Continuous pushing self-moving machine tail

A technology of self-moving tail and pushing frame, which is applied to conveyors, conveyor objects, earth-moving drilling and other directions, can solve the problems of unrealistic realization of long-distance mining face, faulty signal transmission, affecting coal mining efficiency, etc. The effect of reducing labor risks and reducing the chance of misoperation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

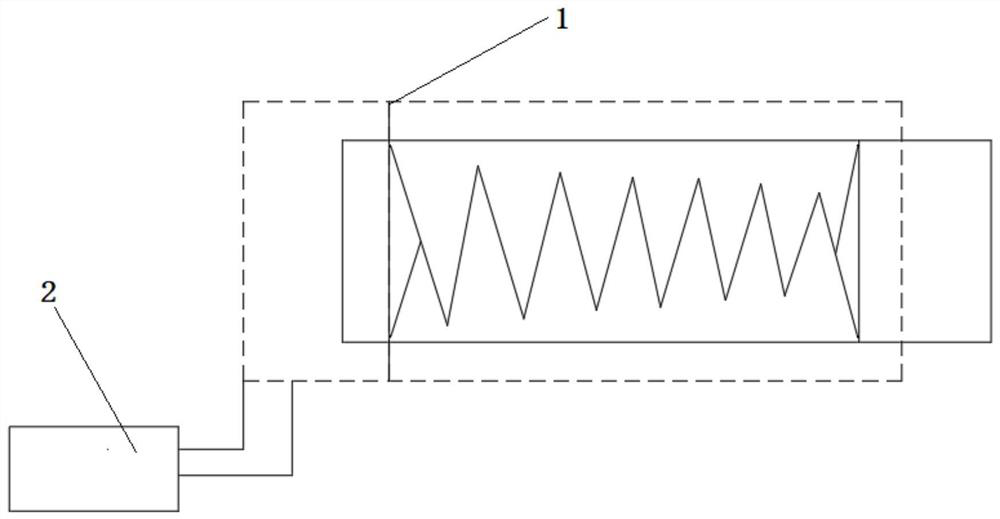

[0043] see figure 1 , a kind of continuous pushing self-moving tail described in a preferred embodiment of the present invention, comprises continuous pushing device 1 and power unit 2,

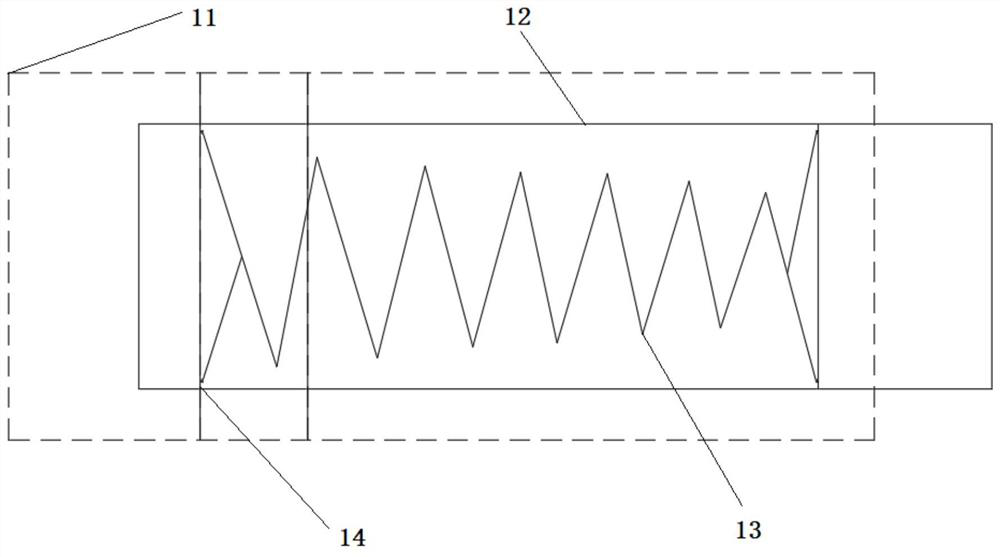

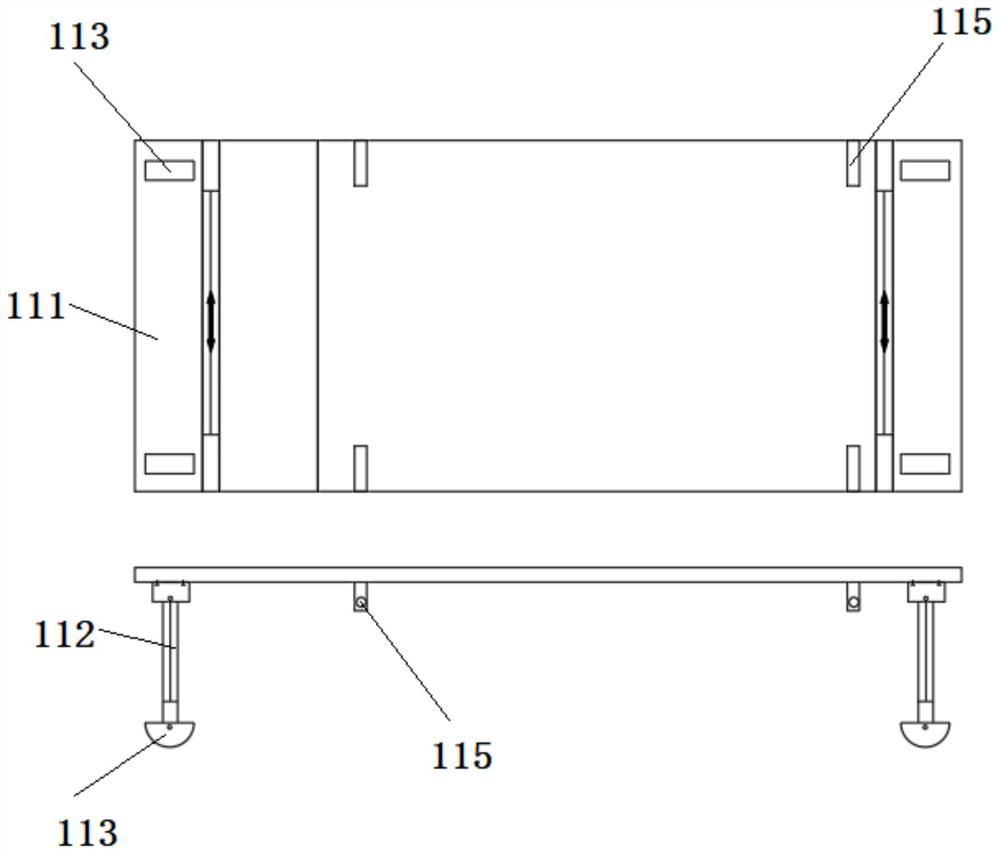

[0044] see figure 2 , the continuous pushing device 1 includes an outer pushing frame device 11, an inner pushing frame device 12, a flexible telescopic device 13, and a pin shaft 14, and the outer pushing frame device 11 is movable across the inner moving frame through a misalignment groove On the surface of the device 12, the outer push frame device 11 and the inner push frame device 12 are on the same horizontal plane; the left and right sides of the flexible telescopic device 13 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com