule that the multiple cutting blades in the second row are shifted to the left by X / 2 in the axis direction relative to the multiple cutting blades in the first row and the multiple cutting blades in the 2nth row are shifted to the left by (2n-1)*X / 2n in the axis direction relative to the multiple cutting blades in the first row, and therefore it is guaranteed that the tracks of all the cutting blades in the peripheral direction in each circulation do not coincide with one another. It is avoided that the cutting blades are influenced by the thickness of the cutting blades when being mounted through the cutting blade distribution mode, and the Teflon short fiber with the fineness smaller than 1dtex can be made.

Owner:ZHEJIANG SCI-TECH UNIV

Cable coiling device

The invention discloses a cable coiling device. The cable coiling device comprises a cable inlet assembly, a winding assembly and a limiting assembly, wherein the cable inlet component comprises an adjusting component, the adjusting component is provided with a stepping component, the stepping component is provided with a cable inlet component, and the cable inlet component is provided with a slitting component; the winding assembly is arranged at one side of the wire inlet assembly and comprises a driving component, the other end of the driving component is provided with a moving component, the moving component is provided with an end supporting component, and the end supporting component is provided with an end pushing component; and the limiting assembly is arranged at one side of the winding assembly and comprises a supporting component, the supporting component is provided with a side pushing component, and the side pushing component is provided with a side limiting component. According to the cable coiling device, cable feeding during cable coiling is facilitated, the coiling speed can be controlled in the coiling process, cable slitting can be achieved after coiling, coiledcoils can be conveniently unloaded, the compactness degree of the coils can be ensured in the coiling operation, the coil coiling efficiency and quality are remarkably improved, and high practicability is achieved.

Owner:SICHUAN NEW CENTURY CABLE

A cable coiling device

A cable coiling device, comprising: an incoming wire assembly, including an adjusting member, the adjusting member is provided with a stepping member, the stepping member is provided with an incoming wire member, and the incoming wire member is provided with a cutting member; the winding assembly is located at One side of the incoming line assembly includes a driving member, the other end of the driving member is provided with a moving member, the moving member is provided with an end support member, and the end support member is provided with an end push member; the limit assembly is provided on one side of the winding assembly, It includes a supporting member, the supporting member is provided with a side pushing member, and the side pushing member is provided with a lateral limiting member. The present invention is convenient for the incoming wire of the cable when the cable is coiled, and can control the coiling speed during the coiling process. During the coiling operation, the compactness of the coil can be ensured, the efficiency and quality of the coil coiling can be significantly improved, and the utility model has strong practicability.

Owner:SICHUAN NEW CENTURY CABLE

Cardboard three-way cutting machine

The invention relates to a cardboard three-way cutting machine. A rack is provided with a cutting plate; the upper portion of the cutting plate is matched with a feeding device and a front and rear cutting device, and the feeding device is matched with a pushing device arranged on the rack; the cutting plate is provided with a cutting groove matched with the front and rear cutting device; the front and rear cutting device comprise a cutting seat arranged on the rack; the cutting seat is provided with a cutting feeding motor and a forward and backward cutting feeding screw rod matched with eachother; the two segments of the screw rod of the cutting feeding screw rod are matched with a first cutting feeding seat and a second cutting feeding seat; the two cutting feeding seats are each provided with vertical cutting knife installation grooves; cutting knifes are arranged in the cutting knife installation grooves; the middle of each cutting knife is fixedly connected with a cutting knifefeeding block; each cutting knife feeding block is connected with the middle of a cutting knife feeding connecting rod; the lower parts of the cutting knife feeding connecting rods are connected to the cutting feeding seats; and the upper parts of the cutting knife feeding connecting rods are matched with the cutting feeding motor. The cardboard three-way cutting machine can ensure good cutting accuracy and has good flexibility, and is convenient to adjust.

Owner:DEZHOU XIANGYU PAPER CO LTD

Dough cutting device capable of carrying out rapid slide cutting

The invention discloses a dough cutting device capable of carrying out rapid slide cutting. The dough cutting device capable of carrying out rapid slide cutting comprises a dough cutting machine frame capable of carrying out rapid slide cutting; a workbench is arranged on the frame; a conveyor belt is arranged on the workbench; a dough pressing mechanism, a longitudinal dough cutting mechanism and a transverse dough cutting mechanism are sequentially arranged above the conveyor belt along the transfer direction; a power mechanism used for driving the conveyor belt to work is arranged at the bottom of the frame; the longitudinal dough cutting mechanism comprises a fixedly arranged longitudinal cutter rest; multiple longitudinal cutters are arranged in parallel on the longitudinal cutter rest; a cutting blade slot is arranged on the conveyor belt under the cutting mechanism; and a powder and residue receiving box is arranged under the cutting blade slot. The dough pressing mechanism is utilized in the dough cutting device so as to press the kneaded raw dough into corresponding shapes; the shaped raw dough is simultaneously pressed under the effects of the dough pressing mechanism and the conveyor belt, and the pressed raw dough block passes through the longitudinal cutters, so that the raw dough block is longitudinally cut; the longitudinally cut raw dough block is then transferred to the transverse dough cutting mechanism so as to be transversely cut; and the transversely cut raw dough block is then manually pushed off the conveyor belt, or pushed off the conveyor belt by using a push rod. Thus, cutting of the raw dough blocks for making caramel treats is realized.

Owner:重庆玖和食品工业有限公司

Full-automatic sawing type noodle cutting equipment

InactiveCN106376626ARealize slittingDough dividingDough shaping and dividing combinationConveyor beltContact sensor

The invention discloses full-automatic sawing type noodle cutting equipment which comprises a noodle cutter rack, wherein a worktable is arranged on the rack; a conveyor belt is arranged on the worktable; a noodle pressing mechanism, a longitudinal sawing mechanism and a transverse noodle cutting mechanism are sequentially arranged above the conveyor belt along the conveying direction; a first power mechanism for driving the conveyor belt to operate and a second power mechanism for driving the longitudinal sawing mechanism are arranged at the bottom of the rack; a baffle is arranged at the tail end of the conveying direction of the conveyor belt; and a contact sensor is arranged on the inner side of the baffle and is electrically connected with the transverse noodle cutting mechanism. According to the invention, kneaded raw dough is pressed into a corresponding shape by utilizing the noodle pressing mechanism, is conveyed to the longitudinal sawing mechanism to be longitudinally cut by virtue of the conveyor belt, is then conveyed to the transverse noodle cutting mechanism to be transversely cut, and can be pushed away from the conveyor belt manually or by virtue of a push rod after transverse cutting; and therefore, raw dough blocks of Sachima can be cut.

Owner:重庆玖和食品工业有限公司

Pulse crosscutting-type dough cutting machine

InactiveCN106386943ARealize slittingDough-sheeters/rolling-machines/rolling-pinsDough shaping and cutting apparatusEngineeringConveyor belt

The invention discloses a pulse crosscutting-type dough cutting machine. The pulse crosscutting-type dough cutting machine comprises a pulse crosscutting-type dough cutting machine frame; a workbench is arranged on the frame; a conveyor belt is arranged on the workbench; a dough pressing mechanism, a longitudinal dough cutting mechanism and a transverse dough cutting mechanism are sequentially arranged above the conveyor belt along the transfer direction; a power mechanism used for driving the conveyor belt to work is arranged at the bottom of the frame; the longitudinal dough cutting mechanism comprises a fixedly arranged longitudinal cutter rest; multiple longitudinal cutters are arranged in parallel on the longitudinal cutter rest; a length sensor is further arranged on the conveyor belt; and a pulse cutter is arranged above a dough outlet of the dough pressing mechanism. The dough pressing mechanism is utilized in the pulse crosscutting-type dough cutting machine so as to press the kneaded raw dough into corresponding shapes; the shaped raw dough is simultaneously pressed under the effects of the dough pressing mechanism and the conveyor belt, and the pressed raw dough block passes through the longitudinal cutters, so that the raw dough block is longitudinally cut; the longitudinally cut raw dough block is then transferred to the transverse dough cutting mechanism so as to be transversely cut; and the transversely cut raw dough block is then manually pushed off the conveyor belt, or pushed off the conveyor belt by using a push rod. Thus, cutting of the raw dough blocks for making caramel treats is realized.

Owner:重庆玖和食品工业有限公司

Film roll cutting device and control method thereof

ActiveCN106698054BRealize slittingImprove convenienceFunction indicatorsArticle deliveryRoll slittingEngineering

The invention discloses a film roll cutting device and its control method. The device comprises: a cutting mechanism, a feeding mechanism and a control mechanism; wherein, the number of the cutting mechanisms is more than two; more than two cutting mechanisms, Adapted to the feeding mechanism respectively, it is used to cut the film roll according to any of the cutting methods according to more than two preset cutting methods; the feeding mechanism is used to load the film roll, And convey the film roll to any of the cutting mechanisms; the control mechanism is adapted to two or more of the cutting mechanisms and the feeding mechanism; The feeding mechanism is controlled to realize cutting of the film roll by any of the cutting methods. The solution of the invention can overcome the defects of inconvenient use, low work efficiency and high cost in the prior art, and realize the beneficial effects of convenient use, high work efficiency and low cost.

Owner:GREE ELECTRIC APPLIANCES INC

Full-automatic plastic suction machine side punching cutter body structure

PendingCN107379102ARealize slittingReduce labor risksMetal working apparatusLaser beam welding apparatusEngineeringMachining process

The invention provides a full-automatic plastic suction machine side punching cutter body structure. Cutter grooves are arranged on an upper wallboard; laser blades which are matched with the corresponding cutter grooves are arranged on a lower wallboard; the full-automatic plastic suction machine side punching cutter body structure also comprises a top plate, a moving plate, punch cutters and punch mother holes which are matched with the corresponding punch cutters and are connected with side edges of the corresponding cutter grooves; each punch cutter is composed of a fixed cutter, a moving cutter and a cylinder; each fixed cutter is fixed in the corresponding cutter groove, close to the corresponding punch mother hole; each cylinder is fixed on the bottom surface of the top plate; the free end of a telescopic shaft of each cylinder is fixedly connected with the top surface of the moving plate; each moving cutter is fixed to the bottom surface of the moving plate; through grooves are arranged on the lower wallboard, close to the corresponding cutter grooves; and each cutter groove penetrates through each through groove. By adopting the full-automatic plastic suction machine side punching cutter body structure provided by the invention, shape cutting and side punching of a plastic product are finished full-automatically once, so that the traditional processing technology is changed, and the labor efficiency is improved; and by adopting the side punching shearing cutter structure, abrasion of the punch cutters is reduced, and the reject rate is lowered.

Owner:TIANJIN HENGFENGDA PACKAGING PROD

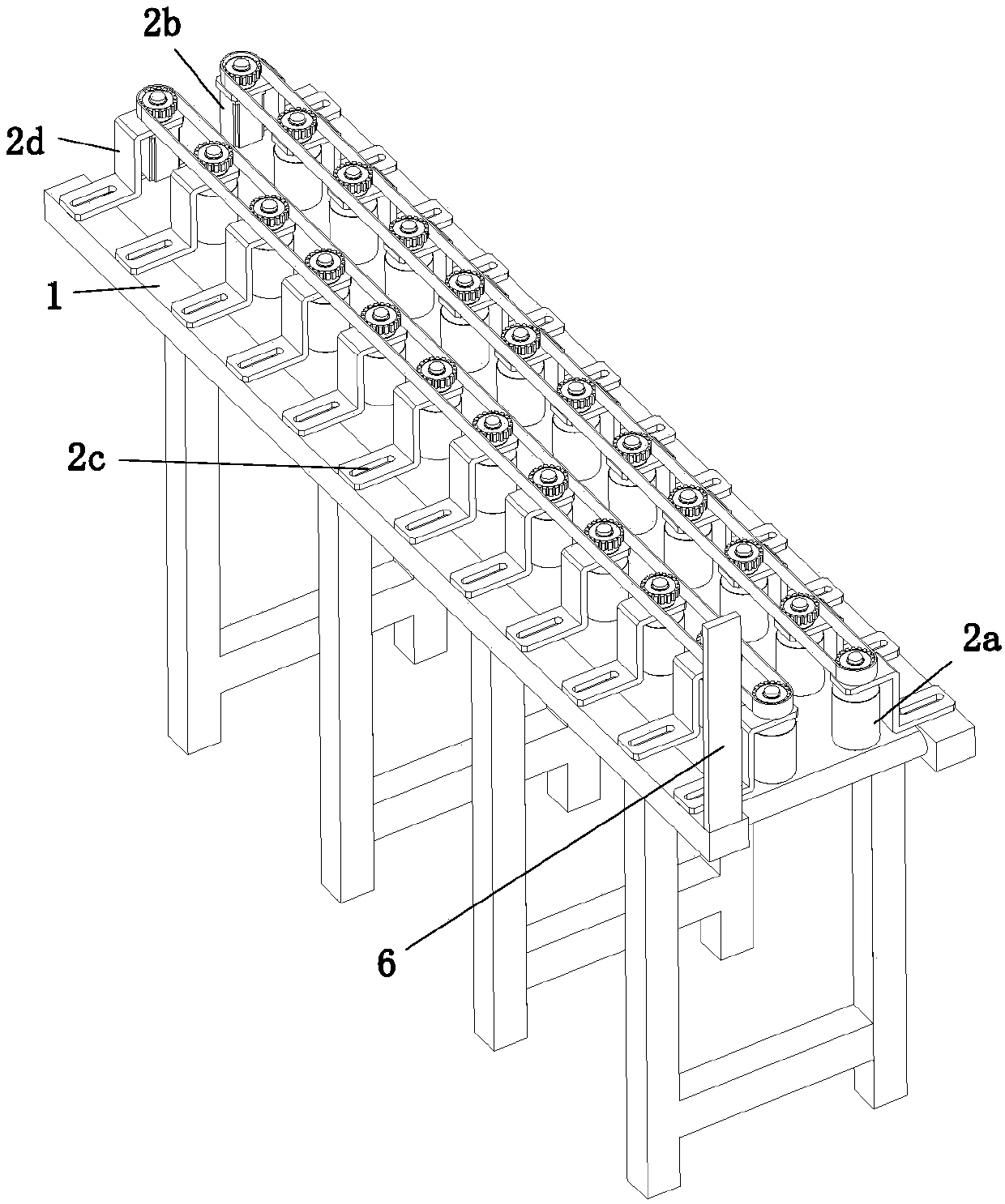

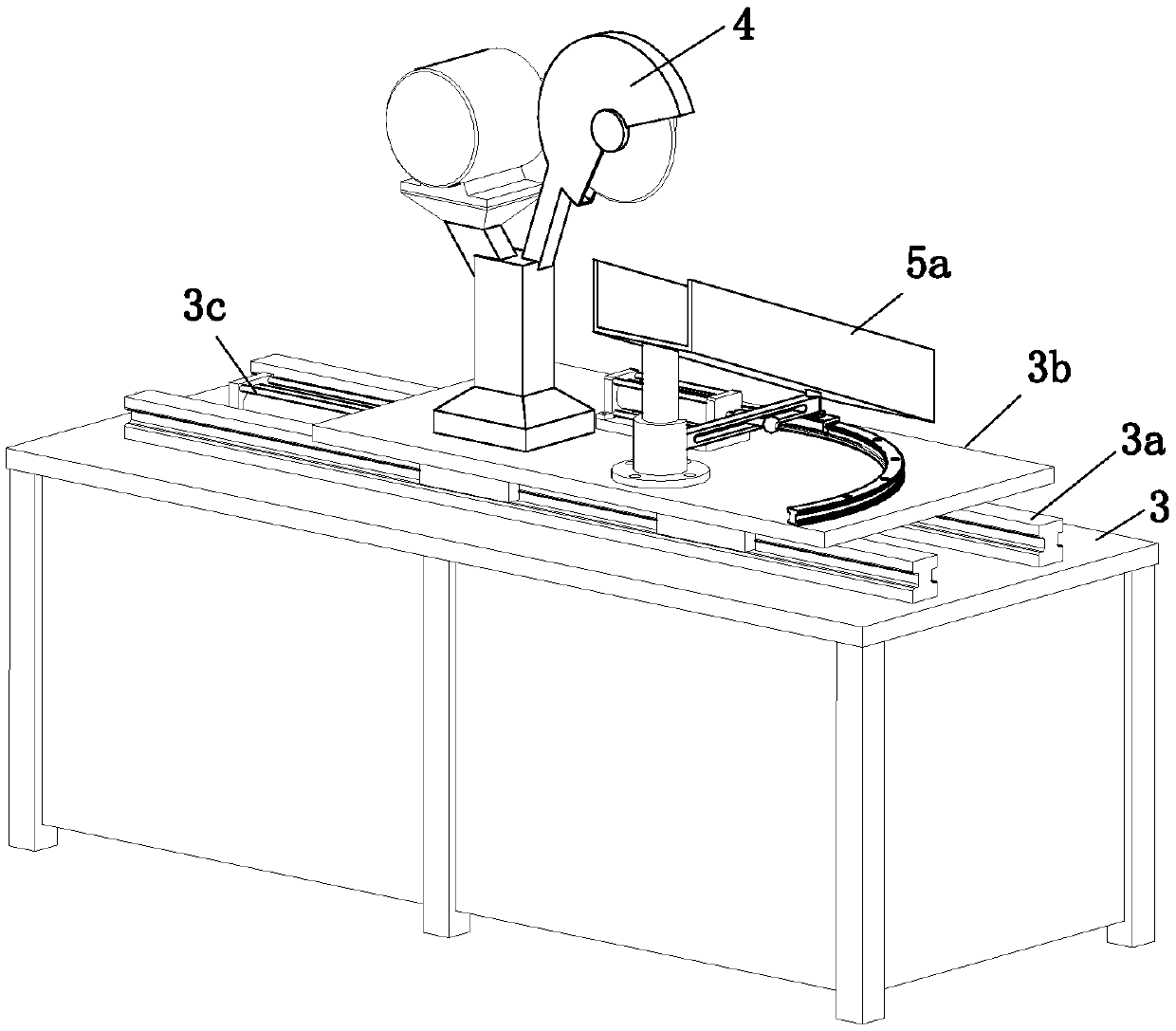

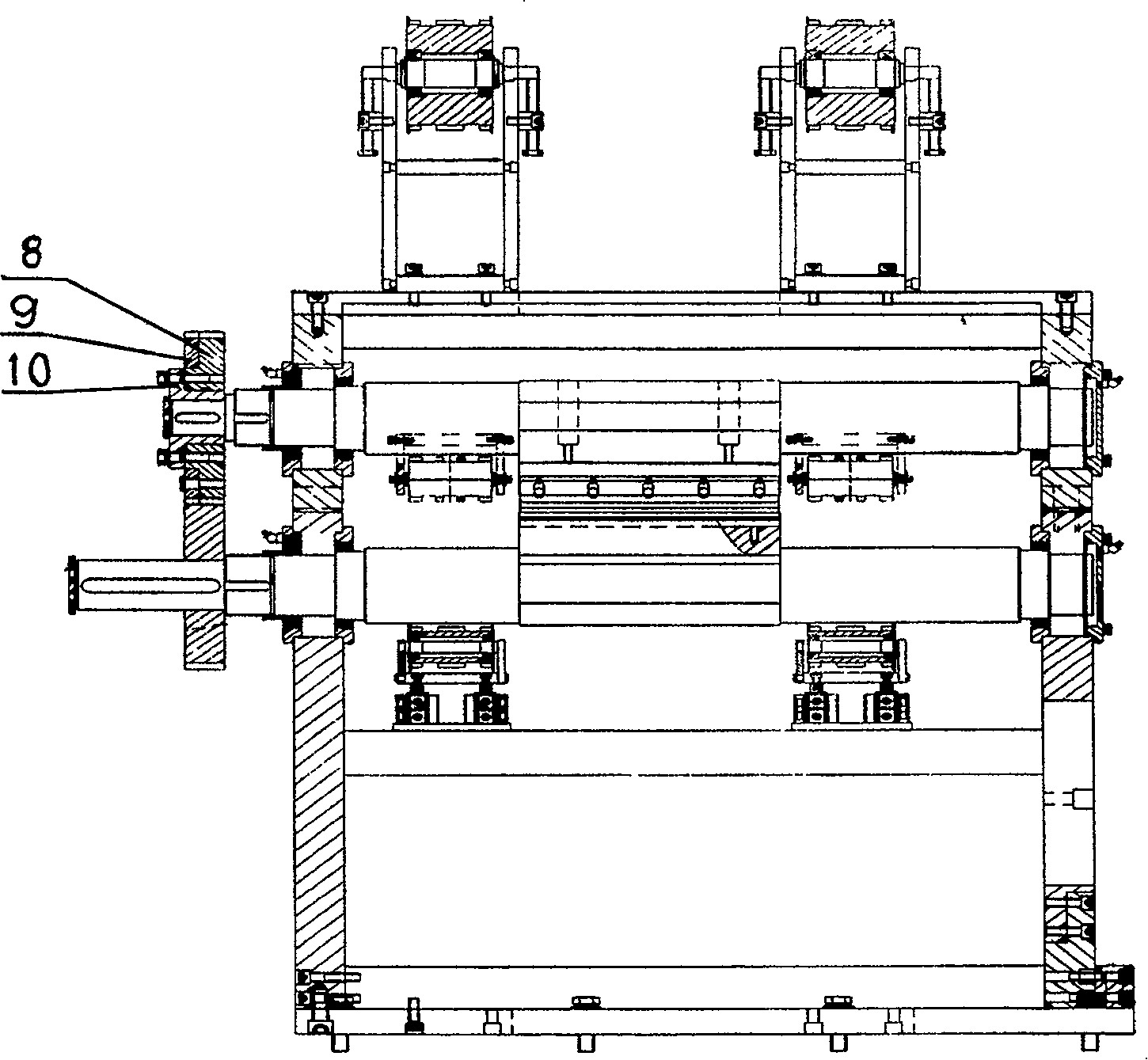

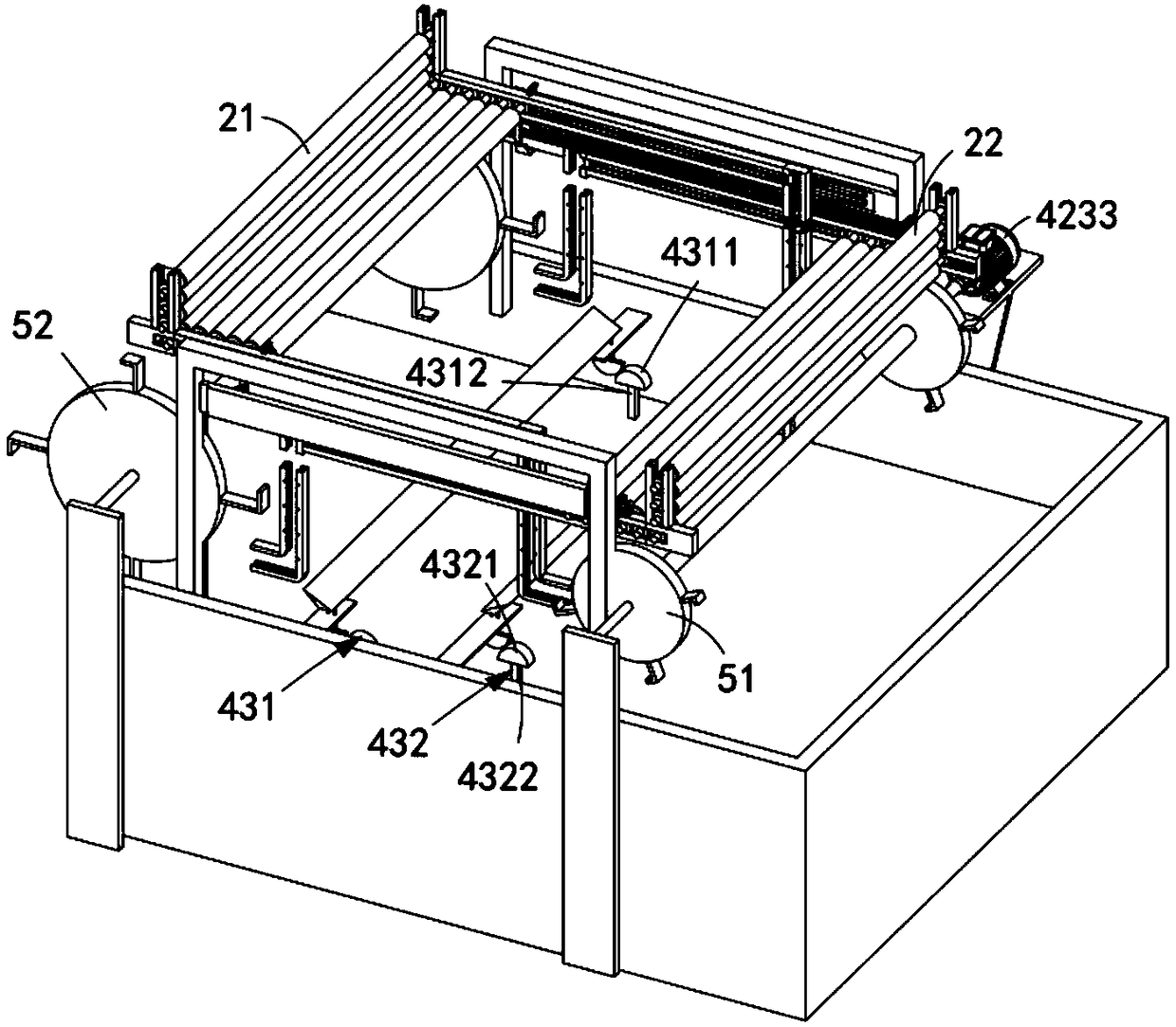

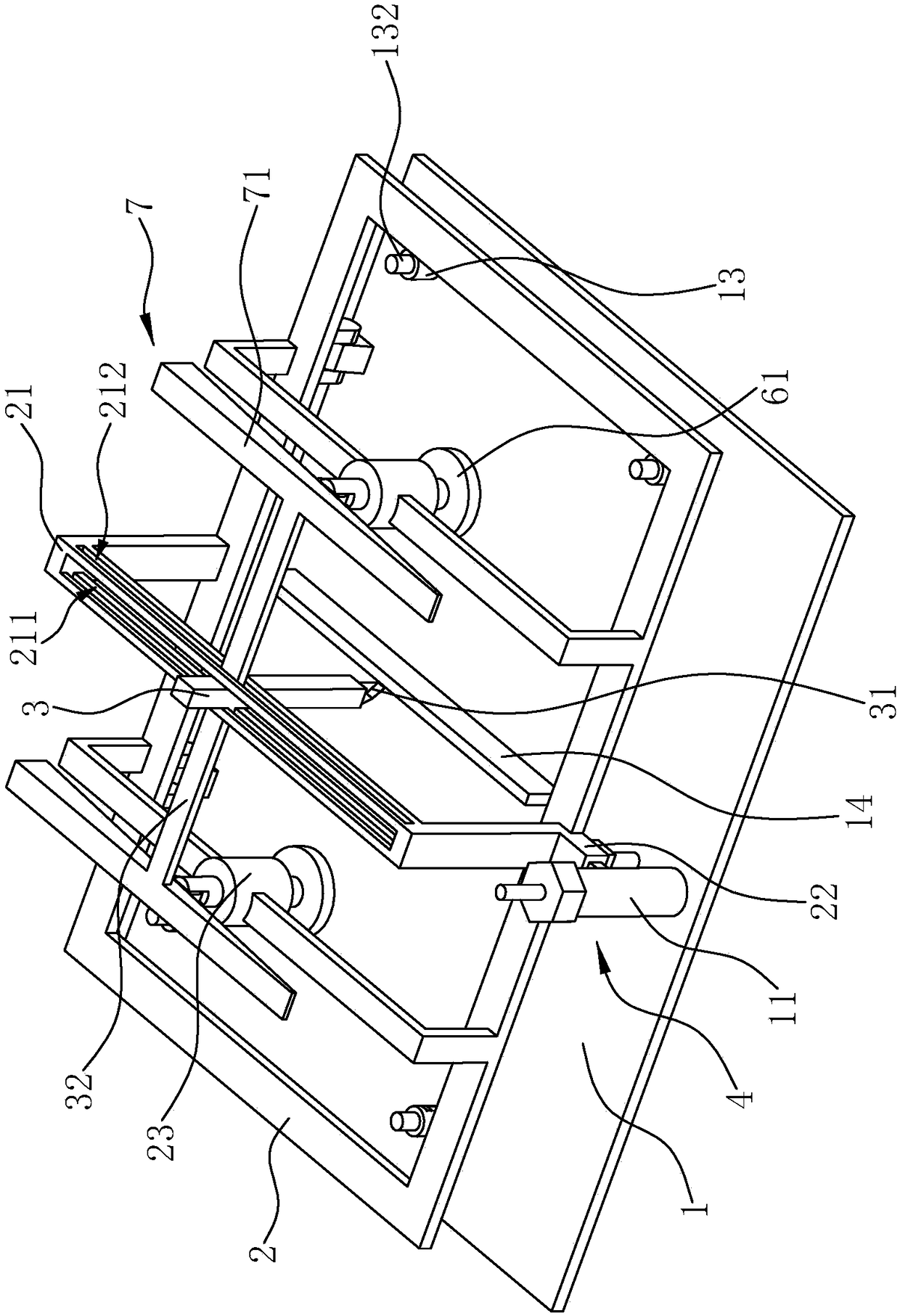

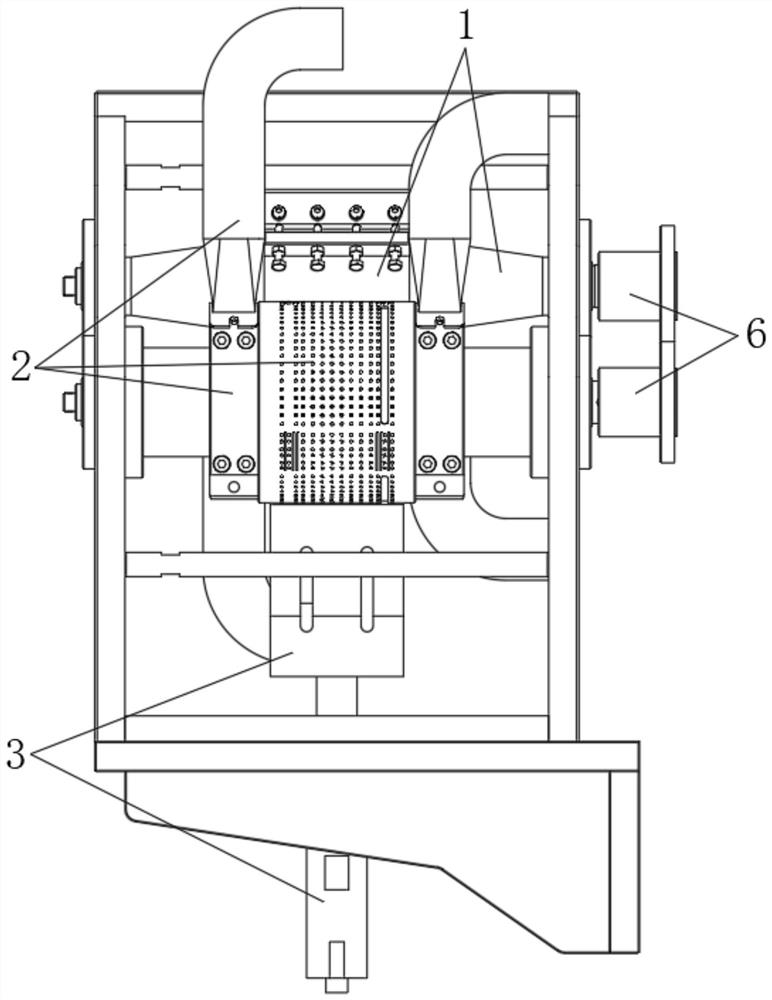

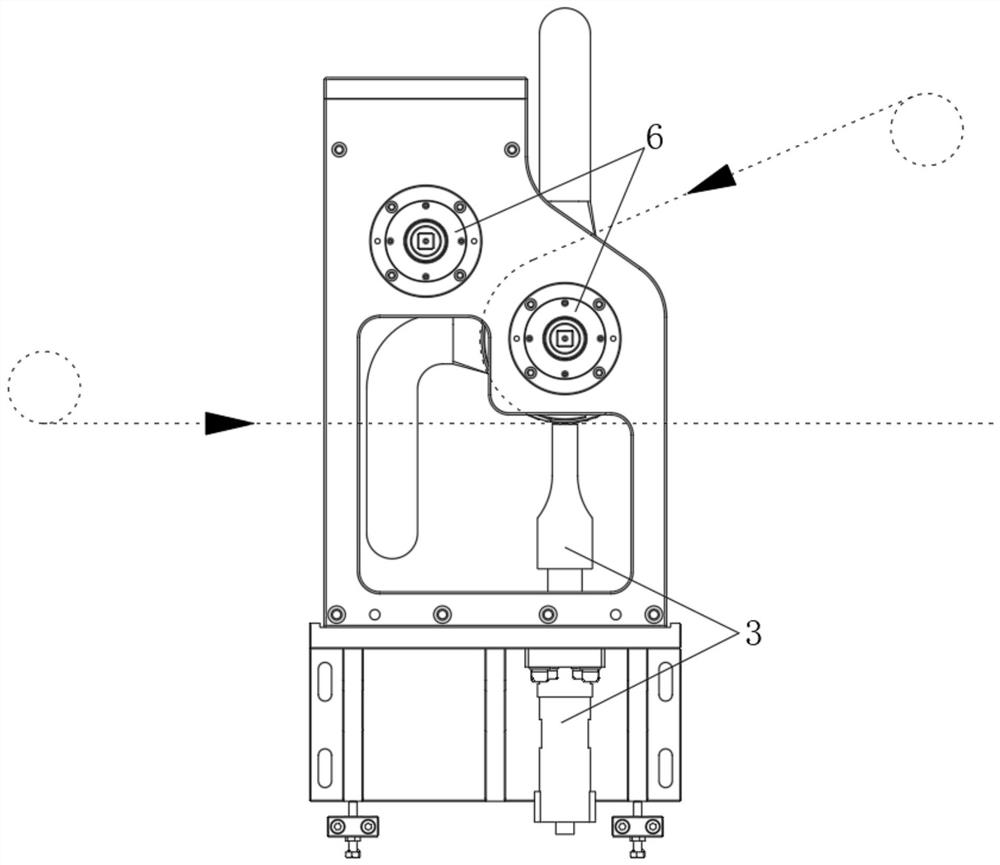

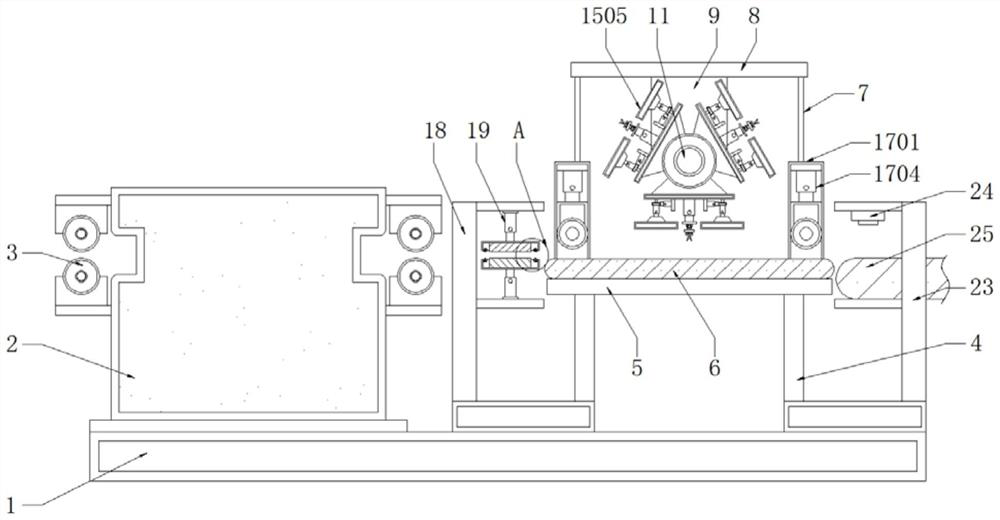

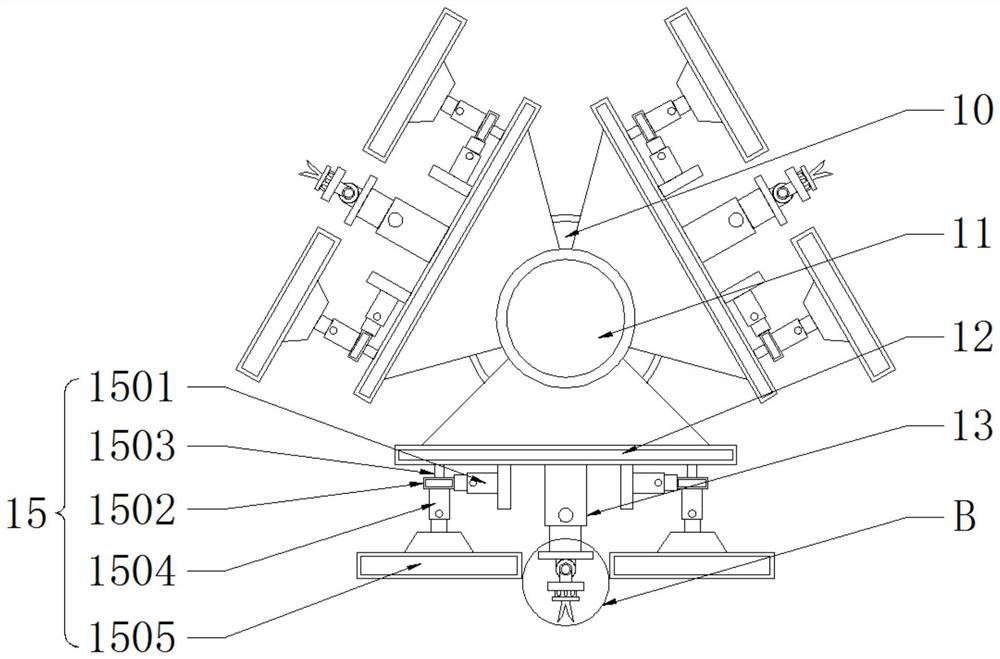

Full-automatic low-voltage reactor iron core binding machine

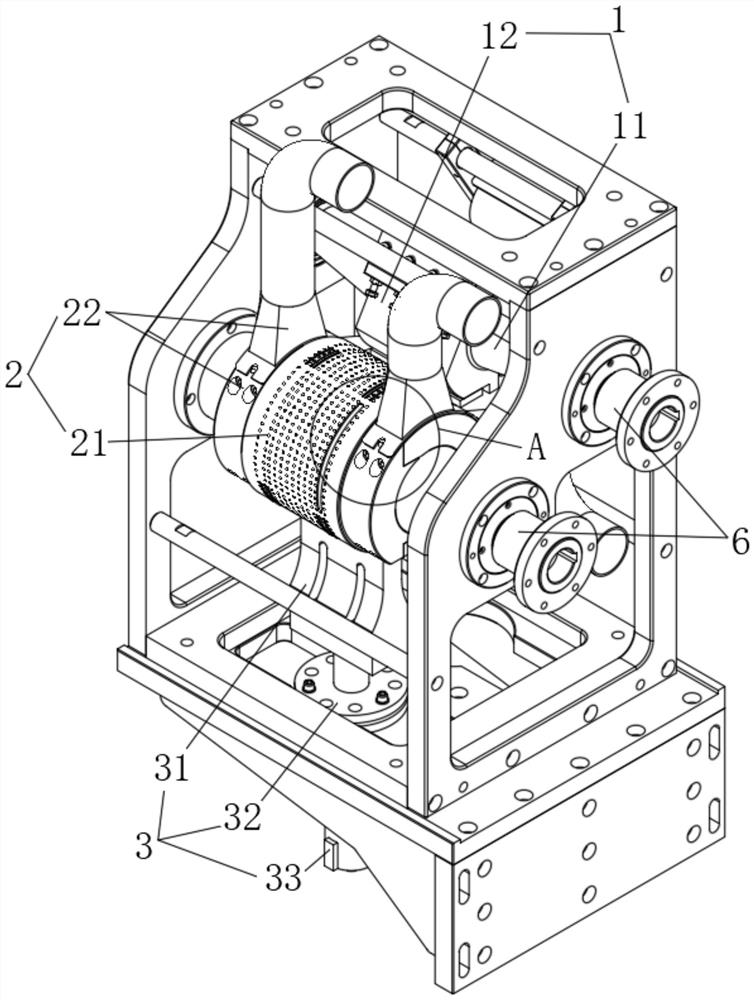

PendingCN113851317AWrapping upGood quality dressingInductances/transformers/magnets manufactureWinding machineLow voltage

The invention relates to the technical field of reactor production, in particular to a full-automatic low-voltage reactor iron core binding machine. The full-automatic low-voltage reactor iron core binding machine comprises a material channel mounted in a downward inclined manner, a material plate driving mechanism, a material cutting mechanism, a feeding and discharging mechanism, a strip winding machine and a stacking mechanism, wherein the material channel is composed of two material plates oppositely arranged on the material frame, and the two material plates can be driven by a material plate driving mechanism to move oppositely. The material cutting mechanism is located at the lower end of the material channel and used for slitting the iron sheets located in the material channel. The feeding and discharging mechanism is used for feeding a set of iron sheets cut by the material cutting mechanism to the tape winding machine, binding the iron sheets into iron cores through the tape winding machine and then discharging the iron cores to the stacking mechanism. The stacking mechanism is used for stacking the iron cores. The full-automatic low-voltage reactor iron core binding machine can bind low-voltage reactor iron cores of various specifications, and is good in binding quality and high in efficiency.

Owner:JIANGSU LTEC ELECTRIC CO LTD

Score type splitting structure of splitting machine

PendingCN108568852APrevent sticking and chippingEasy to cutMetal working apparatusEngineeringTechnical design

The invention discloses a score type splitting structure of a splitting machine and an operation method. The structure comprises a tool support, wherein two tool rest wall panels which are arranged inparallel are arranged on the tool support; a two-sided dovetail groove block is fixedly connected with a position between the tool rest wall panels; the two-sided dovetail groove block is fixedly connected with a pneumatic score cutter; the pneumatic score cutter presses against a coiled material aligned to the surface of a dead knife roll and arranged on the dead knife roll during operation to perform splitting. The structure has the advantages that firstly, the pneumatic score cutter directly presses against the dead knife roll to perform splitting, even thick glue can be cut apart, and a cutter cleaning mechanism is provided, so that glue is not easy to stick the cutter; secondly, the structure adopts a two-sided dovetail groove design, the two-sided dovetail groove adopts a 42-degreeincluded angle design, and the pneumatic score cutter can not only cut the inlet point of the coiled material, but also cut the outlet point of the coiled material according to different technical requirements of adhesive tape materials; thirdly, the dead knife roll adopts a special technical design, tungsten carbide is plated on the surface of the dead knife roll, and tracks are not left on the surface of the dead knife roll while splitting is realized; fourthly, compared with the traditional splitting mode, the structure is convenient, and cutting can be singly performed.

Owner:浙江华创机电科技有限公司

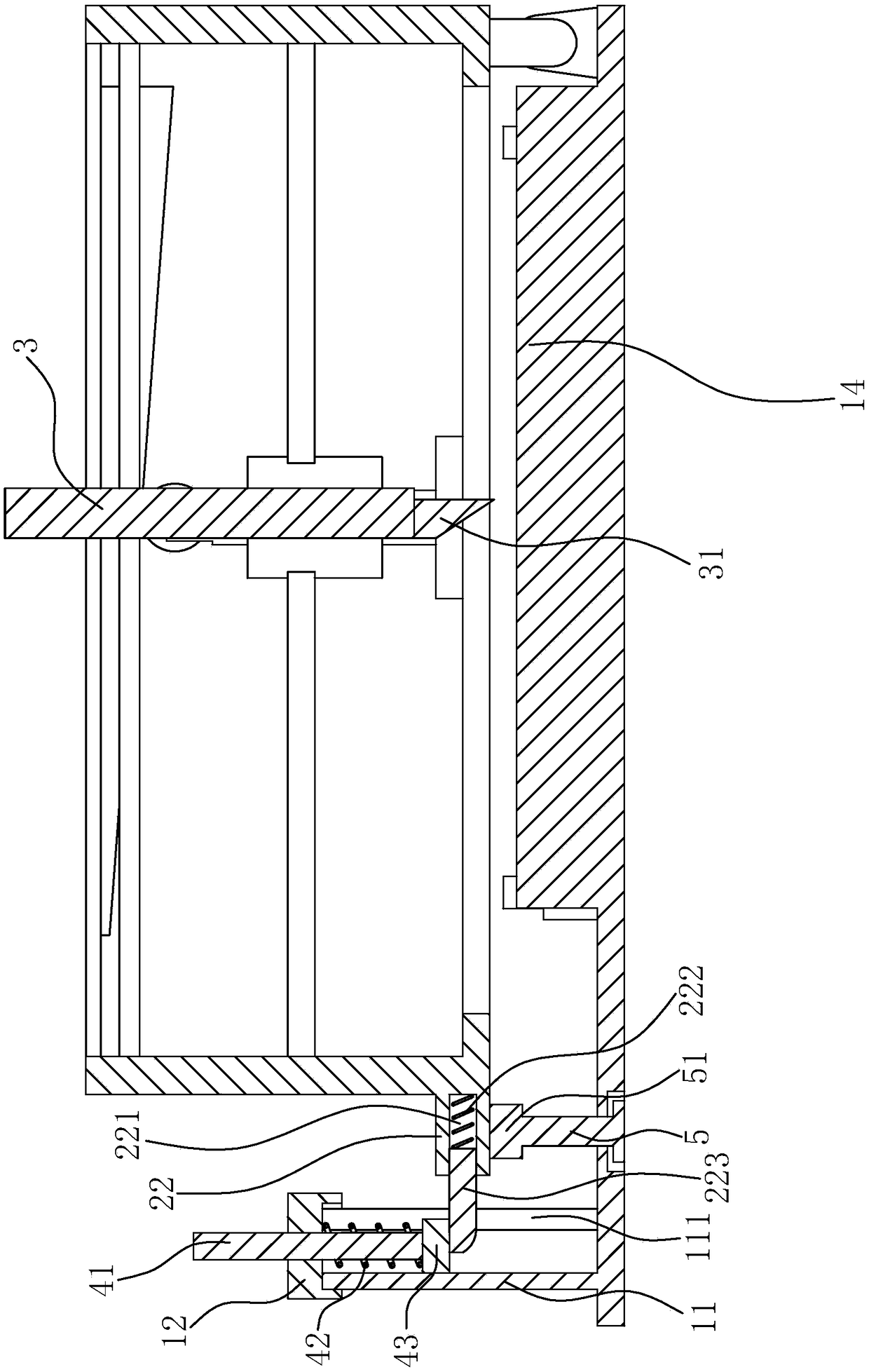

Ear loop slitting and fixing integrated device of masks

PendingCN112917926ARealize slittingAchieve fixationDomestic articlesProtective garmentUltrasonic weldingEngineering

The invention belongs to the technical field of mask production equipment, and discloses an ear loop slitting and fixing integrated device of masks. The device has the advantage of simple structure and comprises a cutting assembly, a positioning assembly and a welding assembly, wherein the cutting assembly comprises a rotatable knife roll, N cutting knives are arranged on the knife roll in an array mode and used for cutting to obtain equal-width ear loops when the knife roll continuously rotates, the positioning assembly is located on one side of the cutting assembly and comprises a rotatable positioning roller, the positioning roller and a knife roller cooperates with each other, the positioning roller and the knife roller rotate oppositely so that the ear loops can enter the position between the cutting assembly and the positioning assembly from the position above the positioning roller, the positioning assembly further comprises a negative pressure generating mechanism, the negative pressure generating mechanism is used for driving the surface of the positioning roller to form a negative pressure state so as to adsorb and position the cut ear loops, and the welding assembly is located under the positioning assembly, comprises an ultrasonic welding head and is used for achieving ultrasonic welding of the ear loops and mask main bodies between the positioning roller and an ultrasonic welding head.

Owner:安徽瑞程机械设备有限公司

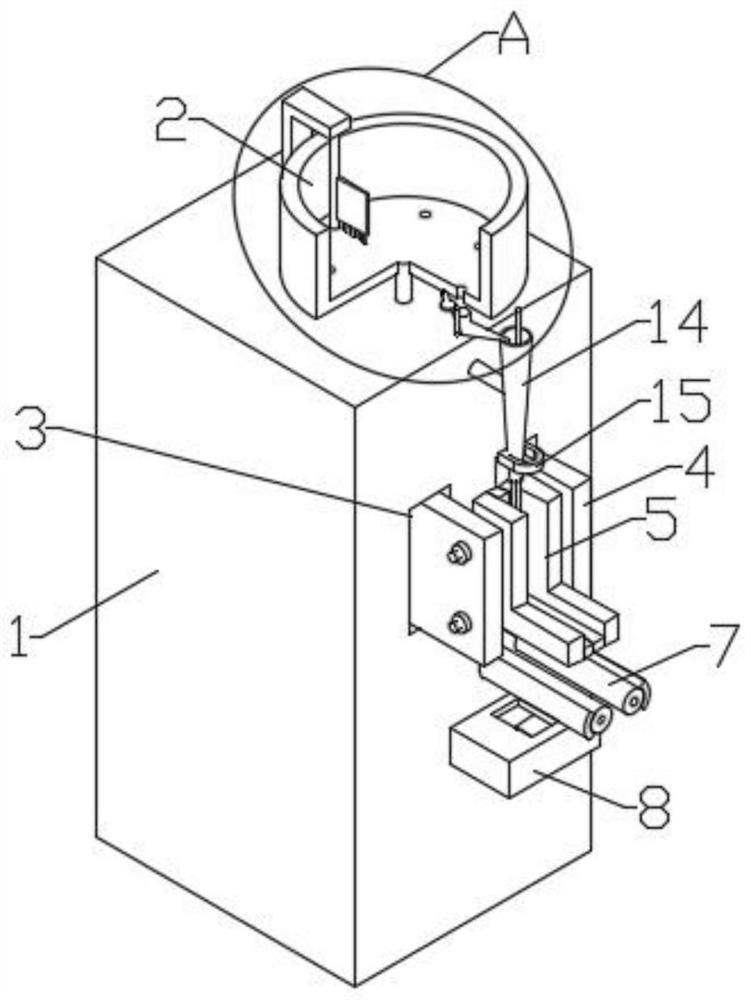

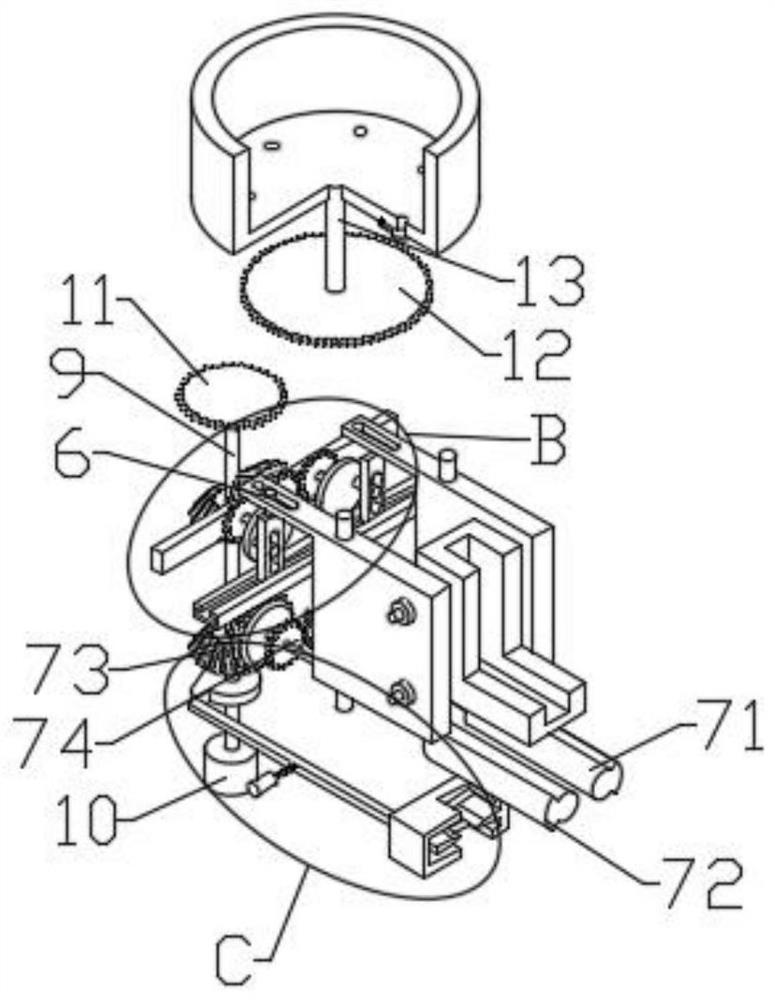

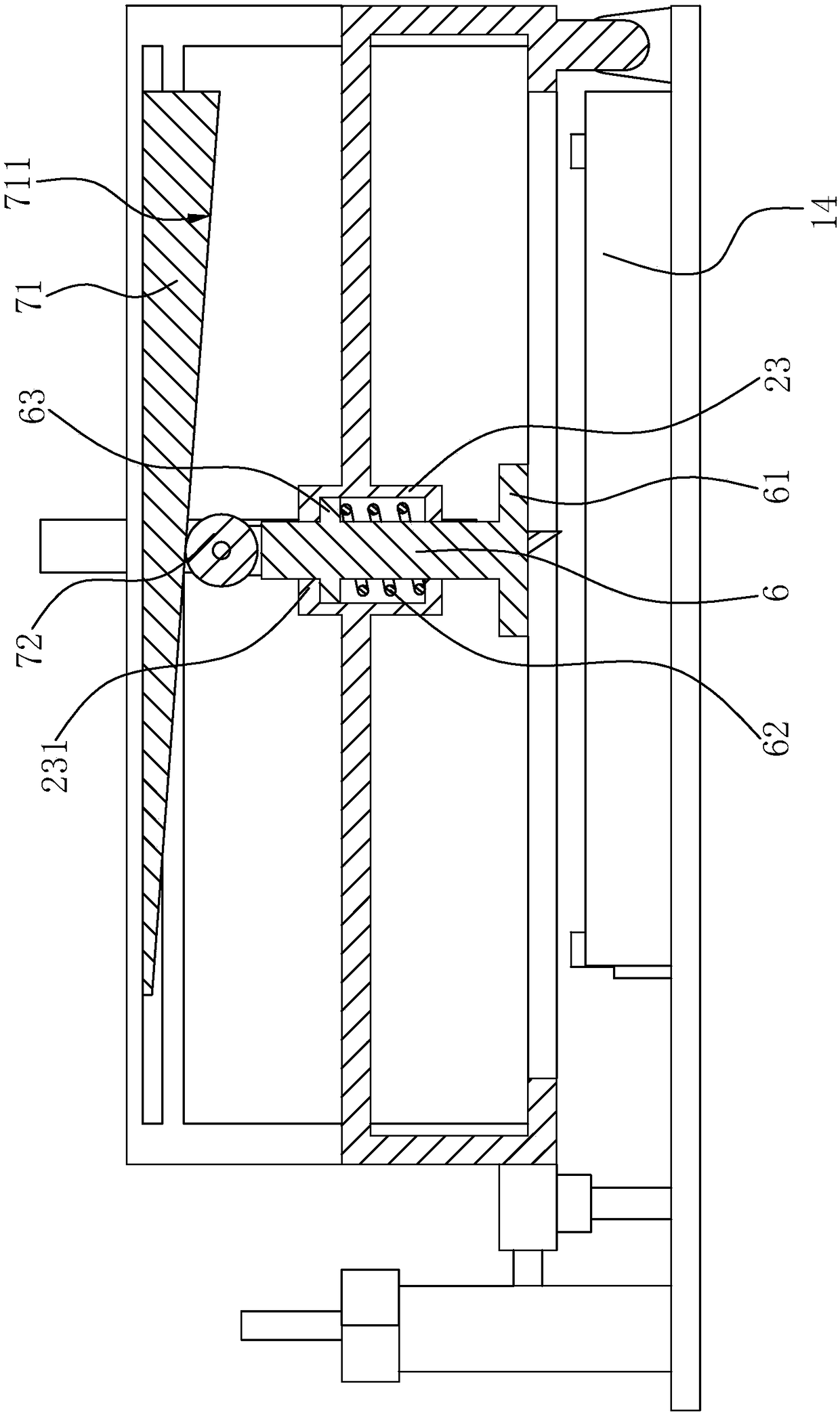

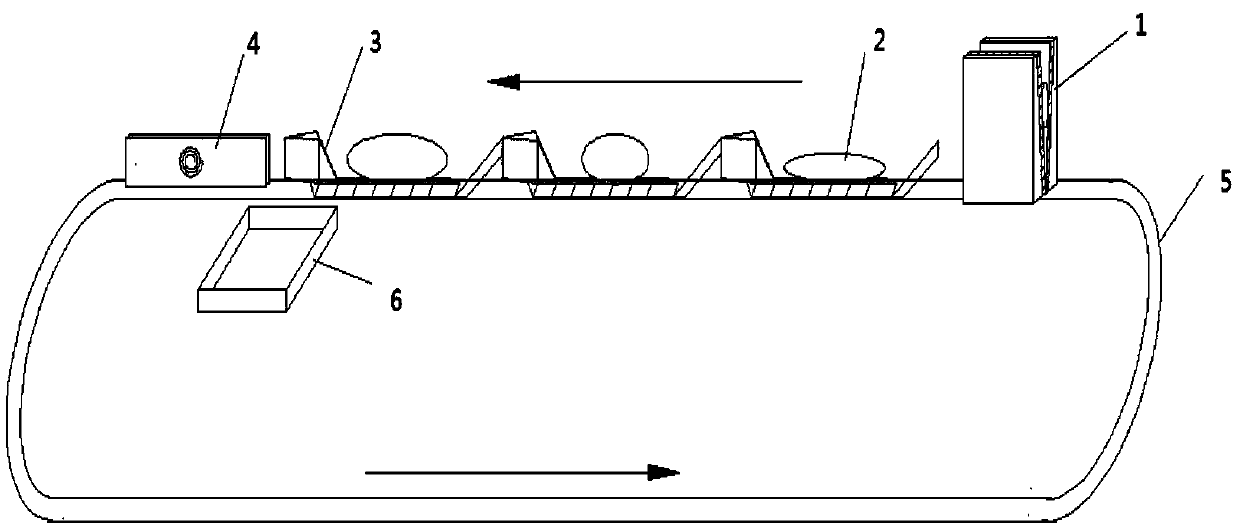

Automatic small trash fish slitting device and slitting method thereof

ActiveCN109588463ANo manual feeding requiredRealize slittingFish filletingEngineeringMechanical engineering

The invention belongs to the field of aquatic products processing and specifically relates to an automatic small trash fish slitting device and a slitting method thereof. The automatic small trash fish slitting device comprises a rail, a conveying trolley, a feeding device, a spring clamping plate and a receiving tray, wherein the feeding device and the spring clamping plate are vertically arranged on the rail, and the rail penetrates through the bottom of the feeding device and the bottom of the spring clamping plate; the conveying trolley is located on the rail and passes the feeding deviceand the spring clamping plate in sequence; the receiving tray is arranged under the spring clamping plate. According to the slitting device and the slitting method thereof, with adoption of the structure of dual conveyors and the spring clamping plate, small trash fish can be automatically fed in sequence; with adoption of the structure of the conveying trolley and the spring clamping plate, fishbodies in different sizes can be slit, so that the small trash fish can be sliced automatically, and the effect of improving the productivity is achieved.

Owner:YANCHENG YIMEI FOOD

Sawing-type dough cutting device

The invention discloses a sawing-type dough cutting device. The sawing-type dough cutting device comprises a dough cutting machine frame; a workbench is arranged on the frame; a conveyor belt is arranged on the workbench; a dough pressing mechanism, a longitudinal sawing mechanism and a transverse dough cutting mechanism are sequentially arranged above the conveyor belt along the transfer direction; and a first power mechanism used for driving the conveyor belt to work and a second power mechanism used for driving the longitudinal sawing mechanism are arranged at the bottom of the frame. The dough pressing mechanism is utilized in the sawing-type dough cutting device so as to press the kneaded raw dough into corresponding shapes; the shaped raw dough is transferred to the longitudinal sawing mechanism via the conveyor belt so as to longitudinally cut the shaped raw dough; the longitudinally cut raw dough is then transferred to the transverse dough cutting mechanism so as to be transversely cut; and the transversely cut raw dough is then manually pushed off the conveyor belt, or pushed off the conveyor belt by using a push rod. Thus, cutting of the raw dough blocks for making caramel treats is realized.

Owner:重庆玖和食品工业有限公司

Intermittent film cutting printing equipment and intermittent film cutting method thereof

PendingCN114590024AAvoid affecting the cutting resultsEasy to adjust cutting frequencyRotary pressesOther printing apparatusRotational axisComputer printing

The invention discloses intermittent film cutting printing equipment and an intermittent film cutting method thereof, and relates to the technical field of intermittent film cutting of printing, the equipment comprises a base, a printer body, a die cutter assembly and an adsorption fixing assembly, the printer body is installed on one side of the upper portion of the base, and traction rollers are arranged on the left side and the right side of the printer body correspondingly; a supporting rod is fixed to the other side of the upper portion of the base, a mounting base is fixed to the upper portion of the supporting rod, a conveying belt is arranged on the upper side of the mounting base, an upper frame body is fixed to the outer side of the upper portion of the mounting base, a top plate is fixed to the top of the upper frame body, and mounting side plates are fixed to the front side and the rear side of the lower portion of the top plate. According to the intermittent film cutting printing equipment and the intermittent film cutting method thereof, the film cutting frequency of intermittent film cutting can be adjusted by adjusting the rotating speed of the main motor and the rotating shaft, printing paper can be adsorbed and fixed in the intermittent film cutting process, and then the situation that the cutting result is affected by movement of the printing paper in the intermittent film cutting process is prevented.

Owner:温州鸣旭机械科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com