Patents

Literature

30results about How to "Reduce labor risks" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

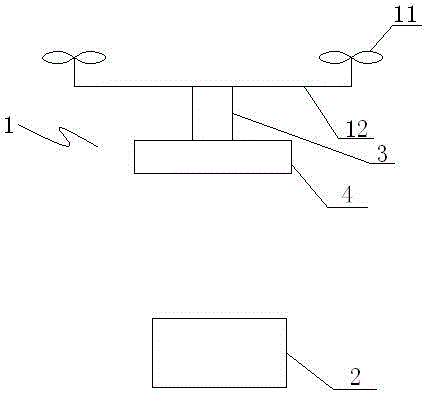

Photovoltaic power station survey, operation and maintenance system based on unmanned aerial vehicle

InactiveCN105786017AImprove the efficiency of identification workImprove efficiencyPosition/course control in three dimensionsFlight control modesMemory module

The invention discloses a photovoltaic power station survey, operation and maintenance system based on an unmanned aerial vehicle (UAV). The photovoltaic power station survey, operation and maintenance system comprises a UAV composed of a wing and a rack, and a ground system, and is characterized in that the rack is internally equipped with a positioning module, a laser ranging module, a wired / wireless communication module, a flight control module, a memory module, a visible light camera, and a power system; the UAV is in communication connection with the ground system through the wireless communication module; the flight control module receives a flight control instruction of the ground system and controls flight of the UAV; the power system provides power for the UAV; the laser ranging module detects the flight height of the UAV and the distance between the UAV and an obstacle below in real time; and the ground system includes a flight control program, a remote control transmitting device, database software, analysis and calculation software, image processing software, and a wireless charging transmitting device.

Owner:TRINA SOLAR CO LTD

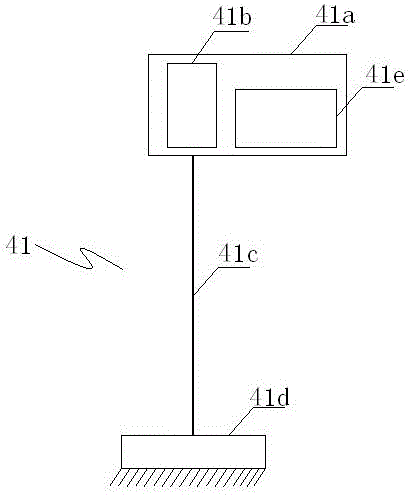

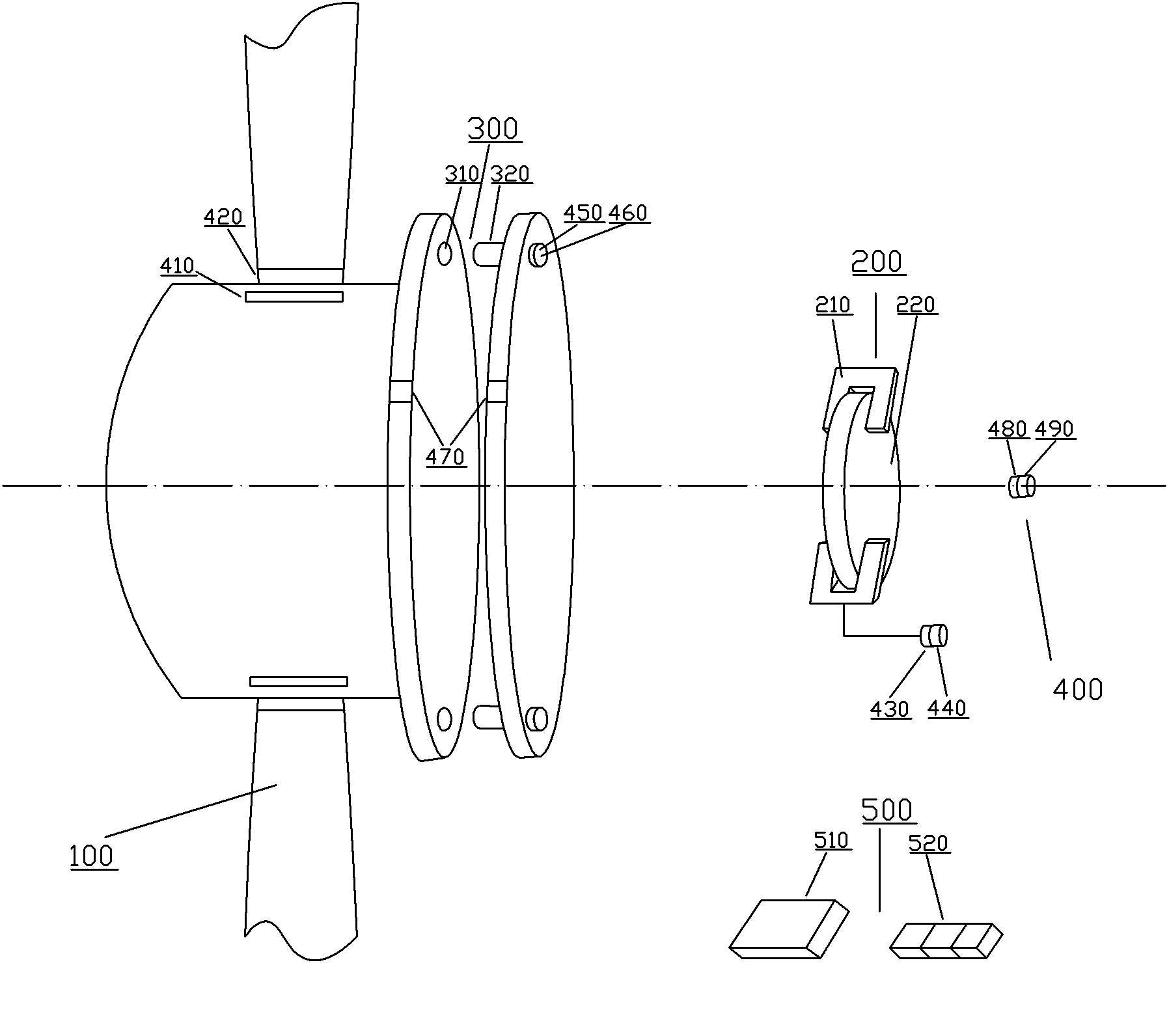

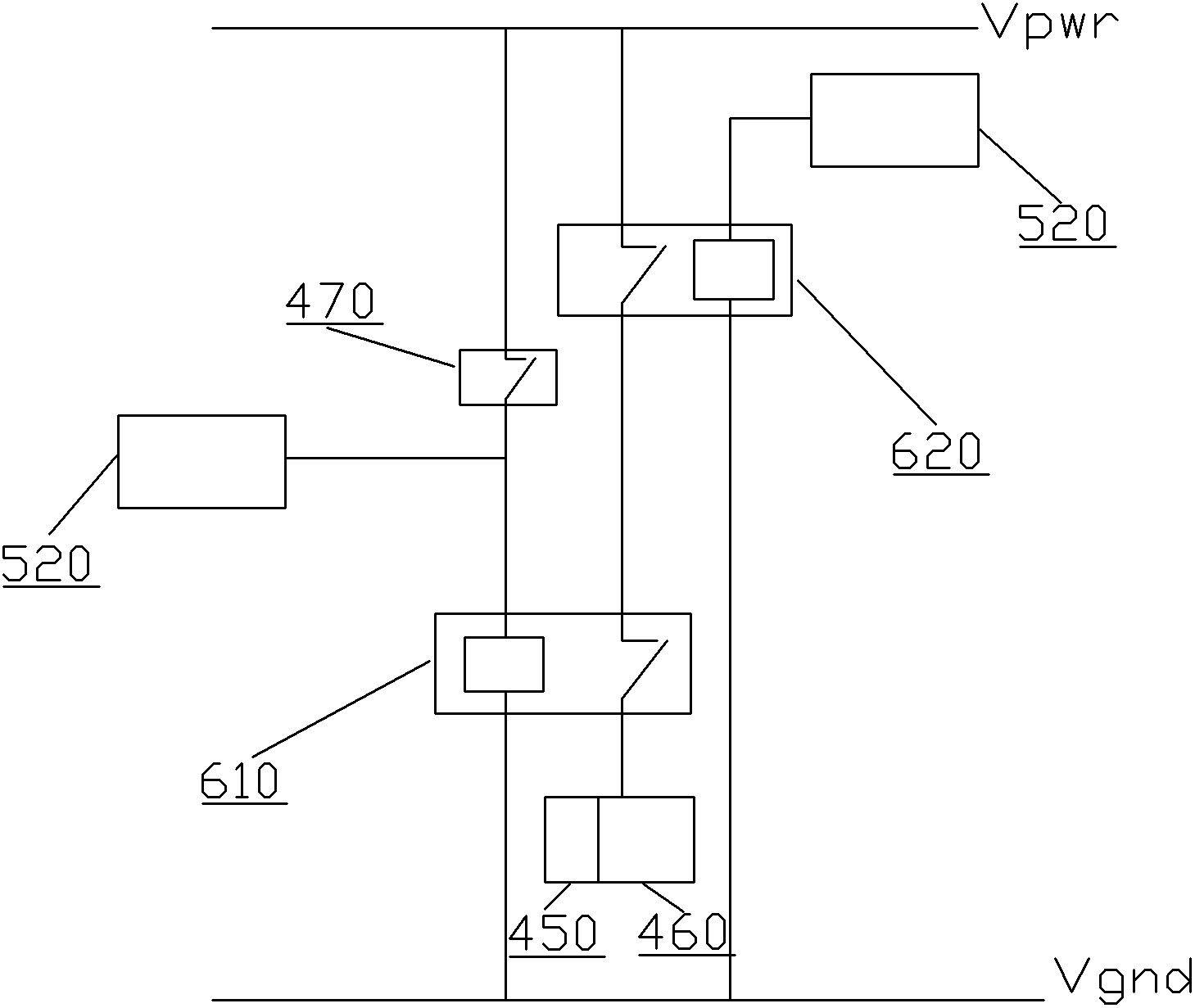

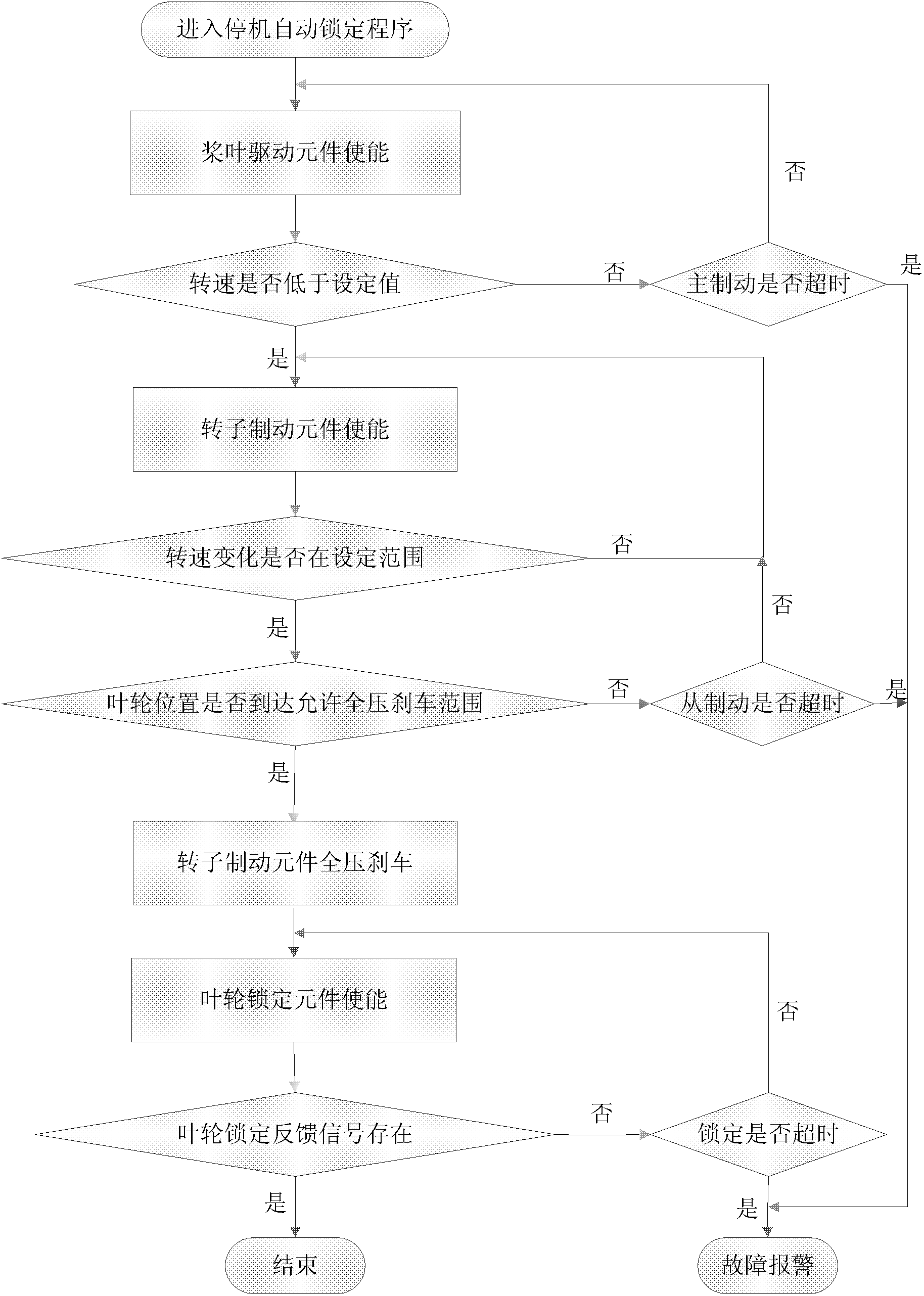

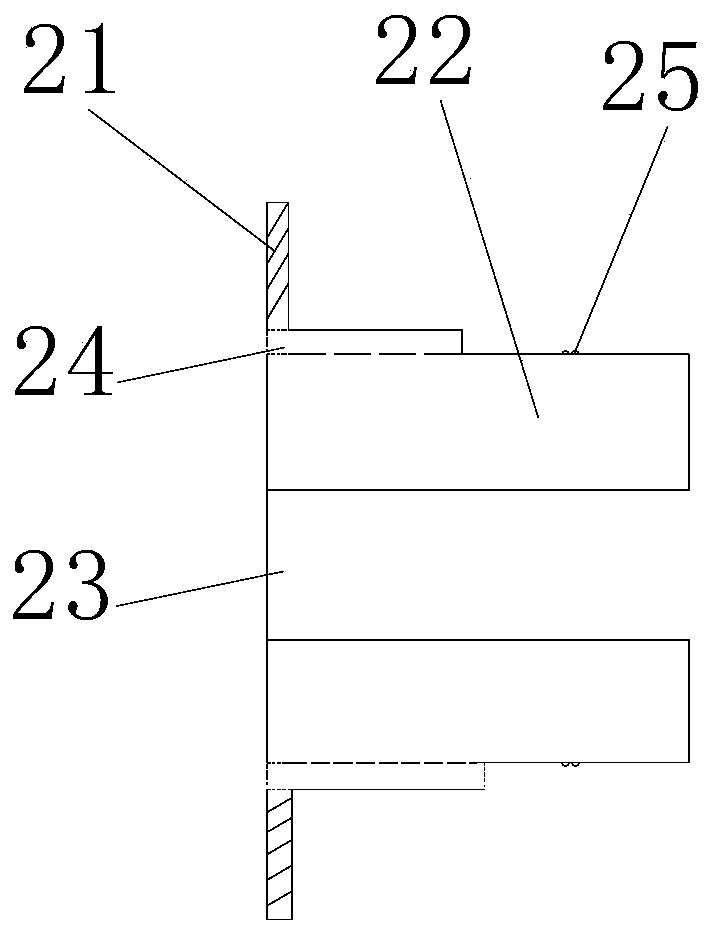

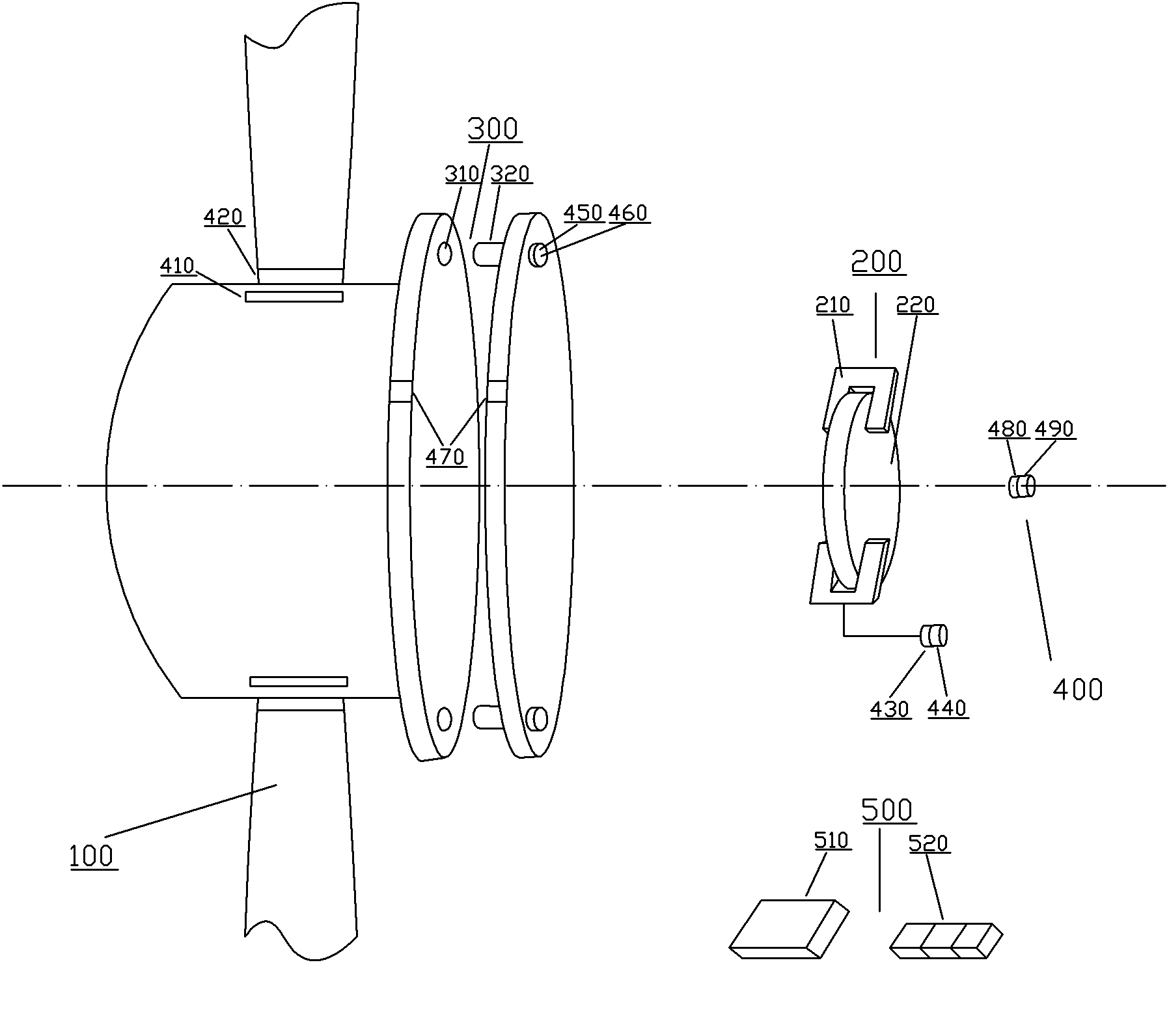

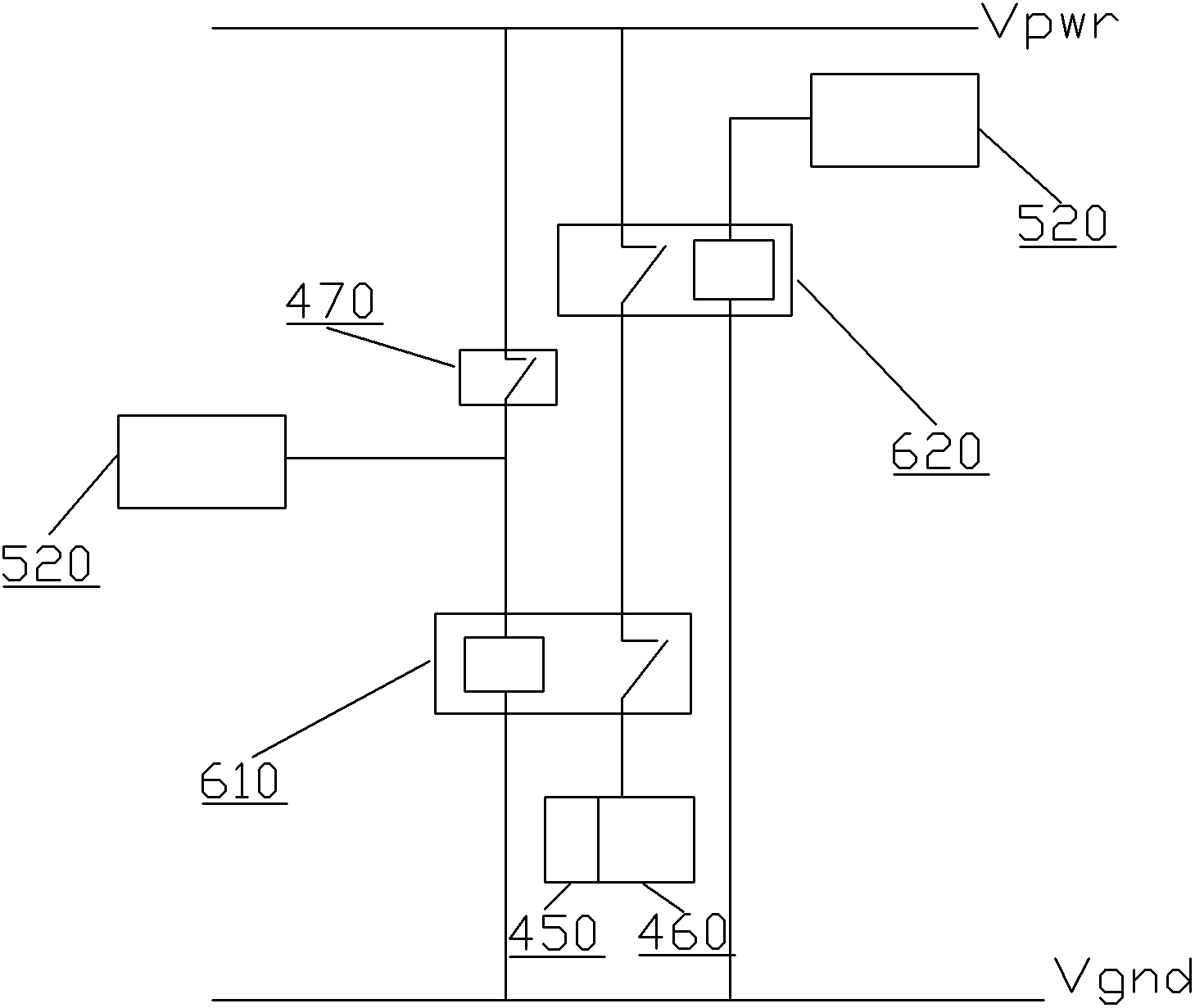

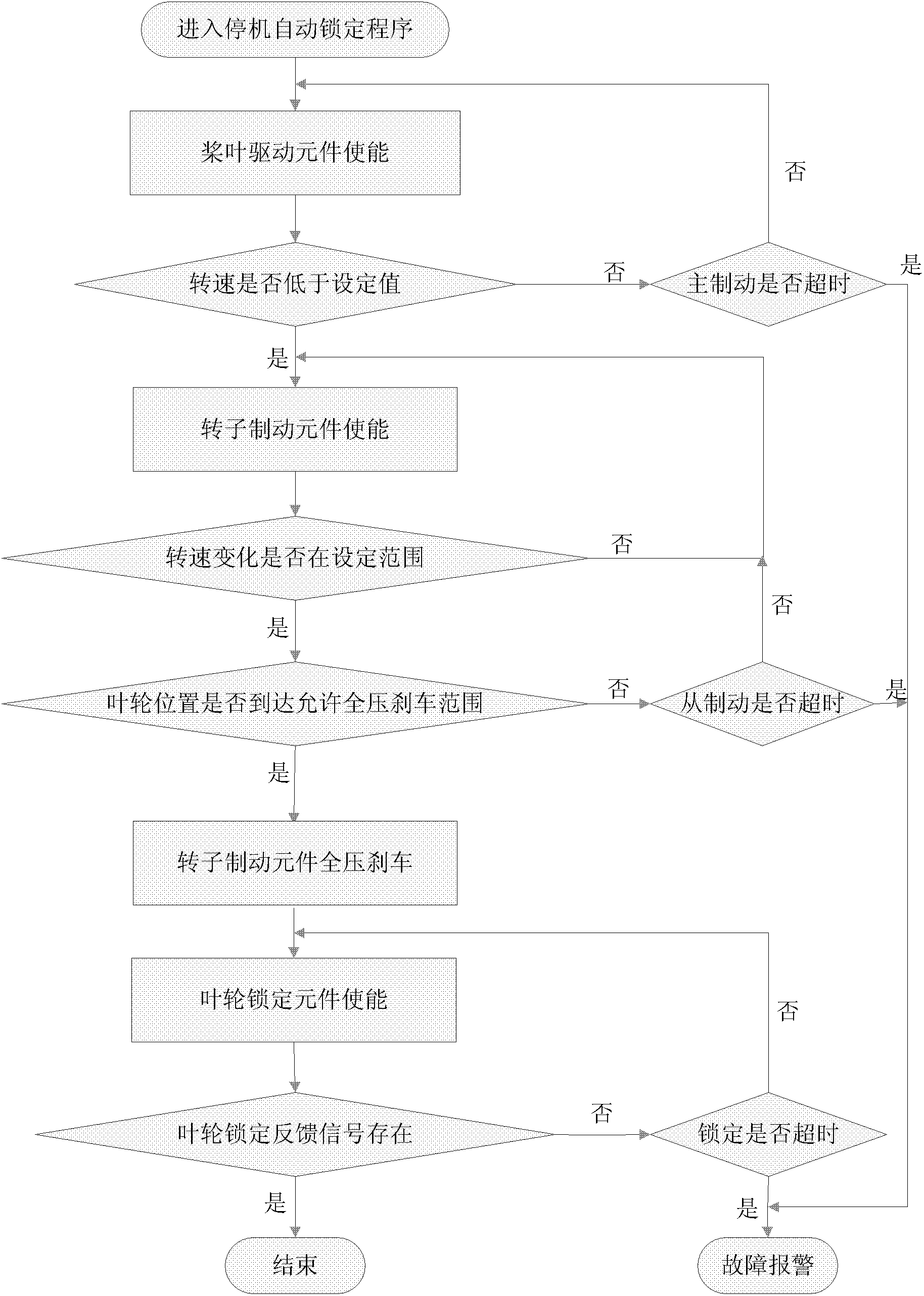

Impeller locking automatic control system and method for large wind power generator

ActiveCN102536659AEnsure safetyPrecise Control RequirementsWind motor controlMachines/enginesImpellerAutomatic train control

The invention discloses an impeller locking automatic control system and method for a large wind power generator. The impeller locking automatic control system comprises master and slave brake devices, an impeller locking device, a control element and a controller, and is in combination with the automatic control method obtained by programming of the element. The aim of the invention is to provide an automatic control system and method for realizing automatic braking and locking of a fan on an impeller in a halt process.

Owner:青海明阳新能源有限公司

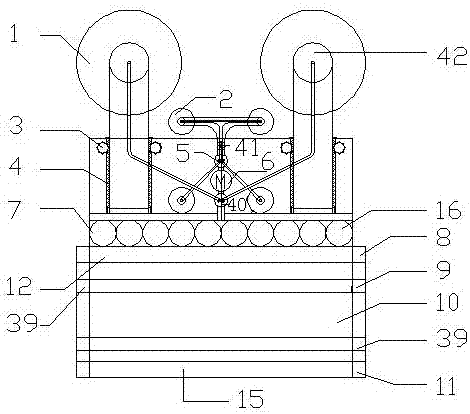

Cleaning robot

InactiveCN106725067AReduce labor risksSave human effortBuilding repairsWindow cleanersLabor risksBuilding environment

The invention provides a cleaning robot. The robot comprises a robot body and a roof safe lifting cable car. The robot body comprises an adsorption device, a cleaning system, a power supply system and a recovery system. The robot body uses the roof safe lifting cable car to control the lifting elevation and arrive at the cleaning positions. The adsorption device fixes the robot body to a glass curtain wall. The cleaning system conducts the cleaning of glass. The recovery system collects the filth generated in the aftermath of the glass cleaning operation. The power supply system supplies electric power to the adsorption device, cleaning system and the recovery system. The cleaning robot is highly helpful to the high altitude glass curtain wall cleaning work, saves labor and time, reduces the labor risks to the minimum, the robot uses the cleaning tools and the positioning of positions to clean the high altitude glass curtain wall without the need of installing external rails, therefore the building environment is embellished.

Owner:SHENYANG SIASUN ROBOT & AUTOMATION

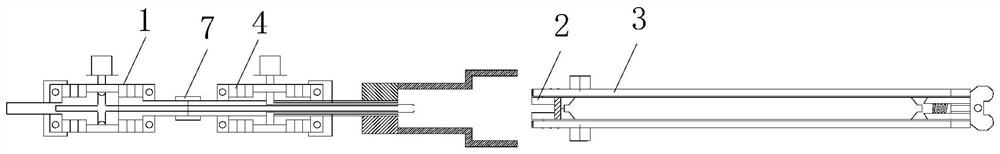

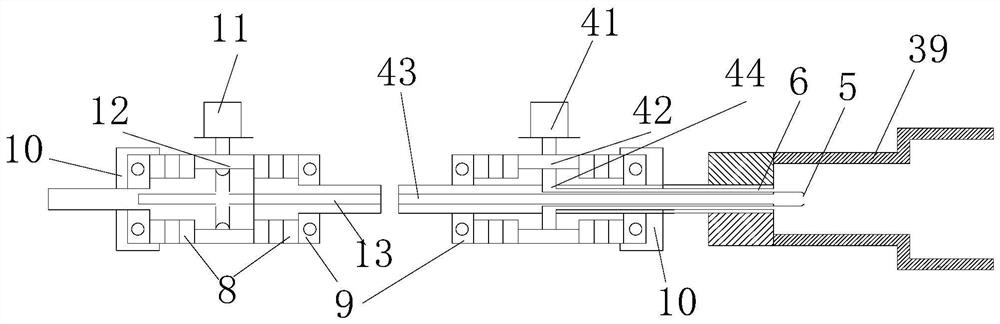

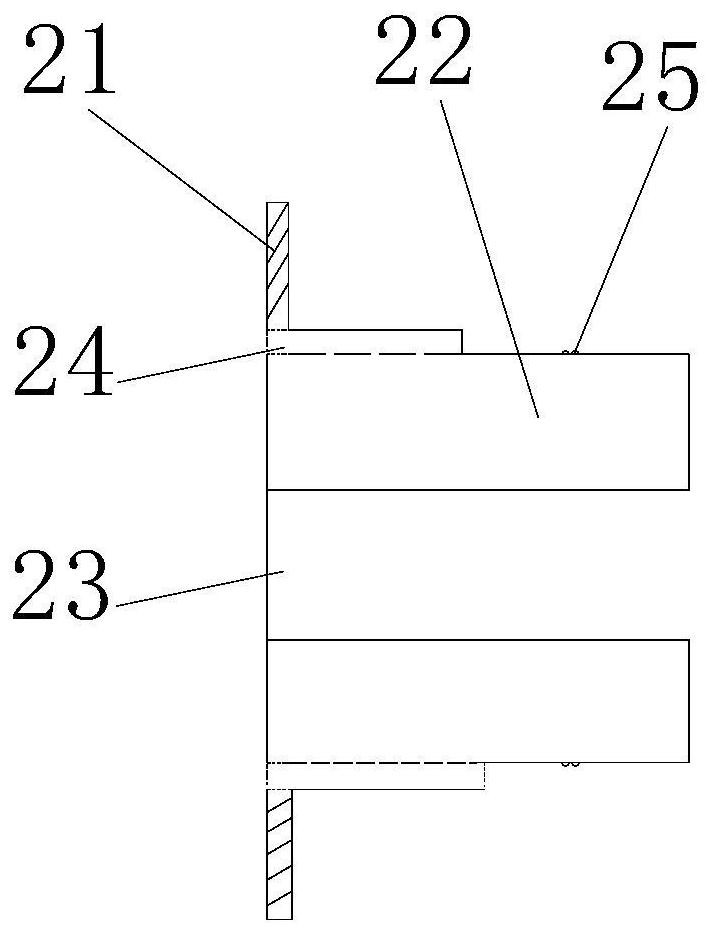

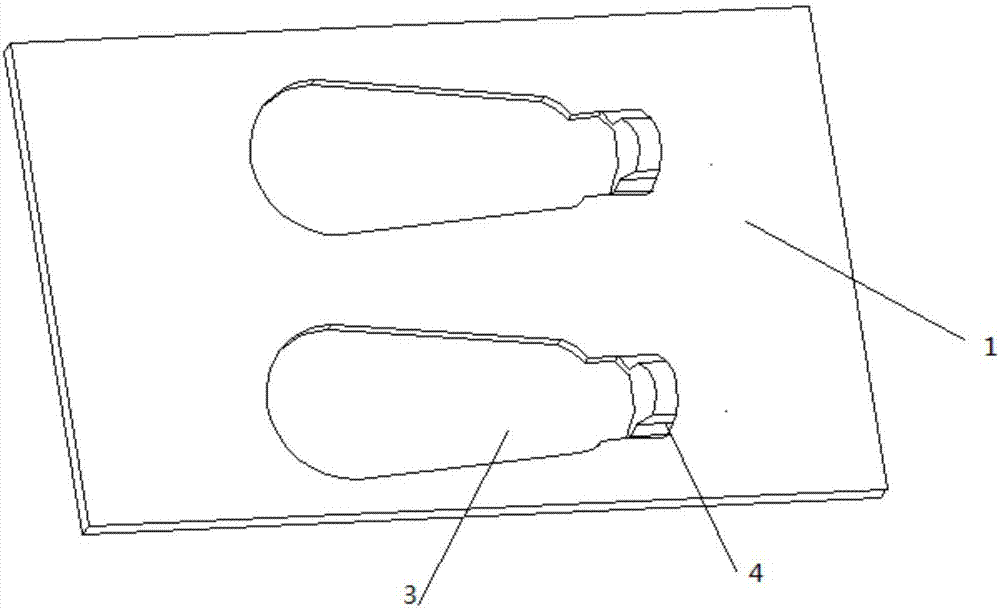

A full-length anchoring self-drilling anchor rod and anchoring method

ActiveCN110259493BRealize cooling constructionChange the support methodFlushingAnchoring boltsEngineeringHigh pressure water

The invention discloses a full-length anchoring self-drilling anchor rod and an anchoring method. A first through hole and a first ring hole which are not connected to each other are arranged in the first connecting shaft along the axial direction, and the first ring hole is coaxial The ring is arranged outside the first through hole, and the first quick connector communicates with the first ring hole after passing through the first connecting shaft; the second connecting shaft is provided with a second through hole in the axial direction, and the second through hole The hole communicates with the second quick joint; the second quick joint, the first through hole and the second through hole are connected to form an intermediate outlet passage for communicating with high-pressure water, and the first quick joint and the first annular hole are used to communicate with low pressure water. A peripheral outlet passage for water; the outer passage communicates with the gap between the steel pipe and the rod body, the central passage communicates with the end of the steel pipe, and the drill bit is connected to the head end of the steel pipe. The overall installation process of the present invention is simple, and the bolt can be successfully installed through the bolter, which improves the operating safety of workers, reduces labor risks, and realizes mechanized operations at the same time.

Owner:陶文斌

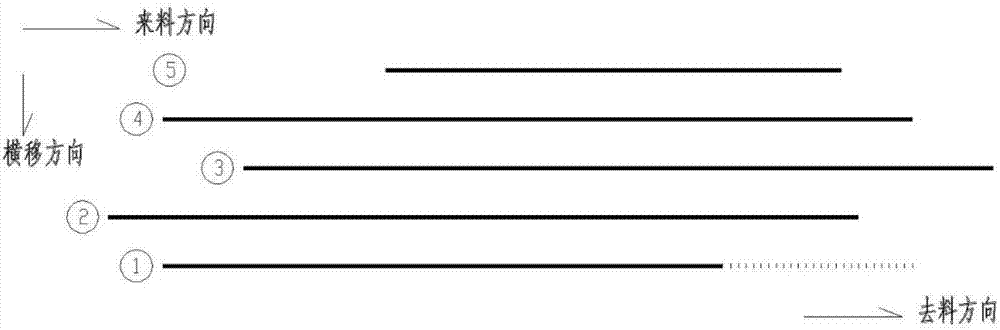

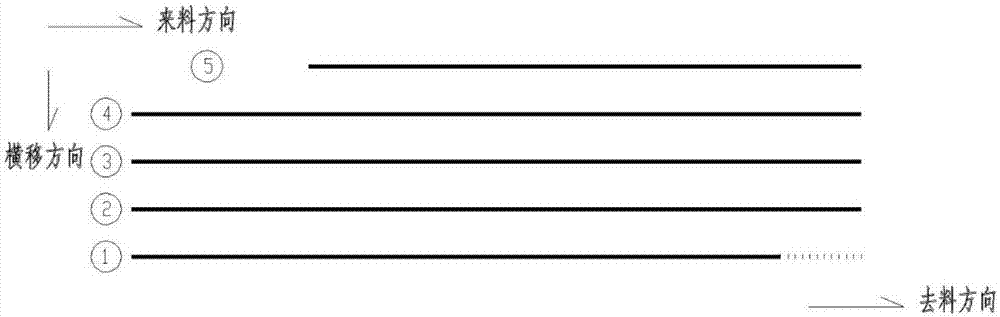

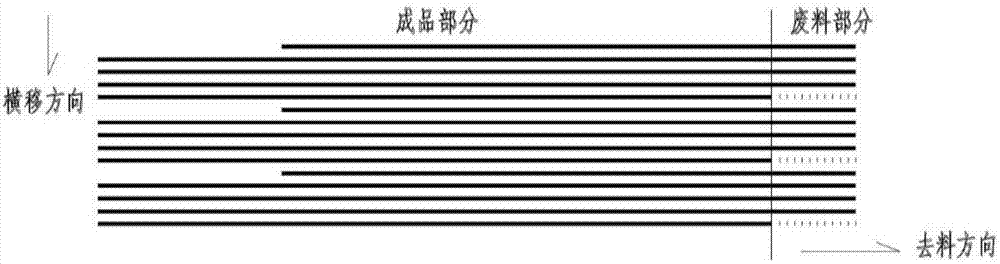

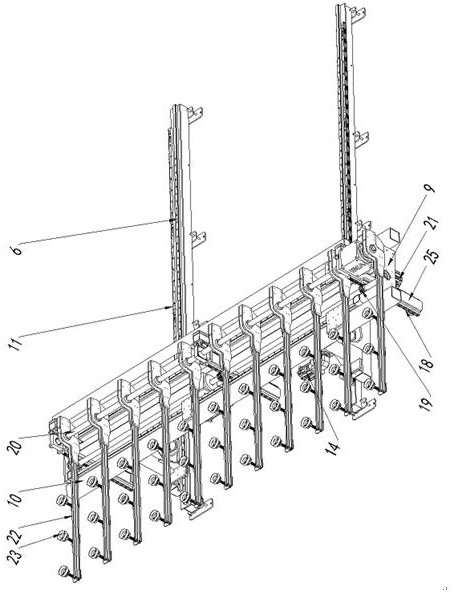

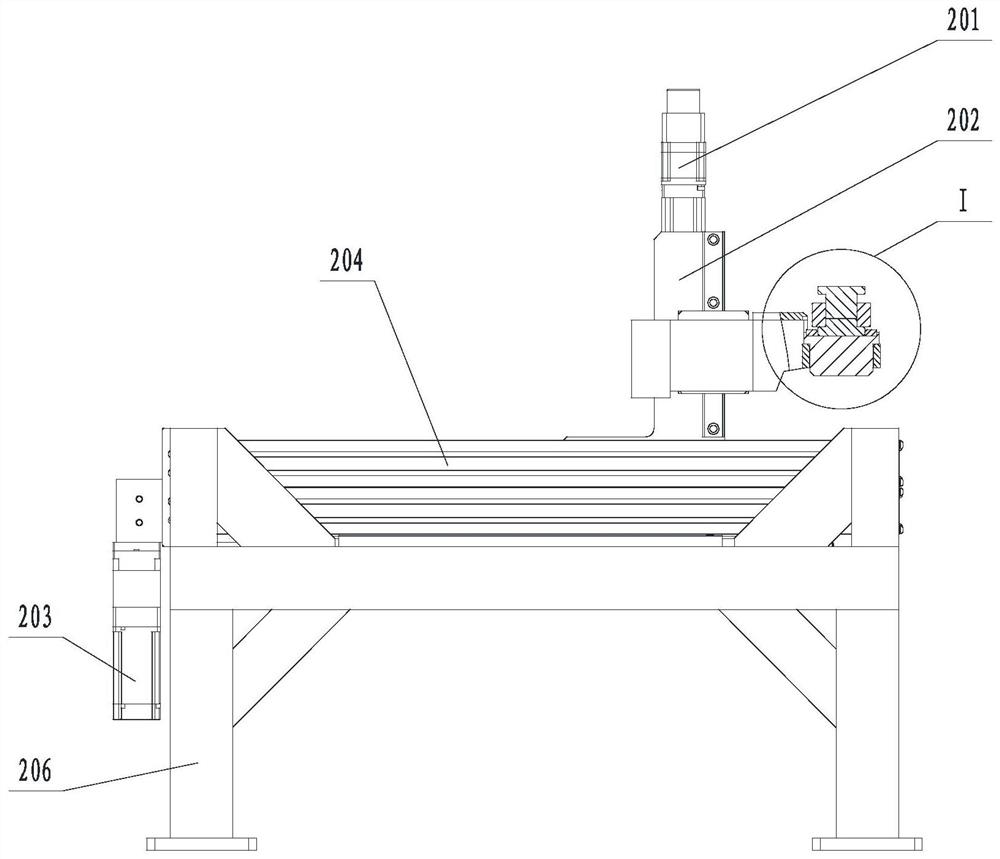

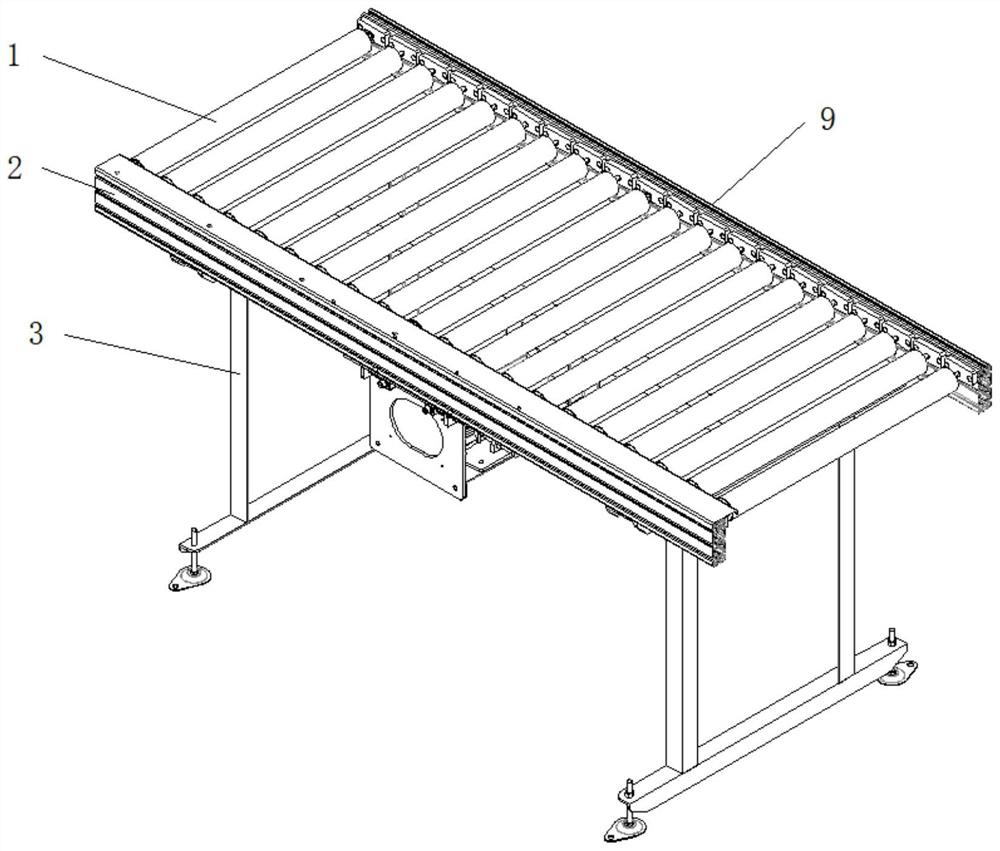

Cold bed and automatic picking device for cold bed finished product

InactiveCN107876567AReduce generationRealize automatic control modeMeasuring devicesCooling bedsAutomatic controlControl manner

The invention discloses a cold bed. The cold bed comprises an aligning device arranged at the preset stepping position of the cold bed and a picking device body arranged on the downstream portion of the aligning device. The aligning device comprises two or more first aligning roller ways which are arranged in parallel, and a first fixed baffle is arranged at one sides of the first aligning rollerways. The picking device body comprises a second aligning roller way, and a movable baffle is arranged at the same side of the aligning device and further corresponds a first position. A second fixedbaffle is arranged at the side, away from the aligning roller ways by a preset distance, of the movable baffle. The fixed baffles and the movable baffle are arranged corresponding to the moving direction of the aligning roller ways. The second aligning roller way is controlled to move towards the fixed baffles, and meanwhile the movable baffle is controlled to withdraw from the motion trail elongation line of the aligning roller ways; or the second aligning roller way is controlled to stop moving, and meanwhile the movable baffle is controlled to block the motion trail elongation line of the aligning roller ways. By adoption of the cold bed, the automatic control mode can be realized, and the yield is increased; and meanwhile automatic selection can be conducted to do sampling work, the labor risks are lowered and production safety is improved.

Owner:MCC HUATIAN NANJING AUTOMATION ENG

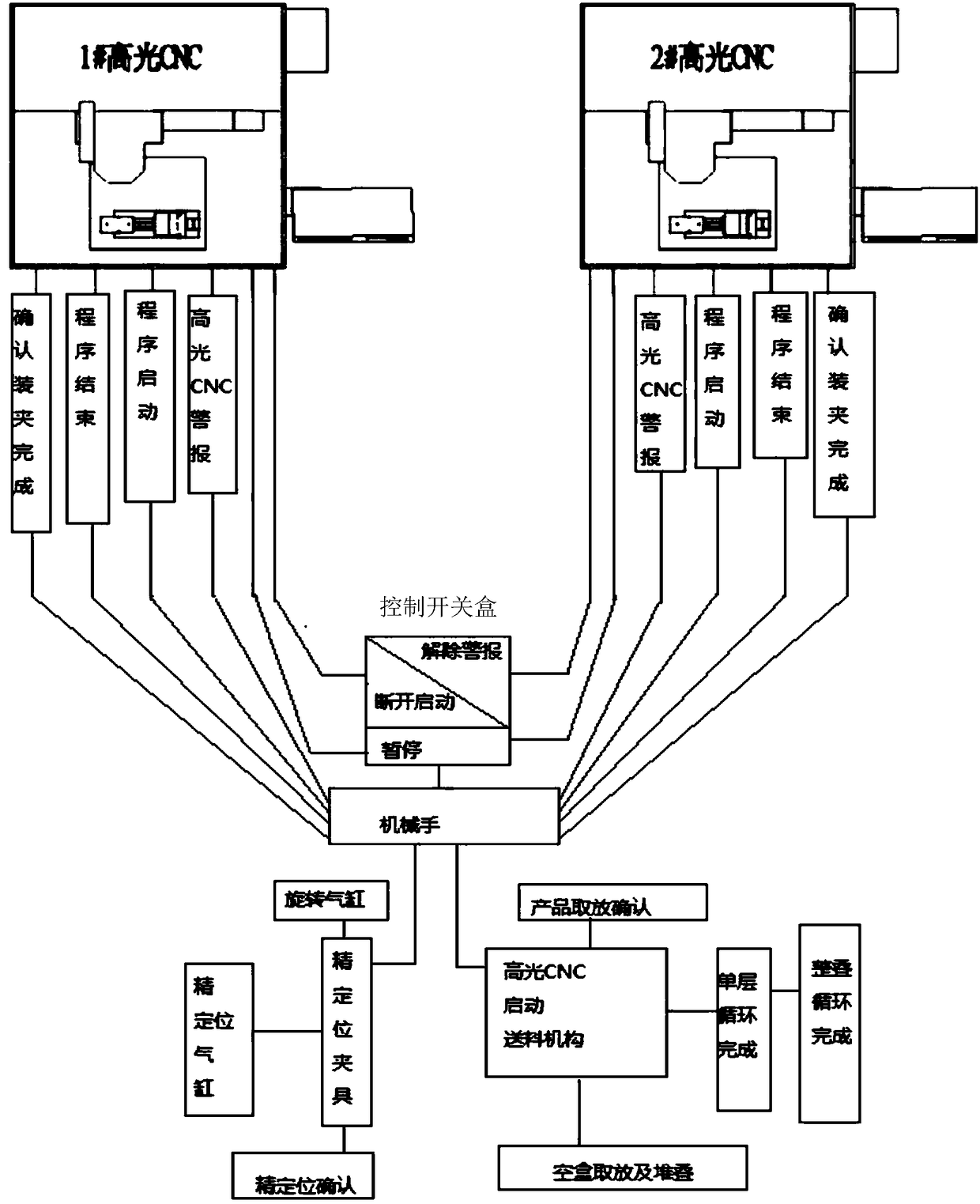

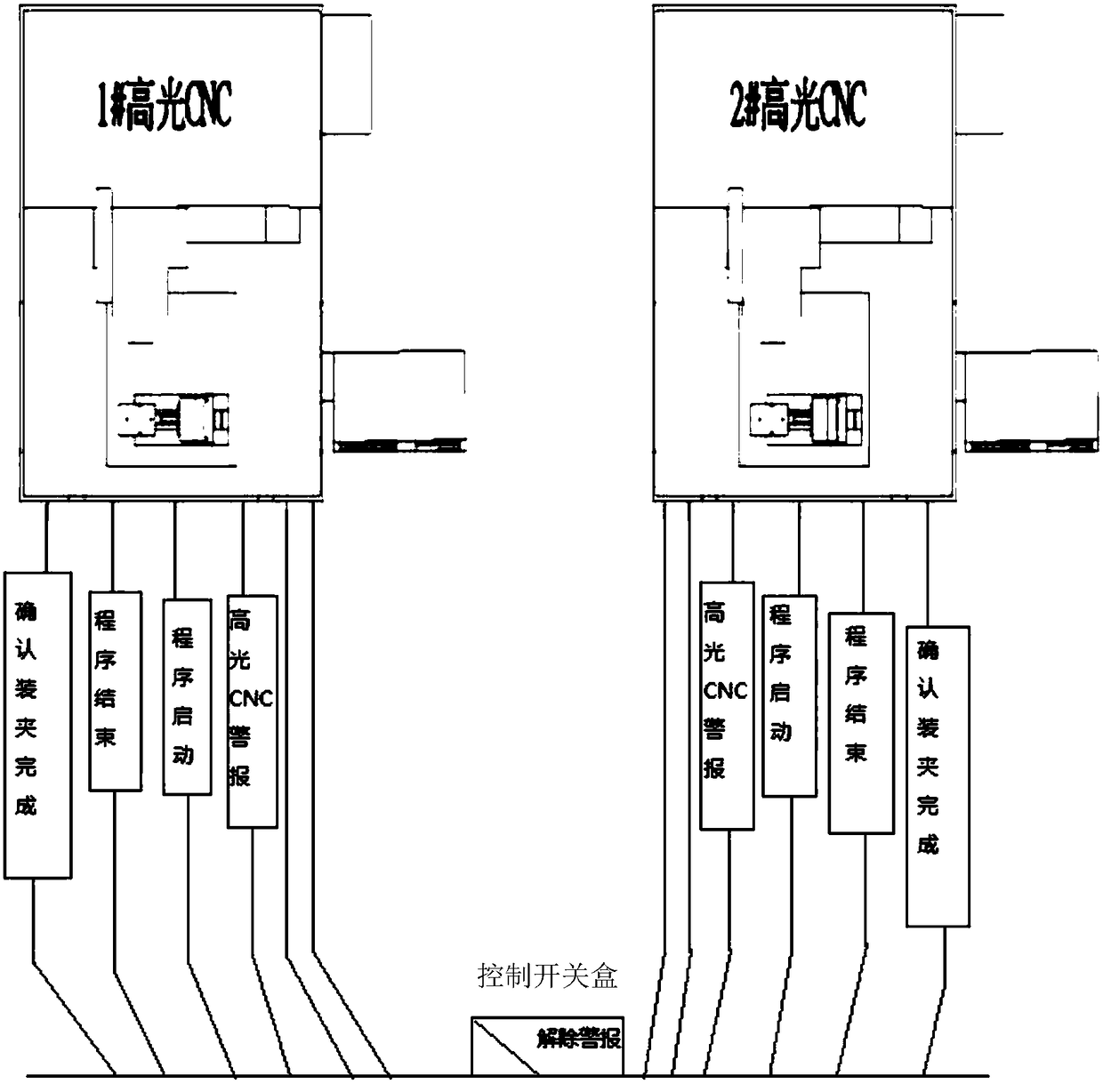

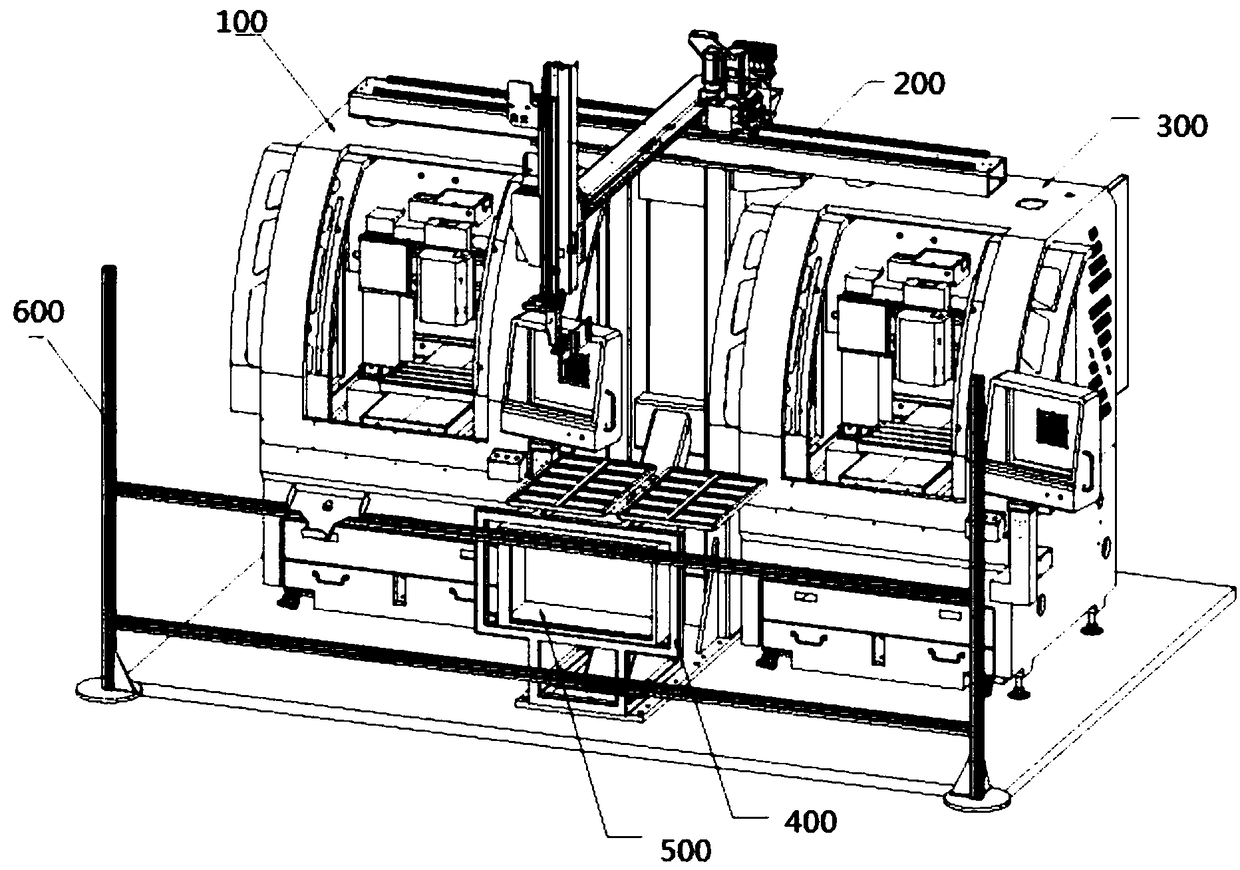

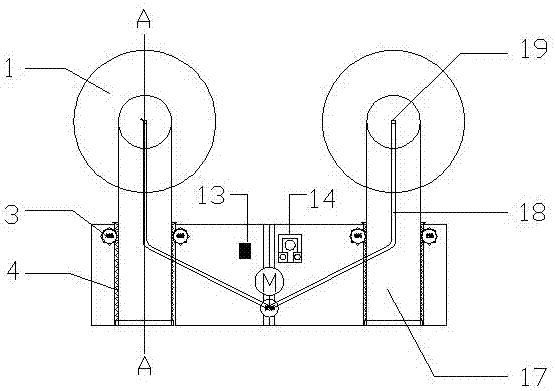

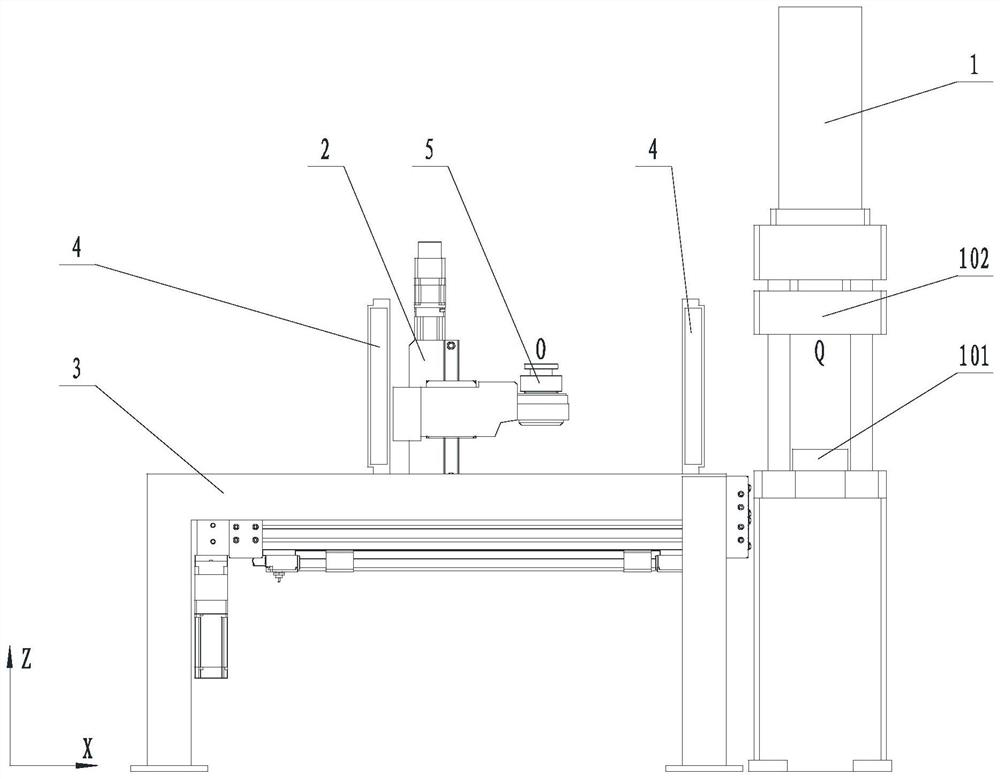

Two-driven-by-one mechanical arm and highlight CNC cooperating automatic feeding and discharging system

InactiveCN108127470AReduce labor intensityUniform product qualityMetal working apparatusGratingManipulator

The invention discloses a two-driven-by-one mechanical arm and highlight CNC cooperating automatic feeding and discharging system. The system comprises a two-driven-by-one mechanical arm, a highlightCNC machining automatic feeding mechanism, a mechanical arm control box, a safety optical grating, a first highlight CNC machine and a second highlight CNC machine, wherein the two-driven-by-one mechanical arm is connected to the first highlight CNC machine in a matching mode and connected to the second highlight CNC machine in a matching mode; the highlight CNC machining automatic feeding mechanism is disposed between the first highlight CNC machine and the second highlight CNC machine in a matching mode; the mechanical arm control box is disposed in the highlight CNC machining automatic feeding mechanism; and the safety optical grating is disposed on the front side of the highlight CNC machining automatic feeding mechanism. By means of the two-driven-by-one mechanical arm and highlight CNC cooperating automatic feeding and discharging system, the two-driven-by-one mechanical arm can cooperate with two highlight CNC machines to perform feeding and discharging, the cost is reduced, theproduction efficiency is improved, the maintaining cost is low, and the floor space is small; and the system is particularly applied to the two processes of the same product needing highlight machining for the two ends and needing two highlight CNC machines, the efficiency is obviously improved, the transfer space is saved, and various resource cost caused by transferring is reduced.

Owner:东莞市铭航智能科技有限公司

Quick replacement device for furnace roller of thermal treatment furnace

ActiveCN105567936AMeet replacement needsEasy to installFurnace typesHeat treatment furnacesThermal treatmentMechanical engineering

The invention discloses a quick replacement device for a furnace roller of a thermal treatment furnace. The quick replacement device comprises a clamping device, a mobile guide device and a fixed guide device. The clamping device comprises a trolley and a demounting platform fixedly provided with sliding blocks, and a gantry framework is fixed to the trolley. A bench clamp is fixed to the demounting platform. The quick replacement device further comprises a hydraulic jack fixed to the trolley; the hydraulic jack is connected with the demounting platform through a chain and a chain wheel. The mobile guide device comprises a first U-type bolt and a first cross beam in threaded connection with the first U-type bolt. The two ends of the first cross beam are in rolling connection with furnace rollers arranged on two sides of a furnace roller needing to be replaced in an adjacent mode correspondingly. The fixed guide device comprises a second U-type bolt and a second cross beam in threaded connection with the second U-type bolt. The arc section of the second U-type bolt is provided with at least one second idler wheel. The two ends of the second cross beam are fixedly provided with second supporting frames with magnets.

Owner:LAIWU IRON & STEEL GRP

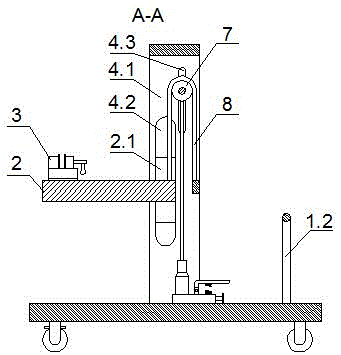

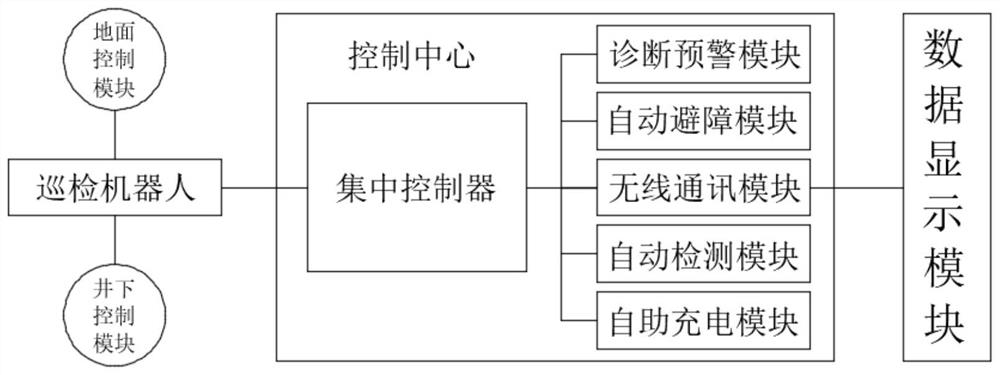

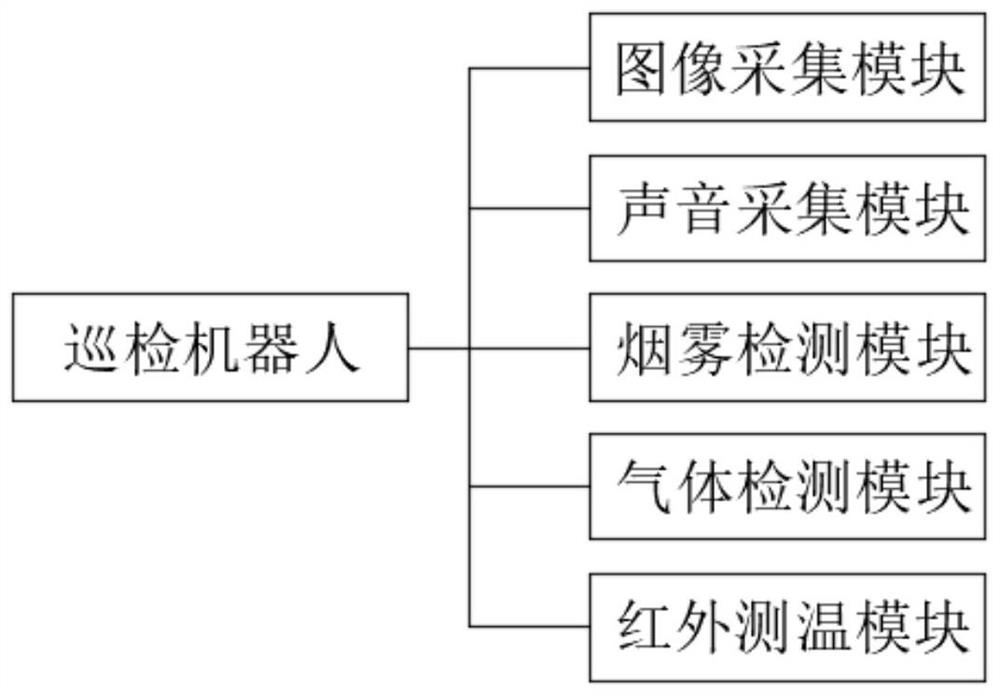

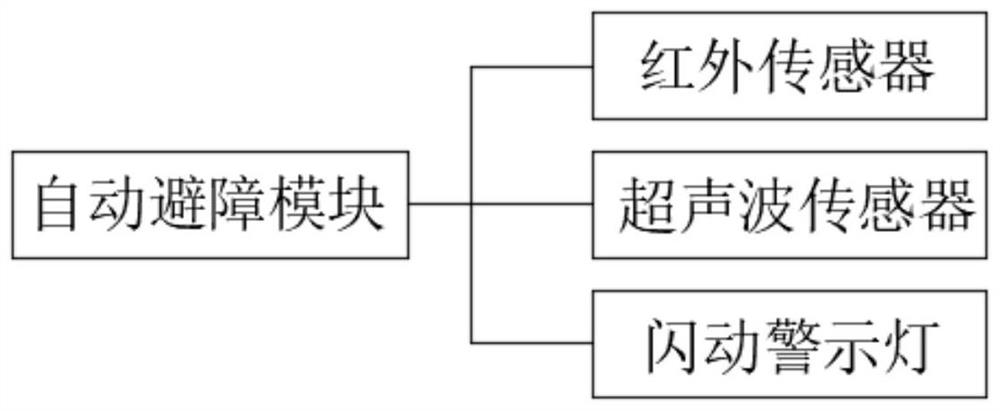

Intelligent inspection and detection system for coal conveying belt conveyor in coal conveying bin area

InactiveCN114772207AReduce labor intensityReduce labor risksControl devices for conveyorsData displayControl engineering

The invention discloses an intelligent inspection and detection system for a coal conveying belt conveyor in a coal conveying bin area, which relates to the technical field of detection systems and comprises an inspection robot, a ground control module, a control center, an underground control module and a data display module. The control center comprises a centralized controller, a diagnosis early warning module, an automatic obstacle avoidance module, a wireless communication module, an automatic detection module and an automatic charging module, the ground control module and the underground control module are connected with the inspection robot through signal lines, and the inspection robot is connected with the centralized controller. The integrated controller is connected with the diagnosis early warning module, the automatic obstacle avoidance module, the wireless communication module, the automatic detection module and the automatic charging module. According to the method, the labor intensity of workers is relieved, the labor risk is reduced, the problems are found in time, accident expansion is avoided, and the abnormal shutdown time in the production process is greatly shortened.

Owner:内蒙古东蒙工贸有限责任公司 +1

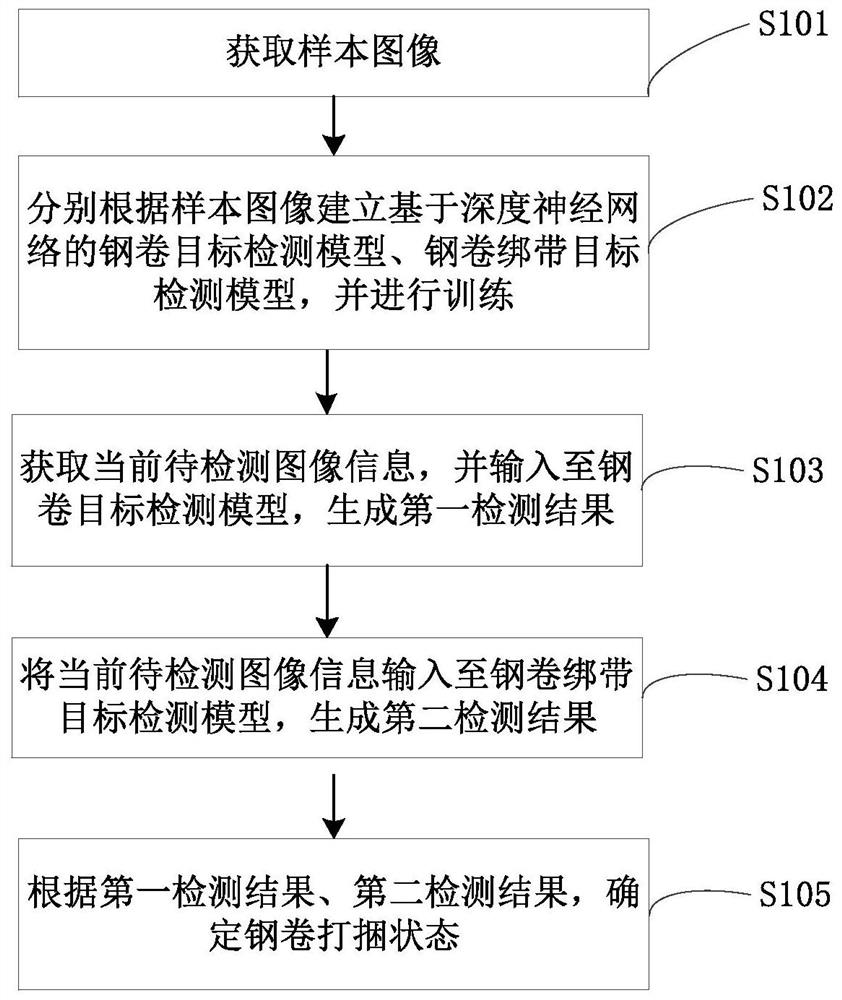

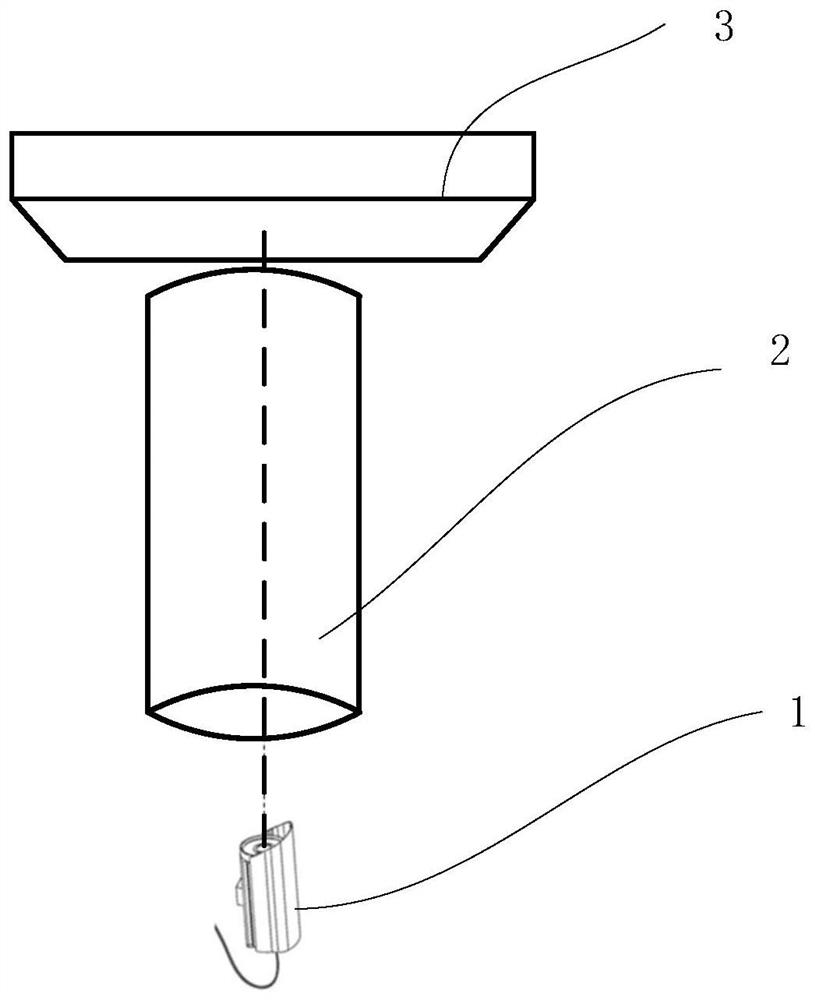

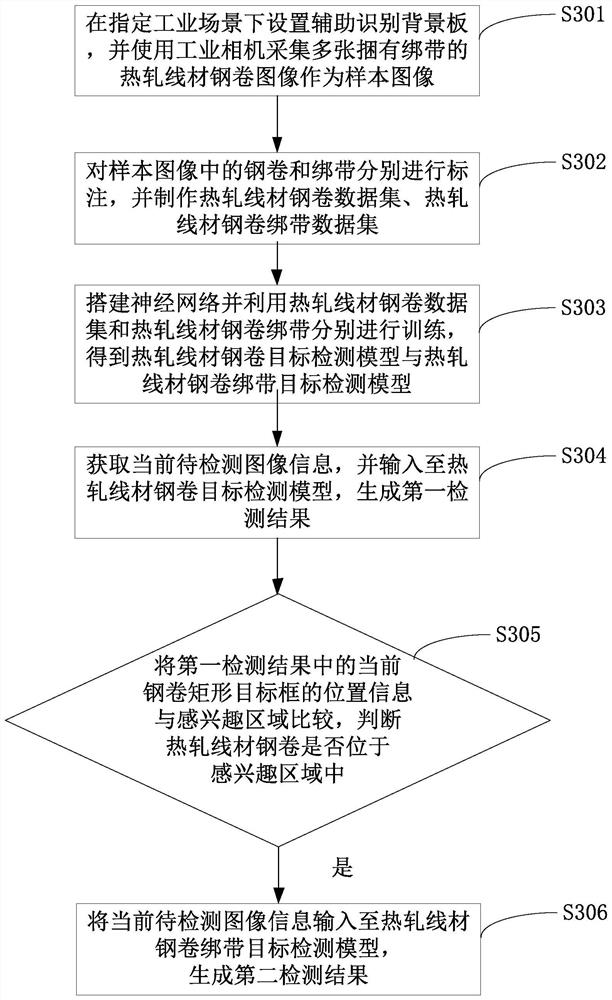

Steel coil bundling state detection method and system, terminal and medium

The invention provides a steel coil bundling state detection method and system, a terminal and a medium, and the method comprises the steps: obtaining a sample image, building a steel coil target detection model and a steel coil bandage target detection model based on a deep neural network according to the sample image, carrying out the training, and obtaining the current to-be-detected image information, and inputting the information into the steel coil bandage target detection model to generate the first detection result. The image information to be detected is input into the steel coil binding belt target detection model to generate a second detection result, and the steel coil binding state is determined according to the first detection result and the second detection result; the technical problems that the bundling state of the hot-rolled wire rod steel coil still needs to be detected by workers on site and is not detected timely, accurately and comprehensively, the labor risk ofthe workers is large, and the cost is high are solved, detection is more timely and accurate, the bundling state of the steel coil is detected through a machine, the labor risk of the workers is reduced, and the cost is reduced.

Owner:CISDI INFORMATION TECH CO LTD

Full-length anchoring self-drilling anchor rod and anchoring method

ActiveCN110259493ARealize cooling constructionChange the support methodFlushingAnchoring boltsRing modeHigh pressure water

The invention discloses a full-length anchoring self-drilling anchor rod and an anchoring method. A first through hole and a first ring hole which do not communicate with each other are formed in a first connecting shaft in the axial direction, the first ring hole is coaxially arranged outside the first through hole in a ring mode, and a first quick joint communicates with the first ring hole after penetrating through the first connecting shaft; a second connecting shaft is internally provided with a second through hole in the axial direction, and the second through hole communicates with a second quick joint; the second quick joint, the first through hole and the second through hole communicate to constitute an intermediate exit passage for communicating with high-pressure water, and the first quick connector and the first ring hole constitute a peripheral outlet passage for communicating with low-pressure water; and an outer edge passage communicates with a gap between a steel pipe and a rod body, a center passage communicates with the tail end of the steel pipe, and a drill bit is connected to the head end of the steel pipe. According to the full-length anchoring self-drilling anchor rod and the anchoring method, the overall installation process is simple, the anchor rod can be installed successfully through a roof bolter, the safety of the operation of workers is improved, the labor risk is reduced, and meanwhile, mechanization operation is realized.

Owner:陶文斌

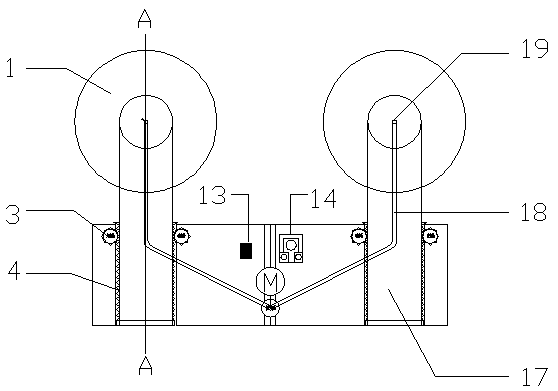

Intelligent whitewashing device

The invention relates to an intelligent whitewashing device. The intelligent whitewashing device comprises two linkage large suction cups, two retractable guiding rails, four medium suction cups, a whitewashing chamber, a medium lead storage battery pack, a single chip microcomputer and a guided system, wherein the single chip microcomputer and the guided system are arranged in a driverscope. The front end of each retractable guiding rail is provided with the corresponding linkage large suction cup, and the two sides of the rear portion of each retractable guiding rail is provided with retractable guiding rail gears; the retractable guiding rail gears are engaged with fixed gears which are engaged with motors; a base plate is arranged in the center of each retractable guiding rail and is provided with an advancing suction cup air guide tube, and the advancing suction cup air guide tubes are connected with the linkage large suction cups and a first air pump; the four medium suction cups are fixed to a framework, and four air guide tubes are arranged on the framework and are connected with the medium suction cups and a second air pump; supplying tubes are arranged on the upper portion of the whitewashing chamber, and the whitewashing chamber is internally provided with the forward motor, a roller brush, the backward motor and the medium lead storage battery pack; and the multiple supplying tubes are connected with a slurry inlet pipeline which is connected with a slurry conveying pump, and the slurry conveying pump is connected with a water head adjuster connected with the guided system. The intelligent whitewashing device is good in safety and high in efficiency.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

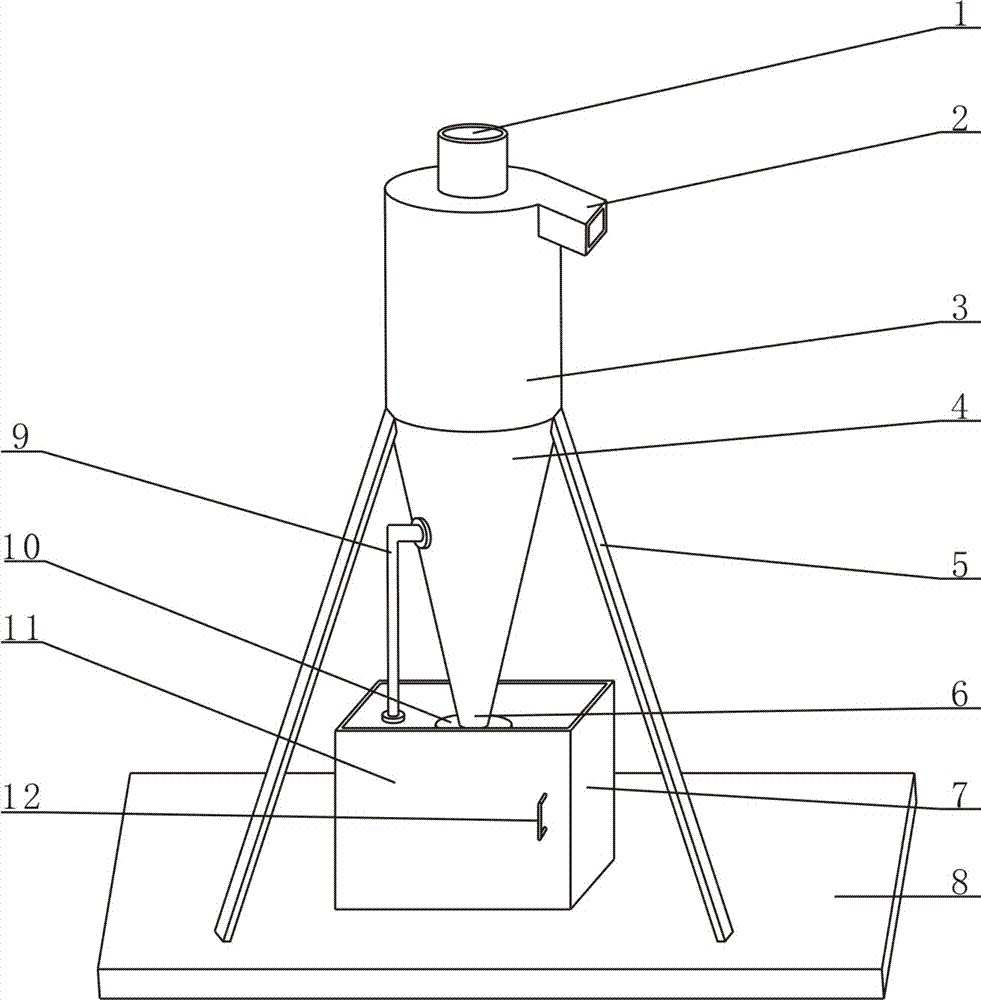

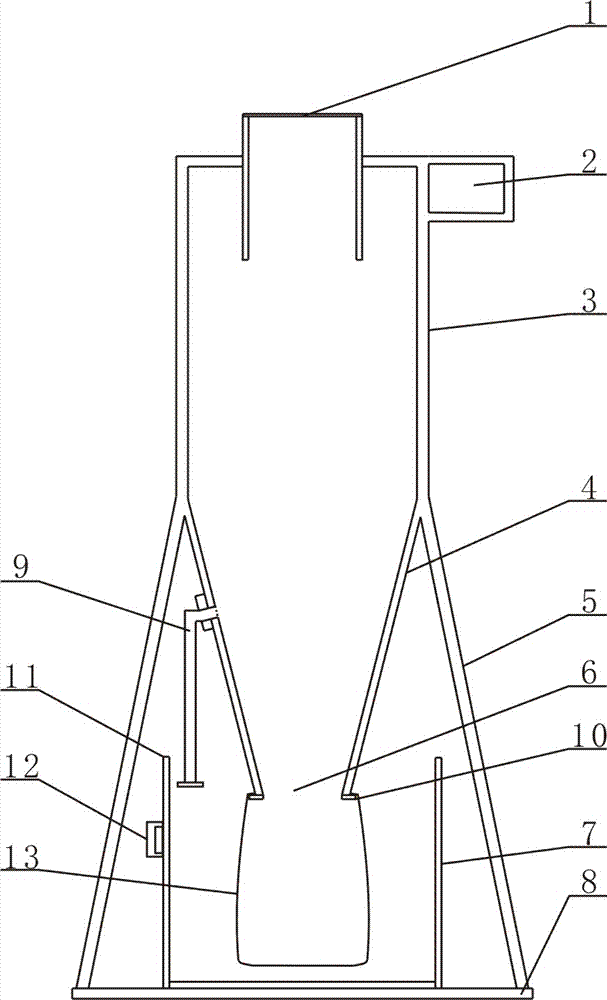

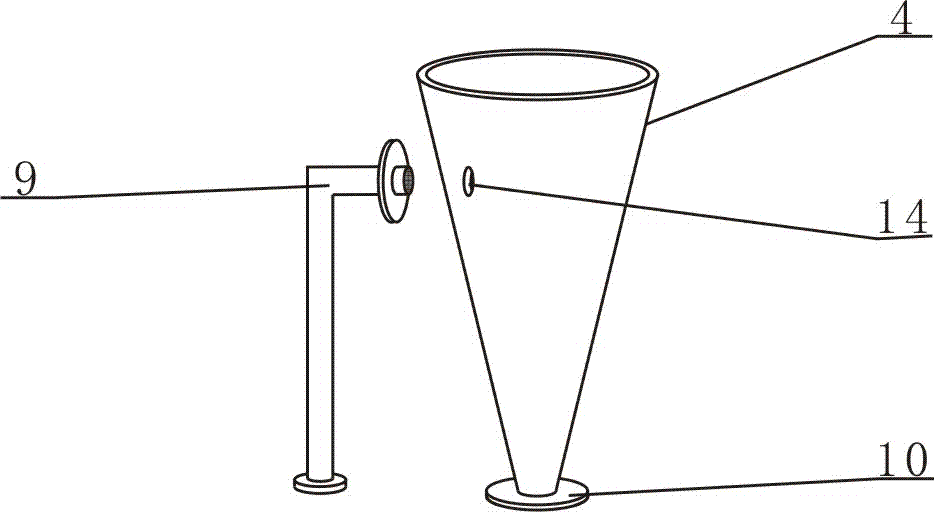

Spraying material receiving port dust collecting device capable of preventing ammonium salt byproduct leakage

PendingCN107138296APromote recoveryReduce pollutionReversed direction vortexEnvironmental engineeringMechanical engineering

The invention provides a spraying material receiving port dust collecting device capable of preventing ammonium salt byproduct leakage, and relates to the field of raw material processing machinery. The spraying material receiving port dust collecting device comprises a supporting device, a collecting device, a feeding device and an air-out barrel, wherein the collecting device is arranged on the supporting device, the feeding device is arranged on the collecting device, and the air-out barrel is arranged on the feeding device. The supporting device is composed of a base and a support, and the support is arranged on the base; the feeding device is composed of an air-intake barrel and an upper tank, and the air-intake barrel is arranged on the upper tank; and the collecting device is composed of a lower tank, a dust collecting device, a material collecting device and a collecting box, the dust collecting device is arranged on the side face of the lower tank, and the material collecting device is arranged on the bottom face of the lower tank. The spraying material receiving port dust collecting device is simple in structure and convenient to operate, ammonium salt byproduct powder can be rapidly recycled, disassembling and cleaning can be convenient to achieve, contamination of floating of the ammonium salt byproduct powder to a working environment can be reduced, body health of workers is protected, the labor risk of a maintainer is reduced, the operation cost of an enterprise is reduced, and enterprise income is increased.

Owner:洛阳蓝斯利科技有限公司

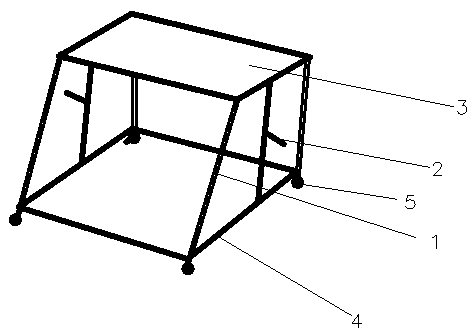

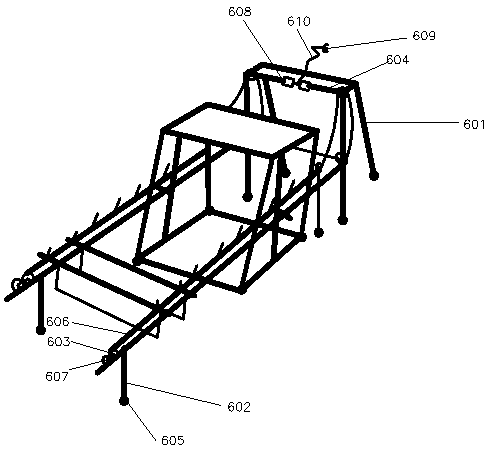

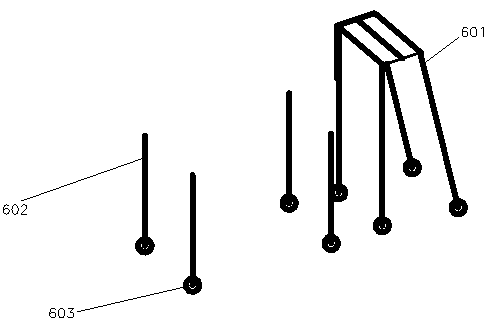

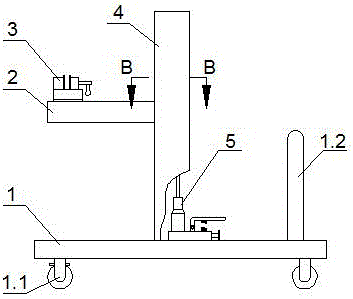

Tobacco leaf baking loading and unloading device and using method thereof

InactiveCN109436672AEasy balance settingPrevent slippingTobacco preparationConveyorsEconomic benefitsEngineering

The invention relates to the technical field of tobacco leaf baking equipment, in particular to a tobacco leaf baking loading and unloading device and a using method thereof. The device comprises telescopic rods, a handle, a panel, a fixing rod, universal wheels and a conveying device, the telescopic rods are connected with the panel and the fixing rod, the handle is located in the middle of the two middle telescopic rods, the universal wheels are located at the bottoms of the telescopic rods, and the conveying device is connected with the telescopic rods. According to the tobacco leaf bakingloading and unloading device, the structure is simple, the use is convenient, the device can be used for both baking loading and baking unloading, the number of tobacco growers and the staying time ofthe tobacco growers in a high-temperature baking house can be effectively reduced, the physical and psychological health of the tobacco growers is facilitated, the labor cost is saved, the working efficiency of the baking loading is improved, the tobacco leaf breaking rate is reduced, the economic benefits are increased, the safety hazard of an upper rod on the upper layer can be eliminated through the design of a platform, and the labor risk is reduced.

Owner:河南电翼电力科技有限公司

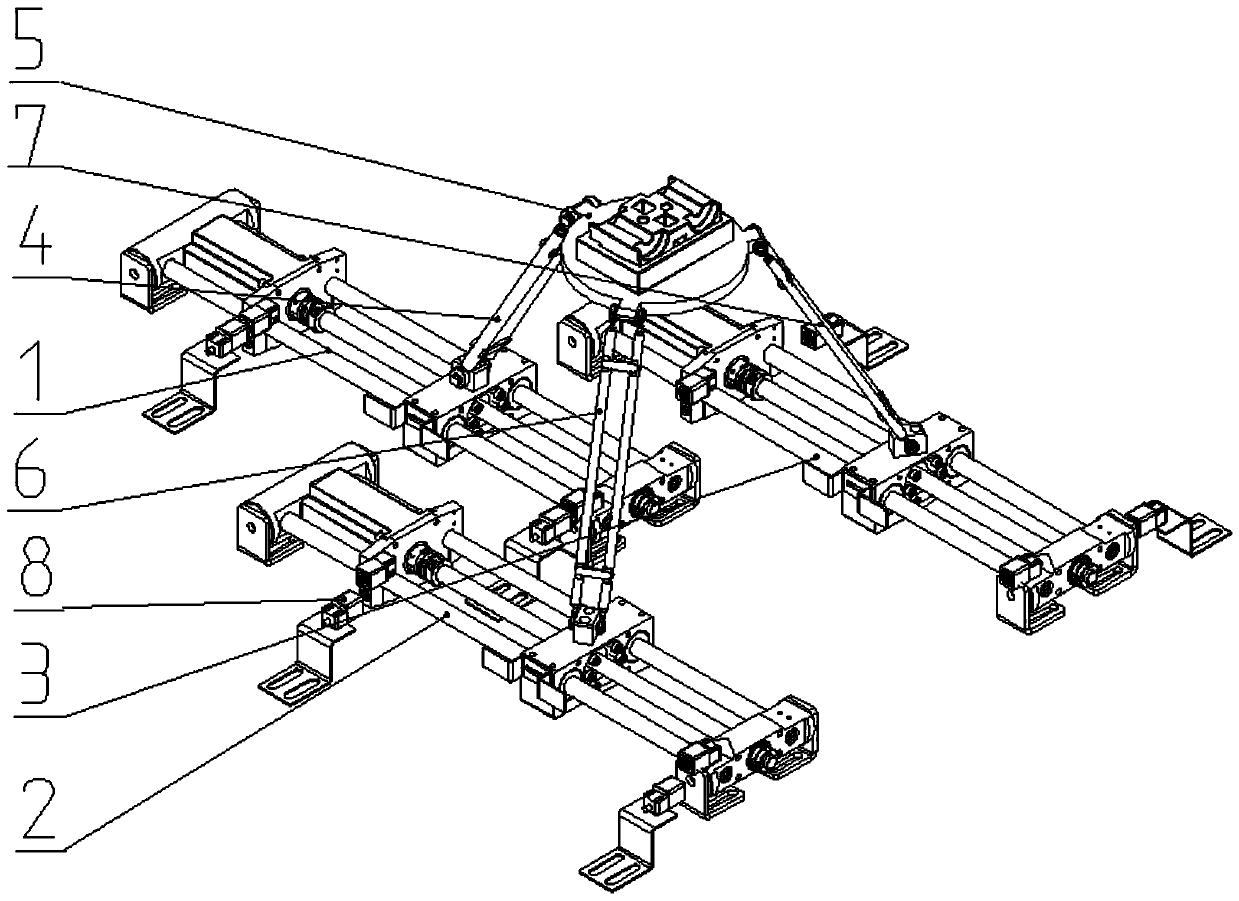

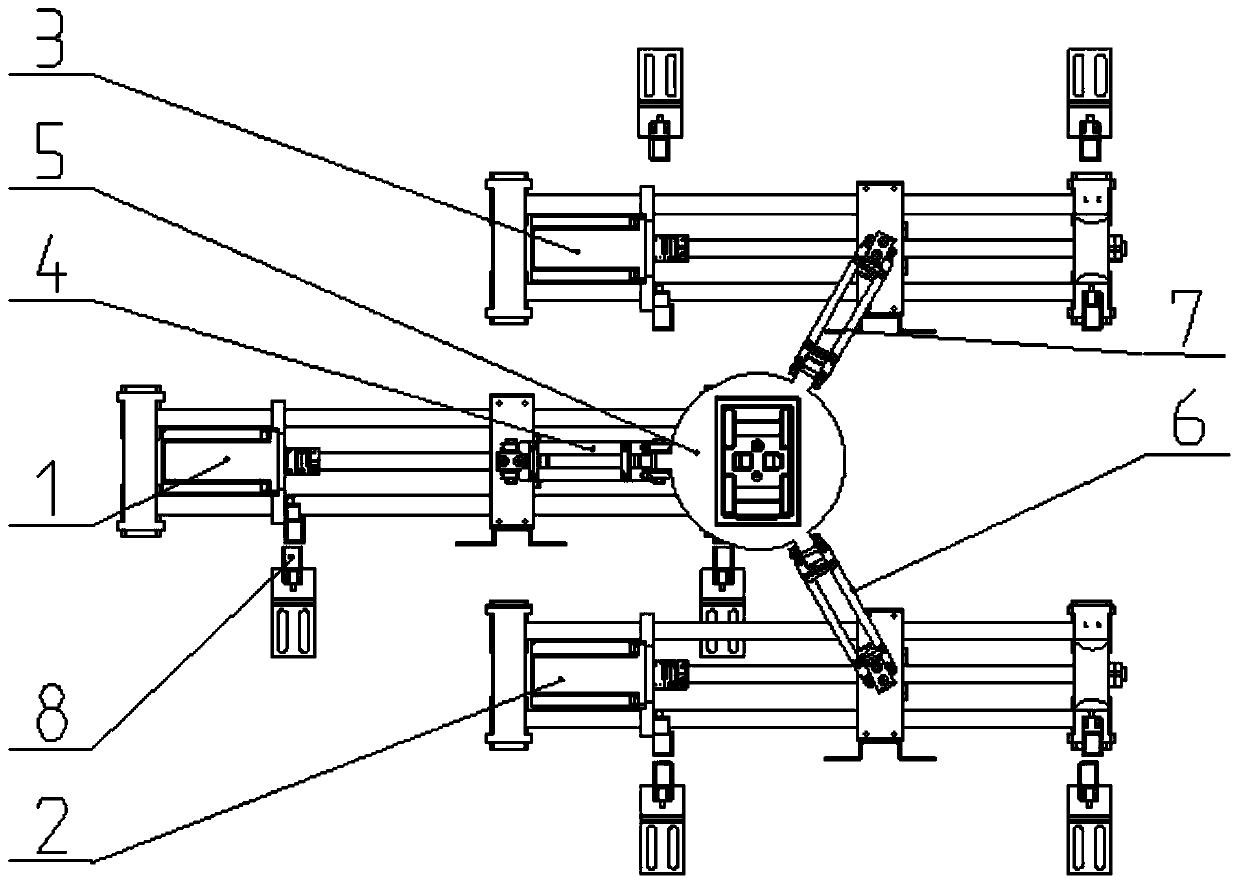

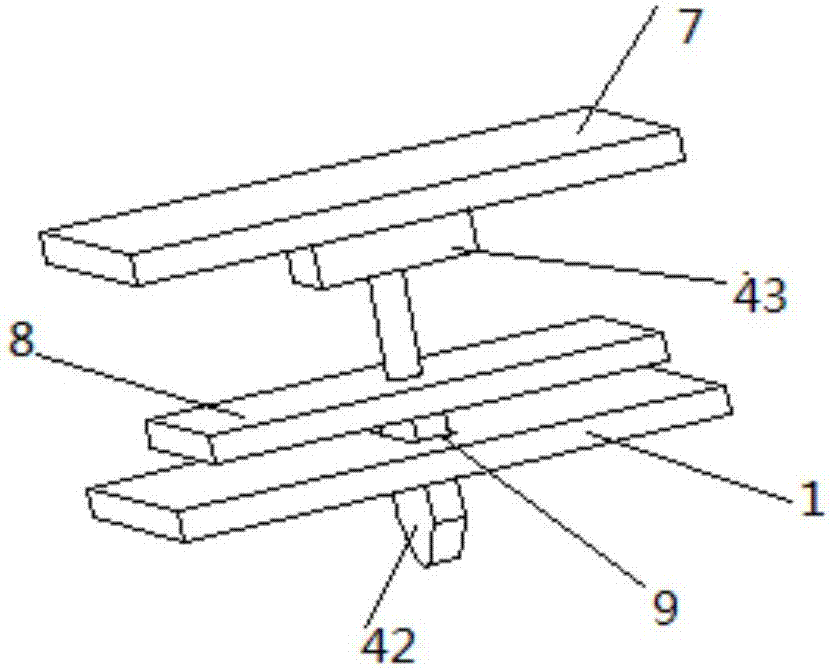

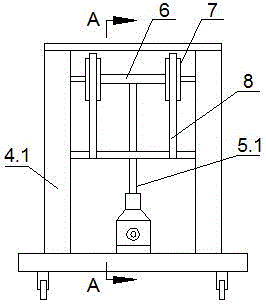

Parallel processing platform robot

PendingCN110170984AFully automatedImprove work performanceProgramme-controlled manipulatorEngineeringOperational capabilities

The invention relates to a parallel processing platform robot. The parallel processing platform robot comprises a controller, a first moving mechanism, a second moving mechanism, a third moving mechanism and a processing platform. The first moving mechanism is connected with the processing platform through a first connecting rod. The second moving mechanism is connected with the processing platform through a second connecting rod. The third moving mechanism is connected with the processing platform through a third connecting rod. The controller is used for controlling the first moving mechanism, the second moving mechanism and the third moving mechanism to drive the three connecting rods to move to drive the processing platform to remain horizontal and rise and drop in the vertical direction. The first moving mechanism, the second moving mechanism and the third moving mechanism of the parallel processing platform robot are arranged in parallel, and the space can be saved; the parallelprocessing platform robot is simple in overall structure, easy to produce and machine and capable of increasing production benefits, reducing the labor risk and realizing factory automation and can beapplied to various types of processing and manufacturing fields, save the development cost and improve the operational capability of the processing platform.

Owner:霸州市华硕汽车零部件有限公司

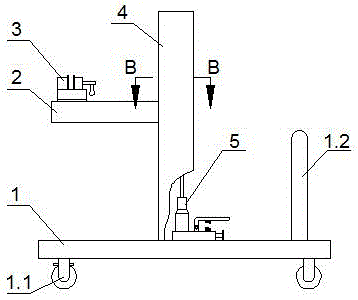

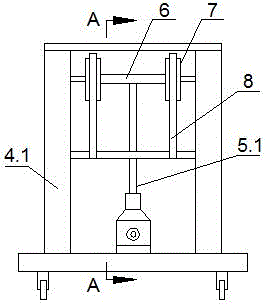

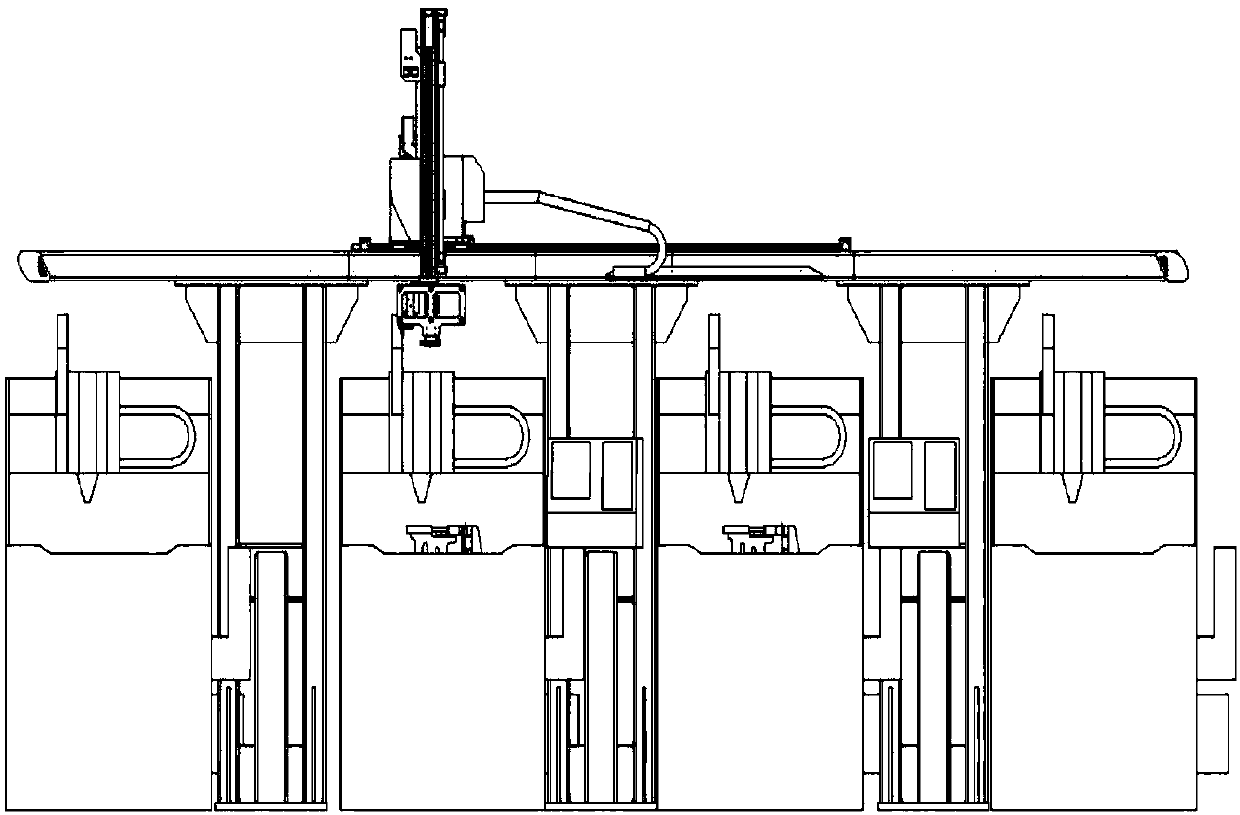

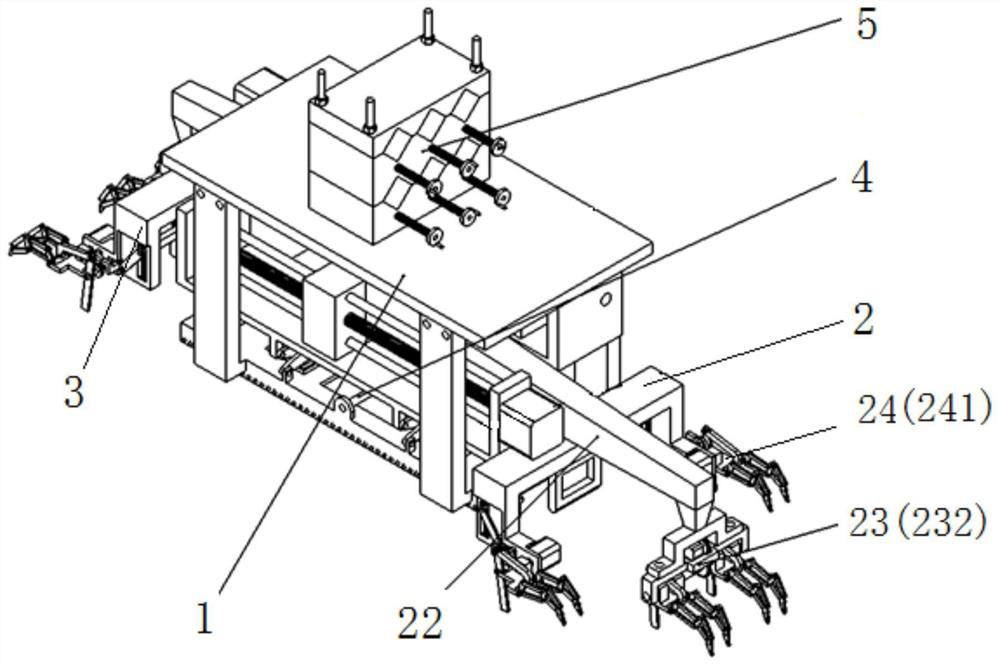

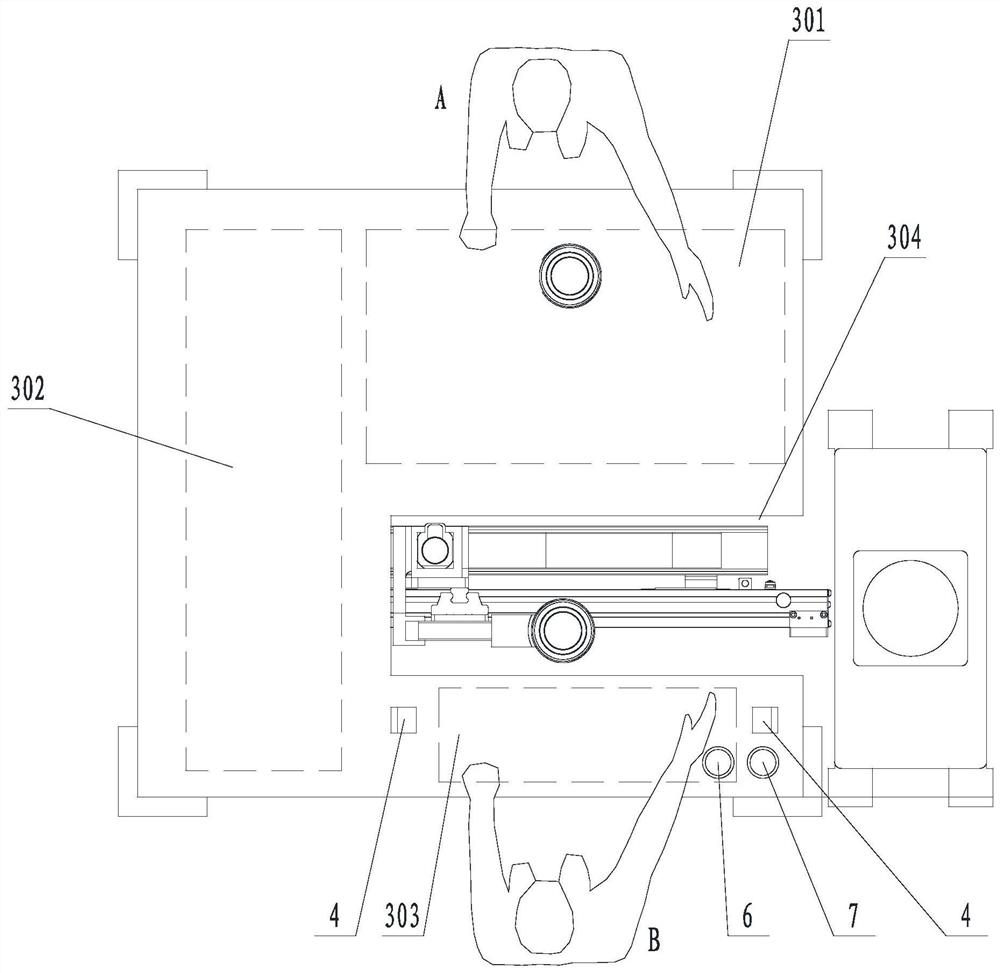

One-driving-four manipulator and high-ray CNC matched type automatic charging and discharging system

InactiveCN107932165AImprove competitivenessReduce labor intensityMetal working apparatusProcess engineeringManipulator

The invention discloses an one-driving-four manipulator and high-ray CNC matched type automatic charging and discharging system. The system comprises an one-driving-four manipulator, a high-ray CNC processing automatic conveying mechanism, a manipulator control box, a first high-ray CNC machine, a second high-ray CNC machine, a third high-ray CNC machine and a fourth high-ray CNC machine; the fourCNC machines are connected to the one-driving-four manipulator by matching; the high-ray CNC processing automatic conveying mechanism is arranged between the second high-ray CNC machine and the thirdhigh-ray CNC machine by matching; the manipulator control box is arranged in the high-ray CNC processing automatic conveying mechanism. According to the system, the one-driving-four manipulator can be matched with the four high-ray CNC machines to charge and discharge materials, so that the cost is decreased, and the production efficiency is improved; the maintenance cost is low; the used space is small; the efficiency is obviously improved; and various resource costs caused by transferring spaces and transferring can be saved.

Owner:东莞市铭航智能科技有限公司

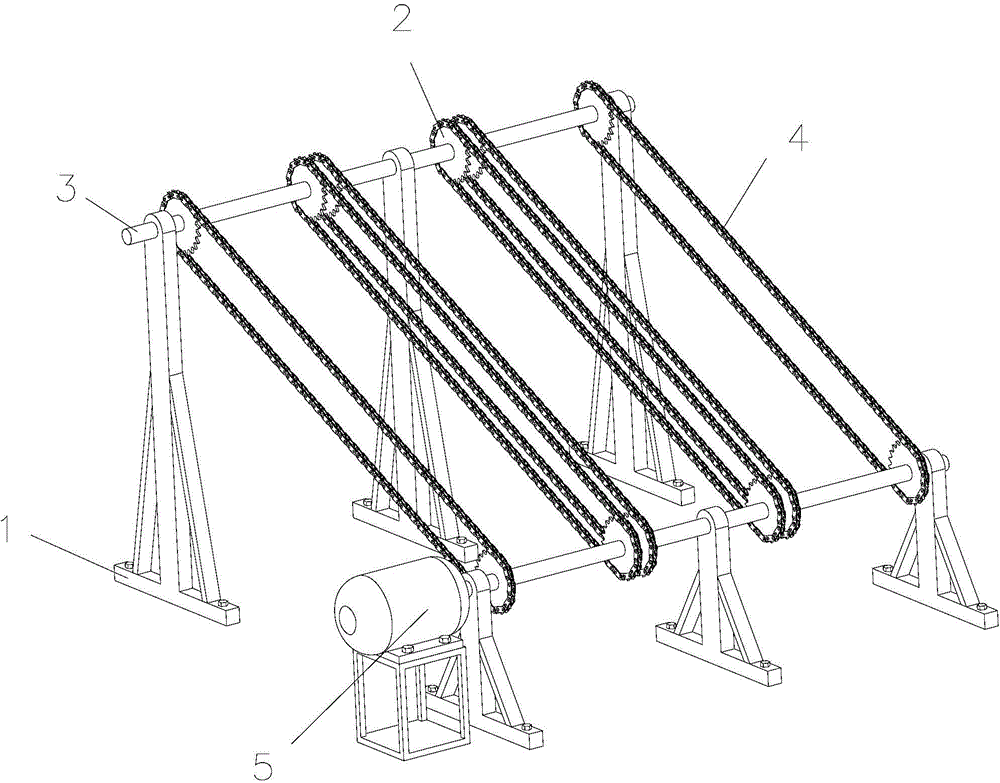

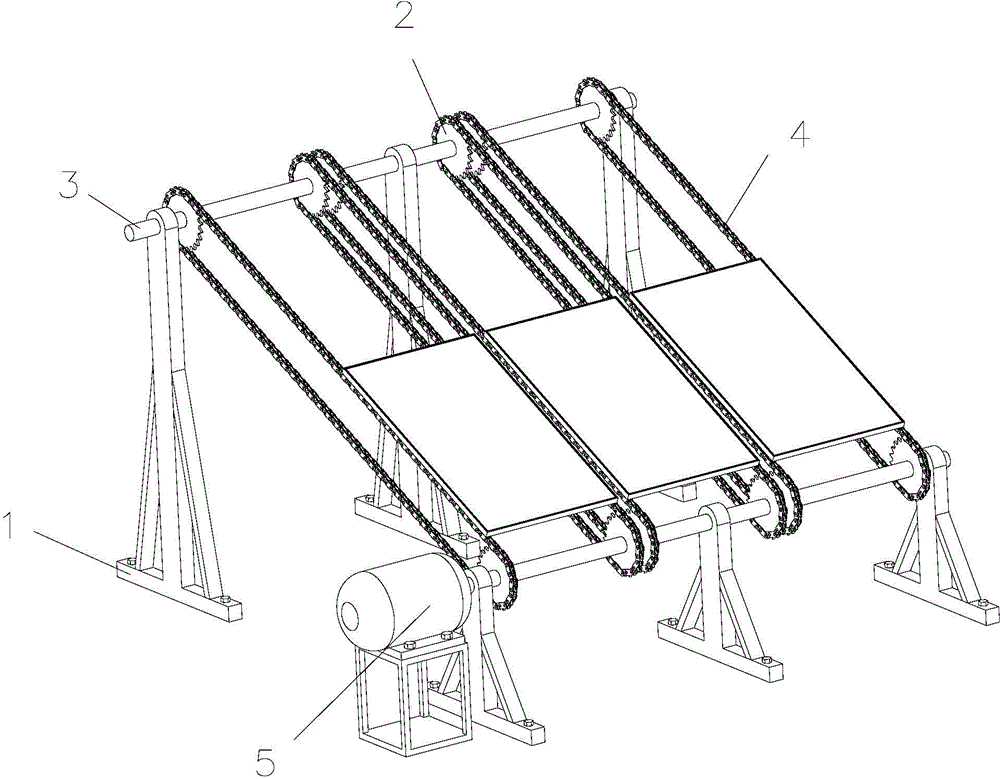

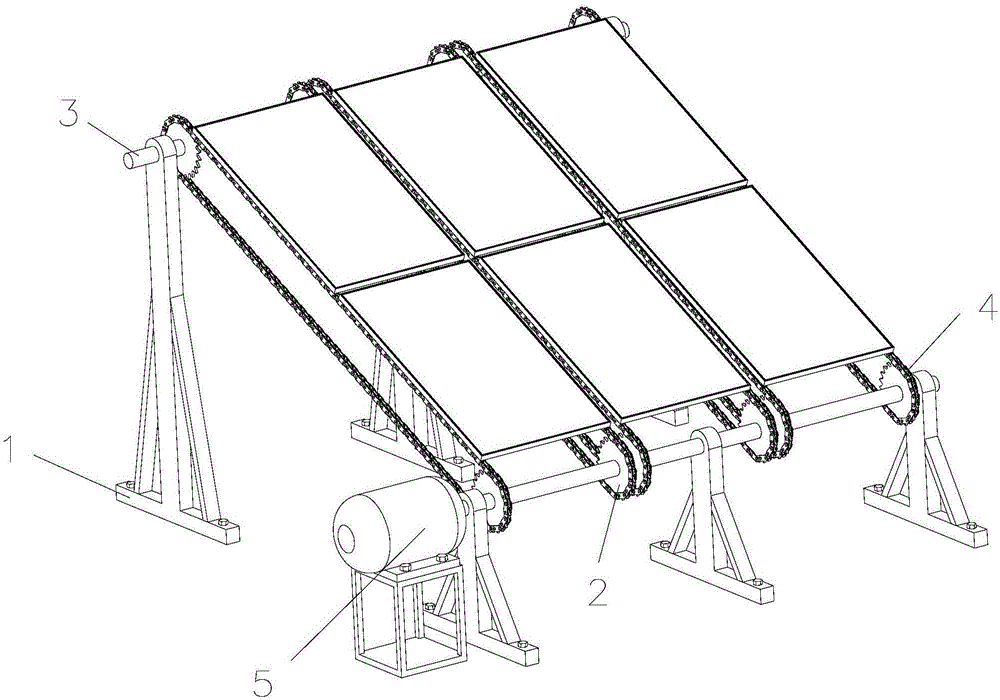

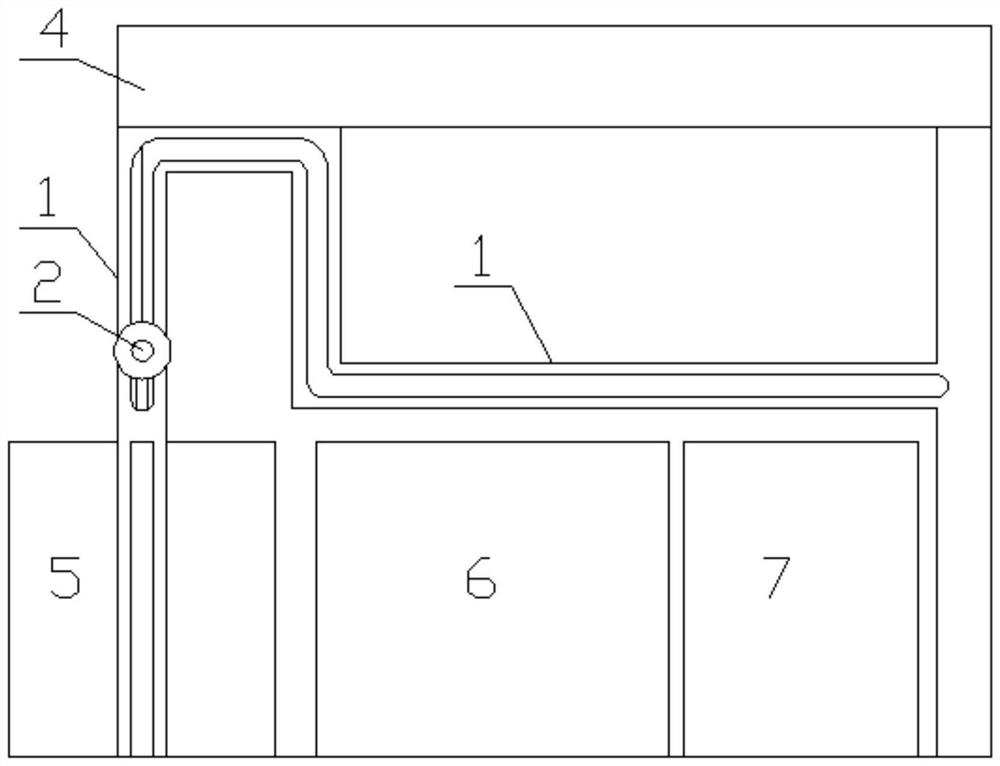

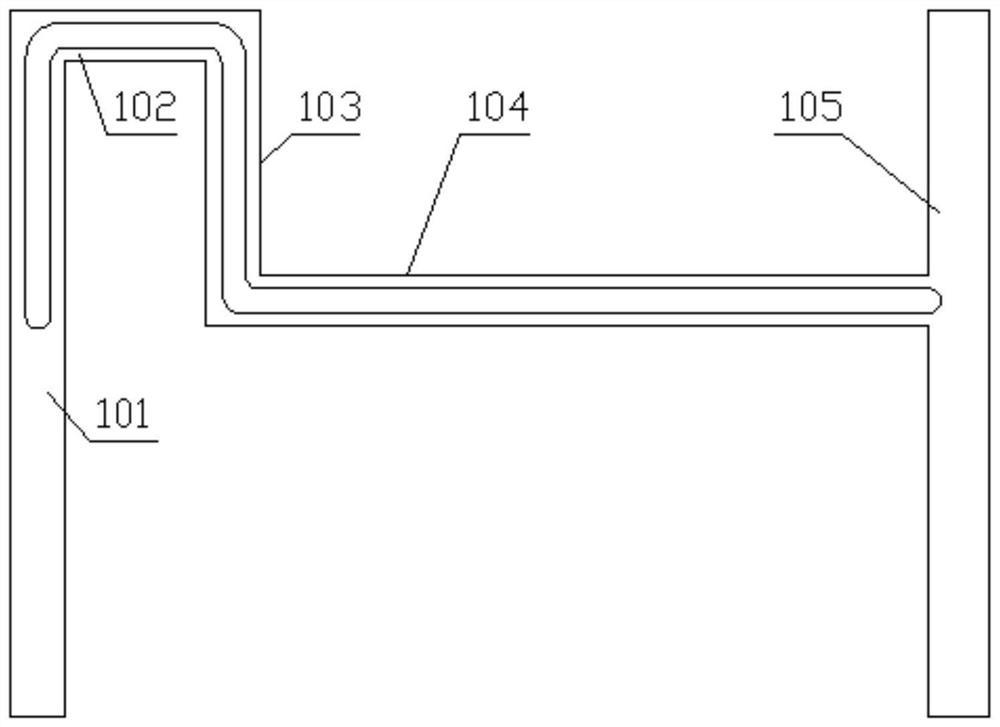

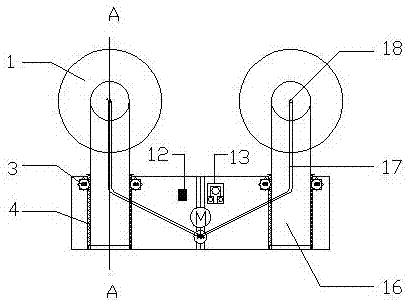

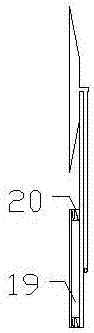

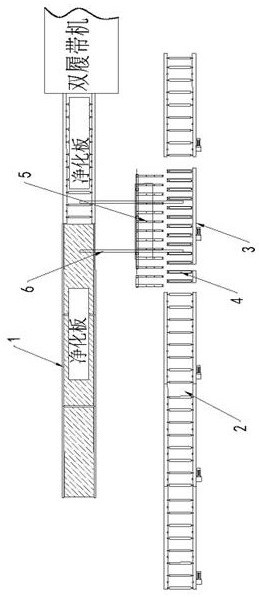

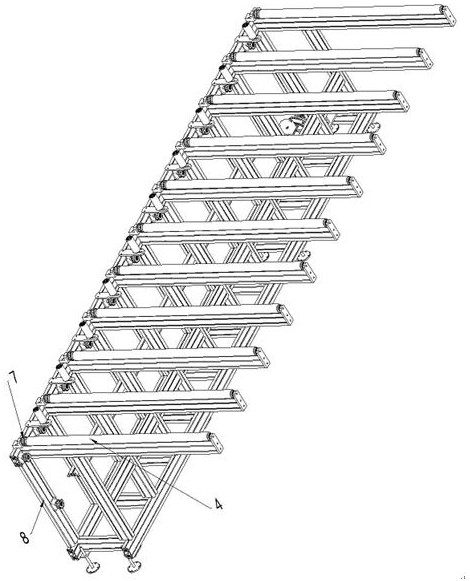

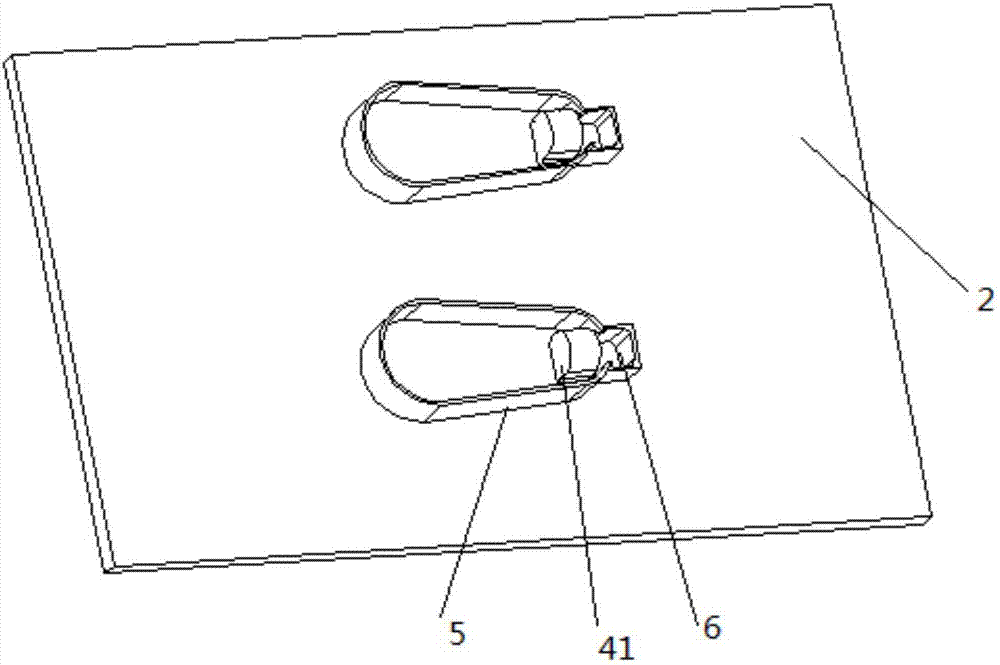

Chain transmission photovoltaic module installing frame

InactiveCN104539226ASave human effortImprove work efficiencyPhotovoltaic supportsPhotovoltaic energy generationEngineeringLabor risks

Owner:EGING PHOTOVOLTAIC TECHNOLOGY CO LTD

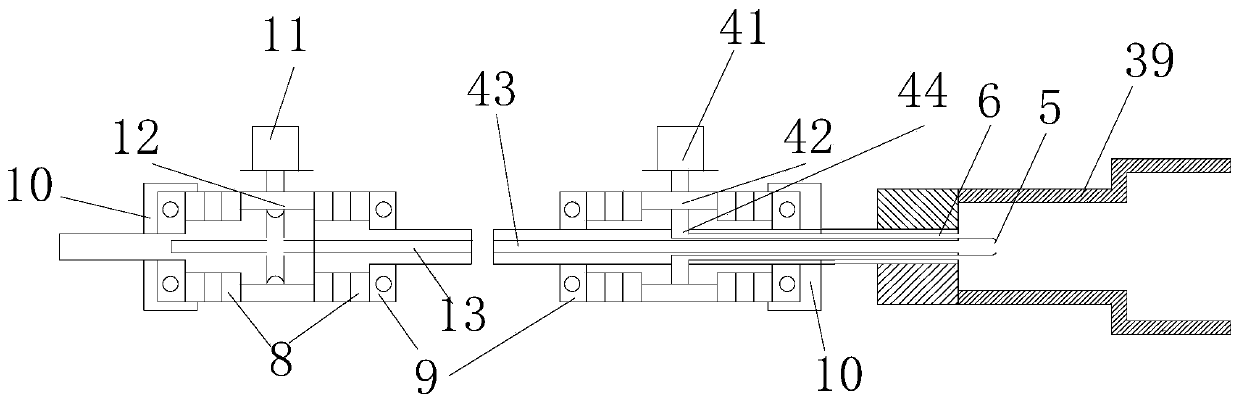

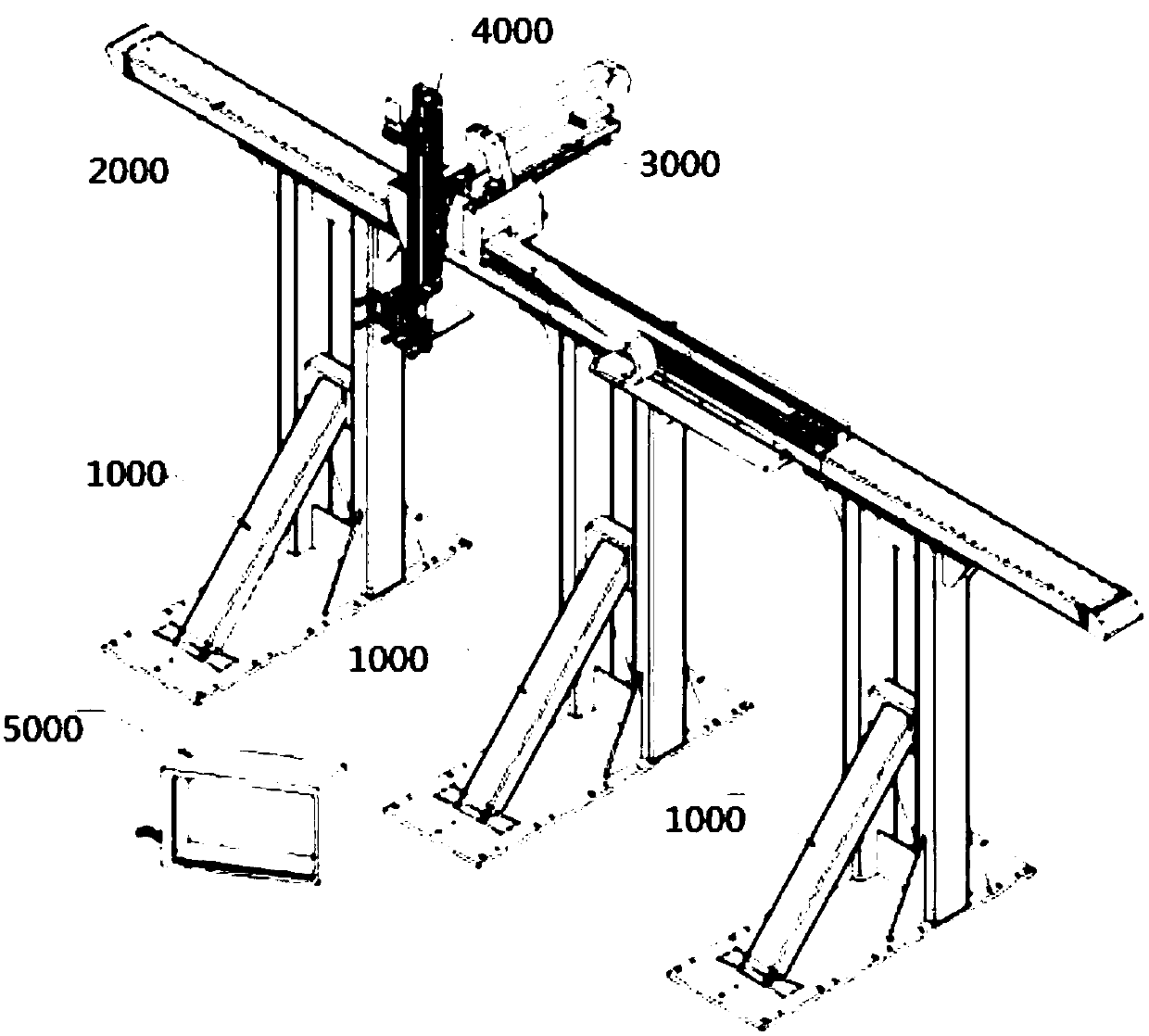

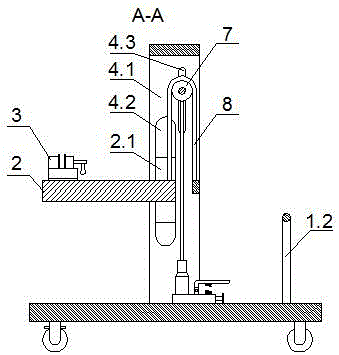

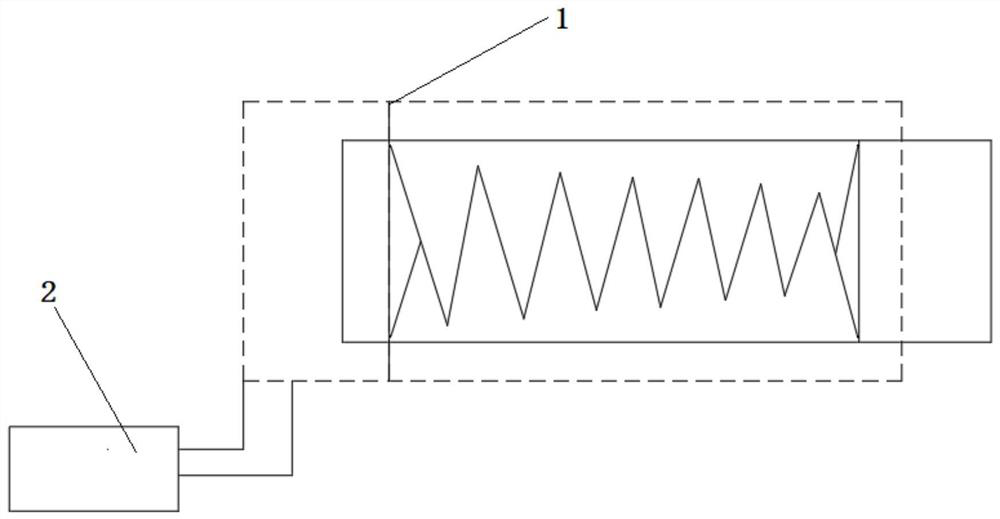

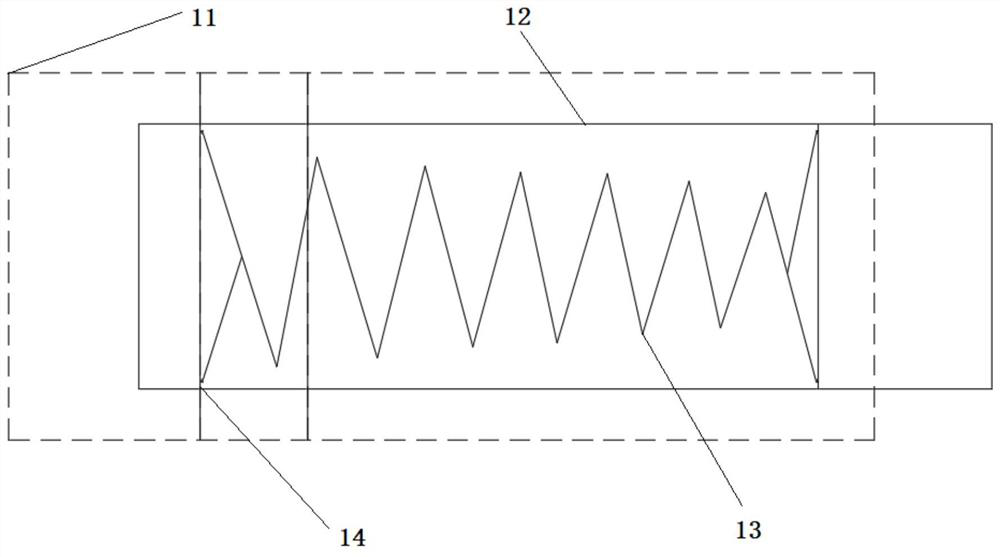

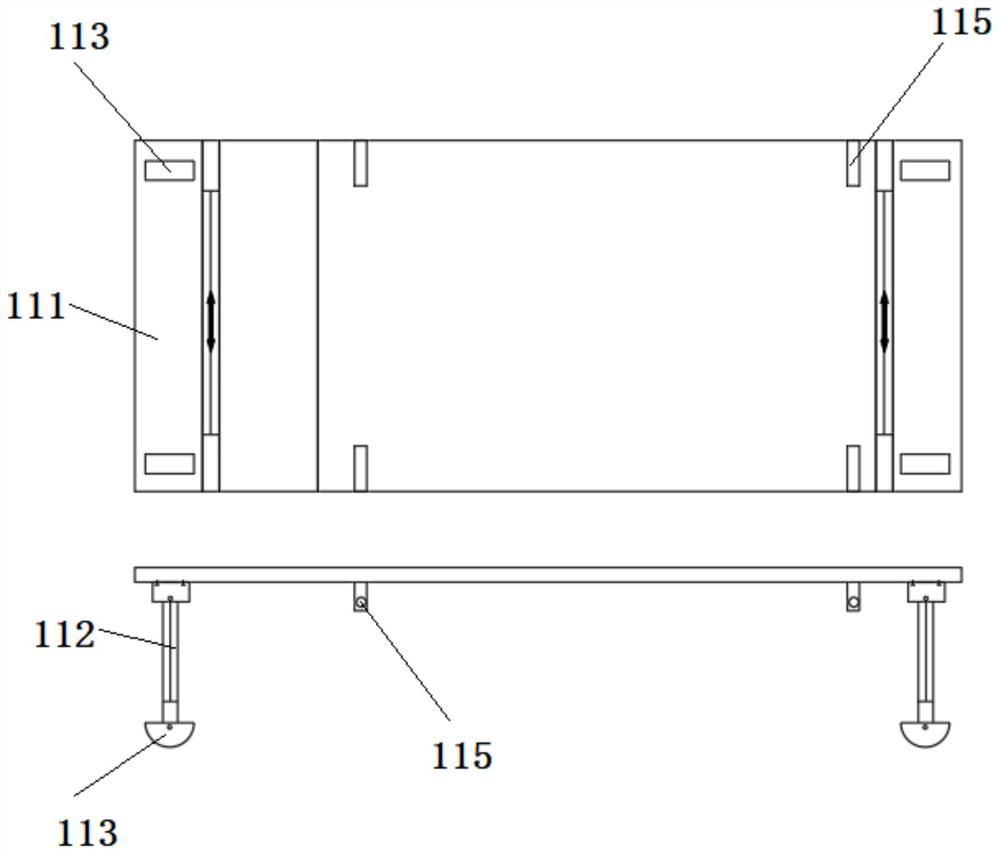

Space truss communication cable threading device

ActiveCN112864955AFully automatedReduce labor risksApparatus for laying cablesEngineeringControl theory

The invention provides a space truss communication cable threading device. The device comprises a main frame, an advancing mechanism, a retreating mechanism and a cable carrying mechanism; the advancing mechanism and the retreating mechanism are provided with a lifting mechanism for descending one mechanism to a working position and lifting the other mechanism to an idle position at the same time; the advancing mechanism comprises a mounting frame, an advancing gripper assembly and a fixing gripper assembly; the mounting frame is connected with the lifting mechanism; a driving assembly for driving a cantilever is arranged on the mounting frame; a mounting rod is arranged on the mounting frame; the advancing gripper assembly and the fixing gripper assembly alternately grasp and loosen a truss; and the advancing gripper assembly and the main frame alternately advance through extension and contraction of the cantilever. The advancing mechanism, the retreating mechanism and the cable carrying mechanism are matched with one another; the main frame and a first gripper alternately advance through fixed-point fixing and loosening, so that the advancing or retreating movement of the device is achieved, and a cable is driven to move; manual threading is replaced; labor risks can be reduced; the efficiency can be improved; and automation is achieved.

Owner:HEFEI UNIV OF TECH

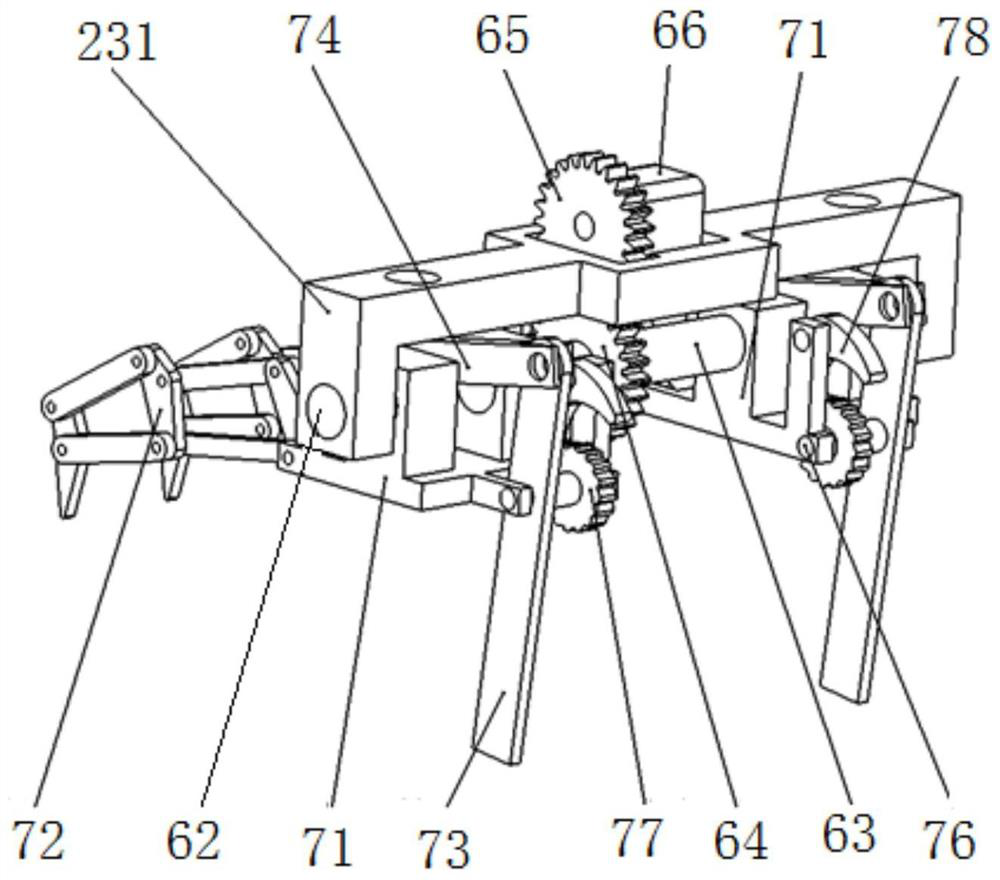

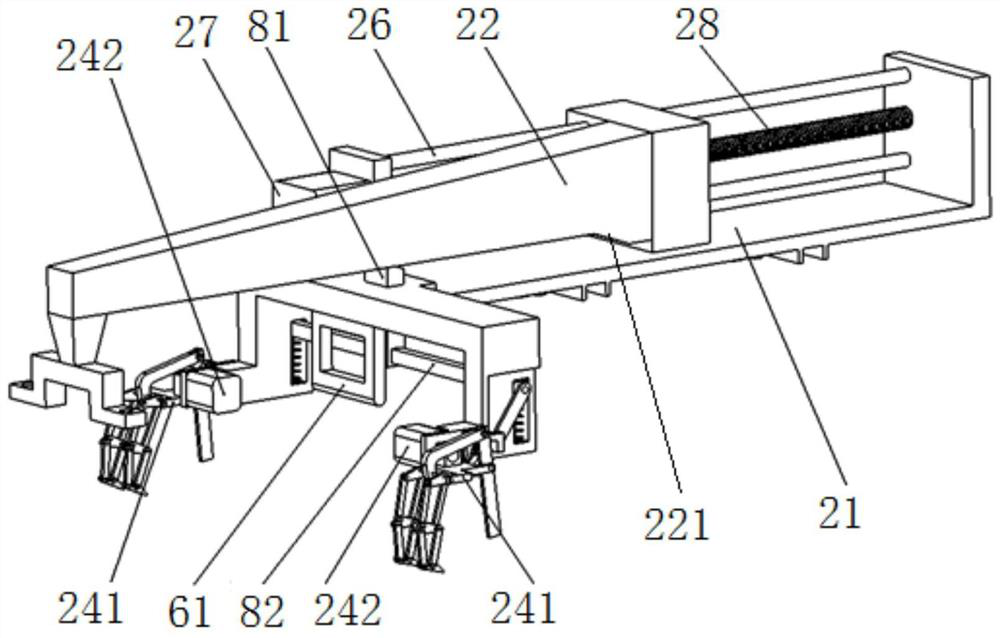

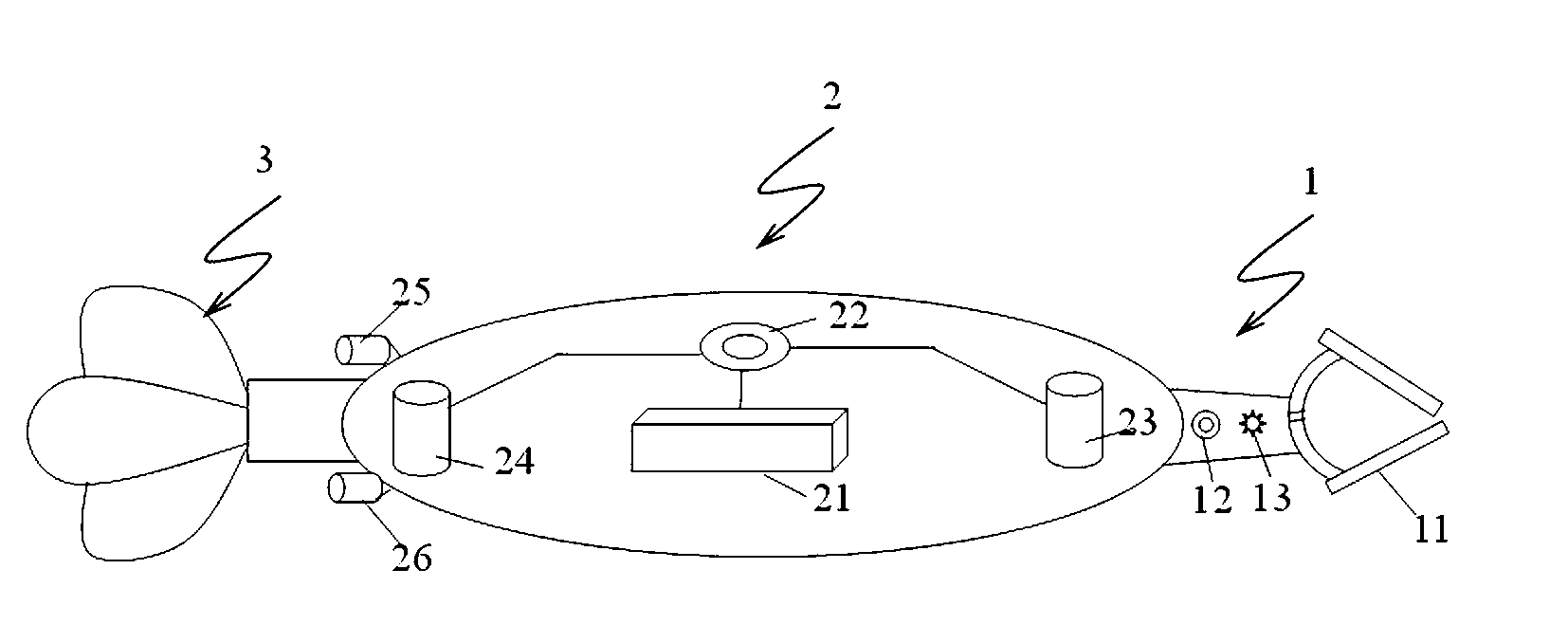

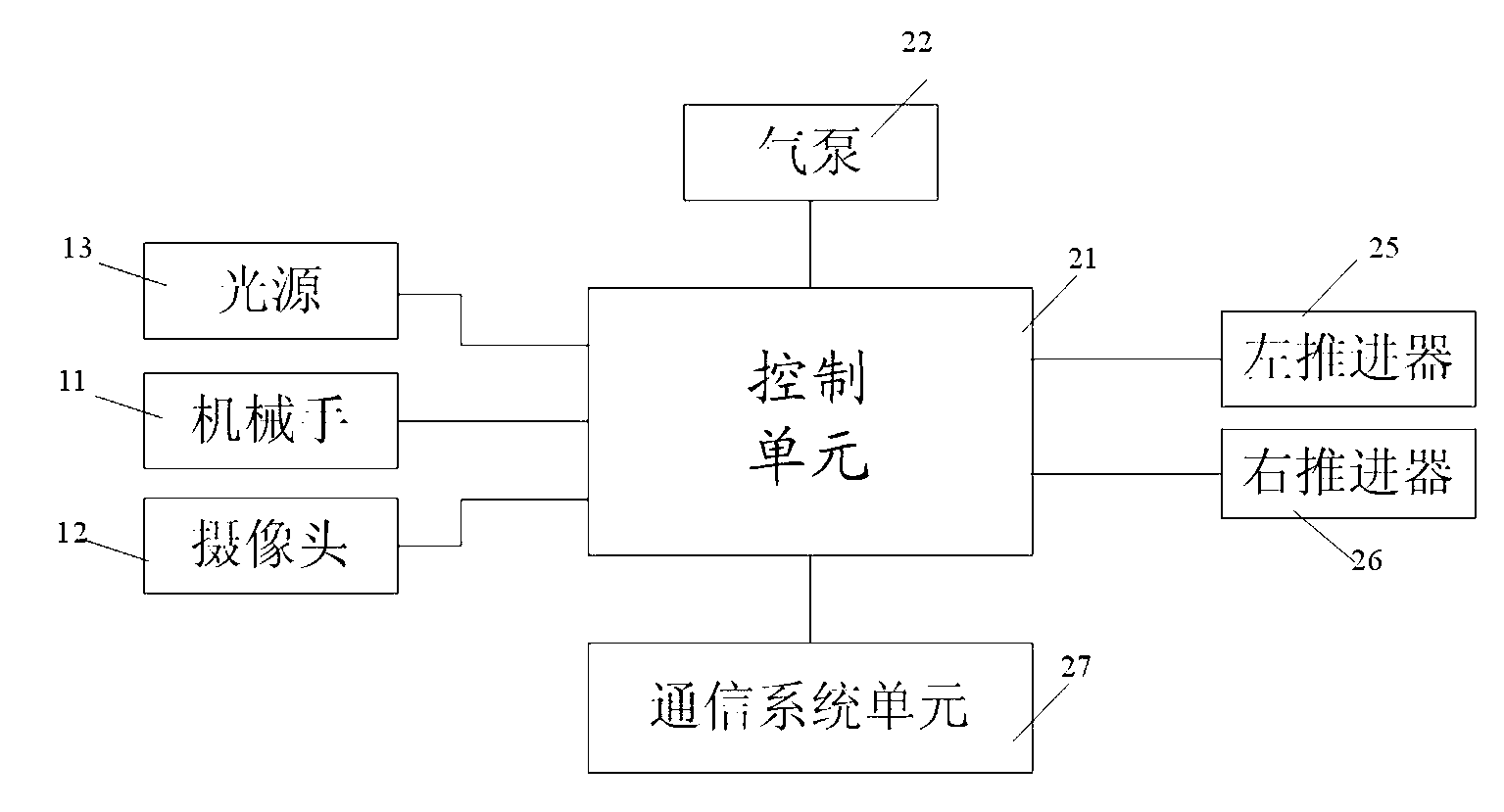

Bionic shrimp underwater detecting robot

InactiveCN102001429BRealize three-dimensional motionAdapt to complex water conditionsUnderwater equipmentShrimpUnderwater

Owner:HOHAI UNIV

A metal material processing system

ActiveCN111850257BRealize automatic circulationAvoid direct contactFurnace typesHeat treatment furnacesLiquid argonIce water

Owner:WUXI FULL ALLOY TECH

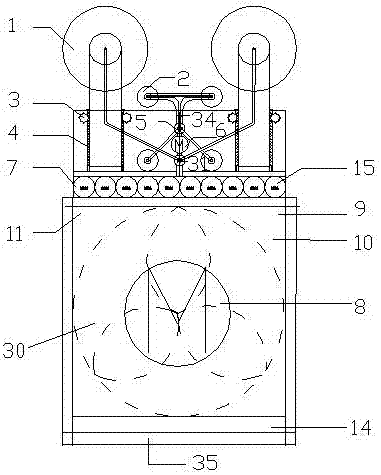

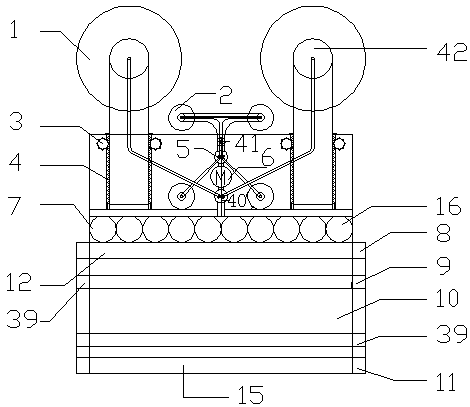

Suction type glass cleaning device

InactiveCN107280596AImprove working environmentReduce labor risksCarpet cleanersFloor cleanersEngineeringNavigation system

The invention relates to a suction type glass cleaning device. The device comprises two big suckers, two telescopic guide rails, four small suckers, a cleaning chamber, a battery pack, and a navigation system and a single chip microcomputer which are disposed in a pilot. The front of each telescopic guide rail is provided with one big sucker, and two sides of the rear of each telescopic guide rail are provided with telescopic guide rail gears; each telescopic guide rail gear is engaged with a fixed gear, and the fixed gears are engaged with a motor I; the center of each telescopic guide rail is provided with a chassis; each chassis is provided with a big sucker gas-guide tube, and the big sucker gas-guide tubes are connected with the big suckers and a suction pump I; the four small suckers are fixed on a supporting frame, and the supporting frame is provided with four small sucker gas-guide tubes; each small sucker gas-guide tube is connected with one small sucker, and the small sucker gas-guide tubes are connected with a suction pump II; an upper portion of the cleaning chamber is provided with a plurality of liquid supply pipes; a sponge brush I, a rotating brush, the battery pack and a sponge brush II are successively disposed in the cleaning chamber from top to bottom; the plurality of liquid supply pipes are connected with a liquid input pipeline, and the liquid input pipeline is connected with an infusion pump; and the top of the infusion pump is provided with a water head adjuster connected with the navigation system. The suction type glass cleaning device is good in safety and high in efficiency.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

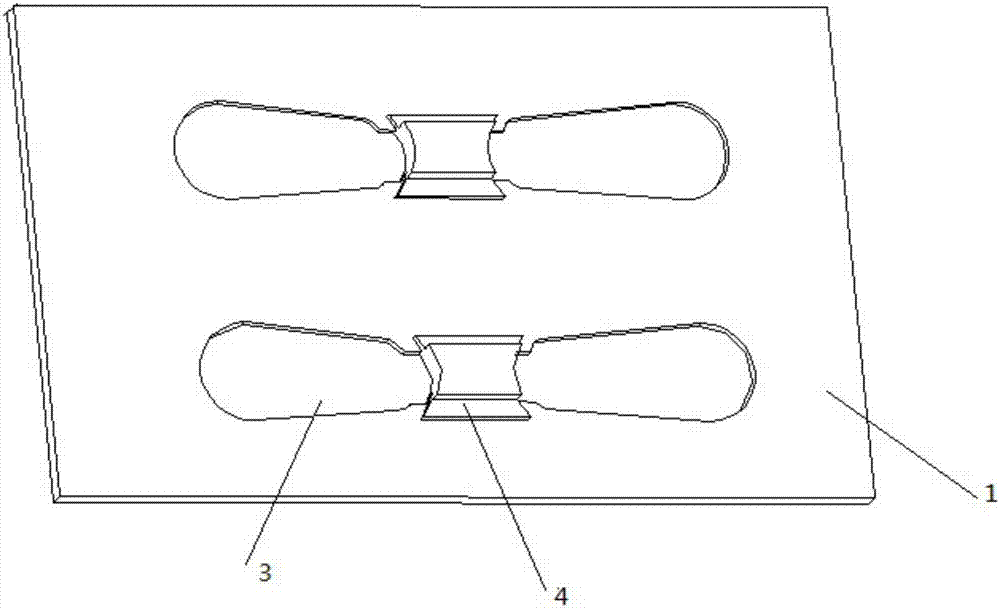

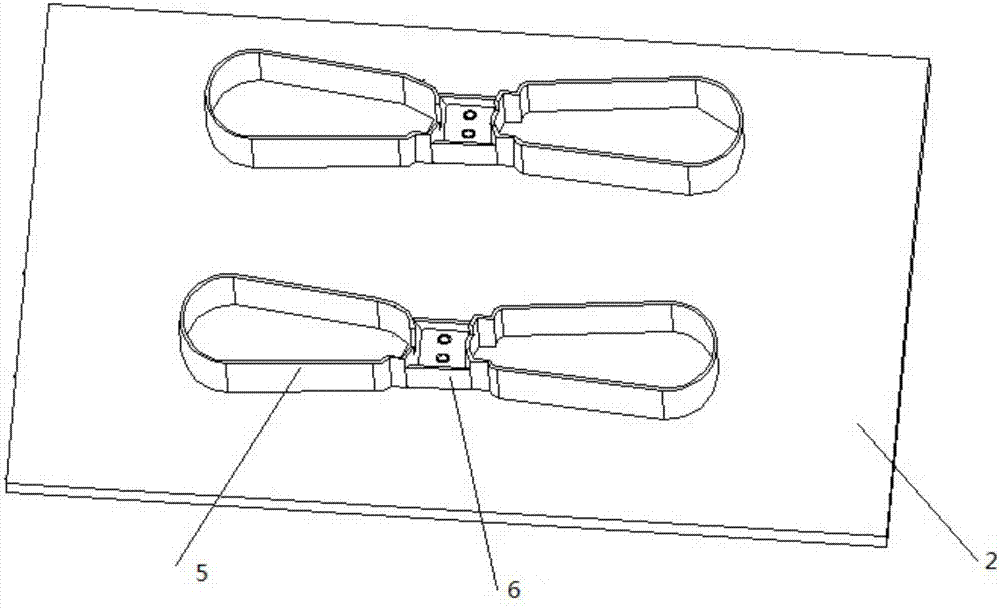

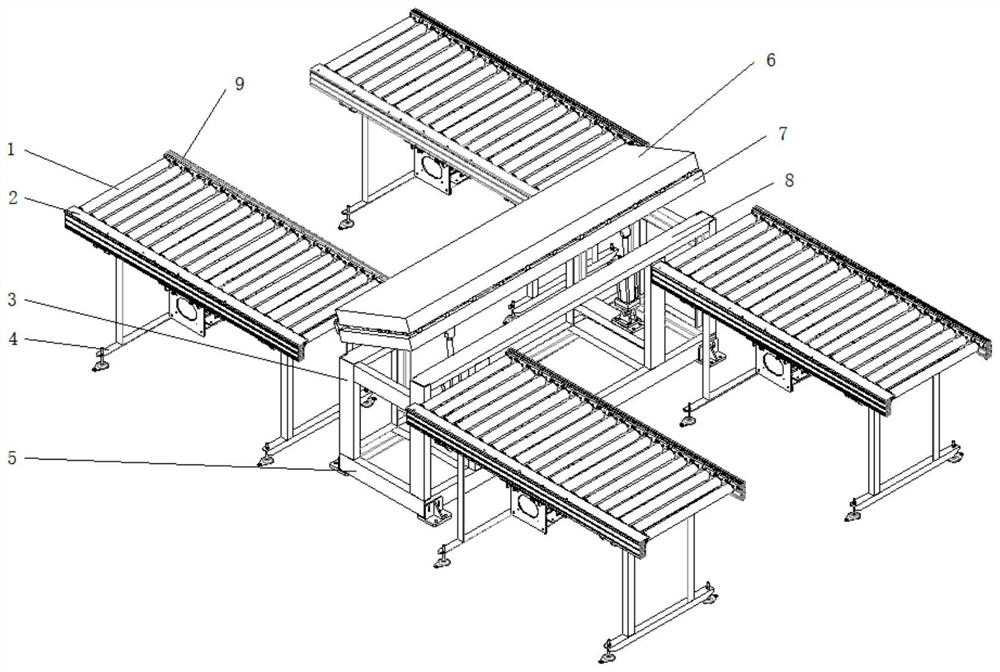

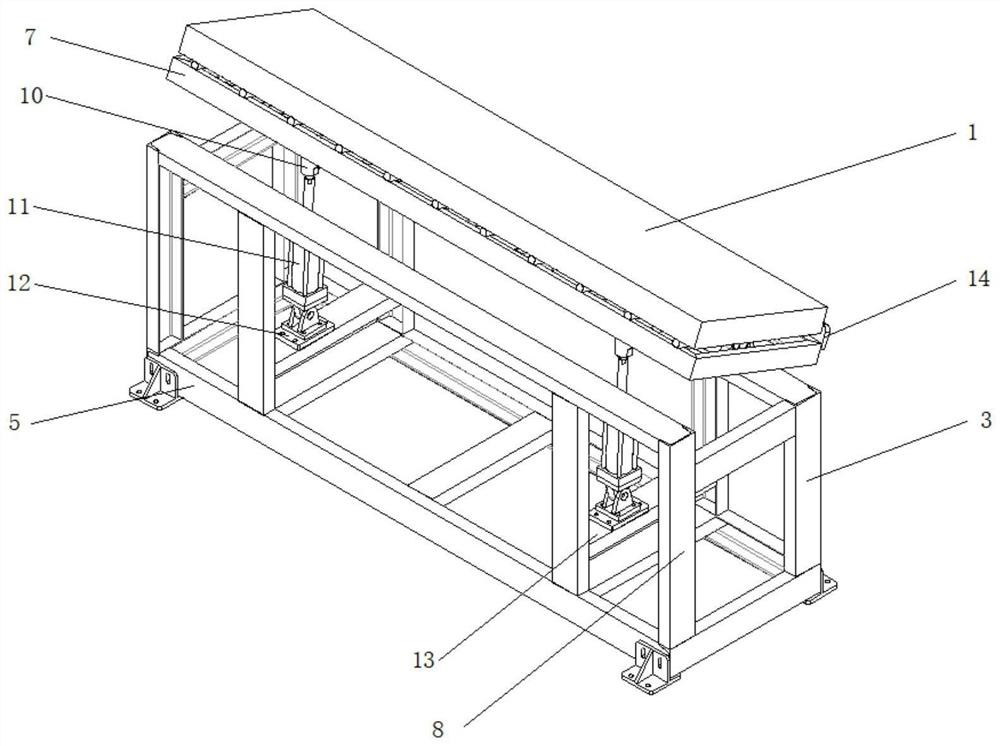

Plate assembling equipment for automatic production line

PendingCN114852682ARealize intelligent transformation serviceReduce operating costsConveyor partsMechanical conveyorsEngineeringManufacturing line

The plate assembling equipment for the automatic production line comprises a plate body conveyor and a plate feeding conveyor which are arranged in parallel at a certain interval, a plate receiving and conveying device is arranged at one end of the plate feeding conveyor, and a plate transferring and buckling device is arranged between the plate receiving and conveying device and the plate body conveyor. And the whole equipment is controlled by the controller. Production links such as automatic carrying, positioning and compositing can be achieved, the production speed is increased, the labor intensity is reduced, the labor risk is reduced, the operation cost is reduced for enterprises, and services are provided for overall intelligent transformation of companies.

Owner:山东森成电气科技有限公司

An intelligent painting instrument

The invention relates to an intelligent whitewashing device. The intelligent whitewashing device comprises two linkage large suction cups, two retractable guiding rails, four medium suction cups, a whitewashing chamber, a medium lead storage battery pack, a single chip microcomputer and a guided system, wherein the single chip microcomputer and the guided system are arranged in a driverscope. The front end of each retractable guiding rail is provided with the corresponding linkage large suction cup, and the two sides of the rear portion of each retractable guiding rail is provided with retractable guiding rail gears; the retractable guiding rail gears are engaged with fixed gears which are engaged with motors; a base plate is arranged in the center of each retractable guiding rail and is provided with an advancing suction cup air guide tube, and the advancing suction cup air guide tubes are connected with the linkage large suction cups and a first air pump; the four medium suction cups are fixed to a framework, and four air guide tubes are arranged on the framework and are connected with the medium suction cups and a second air pump; supplying tubes are arranged on the upper portion of the whitewashing chamber, and the whitewashing chamber is internally provided with the forward motor, a roller brush, the backward motor and the medium lead storage battery pack; and the multiple supplying tubes are connected with a slurry inlet pipeline which is connected with a slurry conveying pump, and the slurry conveying pump is connected with a water head adjuster connected with the guided system. The intelligent whitewashing device is good in safety and high in efficiency.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Impeller locking automatic control system and method for large wind power generator

ActiveCN102536659BEnsure safetyPrecise Control RequirementsWind motor controlMachines/enginesImpellerAutomatic train control

Owner:青海明阳新能源有限公司

Full-automatic plastic suction machine side punching cutter body structure

PendingCN107379102ARealize slittingReduce labor risksMetal working apparatusLaser beam welding apparatusEngineeringMachining process

The invention provides a full-automatic plastic suction machine side punching cutter body structure. Cutter grooves are arranged on an upper wallboard; laser blades which are matched with the corresponding cutter grooves are arranged on a lower wallboard; the full-automatic plastic suction machine side punching cutter body structure also comprises a top plate, a moving plate, punch cutters and punch mother holes which are matched with the corresponding punch cutters and are connected with side edges of the corresponding cutter grooves; each punch cutter is composed of a fixed cutter, a moving cutter and a cylinder; each fixed cutter is fixed in the corresponding cutter groove, close to the corresponding punch mother hole; each cylinder is fixed on the bottom surface of the top plate; the free end of a telescopic shaft of each cylinder is fixedly connected with the top surface of the moving plate; each moving cutter is fixed to the bottom surface of the moving plate; through grooves are arranged on the lower wallboard, close to the corresponding cutter grooves; and each cutter groove penetrates through each through groove. By adopting the full-automatic plastic suction machine side punching cutter body structure provided by the invention, shape cutting and side punching of a plastic product are finished full-automatically once, so that the traditional processing technology is changed, and the labor efficiency is improved; and by adopting the side punching shearing cutter structure, abrasion of the punch cutters is reduced, and the reject rate is lowered.

Owner:TIANJIN HENGFENGDA PACKAGING PROD

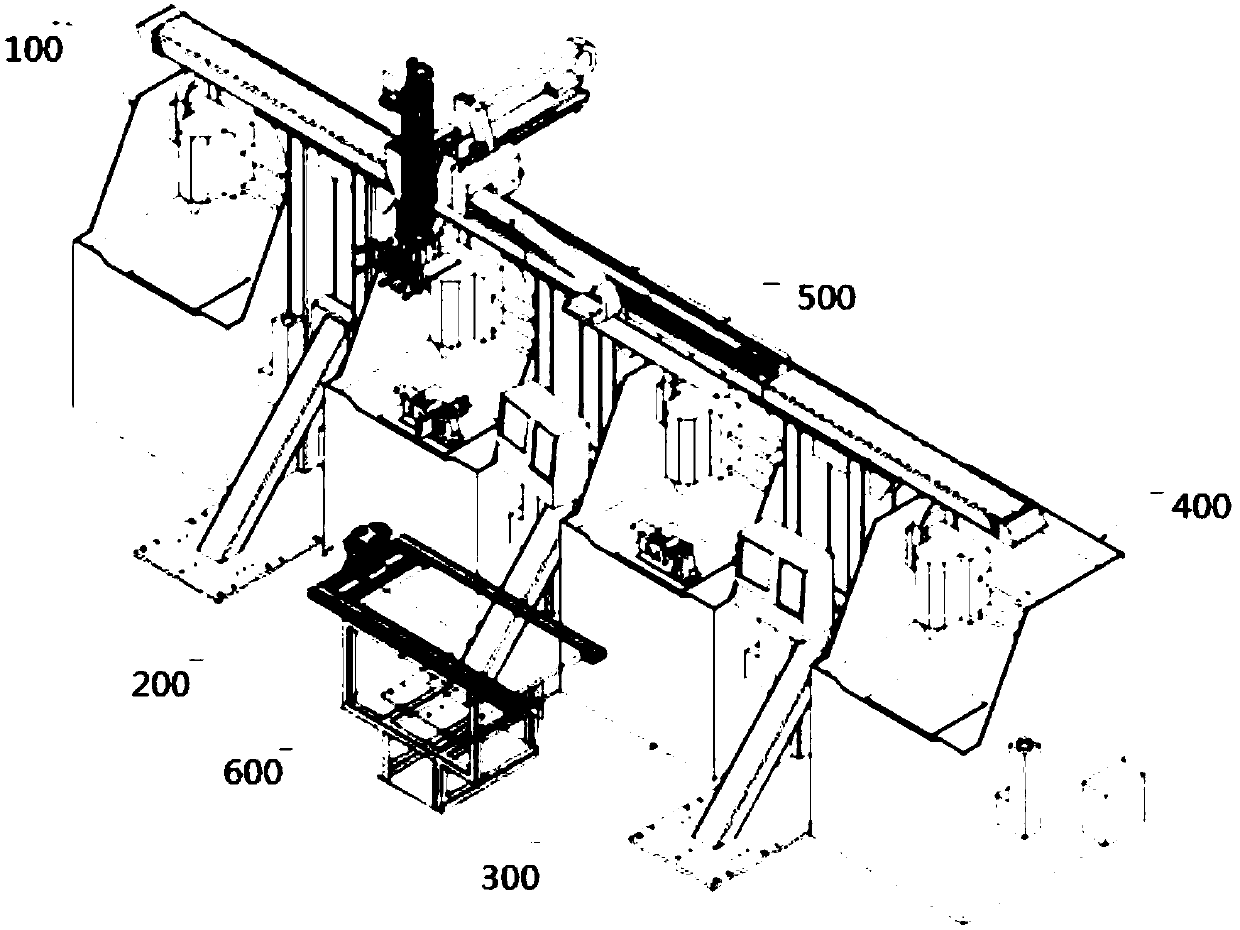

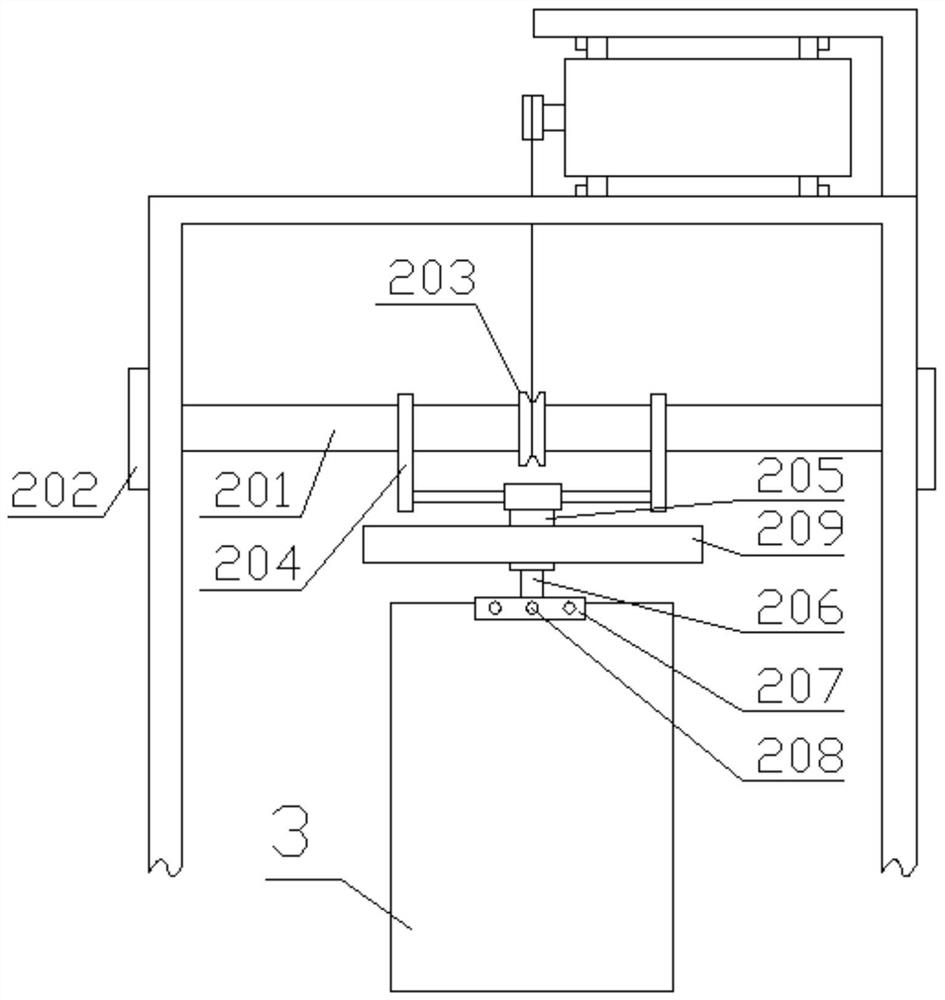

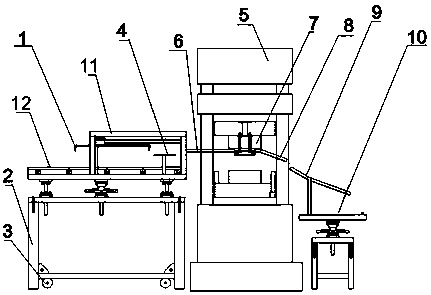

A pressing system with mold automatic transfer function and its application method

The invention relates to powder metallurgy equipment, in particular to a pressing system with mold automatic transfer function and its use method. The operating table is respectively provided with an operation pretreatment area, a transfer channel, a mold pick-and-place position, a notch and a start button , the transmission channel is located between the operation pretreatment area and the mold pick-and-place position; the X-axis module is installed on the mounting bracket, the X-axis driving motor is installed on the X-axis module, and the X-axis driving motor drives the X-axis module to move. The axis module can be relatively slidably connected to the X-axis module, and protrudes from the slot; the mold is placed on the execution end of the Z-axis module, and driven by the Z-axis drive motor installed on the Z-axis module along the Z axis. Shaft lifting; the actuator of the press includes the press head and the press platform for bearing, and the mold is sent to press between the press head and the press platform through the mold transfer manipulator. The invention can automatically place the mold on the press platform, and then automatically transport it back to the operation area after the pressing is completed, avoiding the operator from directly contacting the press, improving production efficiency and reducing labor risks.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

Full-automatic side-punching equipment for plastic vacuum forming machine

InactiveCN107263602AReduce labor risksLow pollution rateMetal working apparatusLaser beam welding apparatusPunchingEngineering

The invention provides full-automatic side-punching equipment for a plastic vacuum forming machine. The full-automatic side-punching equipment comprises an upper wall plate and a lower wall plate, wherein cutting grooves are formed in the upper wall plate; and matched laser blades are arranged on the lower wall plate. The full-automatic side-punching equipment further comprises subsidiary punches and punch female mouths, wherein the subsidiary punches are bulged; the punch female mouths are grooves matched with the subsidiary punches; and the subsidiary punches are arranged between the laser blades in axisymmetric arrangement. Through development and research, shape cutting and side punching of a plastic product are finished fully automatically at a time, a traditional processing technology is changed, the labor efficiency is improved, the labor risk of labors is reduced, and meanwhile, the contamination probability of food packages is lowered.

Owner:TIANJIN HENGFENGDA PACKAGING PROD

Automatic workpiece positioning mechanism of edge milling machine

PendingCN114473562ARealize automatic processingReduce labor intensityPositioning apparatusMetal working apparatusAutomatic controlControl system

The invention relates to the technical field of edge milling machine machining equipment, in particular to an edge milling machine workpiece automatic positioning mechanism which comprises a left support, a base and a right support, the left support is fixedly welded to the left side of the upper end of the base, and the right support is fixedly welded to the right side of the upper end of the base. Two sets of connecting plates are welded and fixed between the left support and the right support, a base is fixed to the upper ends of the connecting plates through screws, and a hydraulic oil cylinder is rotationally connected to the base. The device is matched with an automatic control system of an edge milling machine truss to carry out station adjustment on a workpiece, automatic machining of the workpiece is achieved, a safer working environment is provided, the labor intensity of workers is reduced, the labor risk is reduced, the workload in the technological process is reduced, the enterprise competitiveness is improved, the labor condition is improved, and the production efficiency is gradually improved. And the production capacity is stronger and controllable, the upgrading of products is accelerated, the product quality is improved, boring and odorless work is eliminated, and the labor force is saved.

Owner:江苏隆宝重工科技有限公司

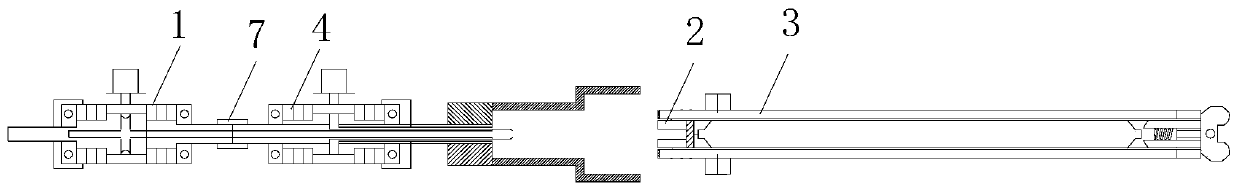

A rapid replacement device for heat treatment furnace rollers

ActiveCN105567936BMeet replacement needsEasy to installFurnace typesHeat treatment furnacesSprocketEngineering

The invention discloses a quick replacement device for a furnace roller of a thermal treatment furnace. The quick replacement device comprises a clamping device, a mobile guide device and a fixed guide device. The clamping device comprises a trolley and a demounting platform fixedly provided with sliding blocks, and a gantry framework is fixed to the trolley. A bench clamp is fixed to the demounting platform. The quick replacement device further comprises a hydraulic jack fixed to the trolley; the hydraulic jack is connected with the demounting platform through a chain and a chain wheel. The mobile guide device comprises a first U-type bolt and a first cross beam in threaded connection with the first U-type bolt. The two ends of the first cross beam are in rolling connection with furnace rollers arranged on two sides of a furnace roller needing to be replaced in an adjacent mode correspondingly. The fixed guide device comprises a second U-type bolt and a second cross beam in threaded connection with the second U-type bolt. The arc section of the second U-type bolt is provided with at least one second idler wheel. The two ends of the second cross beam are fixedly provided with second supporting frames with magnets.

Owner:LAIWU IRON & STEEL GRP

Continuous pushing self-moving machine tail

PendingCN111846768AReduce the number of demolitionAdapt to skewed conditionsConveyorsEarth drilling and miningStructural engineeringMachine

The invention relates to a continuous pushing self-moving machine tail, and belongs to the technical field of coal mine fully-mechanized coal mining and fully-mechanized excavation working face transportation equipment. The continuous pushing self-moving machine tail comprises a continuous pushing device and a power device, wherein the continuous pushing device comprises an outer pushing frame device, an inner pushing frame device, a flexible telescopic device and pin shafts; the left side and the right side of the flexible telescopic device are connected with the outer pushing frame device and the inner pushing frame device through the pin shafts correspondingly; and the outer pushing frame device comprises an outer pushing frame body, a plurality of lifting mechanisms mounted at the bottom of a main beam of the outer pushing frame body, paws fixed to the lower portions of the lifting mechanisms, a left-right guiding mechanism fixed to the outer pushing frame body, and a plurality oflongitudinal guiding mechanisms fixed to the outer pushing frame body. The inner pushing frame device comprises an inner pushing frame body, a plurality of lifting mechanisms mounted at the bottom ofa main beam of the inner pushing frame body, paws fixed to the lower portions of the lifting mechanisms, a left-right guiding mechanism fixed to the inner pushing frame body, and a plurality of longitudinal guiding mechanisms fixed to the inner pushing frame body.

Owner:CHANGZHOU LIANLI AUTOMATION TECH

Wheel expansion device

The invention relates to a wheel expansion device which comprises a lower fixed base, an expansion punching machine and a supporting plate. A transmission belt, an upper fixed frame and lifting devices are arranged on the lower fixed base, the lifting devices are symmetrically positioned on the two sides of the transmission belt, and a push plate is arranged at the top of the upper fixed frame. Aloading clamp and an unloading guide pillar are fixedly arranged on an expansion mould of the expansion punching machine, and a receiving guide pillar is fixedly arranged on the supporting plate.

Owner:林继奎

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com