Positioning method of inclined plate based on excavation conditions of anti-slide piles

A positioning method and anti-sliding pile technology, applied in excavation, infrastructure engineering, sheet pile wall and other directions, can solve the problems of inaccurate positioning, low connection reliability, low efficiency, etc., to achieve strong operability and improve overall safety , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] This embodiment is based on the positioning method of the inclined inserting plate based on the excavation condition of the anti-slide pile, including the following steps:

[0061] (1) Production of model boards

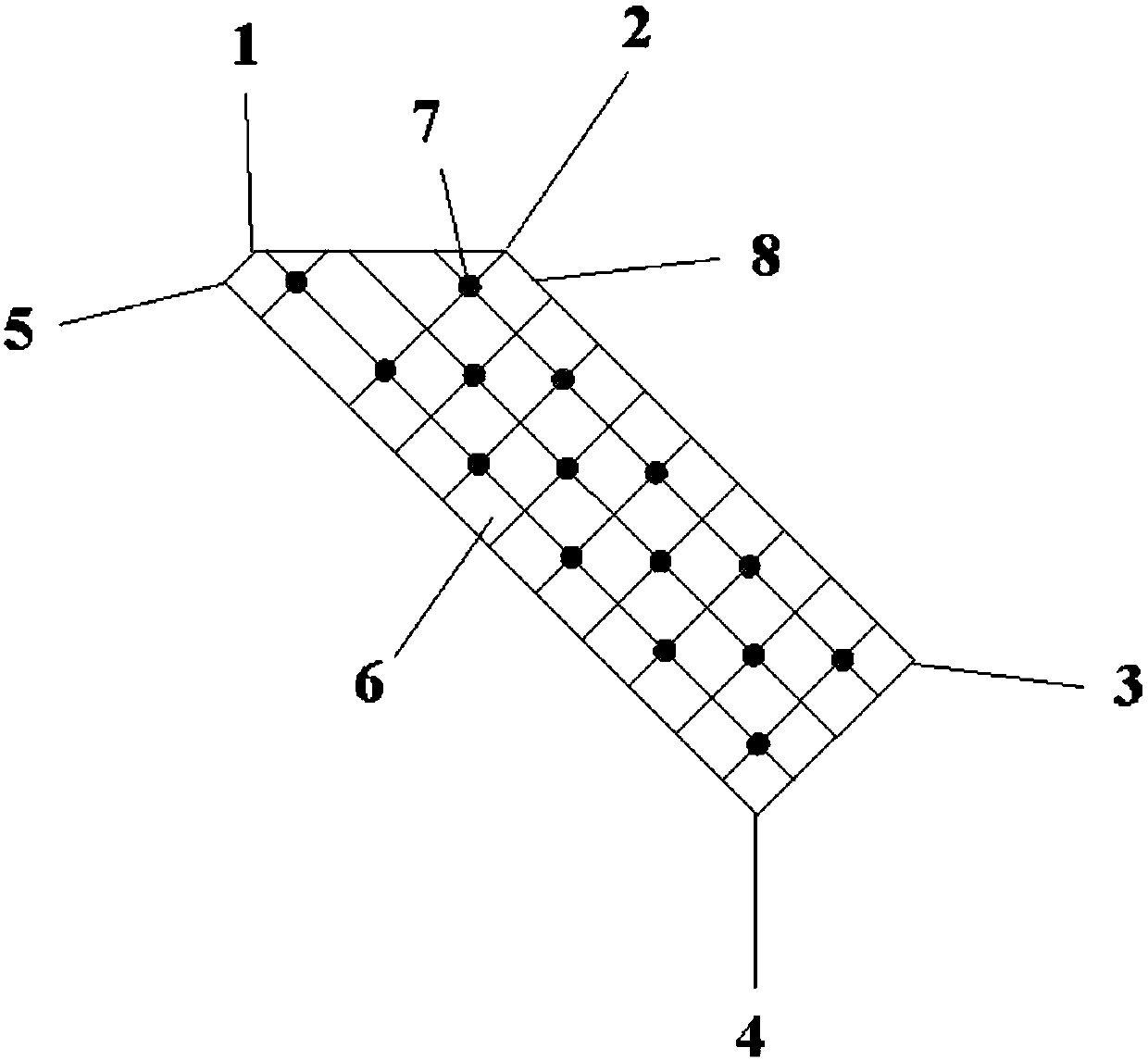

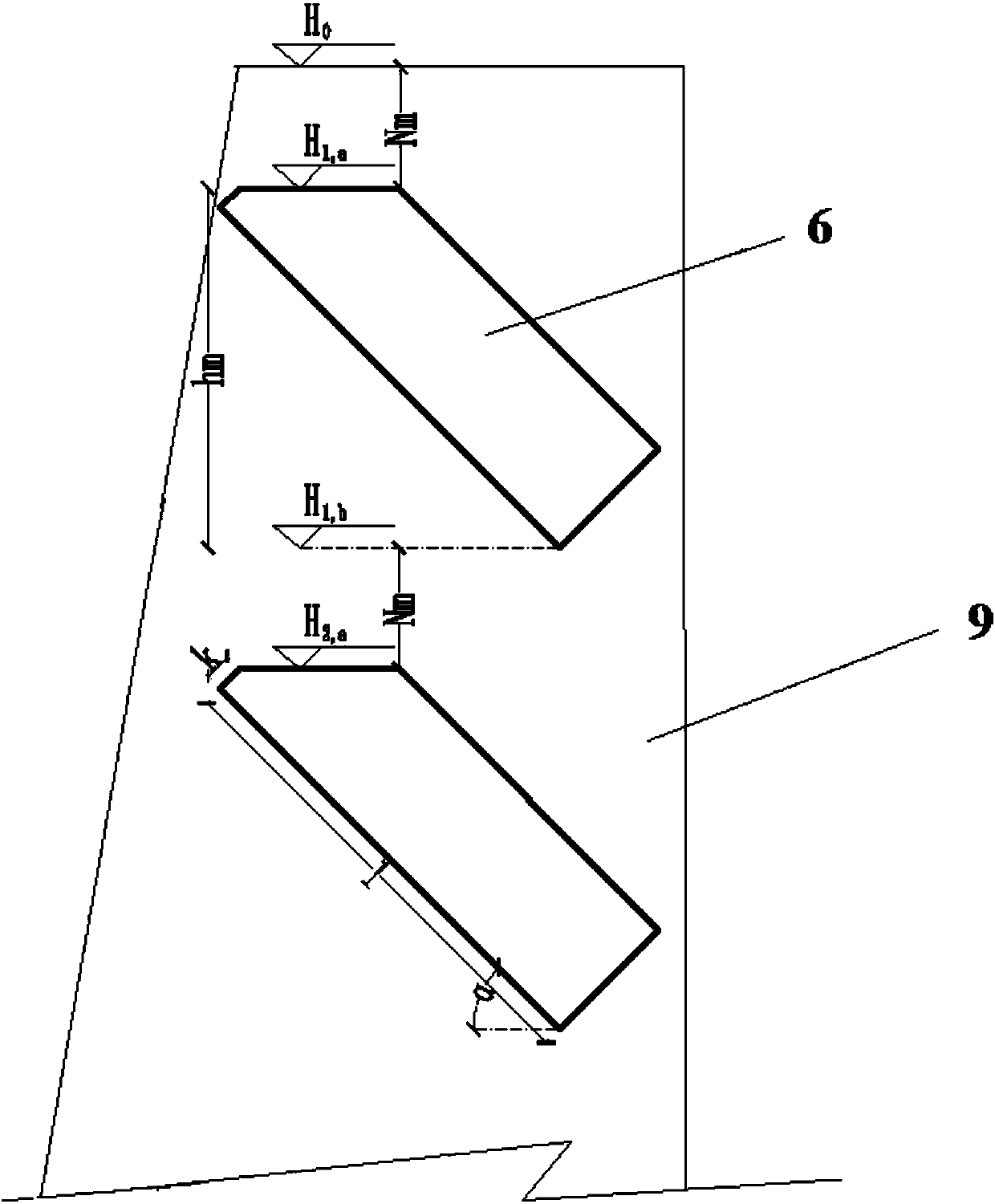

[0062] Such as figure 1 As shown, make the same model board 6 with the cross-section size of the inclined board, the model board cross-section includes a pentagon with three right-angled sides, includes three rows of positioning holes 7, and the distance between each row is the same and each row of holes is the same as The distances between the holes are the same, including the first obtuse angle 1 , the second obtuse angle 2 , the first right angle 3 , the second right angle 4 and the third right angle 5 .

[0063] Choose a 10mm thick wooden board to make a model board with the same cross-sectional size as the inclined board. The model board only determines the position of the reinforcement on the retaining wall and is not poured in the anti-sliding pile. Th...

Embodiment 2

[0105] Using the method of Example 1, the anti-sliding piles on the Dongchuan-Gele Expressway in Kunming City were positioned with inclined inserting plates.

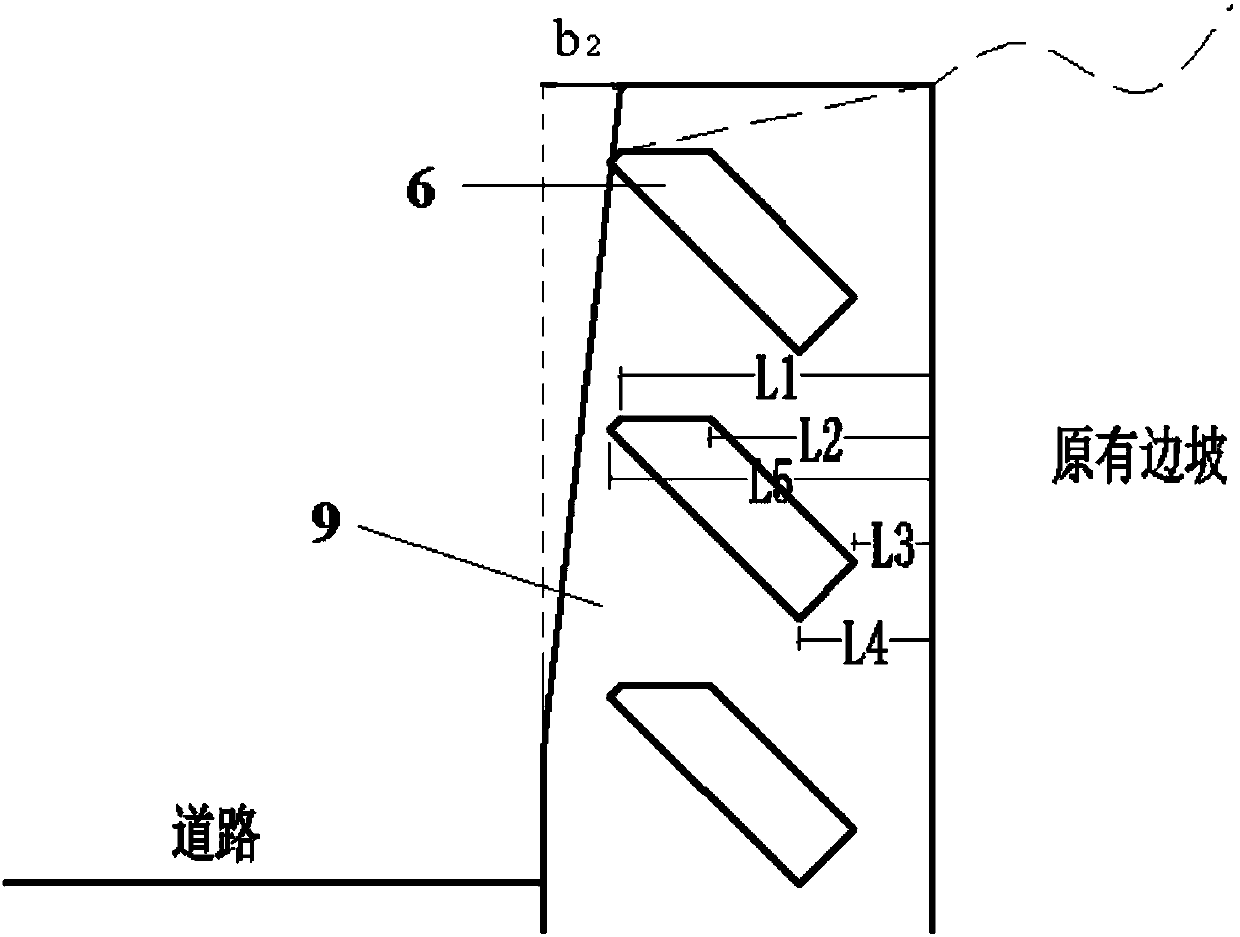

[0106] Take the positioning of the oblique insertion plate of the 1#-2# anti-slide pile on the left pile wall of K32+860~+930 as an example.

[0107] The top design of the anti-slide piles is cut-off after excavation, and the inclination angle of the slanted inserts is designed to be 45°. The basic information of the anti-slide piles and slanted inserts is shown in Table 4. According to the horizontal positioning formula in Example 1, the distance L between the five positioning points of the model plate and the side slope of the anti-slide pile is calculated. j , see Table 1 for Type A plate, see Table 2 for Type B plate,

[0108] Table 1 The distance L between the five anchor points of the A-type plate and the slope side of the anti-slide pile j

[0109]

[0110] Table 2 The distance L between the five anchor poi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com