Plate assembling equipment for automatic production line

A technology for automatic production lines and assembling equipment, which can be used in transportation and packaging, mechanical conveyors, conveyor objects, etc., and can solve problems such as low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Hereinafter, some specific embodiments of the present invention will be described in detail by way of example and not limitation with reference to the accompanying drawings. The same reference numbers in the above figures designate the same or similar parts or parts. It will be understood by those skilled in the art that the drawings are not necessarily to scale.

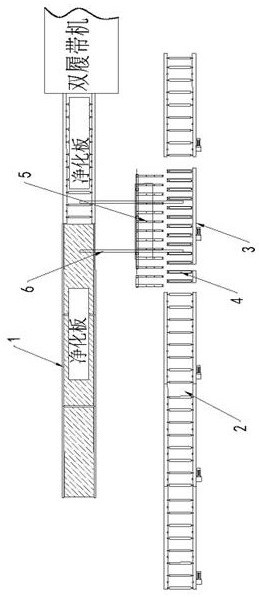

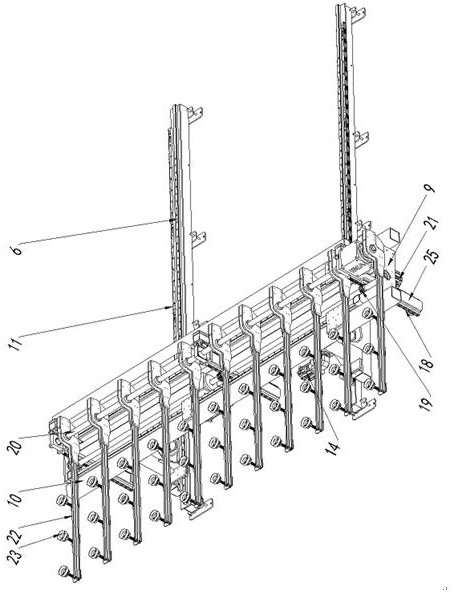

[0036] example, as Figure 1-14 As shown in the figure, a plate assembly equipment for an automatic production line includes a plate body conveyor 1 and an upper plate conveyor 2 arranged in parallel at a certain distance. A transfer gusset device 5 is arranged between the conveying device 3 and the plate body conveyor 1, and the entire equipment is controlled by a controller, which is a PLC controller.

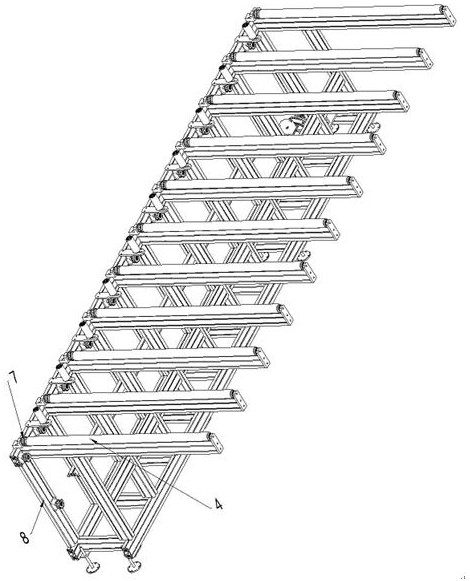

[0037] The length direction of the board conveying device 3 is the same as the length direction of the upper board conveyor 2. The board conveying device 3 includes a board conveying device frame 8, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com