Impeller locking automatic control system and method for large wind power generator

A technology of wind turbines and automatic control systems, applied in the control of wind turbines, wind turbines consistent with the wind direction, wind turbines, etc., can solve the problems of increased labor risk, labor-intensive, unrealistic, etc., to reduce labor risk , save maintenance costs and ensure safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

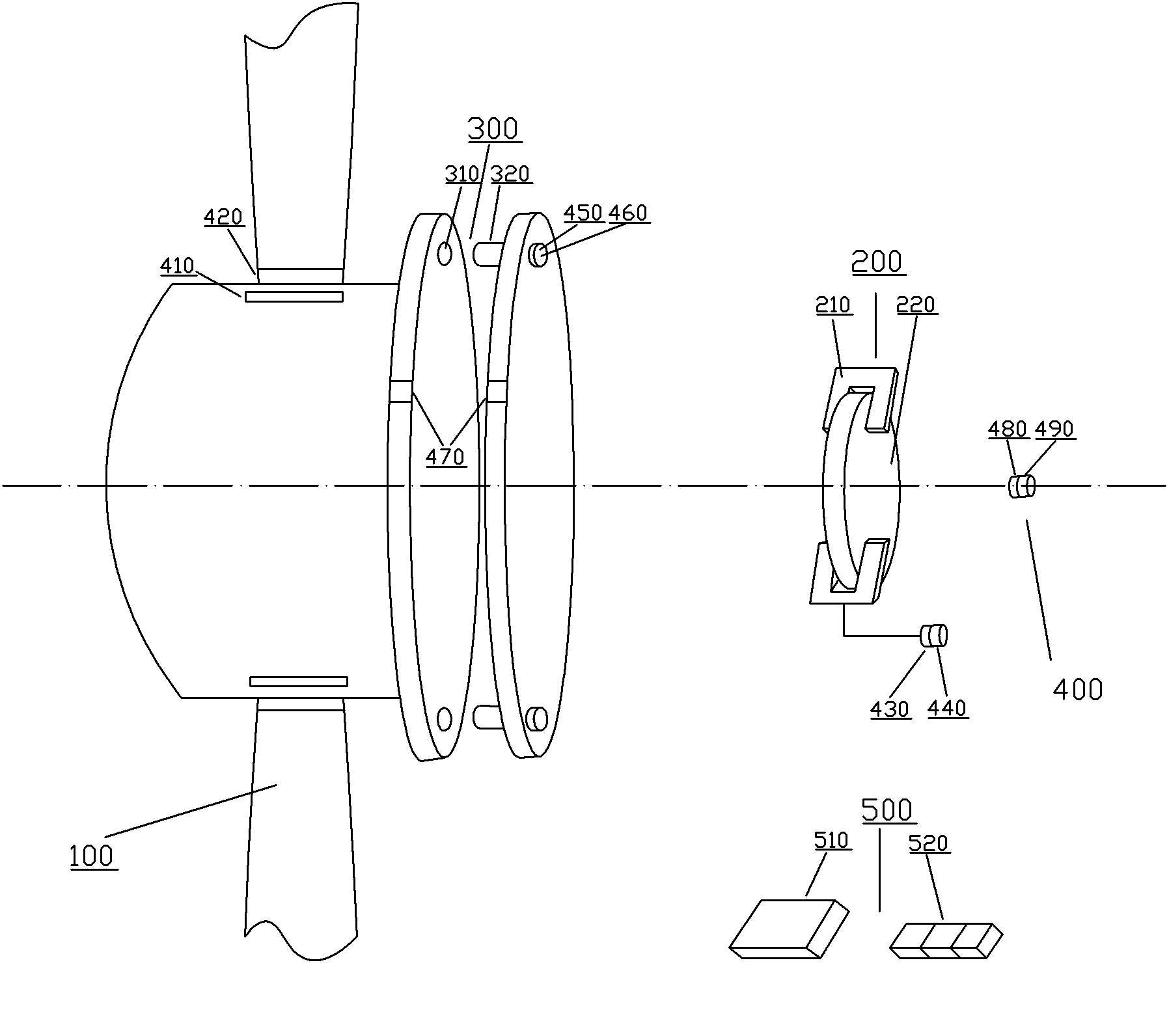

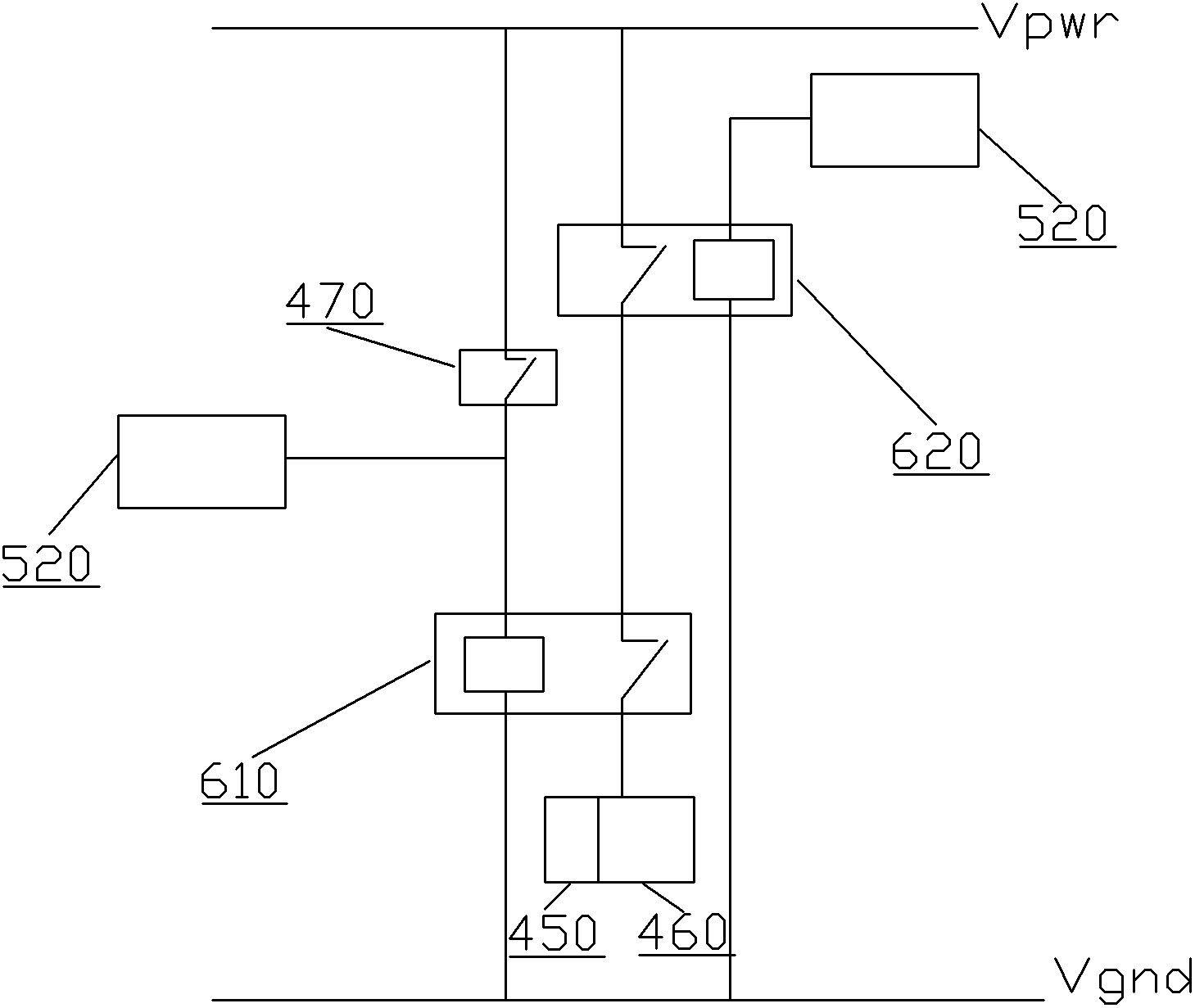

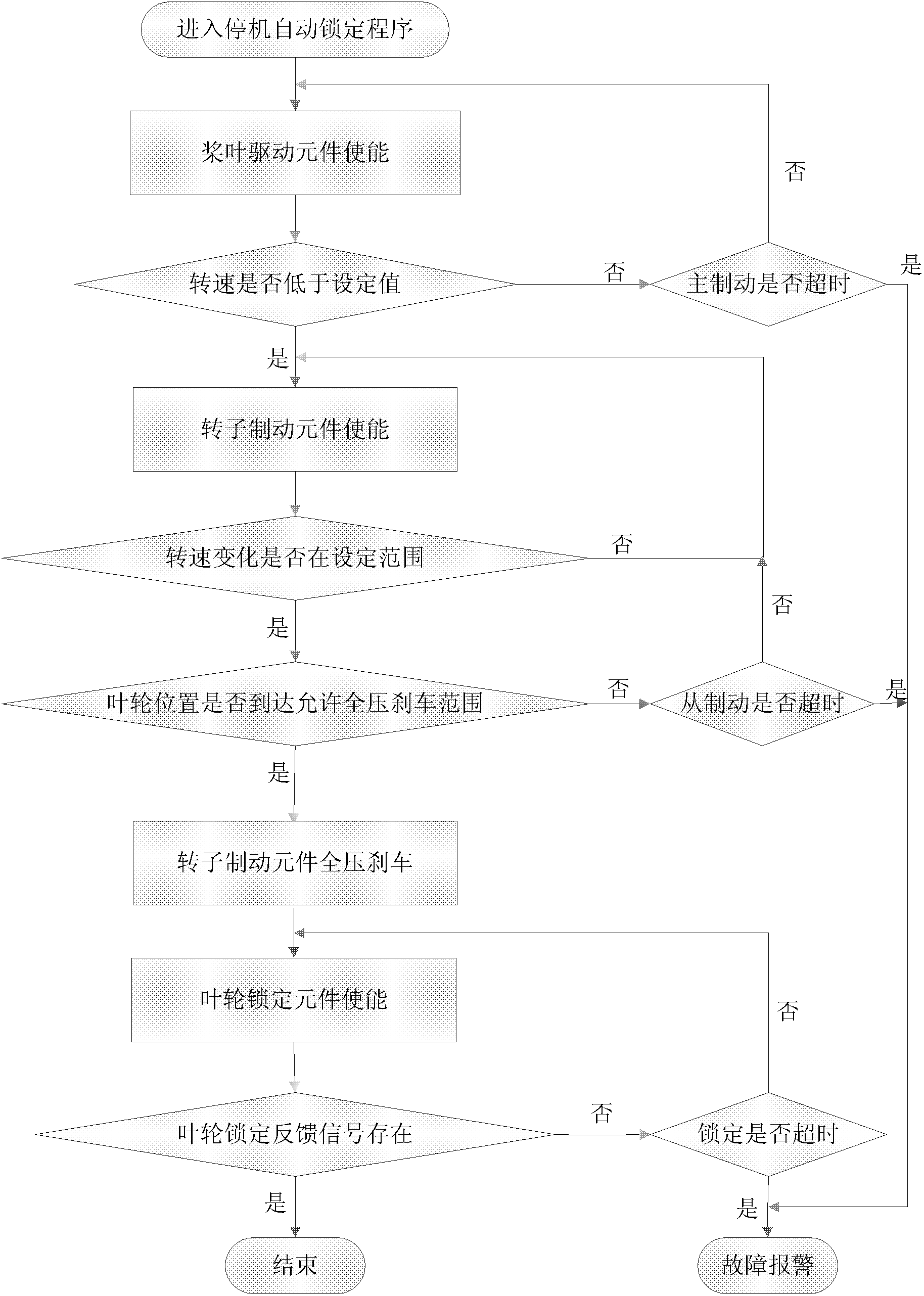

[0027] According to the actual application scenarios of most wind turbines, when the wind turbine needs to be repaired or maintained, the wind turbine is switched from the operation mode to the shutdown mode under the action of its controller. After the fan enters the stop mode, the impeller decelerates rapidly under the action of the pitch device, and then stops under the forced action of the brake clip. If there is a problem with the equipment inside the impeller, the brake clip needs to be released, and the rotor is manually moved to lock the impeller. The wind turbines based on this mechanism basically have the hardware structure that can realize automatic locking: impeller braking device (including pitch and rotor braking device) and locking device, only need to upgrade part of the hardware on this basis, write the appropriate The control software can establish an automatic control system for impeller locking.

[0028] see figure 1 , an automatic control system for impe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com