Parallel processing platform robot

A processing platform and robot technology, which is applied to manipulators, manufacturing tools, program-controlled manipulators, etc., can solve the problems of complex structure of serial platforms, difficult decoupling of motion, and restricted use range, so as to save research and development costs, improve work capacity, increase The effect of large production benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

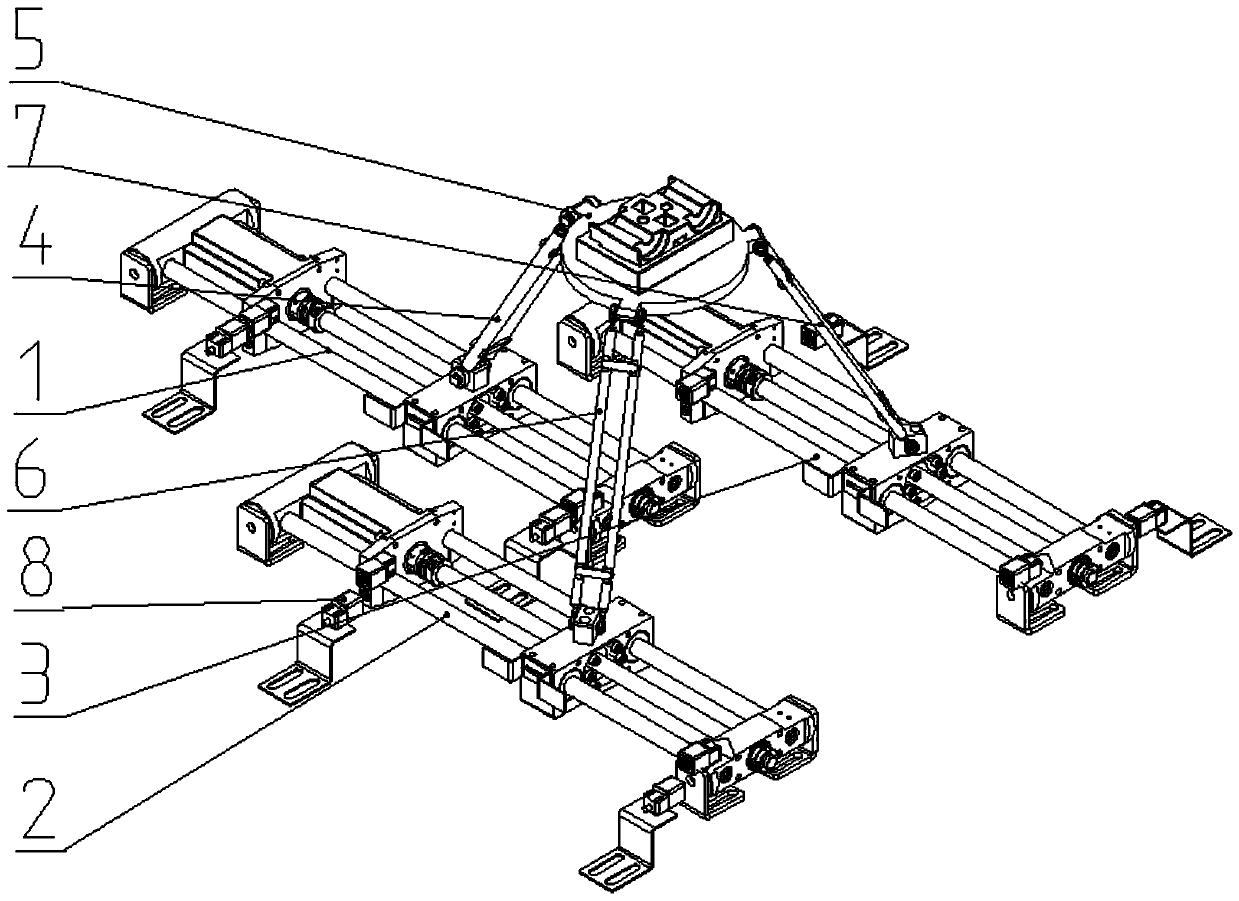

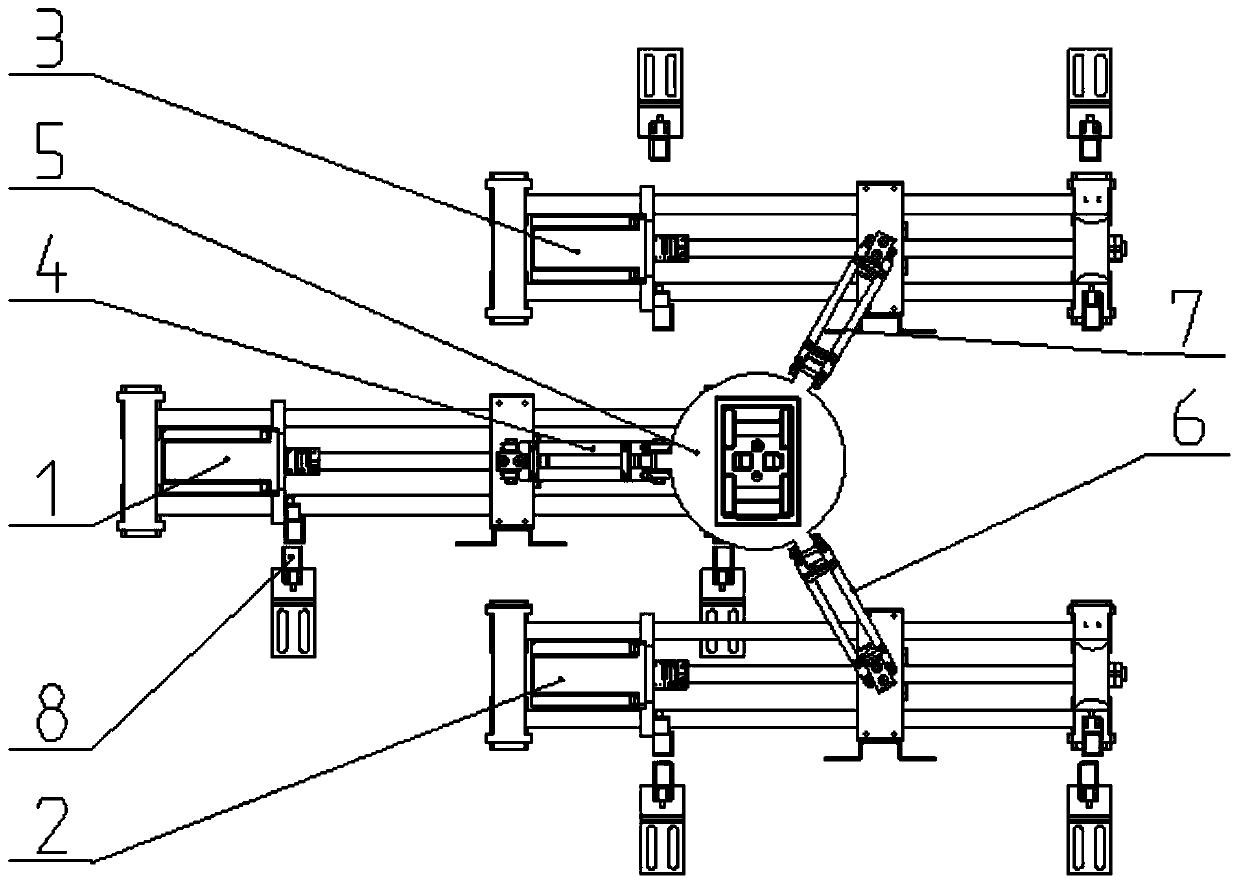

[0019] As an implementation manner, the first moving mechanism 1 , the second moving mechanism 2 and the third moving mechanism 3 are all ball screw mechanisms.

[0020] As an implementation, the first moving mechanism 1, the second moving mechanism 2 and the third moving mechanism 3 are all provided with a sensor 8, and the sensor 8 is used to detect the first slider, the second slider and the second slider. The moving distance of the three sliders, and the detection results are sent to the controller.

[0021] As an embodiment, the first moving mechanism 1 , the second moving mechanism 2 and the third moving mechanism 3 are all provided with guide rods, and the guide rods are used to guide the slider.

[0022] As an embodiment, the line connecting the center points of the first moving mechanism 1 , the second moving mechanism 2 and the third moving mechanism 3 forms an isosceles triangle.

[0023] As an embodiment, the first connecting rod 4 , the second connecting rod 6 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com