Wheel expansion device

A technology for expansion devices and wheels, which is applied to rims, vehicle parts, transportation and packaging, etc., can solve the problems of potential safety hazards, high production costs, and high labor intensity, so as to reduce labor intensity, improve production efficiency, and reduce production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

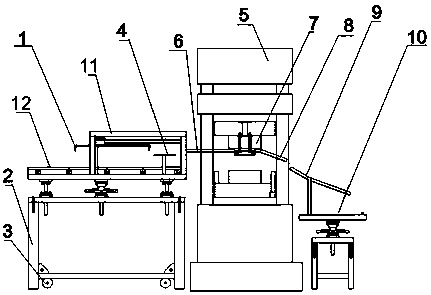

[0011] exist figure 1 Among them, a wheel expansion device, which consists of a lower fixed base 2, an expansion punch 5 and a supporting plate 10, is characterized in that: a transmission belt 12, an upper fixed frame 11 and a lifting device 4 are installed on the lower fixed base 2, The lifting device 4 is symmetrically located on both sides of the transmission belt 12, and the push plate 1 is installed on the top of the upper fixed frame 11. The expansion die 7 of the expansion punching machine 5 is fixedly installed with a loading fixture 6 and a blanking guide column 8. The material receiving guide post 9 is fixedly installed on the plate 10 .

[0012] When working, the wheels are first placed on the conveyor belt 12 on the lower fixed base 2, and the transmission belt 12 drives the wheels to run forward. When running to the lifting device 4, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com