Patents

Literature

78results about How to "Reduce the number of targeting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

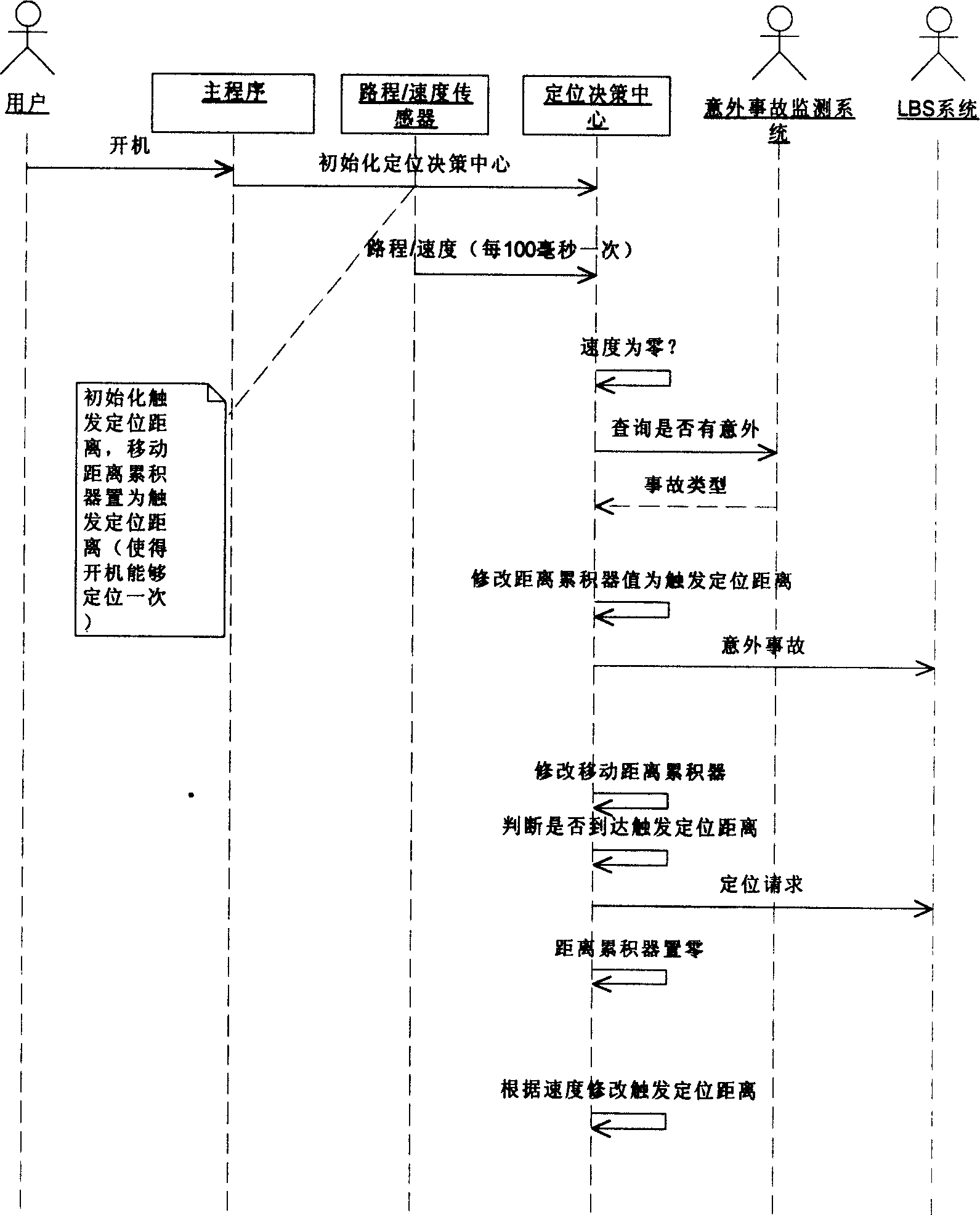

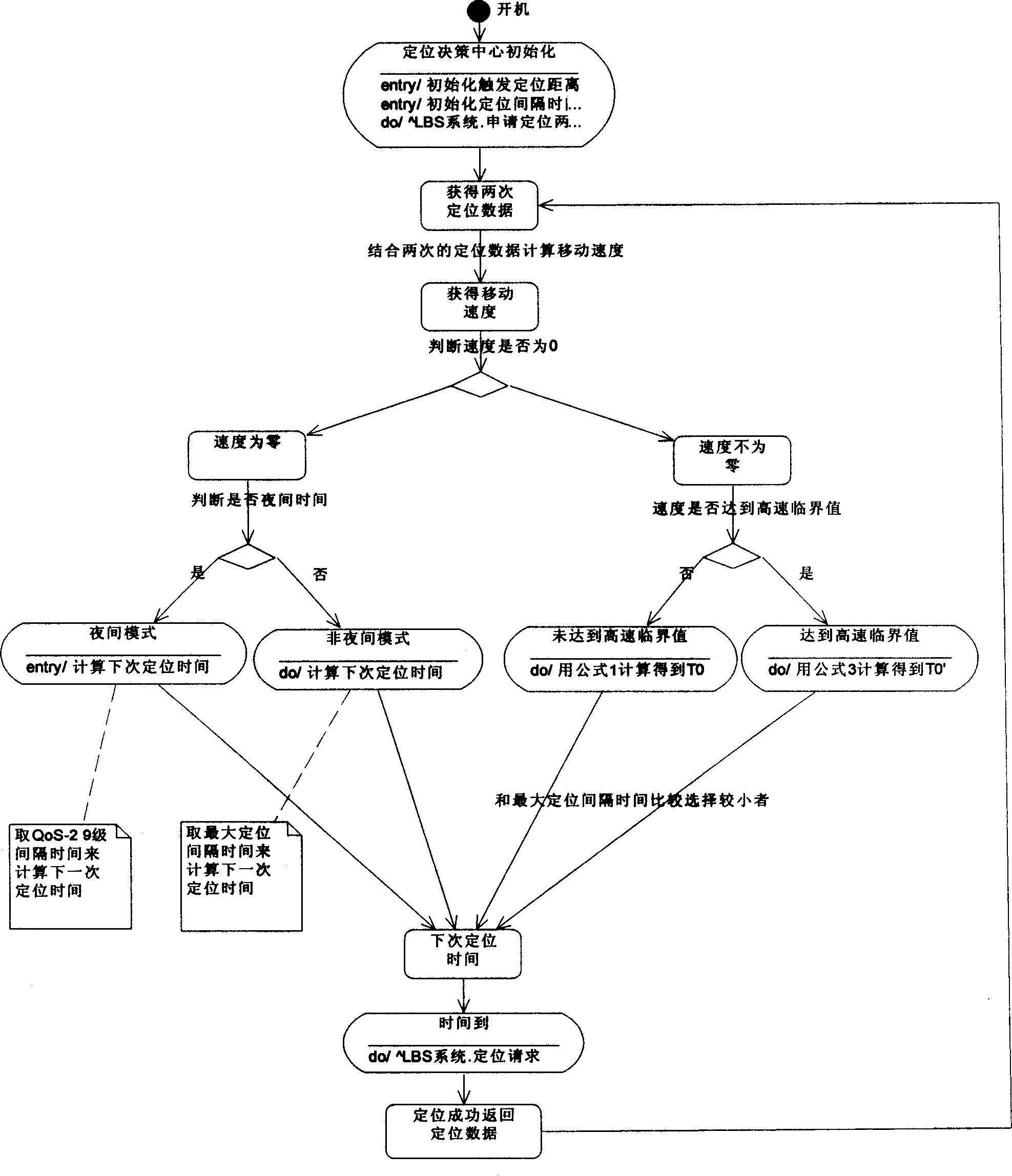

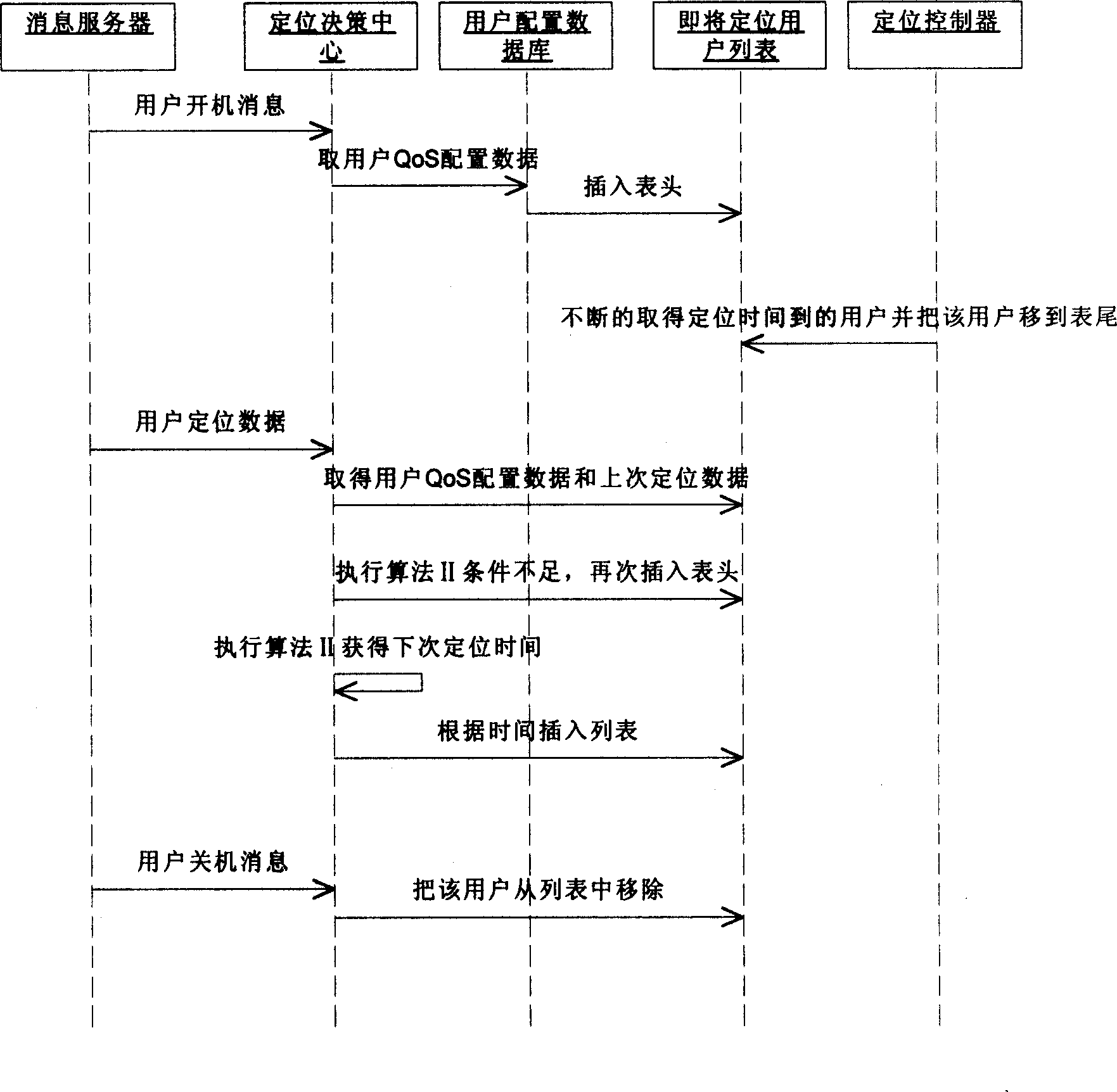

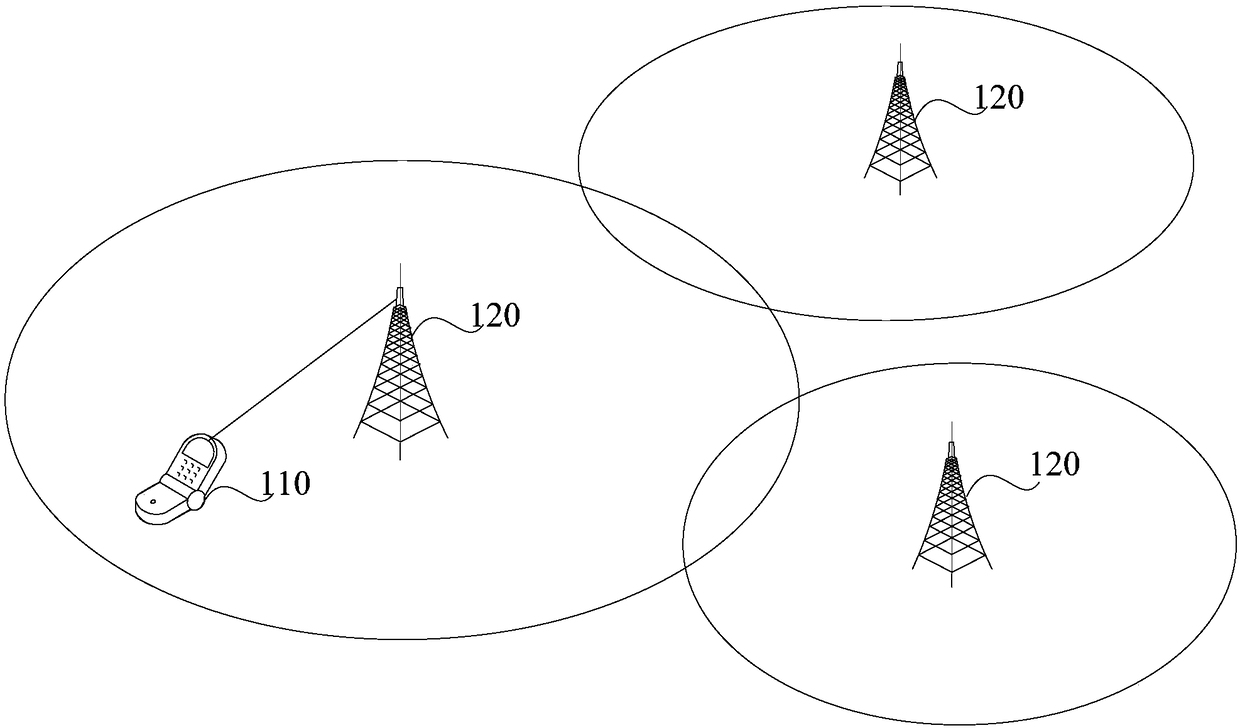

Method of dynamic changing user location frequency in LBS

InactiveCN1794862AReduce the number of targetingMeet the needs of different applicationsWireless communicationSystem capacityExercise state

This invention relates to a method and a system for asking to protect dynamically altering user location frequencies, which calls different algorithm modules combining with the movement state of a mobile user and the quality standard QoS demanded by the user to dynamically alter the location frequencies of the mobile user so that the historic trace recorded of the user is more accurate.

Owner:CHONGQING UNIV OF POSTS & TELECOMM +1

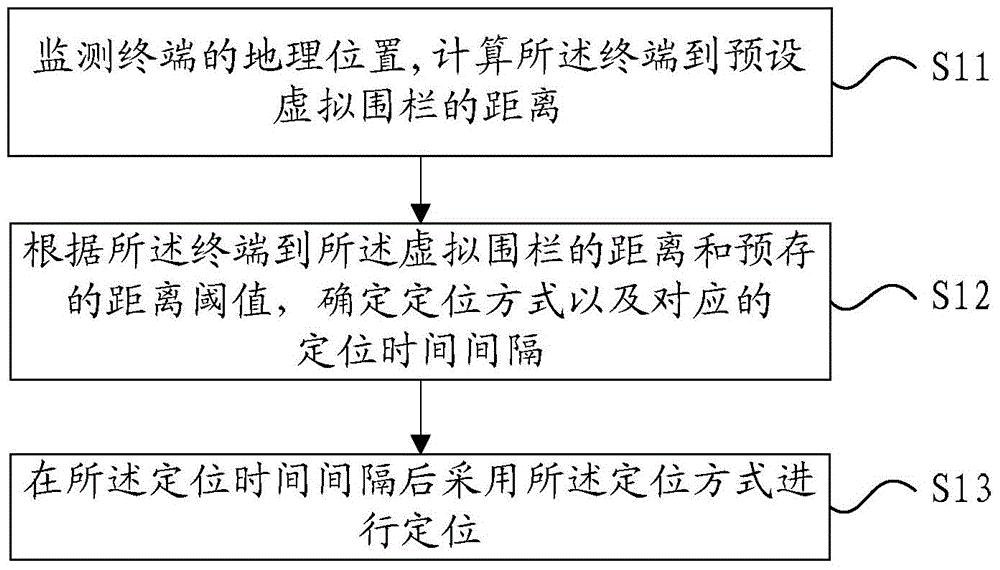

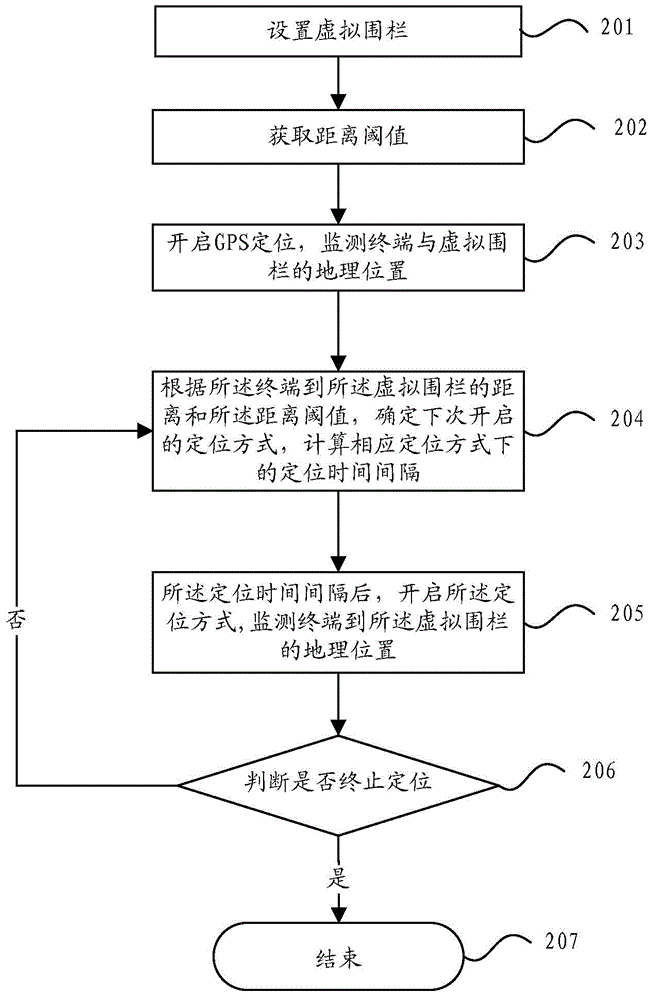

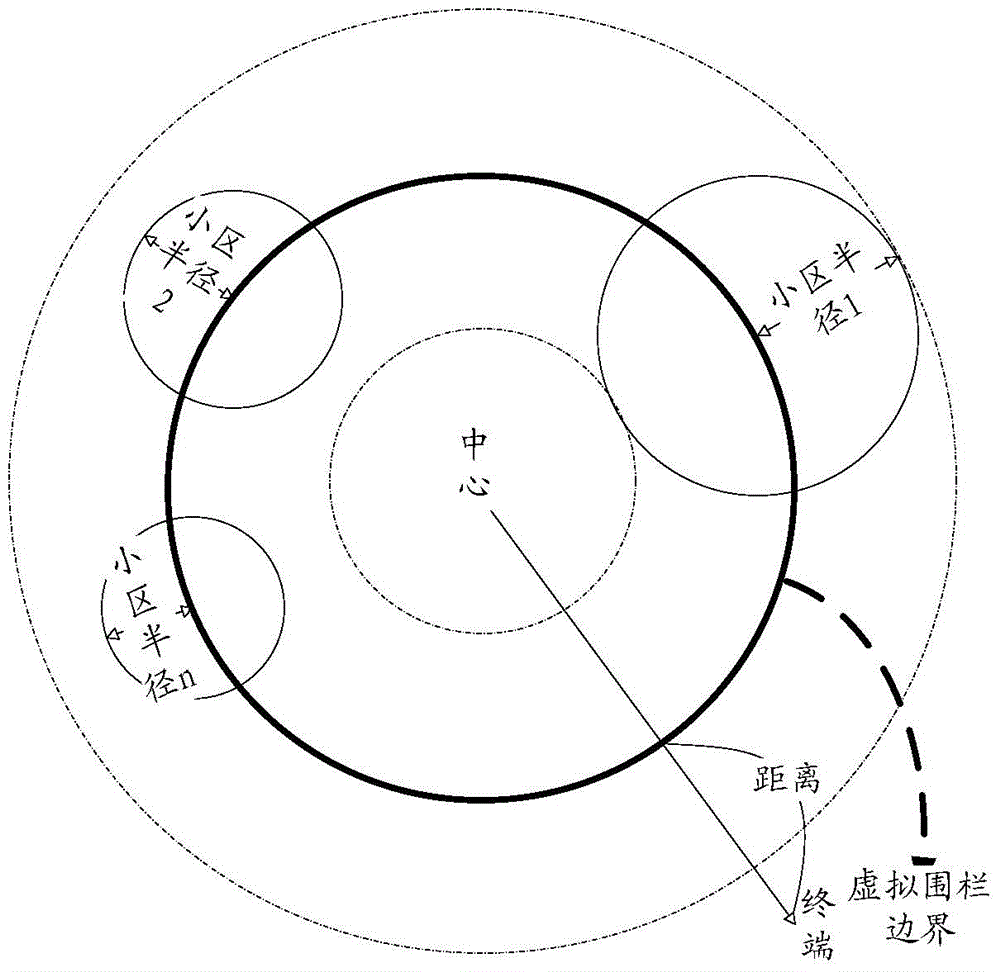

Location method, device and terminal

InactiveCN104678420AReduce the number of GPS positioningReduce battery consumptionSatellite radio beaconingLocation information based serviceSelf adaptiveGeolocation

The invention provides a location method, device and terminal, and relates to the field of communication. In order to solve the problem that a location manner cannot be selected in a self-adaption manner in the current virtual fence location system, the method comprises the steps of monitoring a geological position of the terminal, and calculating the distance between the terminal and a preset virtual fence; determining the location manner and a corresponding location time interval according to the distance between the terminal and the virtual fence and a preset distance threshold value; adopting the location manner for location after the location time interval. According to the location method, device and terminal, a proper location manner can be selected in a self-adaption manner according to location needs.

Owner:ZTE CORP

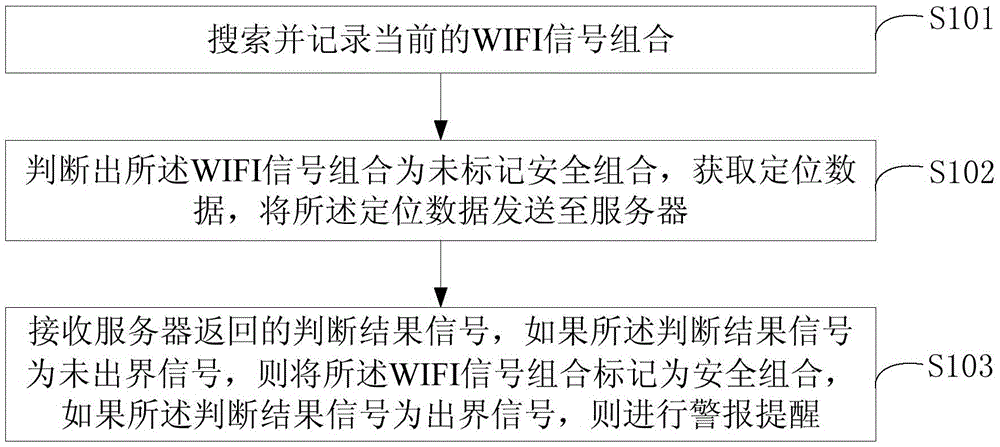

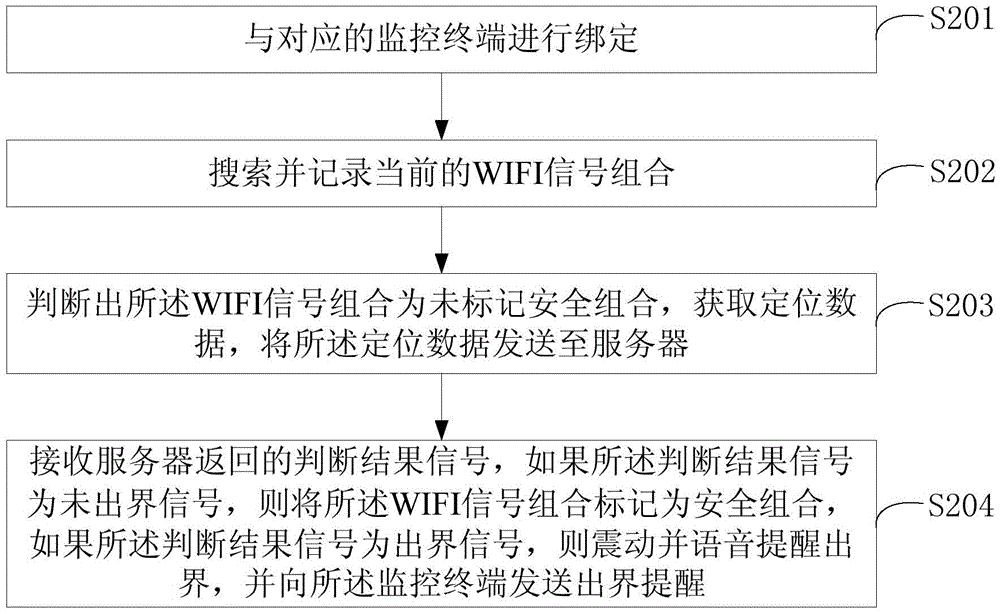

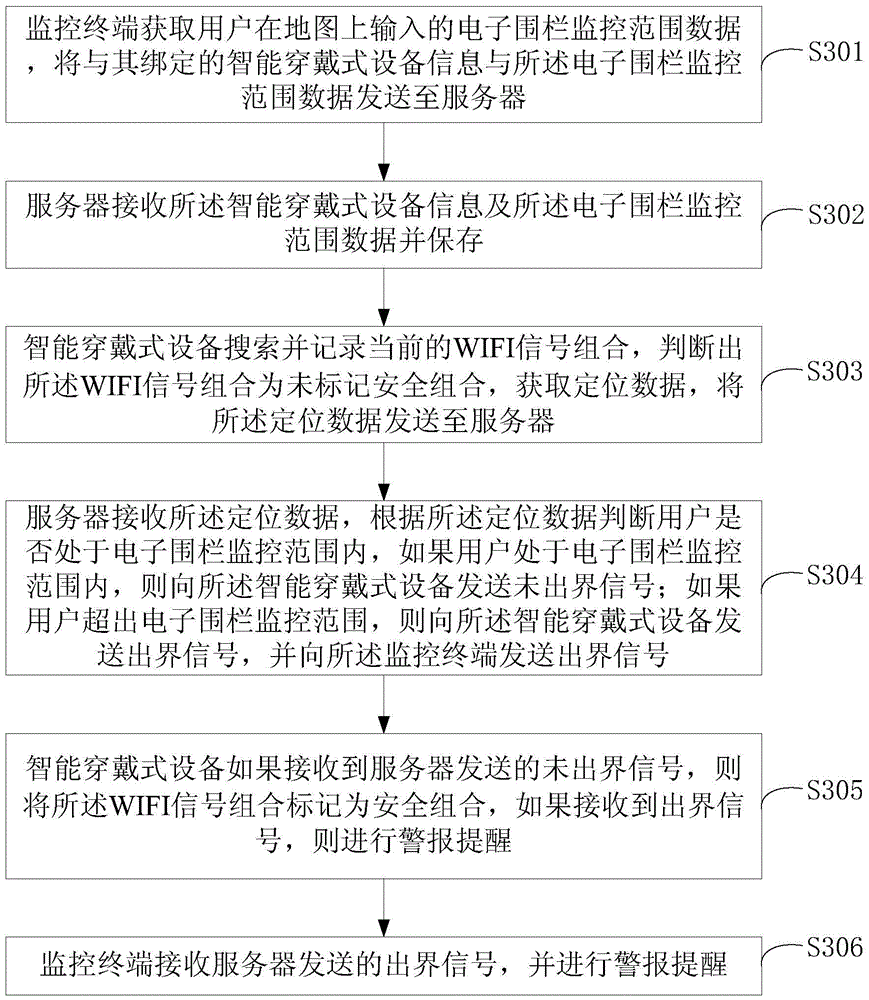

Virtual electronic fence positioning method and apparatus, and virtual electronic fence monitoring method and system

ActiveCN105575044AReduce the number of targetingReduce data transfer volumeAlarmsUse of timeData transmission

The invention discloses a virtual electronic fence positioning method and apparatus, and a virtual electronic fence monitoring method and system. The virtual electronic fence positioning method comprises searching and recording the current WIFI signal combination; determining that the WIFI signal combination is unmarked safe combination, acquiring the positioning data, and the positioning data to a server; receiving a determination result signal returned from the server; if the determination result signal is a not-out-of-range signal, marking the WIFI signal combination as safe combination; and if the determination result signal is an out-of-range signal, alarming to prompt. The virtual electronic fence positioning method and apparatus, and the virtual electronic fence monitoring method and system solve the technical problem that a current children positioning monitoring device consumes great energy and is shot in the stand-by time, so that the virtual electronic fence positioning method and apparatus, and the virtual electronic fence monitoring method and system can reduce the positioning number and the data transmission quantity, can save the energy and prolong the using time for one-time charging, and can realize children or the aged monitoring in a safety area.

Owner:GUANGDONG XIAOTIANCAI TECH CO LTD

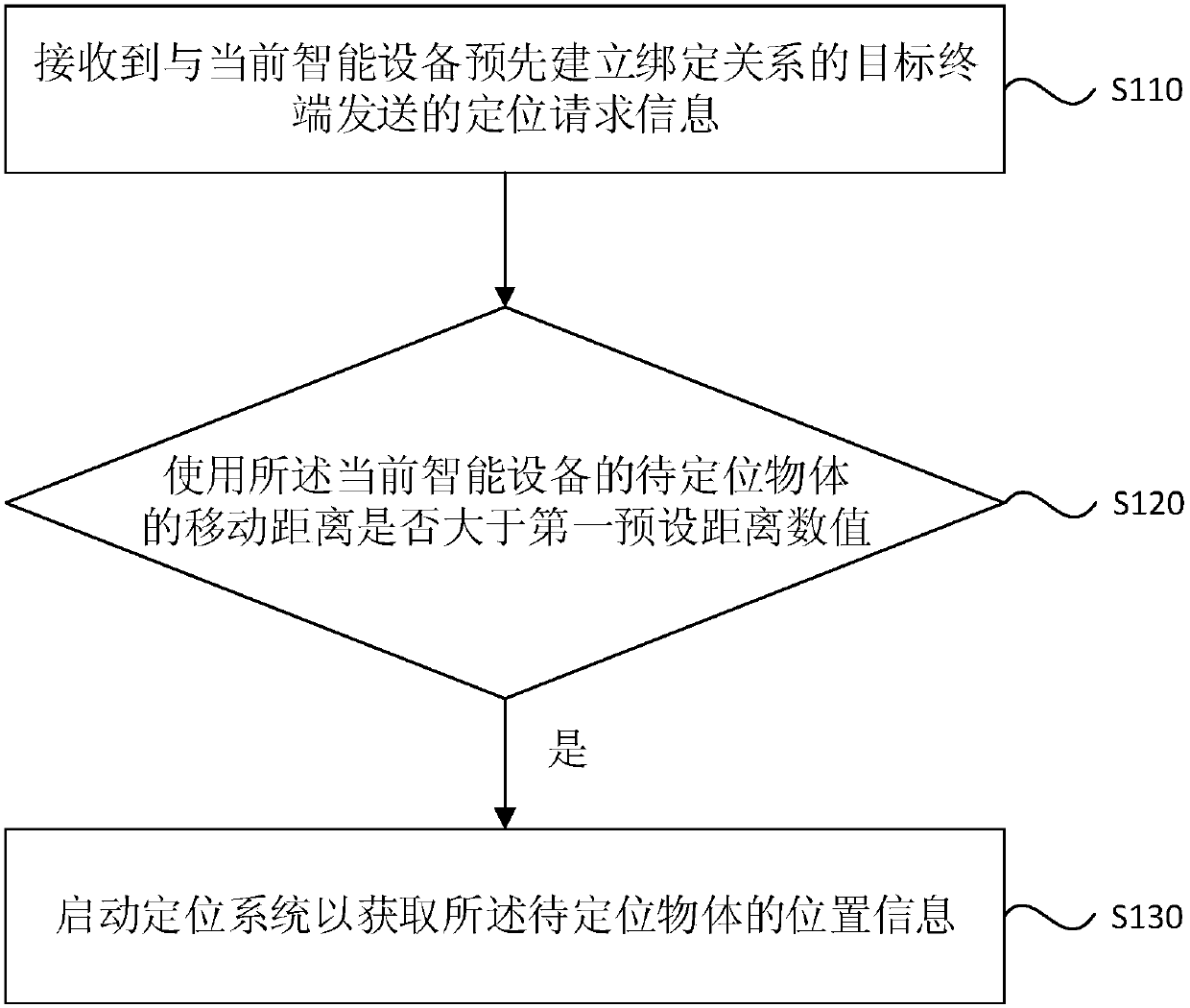

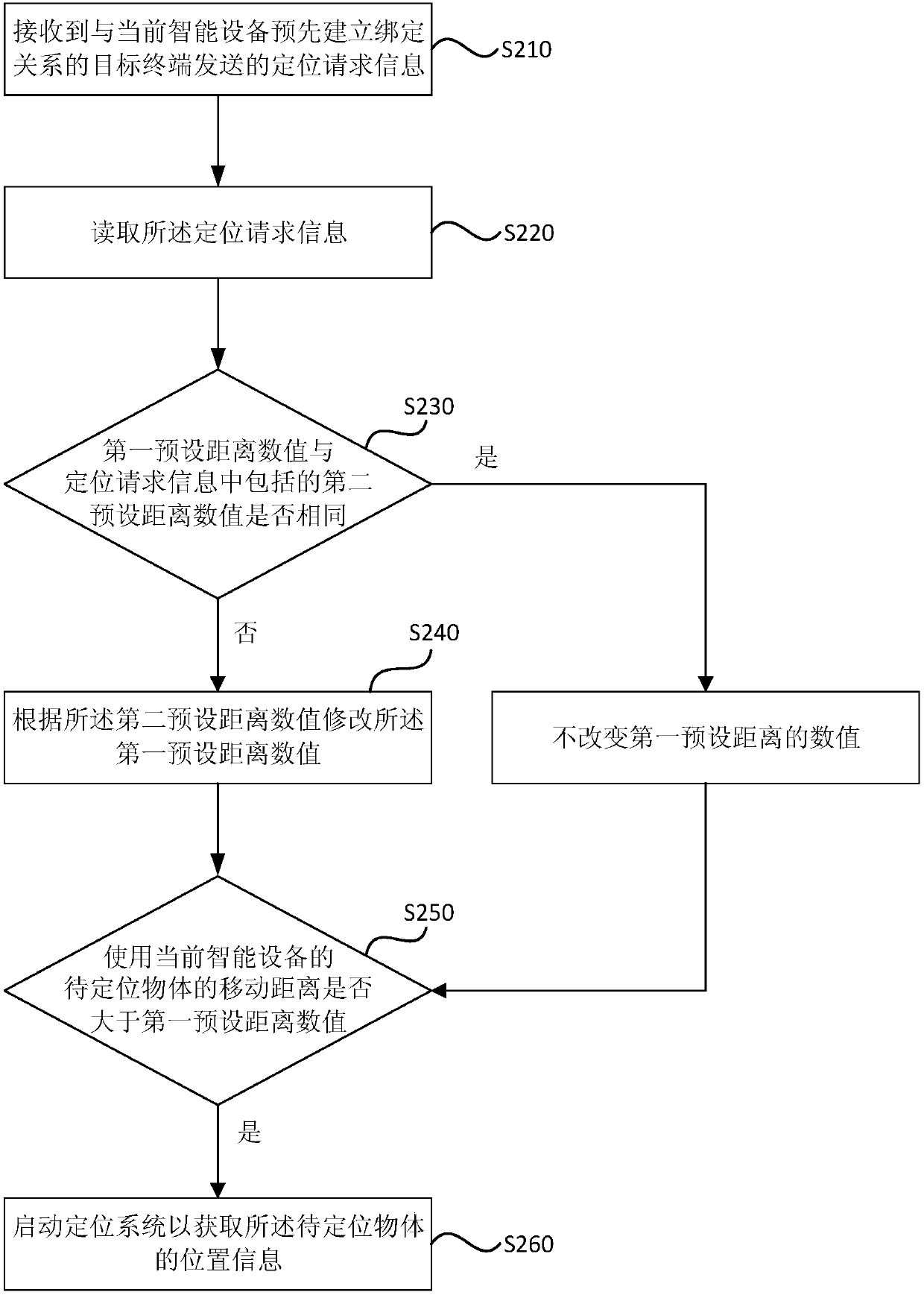

Positioning strategy optimization method and device

ActiveCN105959026AMeet needsReduce the number of targetingPower managementTransmissionPositioning systemReal-time computing

An embodiment of the invention discloses a positioning strategy optimization method and device. The method comprises the following steps: when receiving a positioning request message sent by a target terminal pre-establishing a binding relationship with a current intelligent device; judging whether the moving distance of an object to be positioned using the current intelligent device is larger than a first preset distance value; and if so, starting a positioning system to obtain the position information of the object to be positioned. The technical scheme overcomes the defects that power consumption is increased and endurance time is reduced due to frequent positioning operation in the prior art; existing technology is optimized; and requirements of users are met, and meanwhile, positioning frequency is reduced, power consumption is reduced and endurance time is prolonged.

Owner:GUANGDONG XIAOTIANCAI TECH CO LTD

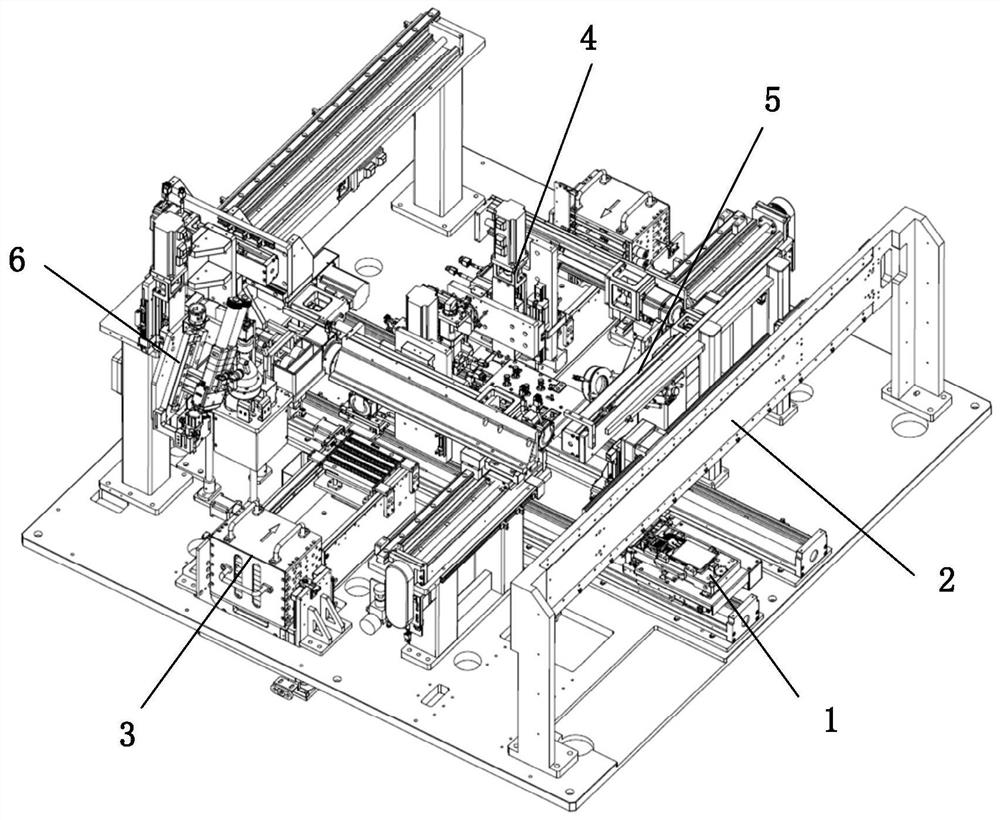

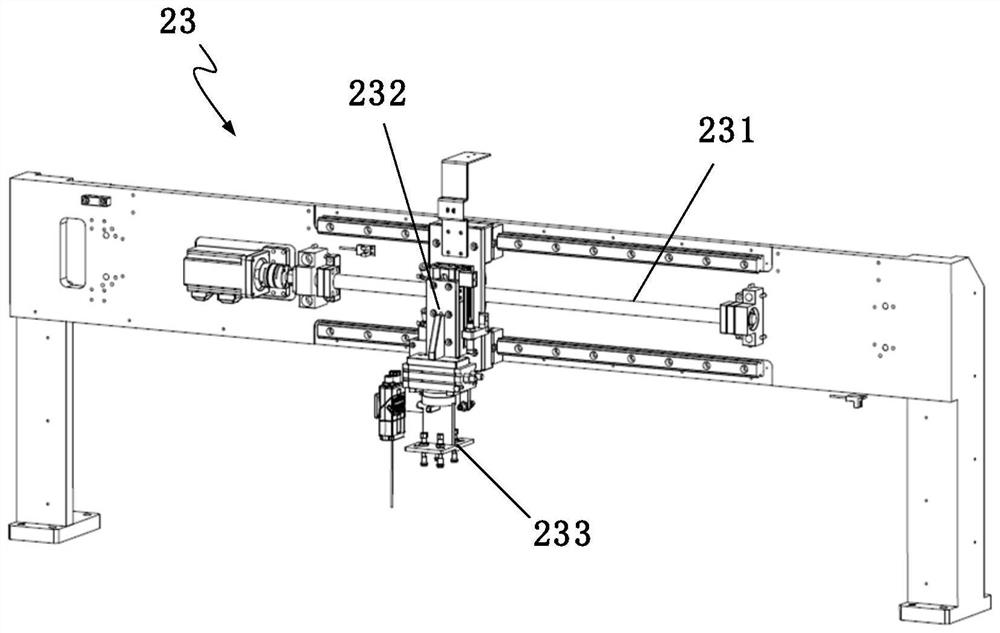

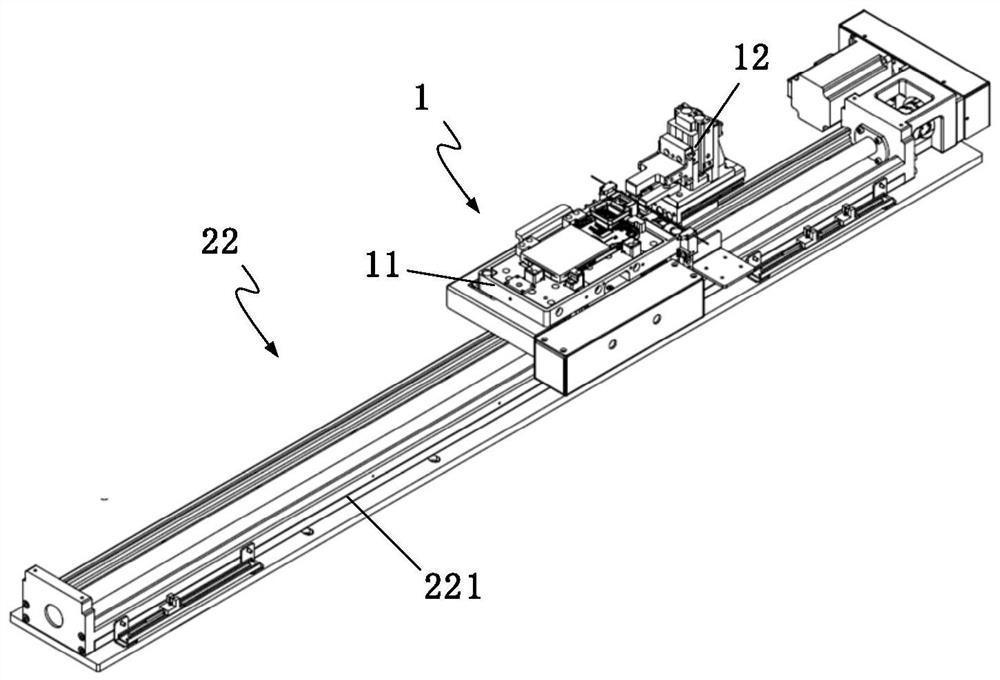

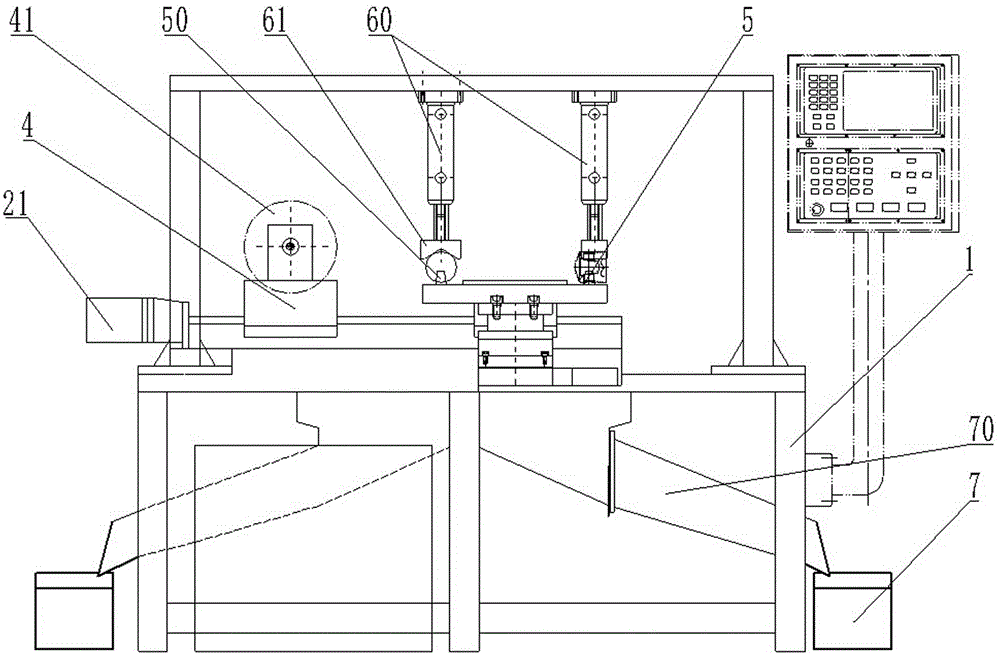

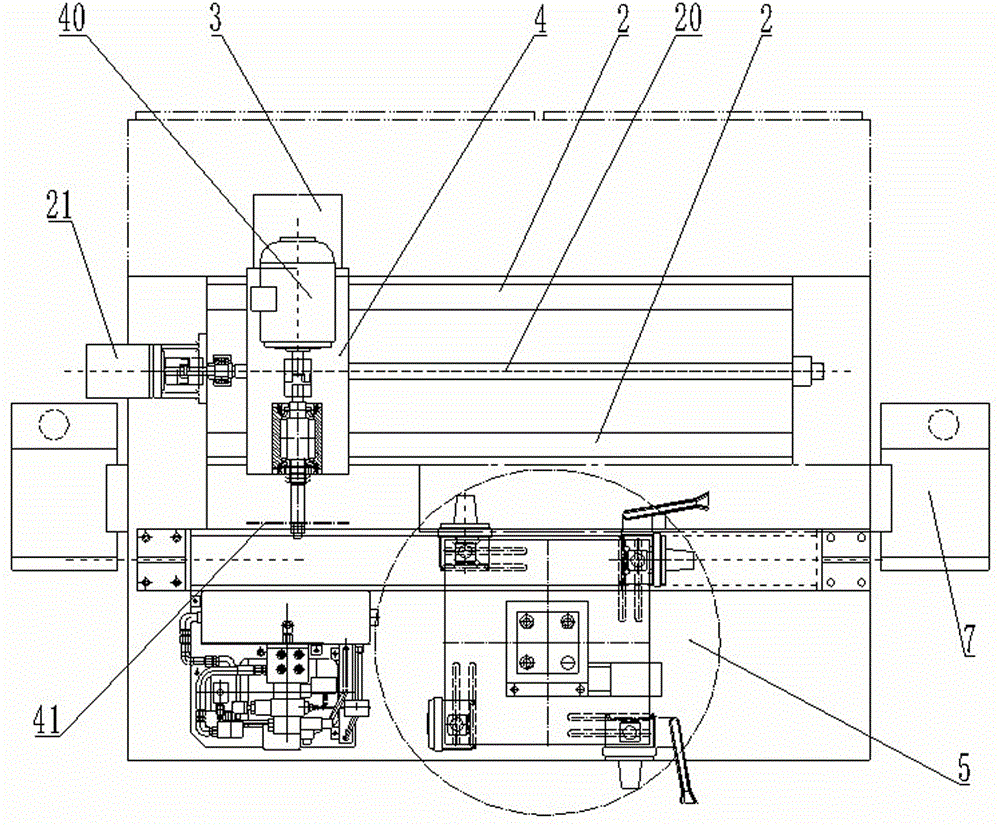

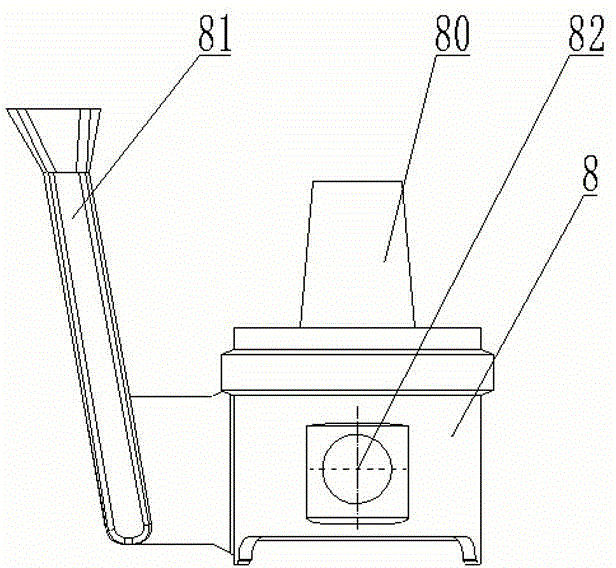

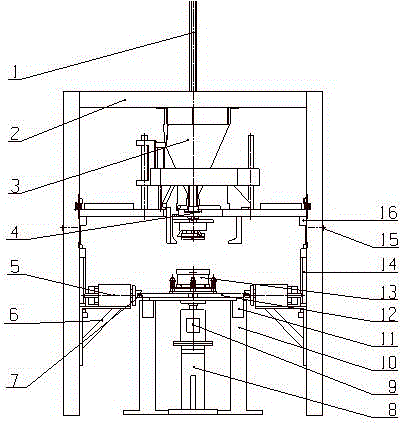

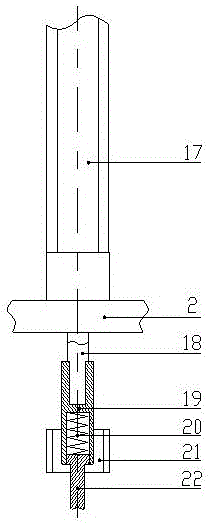

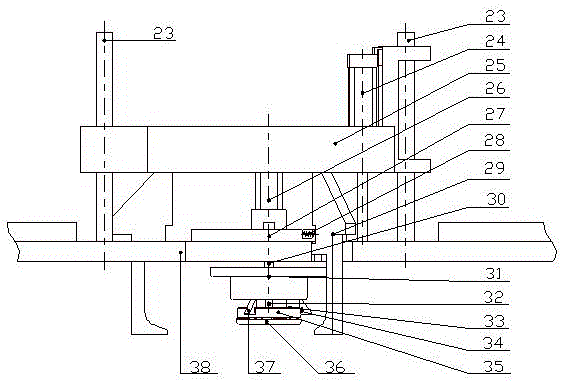

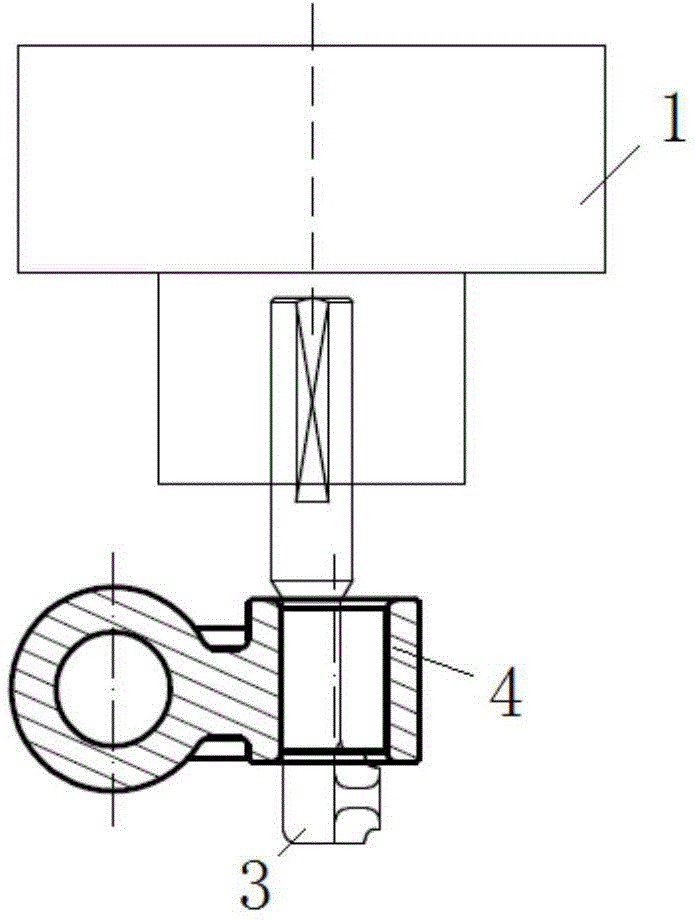

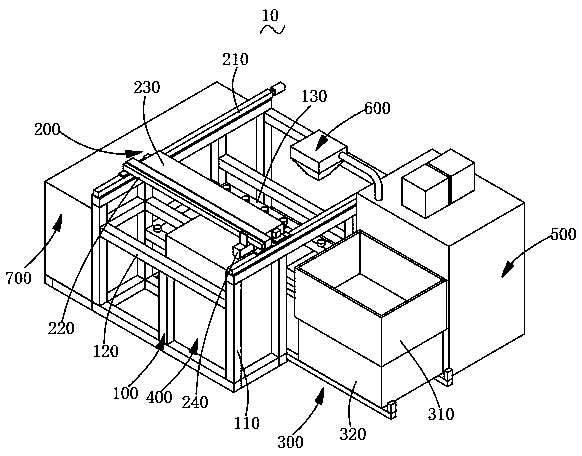

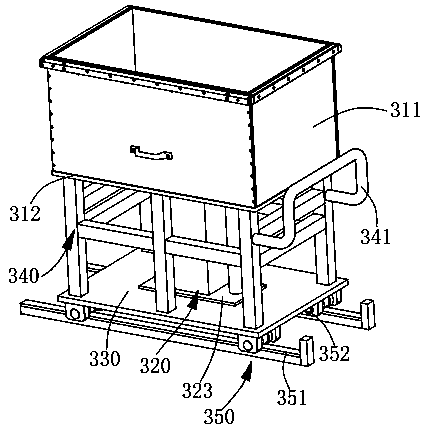

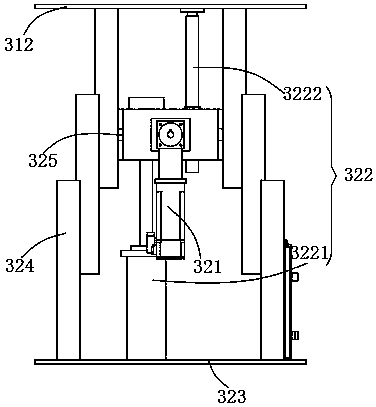

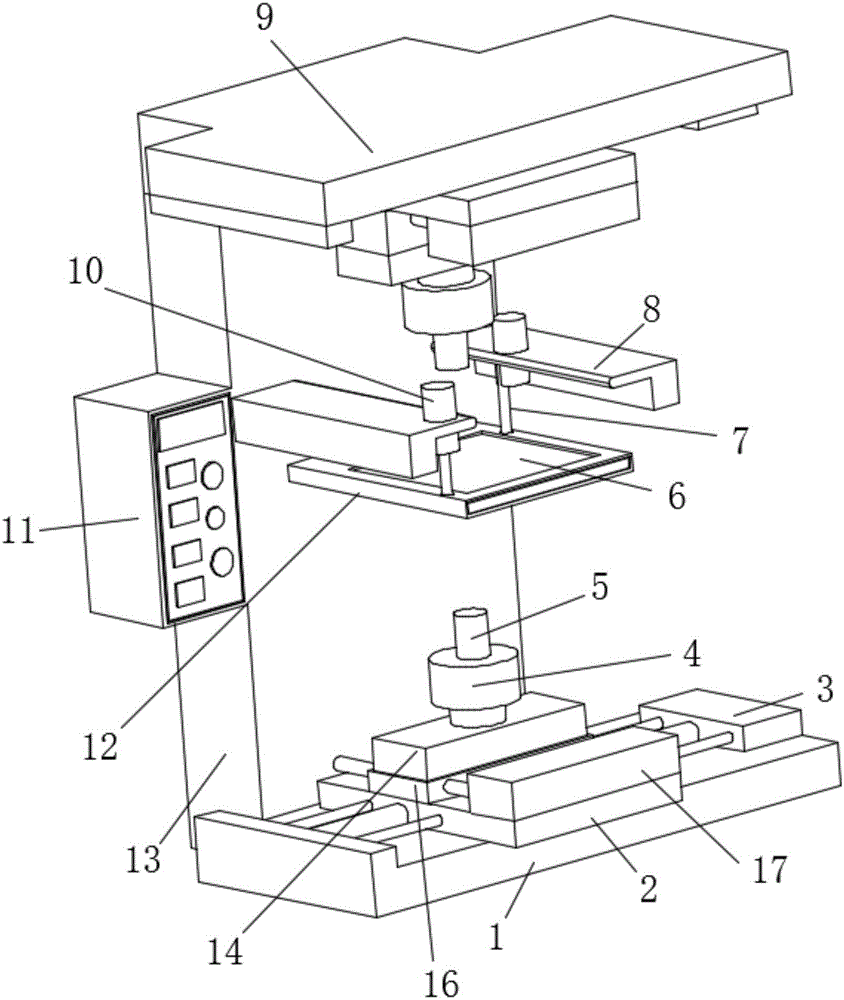

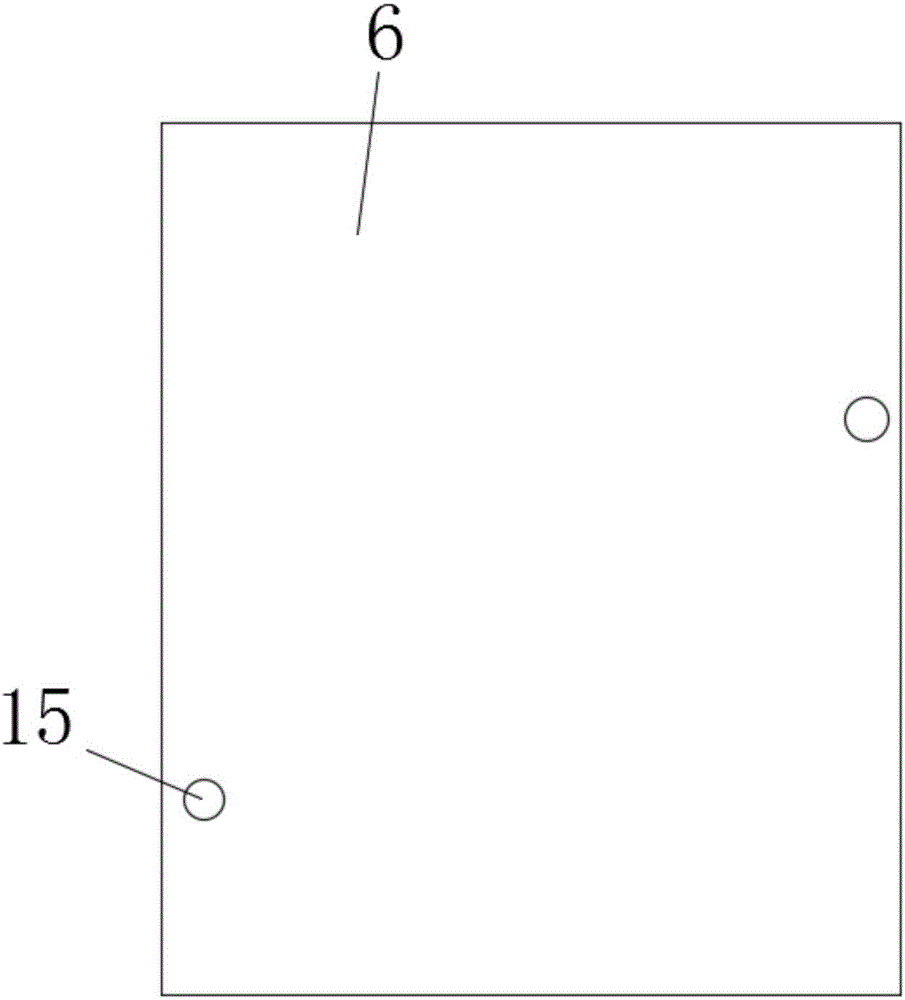

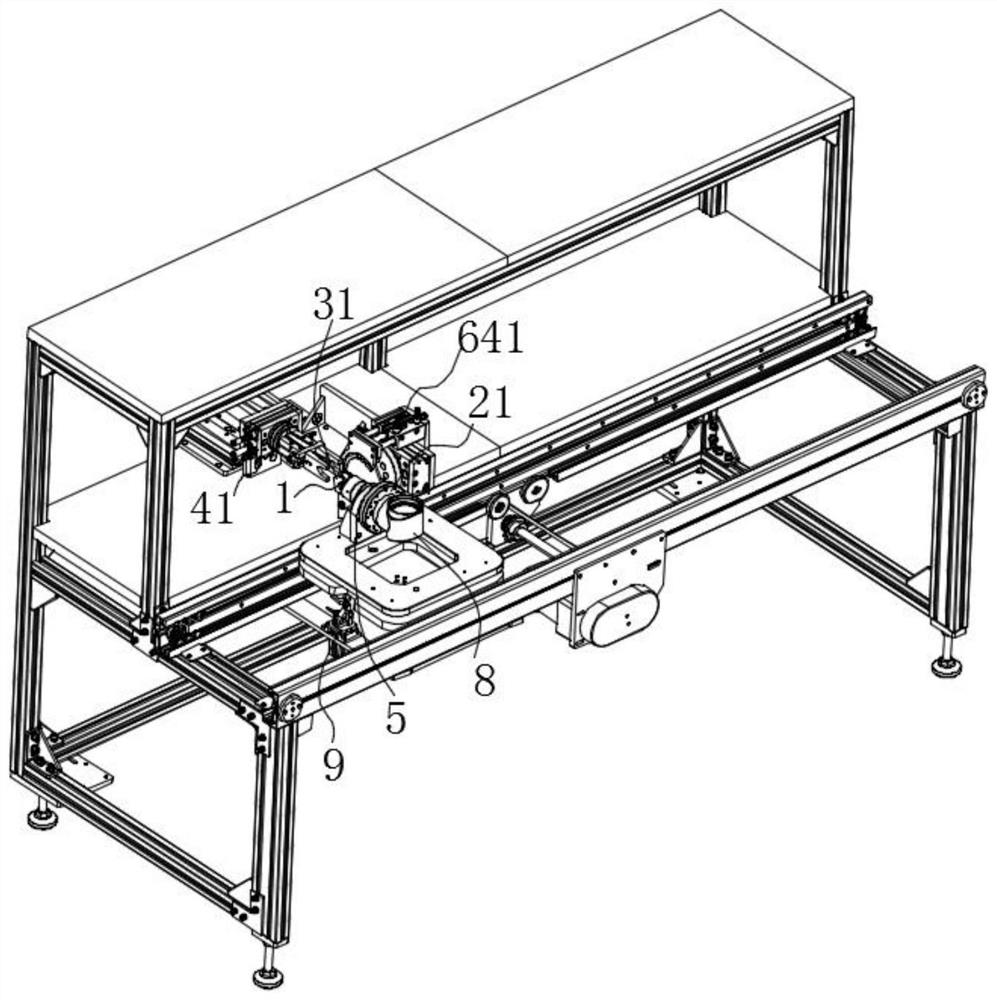

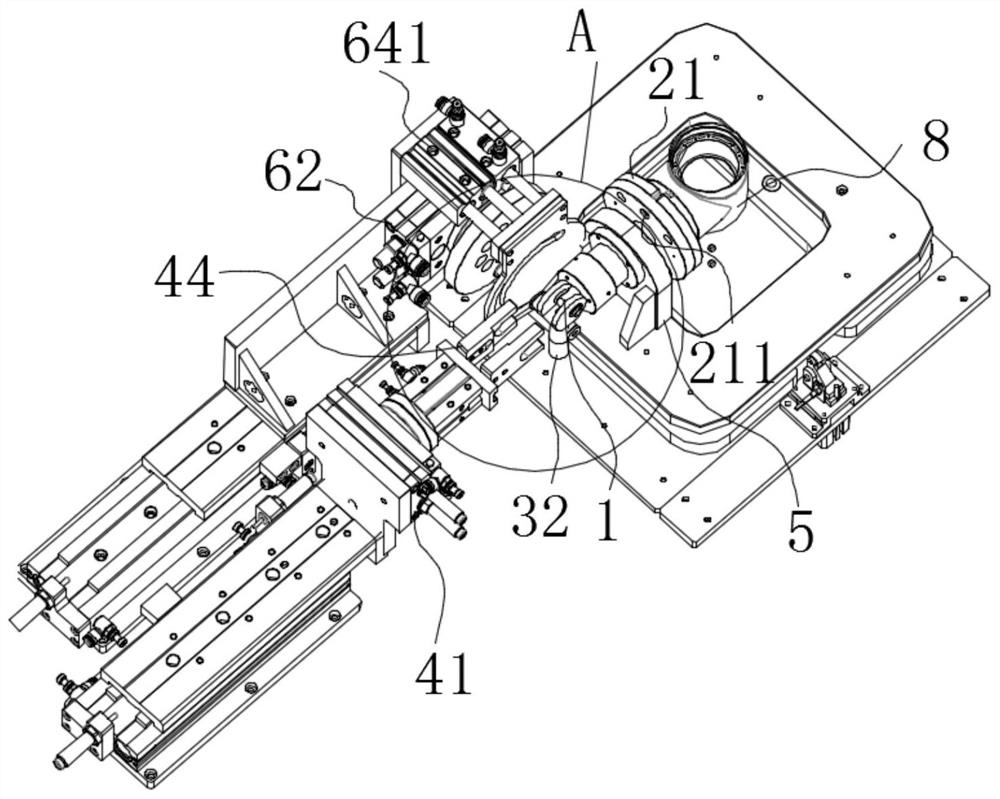

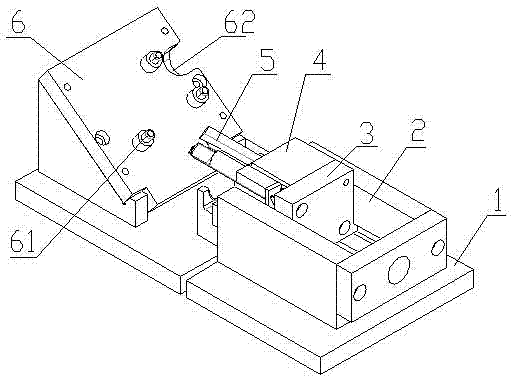

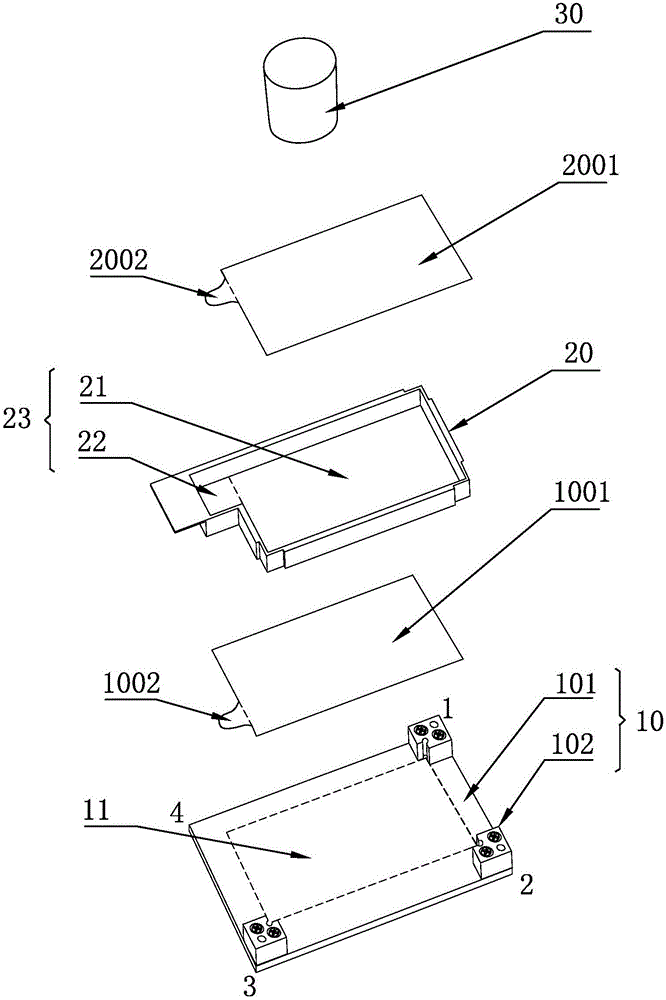

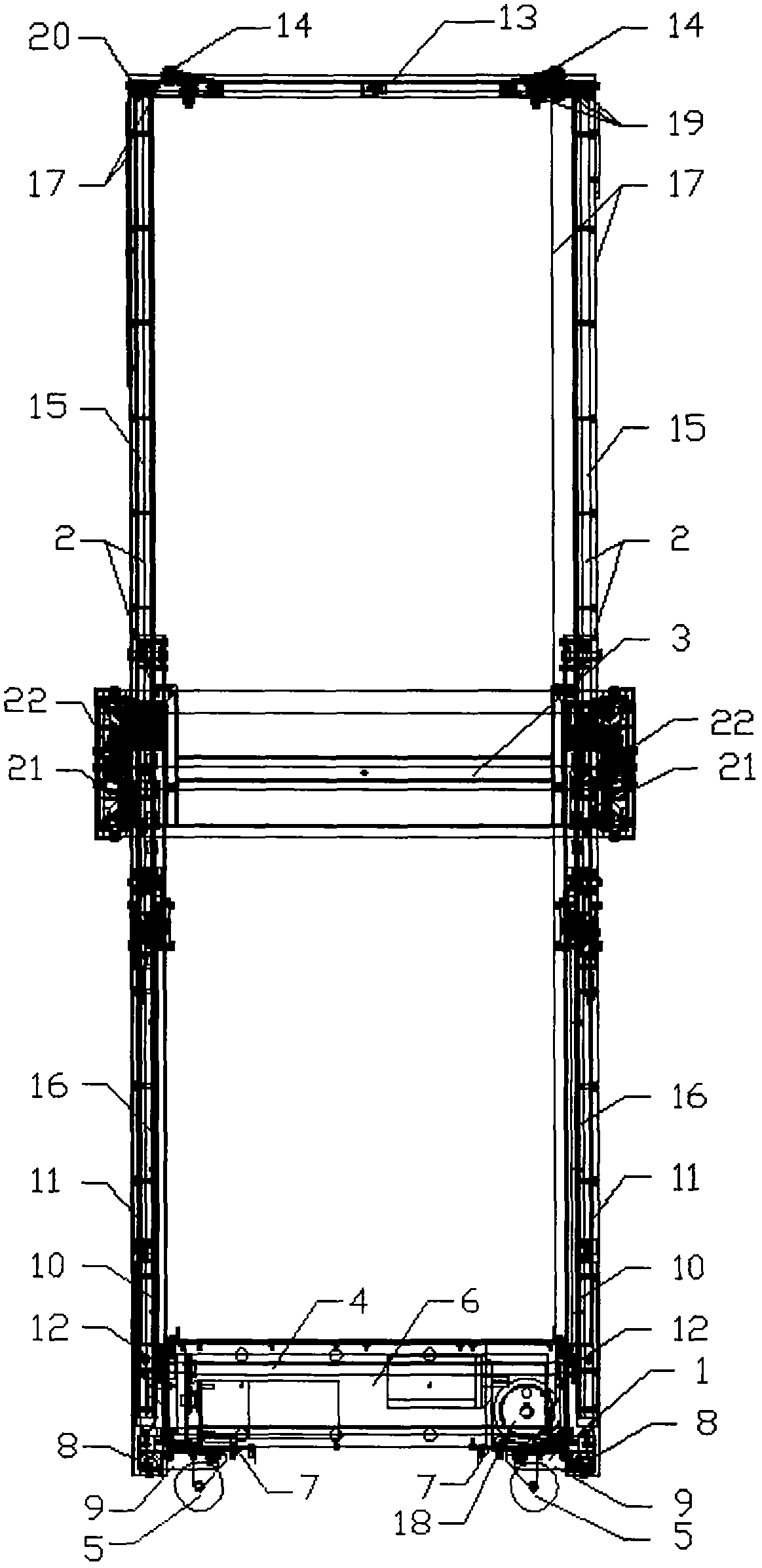

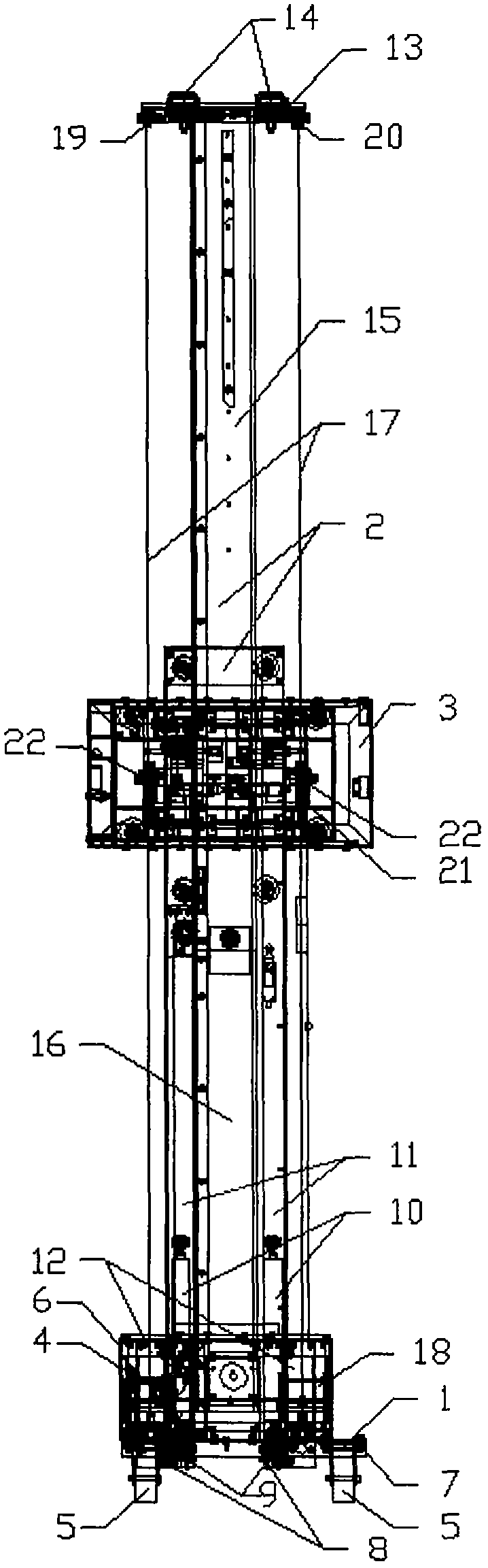

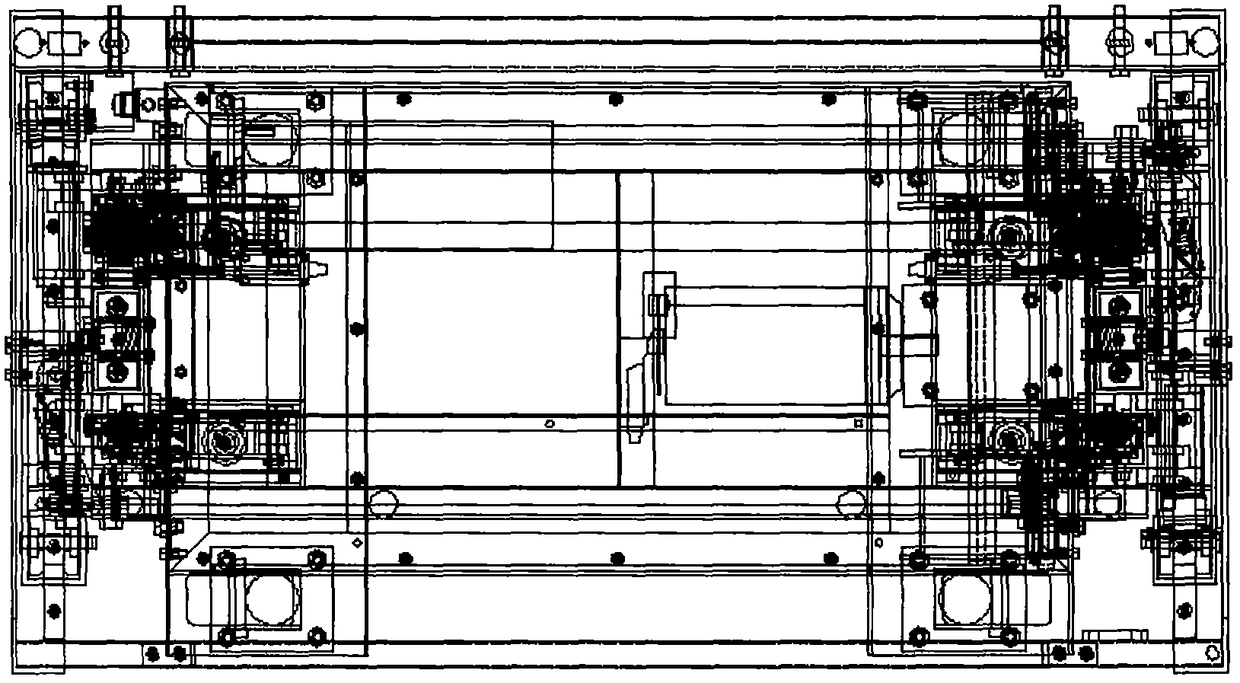

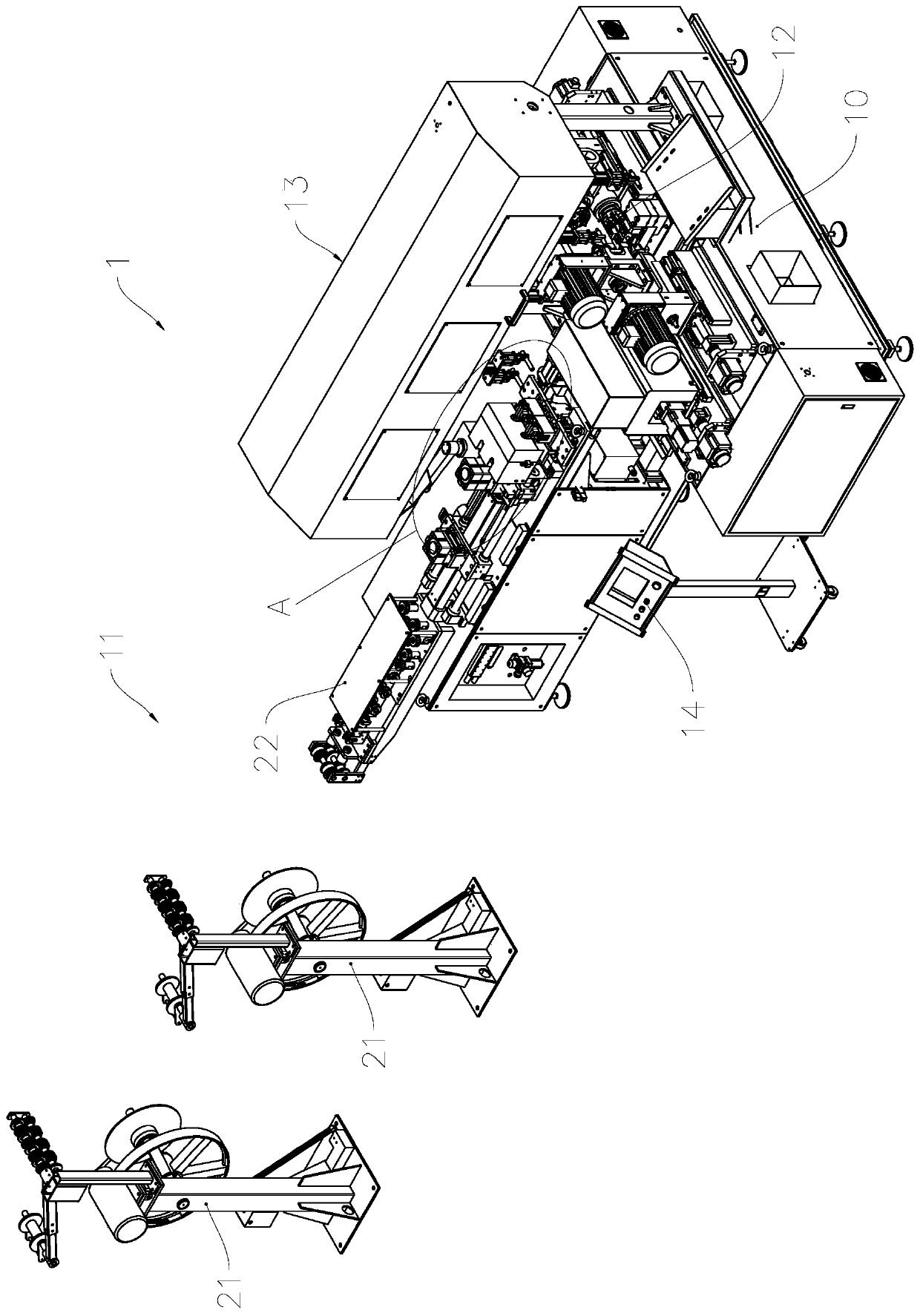

Bonding assembly equipment

InactiveCN112076947AReduce the number of targetingImprove bonding efficiencyLiquid surface applicatorsMaterial gluingEngineeringMechanical engineering

The invention belongs to the technical field of automatic assembly, and discloses bonding assembly equipment which is used for bonding assembly of a first workpiece and a second workpiece. The bondingassembly equipment comprises a jig, a first feeding device, a second feeding device, an assembling device and a glue dispensing device. The jig is configured to clamp the first workpiece. The first feeding device is configured to receive the jig input from the outside and can further transfer the jig to an assembling station and a discharging station. The second feeding device is configured to store and output the second workpiece. And the assembling device can be moved to the position among the second feeding device, the assembling station and the glue dispensing mechanism so as to pick up the second workpiece provided by the second feeding device, and after the glue dispensing device coats glue onto the bonding part of the second workpiece, the second workpiece can be bonded and assembled to the first workpiece located at the assembling station. The bonding assembly equipment provided by the invention can be used for efficiently carrying out bonding assembly operations.

Owner:BOZHON PRECISION IND TECH CO LTD

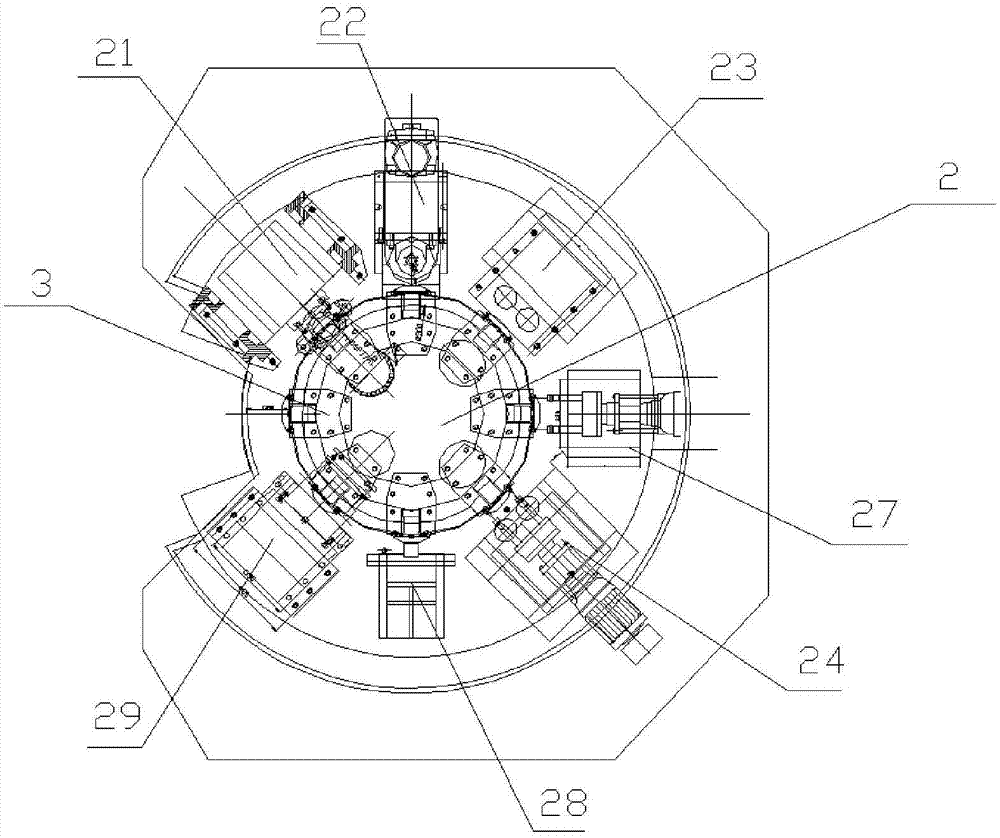

Rotating disc type multiple station drilling machine for processing crankshafts and processing method thereof

InactiveCN104759887AReduce liquidityAvoid damageCrankshaftsMeasurement/indication equipmentsPower apparatusCrankshaft

The invention relates to the technical field of drilling, in particular to a rotating disc type multiple station drilling machine for processing crankshafts. The rotating disc type multiple station drilling machine for processing the crankshafts comprises a rotating disc and a rotating disc power device used to drive the rotating disc to rotate, wherein multiple work stations which can fix work pieces are arranged on the rotating disc, a first drilling device used to form axial holes in the work pieces, a milling device used to mill the total length of the work pieces, a third drilling device used to process oblique oil holes in the work pieces and a forth drilling device used to process axial oil holes in the work pieces are sequentially arranged around the rotating disc and along the rotation direction of the rotating disc, and the first drilling device, the milling device, the third drilling device and the forth drilling device can perform corresponding, multilevel and progressive circulating processing on each work piece on each work station during the rotation process of a rotating platform. The rotating disc type multiple station drilling machine for processing the crankshafts is simple in structure and strong in practicality.

Owner:玉环制冷设备配件有限公司

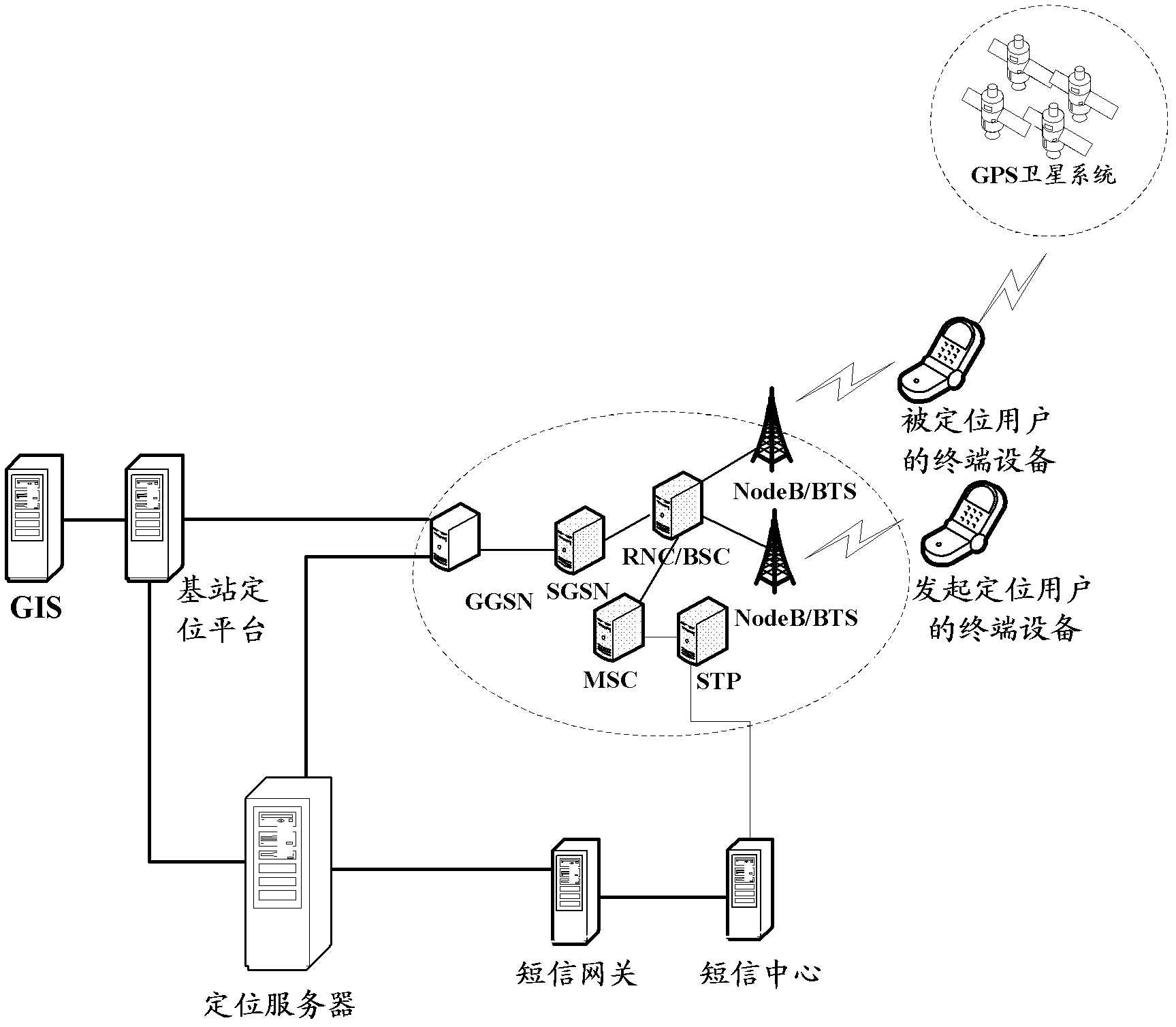

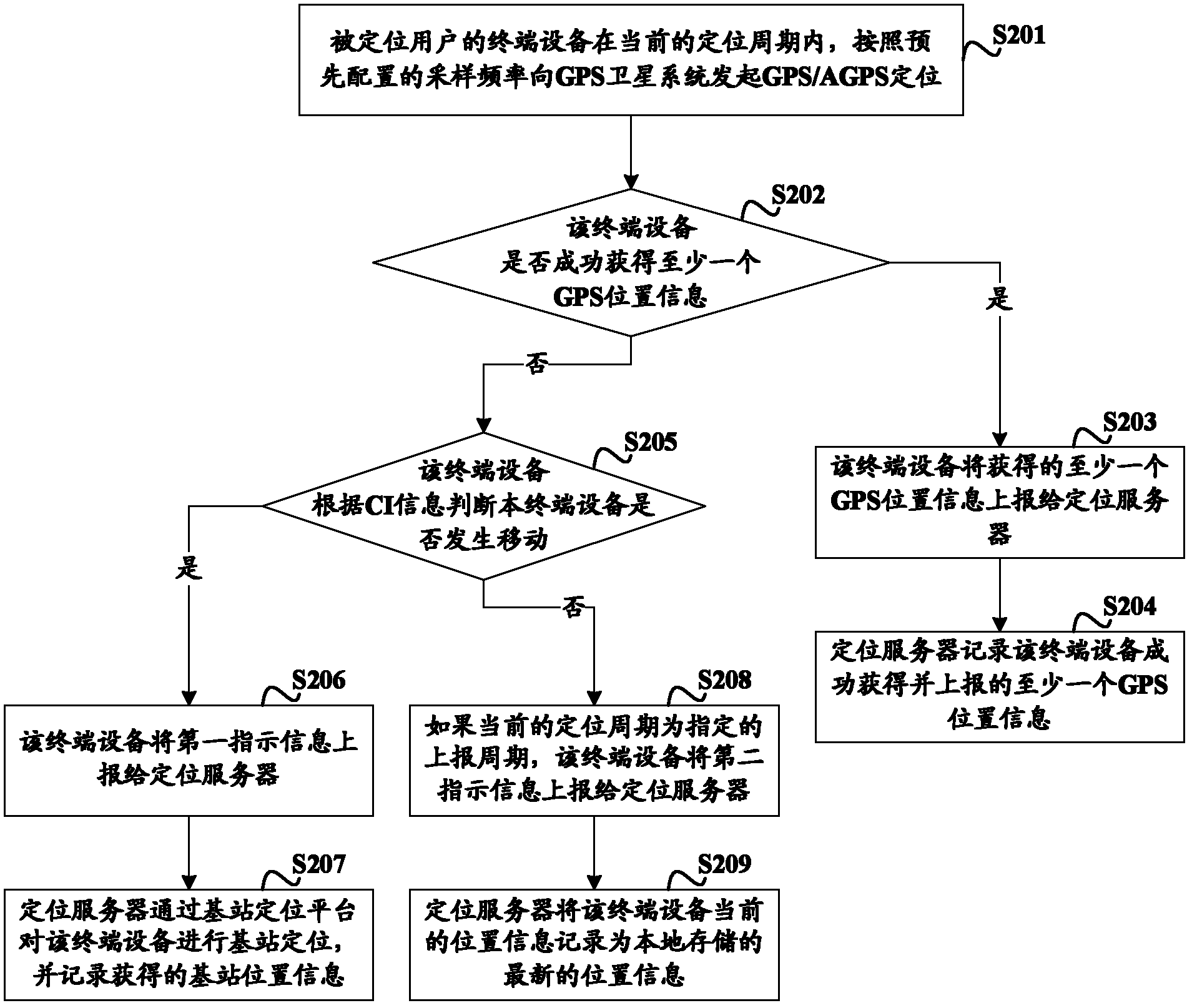

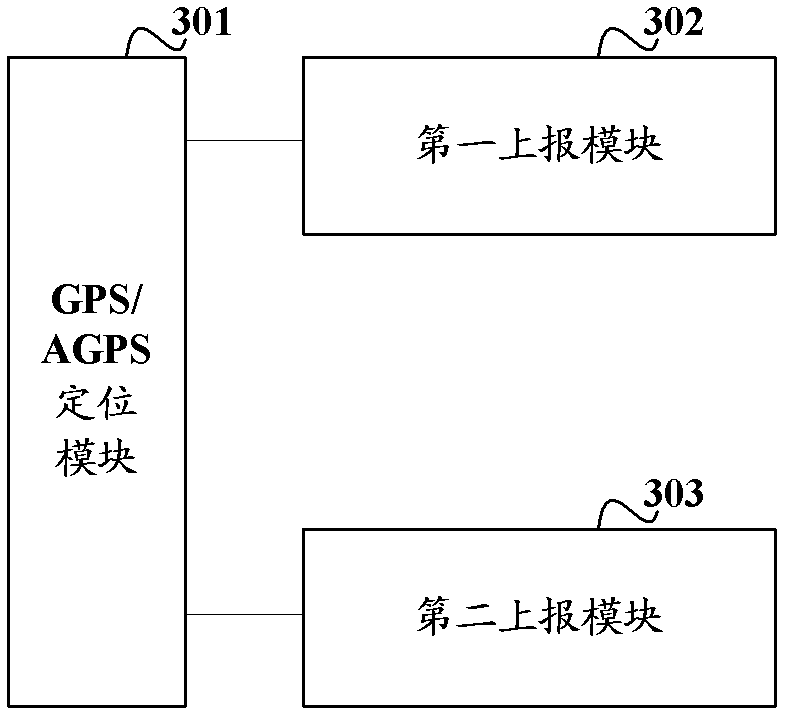

Locating methods, locating system and relevant equipment

ActiveCN103037506AShorten the timeEasy accessSatellite radio beaconingWireless communicationTerminal equipmentEngineering

The invention discloses locating methods, a locating system and relevant equipment. The using frequency of terminal equipment and a base station locating platform of a located user is reduced in a locating process, and locating speed and locating accuracy are improved. One of the locating methods comprises that the terminal equipment carries out global position system (GPS) / assisted global position system (AGPS) locating according to sampling frequency in each locating cycle; if at least one piece of GPS position information is acquired successfully, the GPS position information is reported to a locating server; and if the GPS position information is not acquired and movement is judged according to cellular identify (CI) information, first indicating information is reported. Another locating method comprises that the terminal equipment judges whether moving happens according to the CI information in each locating cycle; when a judged result is that moving happens, GPS / AGPS locating is carried out, if the GPS position information is successfully acquired, the GPS position information is reported to the locating server, and if the GPS position information is not acquired, the first indicating information is reported.

Owner:CHINA MOBILE COMM GRP CO LTD

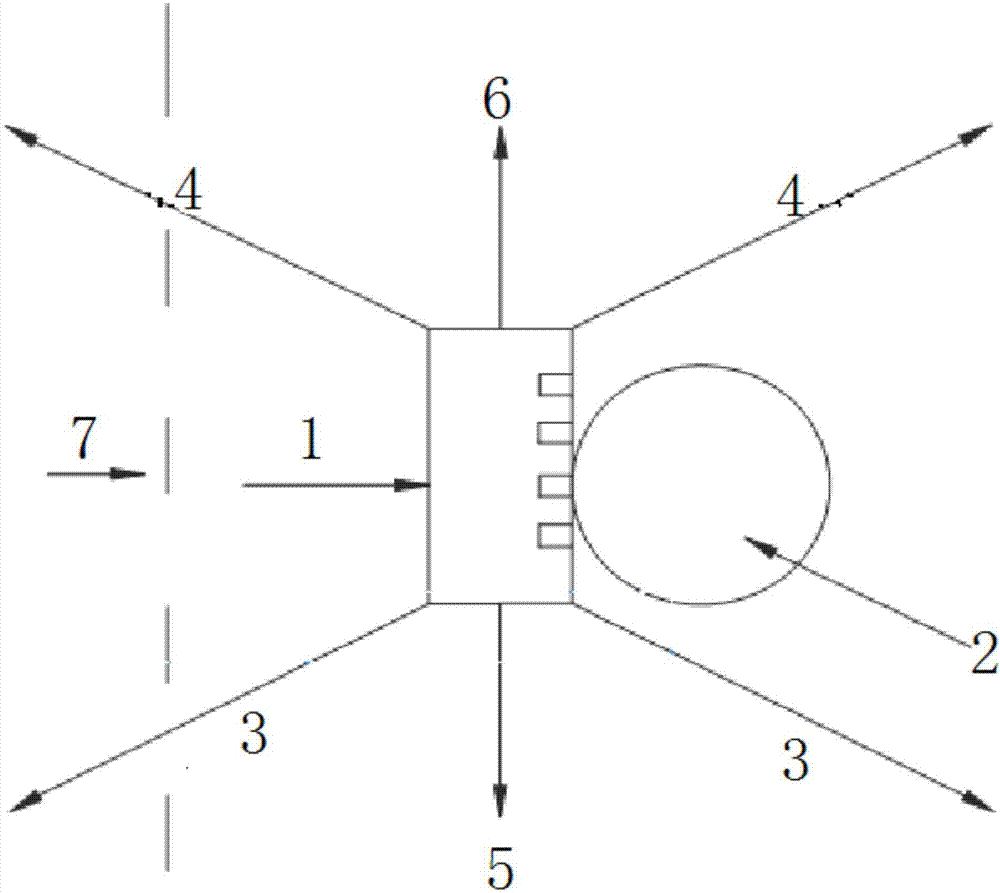

Underwater blasting construction method for deep-water inclined bare rock foundation

ActiveCN107356168AMeet grab size requirementsLower the volumeBlastingGeomorphologyMeasuring instrument

The invention discloses an underwater blasting construction method for a deep-water inclined bare rock foundation, and relates to the field of bridge deep-water foundation construction. The method comprises the following steps that before formal blasting, a depth measuring instrument is adopted and RTK-GPS is arranged to conduct plane and elevation three-dimensional scanning-measuring on an original river bed in a blasting area, and a reasonable blasting design is made according to foundation geological survey and three-dimensional scanning-measuring data; underwater blasting is constructed through a peripheral slope-making method, blasting is conducted in sequence from the low position to the high position of the river bed, vertical layering is avoided, drilling is conducted to the designed hole depth (including the over-drilling depth 1-2.0 m) each time, blasting is conducted once a day, and finally slag is removed at a time; and after a drilling-blasting ship is positioned through a six-cable positioning method, a casing is put downwards, underwater drilling is conducted through a down-hole drilling machine, a hole is filled with a processed explosive roll and blocked after the hole is cleaned, and blasting operation is carried out after blasting network connection. The method has the characteristics of fast positioning, low cost, less construction interference, rapid construction progress and the like, and is suitable for underwater blasting construction of the deep-water inclined bare rock foundation.

Owner:THE SECOND CONSTR OF CTCE GROUP +1

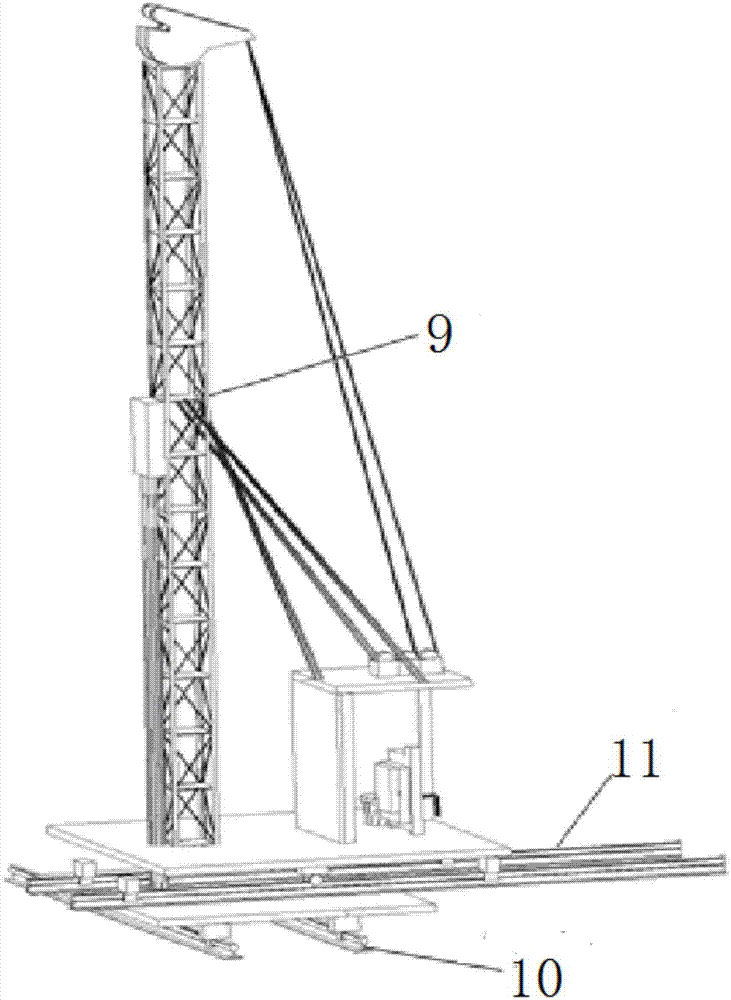

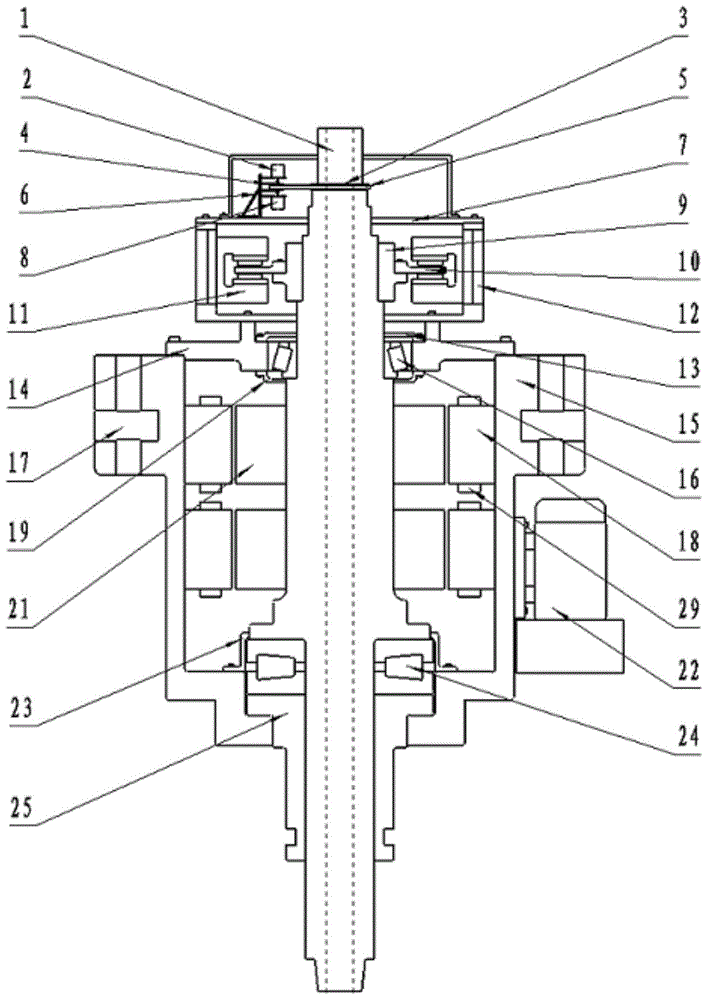

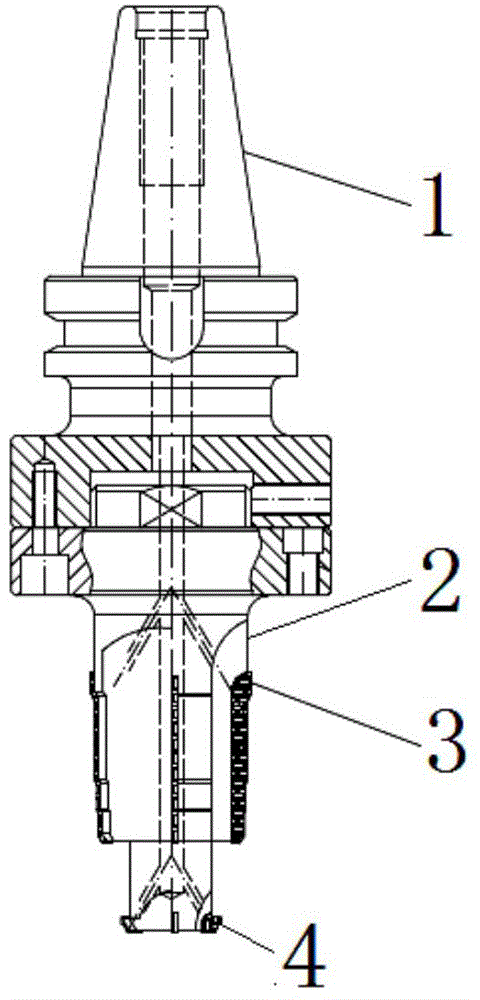

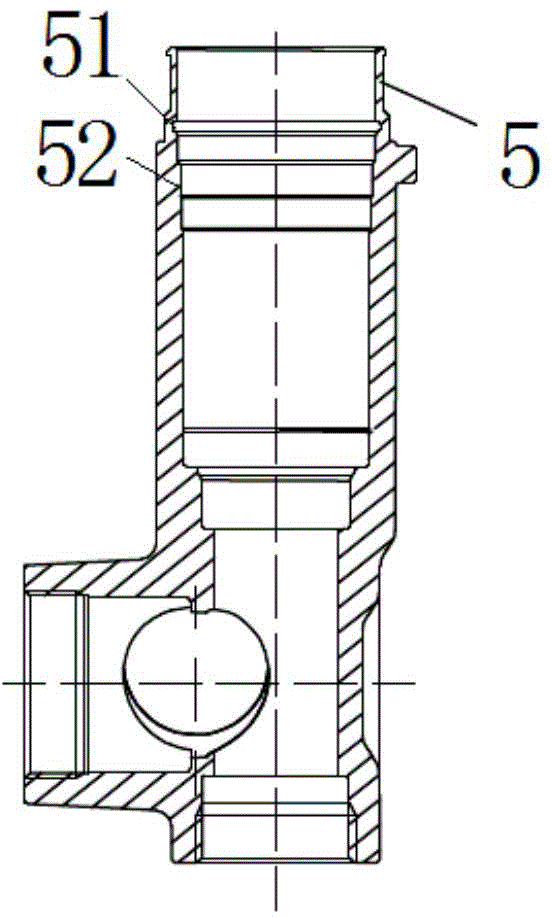

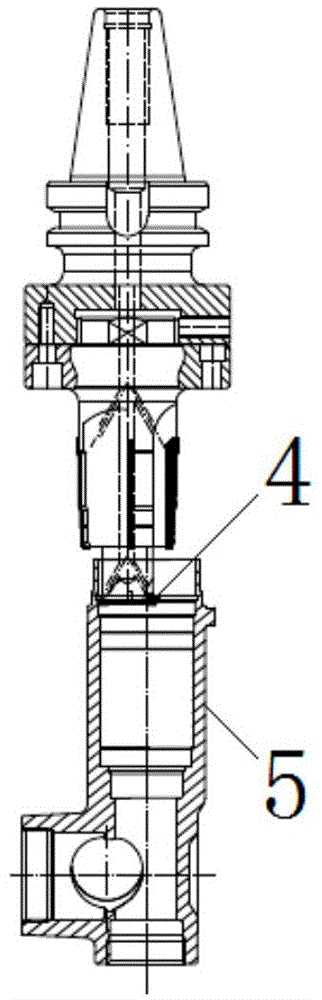

Low-speed motor direct driving mechanism used for top part driving well drilling device

InactiveCN103607068AEasy to controlPrecise positioningBorehole drivesMechanical energy handlingCold airLow speed

The invention discloses a low-speed motor direct driving mechanism used for a top part driving well drilling device. The low-speed motor direct driving mechanism comprises a hollow main shaft, a motor and a control mechanism. The motor comprises a motor upper end cover, a motor shell, a rotation head internal sleeve and a stator and rotor mechanism. The motor upper end cover, the motor shell and the rotation head internal sleeve are all sleeved on the external side of the hollow main shaft. The stator and rotor mechanism is installed in a sealing space formed by the motor upper end cover, the motor shell and the hollow main shaft. The sealing space is communicated with a cold air mechanism. The stator and rotor mechanism has a protruding-pole structure and is designed in a two-segment type. The control mechanism comprises a speed monitoring device and a brake device which is arranged on the hollow main shaft. According to the low-speed motor direct driving mechanism used for the top part driving well drilling device, the hollow main shaft is utilized to directly drive a drilling rod without an intermediate speed reducing mechanism so that structure of the top part driving well drilling device is greatly simplified, and a large amount of auxiliary components are reduced. Meanwhile, the well drilling process becomes smoother by structural design of the motor.

Owner:SOUTHEAST UNIV

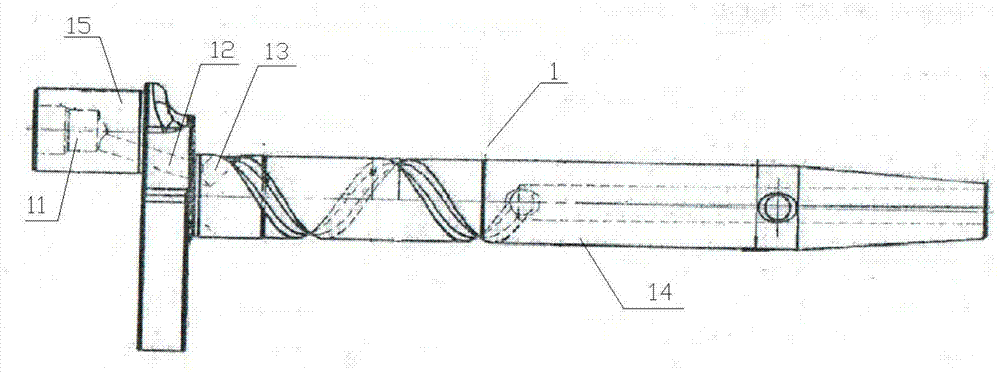

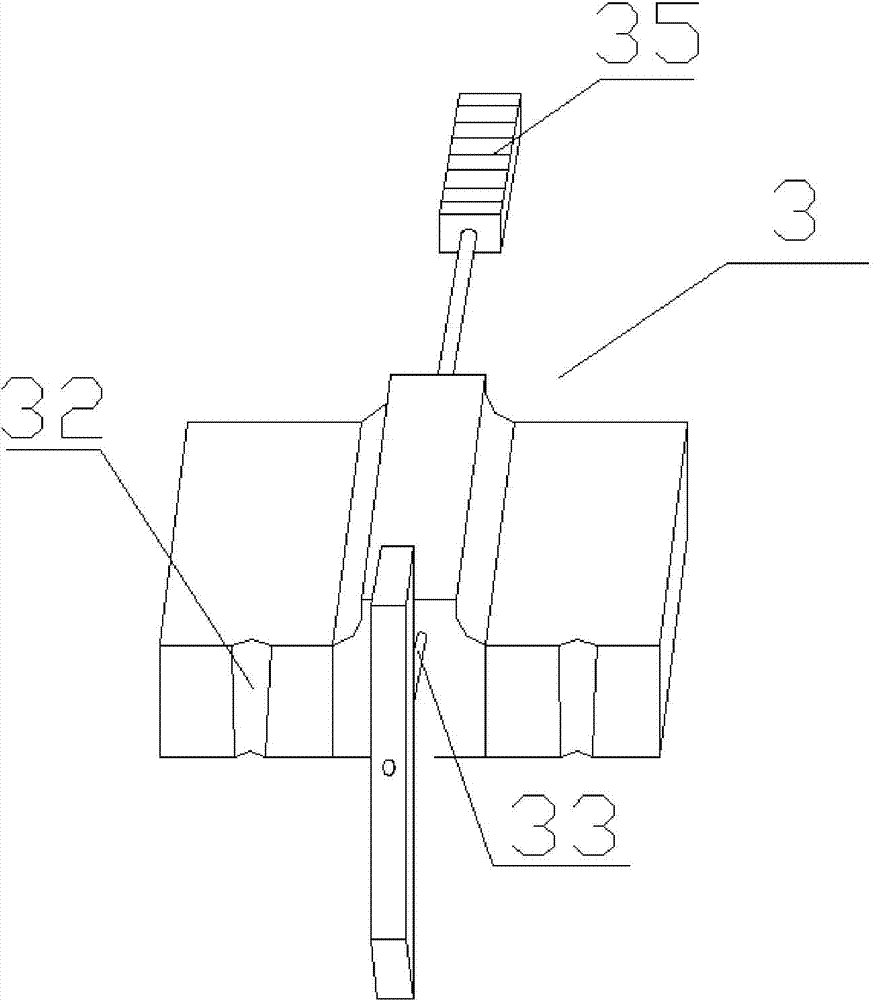

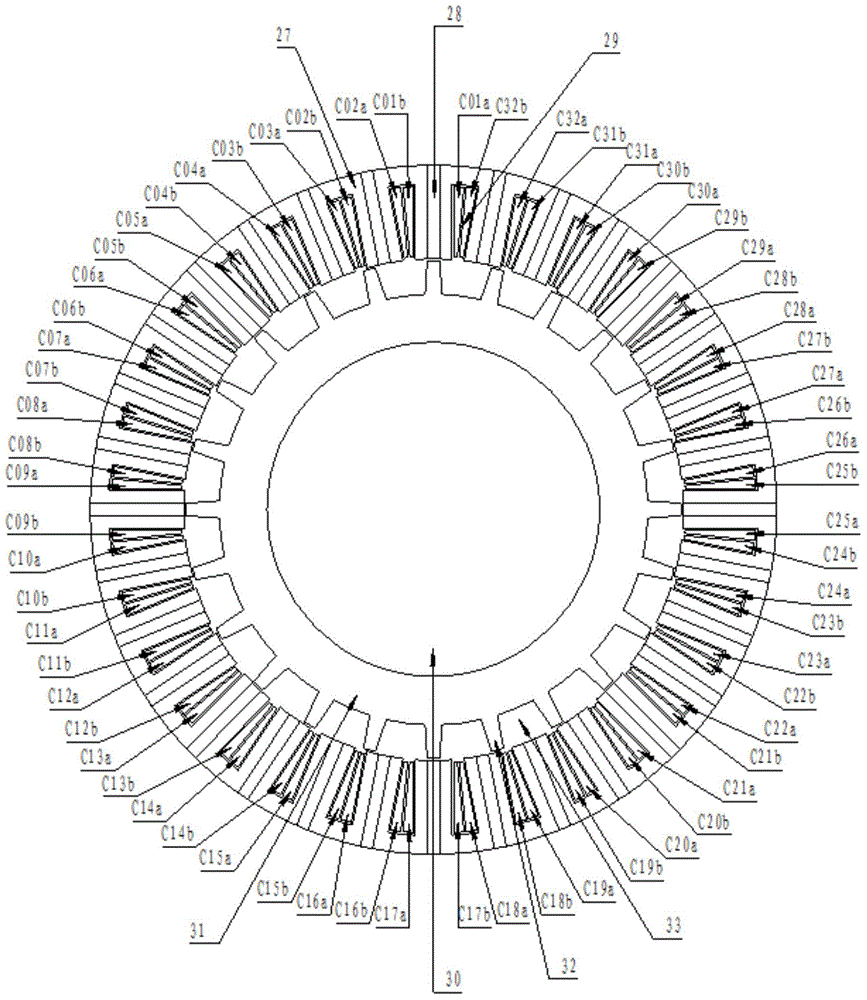

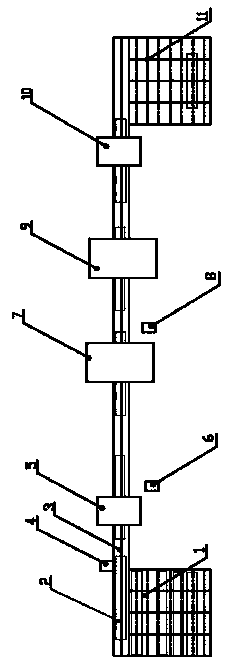

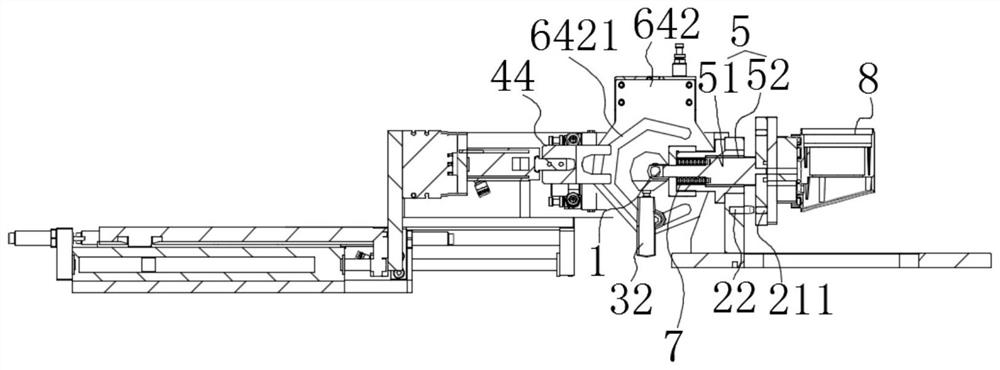

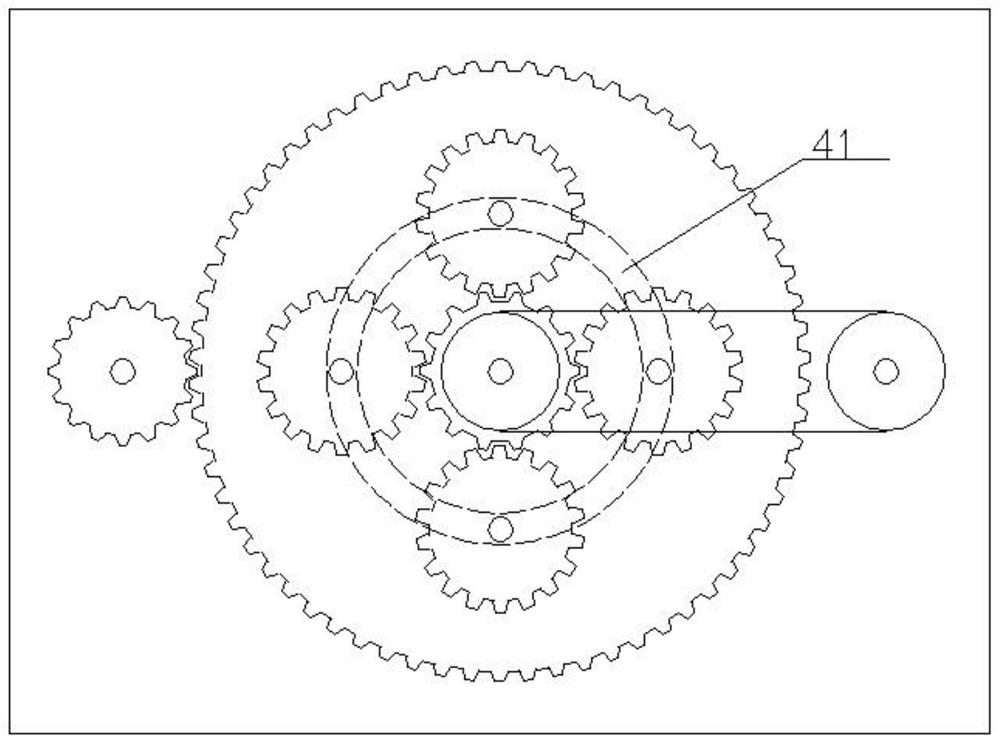

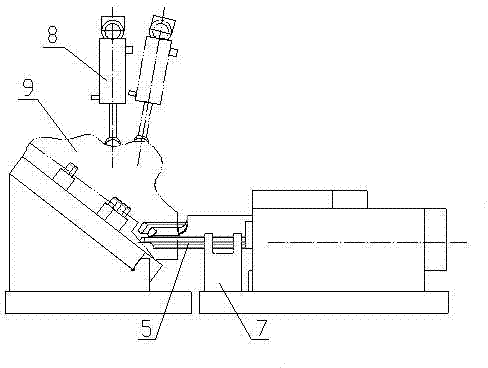

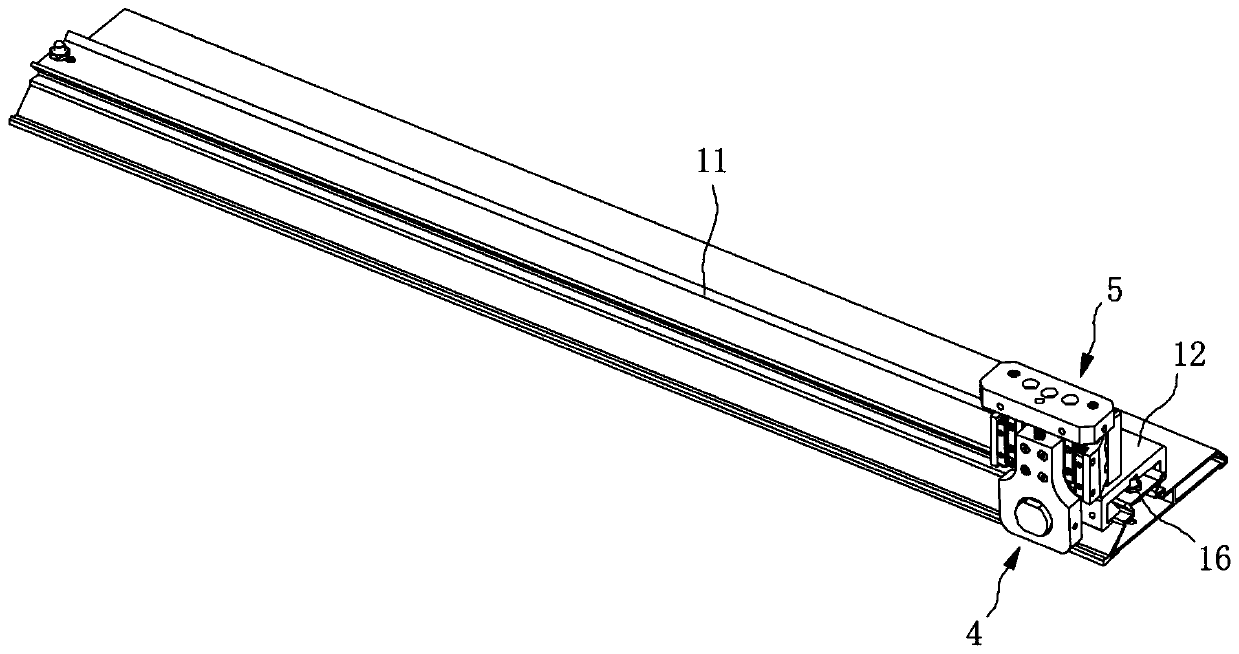

Piston workblank casting head continuous automatic sawing machine tool and continuous automatic sawing method

ActiveCN104551217AEnables continuous sawingAvoid displacementMetal sawing devicesEngineeringMachine tool

The invention discloses a piston workblank casting head continuous automatic sawing machine tool which comprises a machine tool body. A Z-directional running device is arranged on the machine tool body. The Z-directional running device is movably provided with an X-directional running device which is movably provided with a cutting motor pulling plate. The cutting motor pulling plate is provided with a cutting motor. A cutting tool bit is arranged on the main shaft of the cutting motor. The piston workblank casting head continuous automatic sawing machine tool further comprises a four-station rotating table arranged on the machine tool body. Four location pins are distributed uniformly on the table facet of the four-station rotating table along the circumferential direction. Two sets of clamps are arranged above the machine tool in a matching manner. According to the piston workblank casting head continuous automatic sawing machine tool, the continuous cutting of the piston workblank top riser and the side pouring gate can be achieved; the sawing position is accurate; the degree of automation is high; one person can manage multiple machines, thereby improving the working efficiency.

Owner:ANHUI WHITE RABBIT POWER

Machining process for longitudinal beam of heavy truck

The invention belongs to the field of manufacturing of automobiles, and particularly discloses a machining process for a longitudinal beam of a heavy truck. The machining process for the longitudinal beam of the heavy truck is characterized by comprising the following steps: marking; punching; cutting; shot blasting; bending. The machining process has high universality and high efficiency; coding of an intelligent coding machine, numerical control punching, cutting of a robot plasma cutter and shot blasting are all controlled through programs, so that the specification and the length of a section of the longitudinal beam in a certain range, the size and the position of the hole and the machining of the contour of the longitudinal beam can be realized. Trail production and large-scale and multi-species continuous production can be realized. The precision is high; the positioning is consistent; the positioning at all the punching, cutting and bending processes is realized by the front end of the longitudinal beam; the machining is controlled through the program; a three-dimensional numerical control punching machine is adopted as the punching machine, and wing surface holes and ventral surface holes are finished in sequence to reduce the positioning frequency; the shot blasting is performed to remove scales and rust before bending so as to eliminate the influence of the scales on bending.

Owner:SINO TRUK JINAN POWER

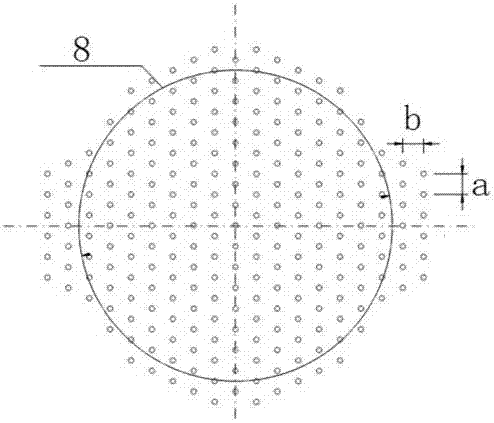

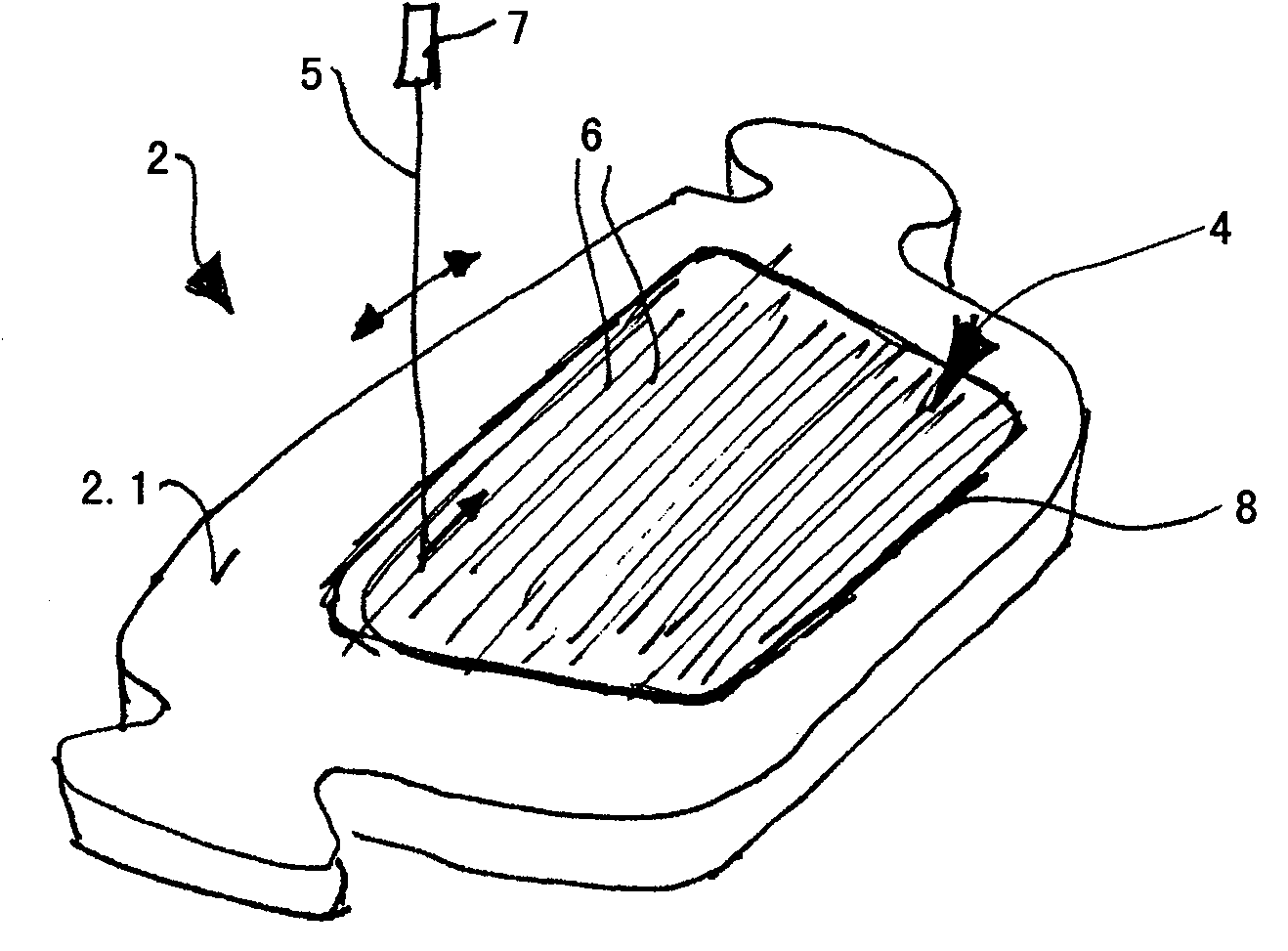

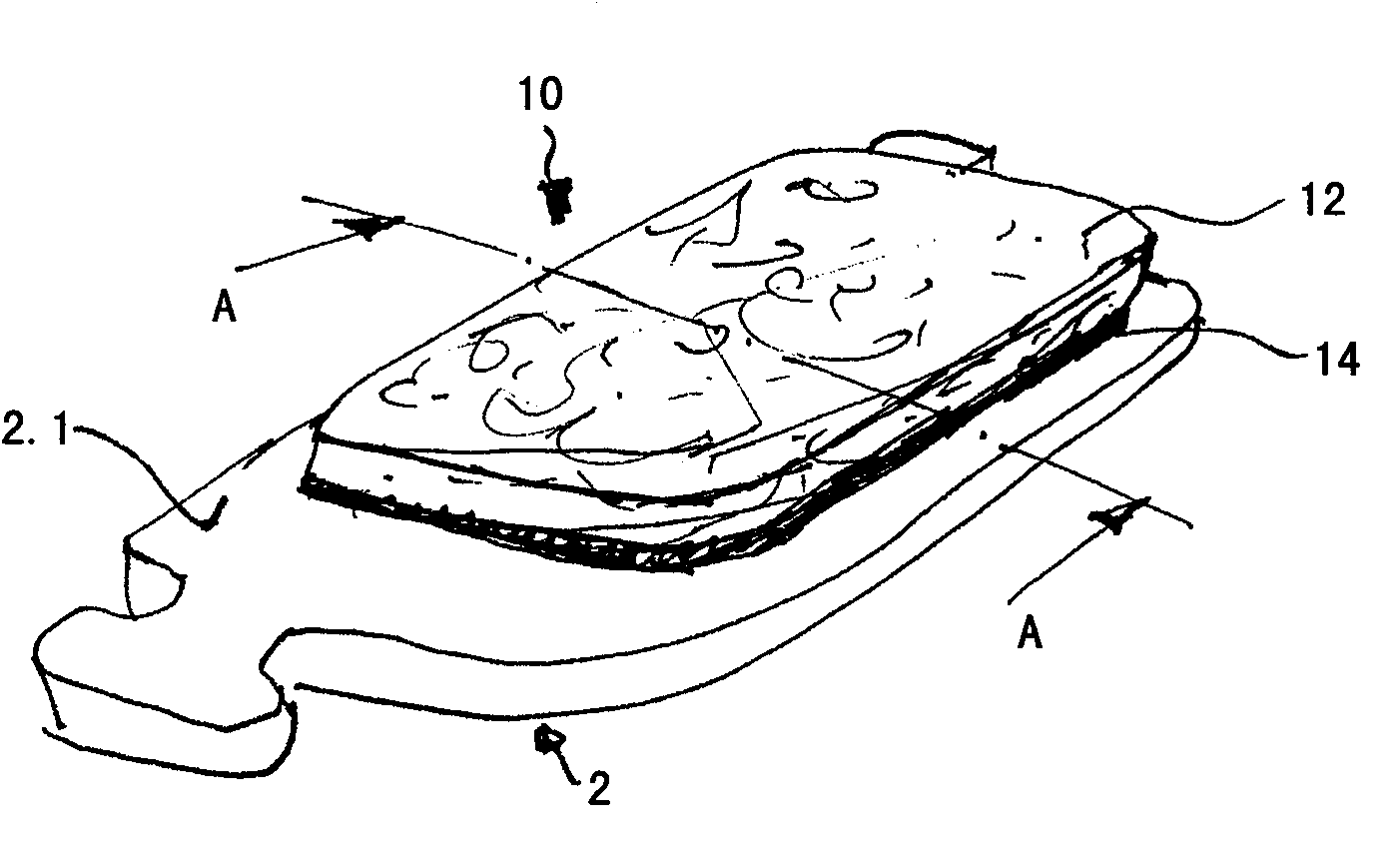

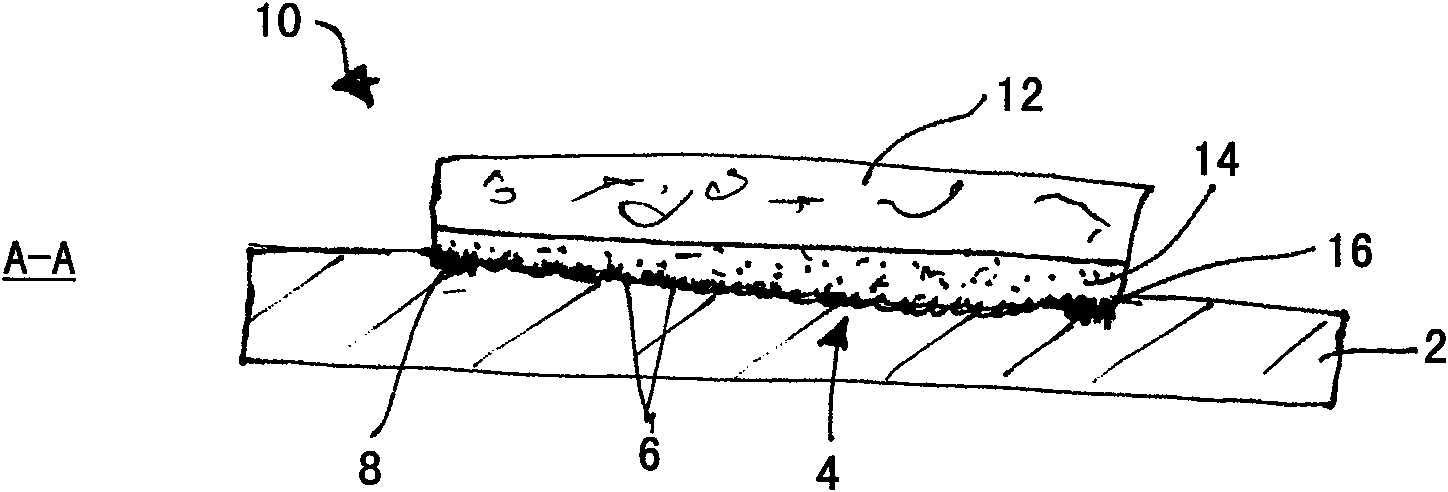

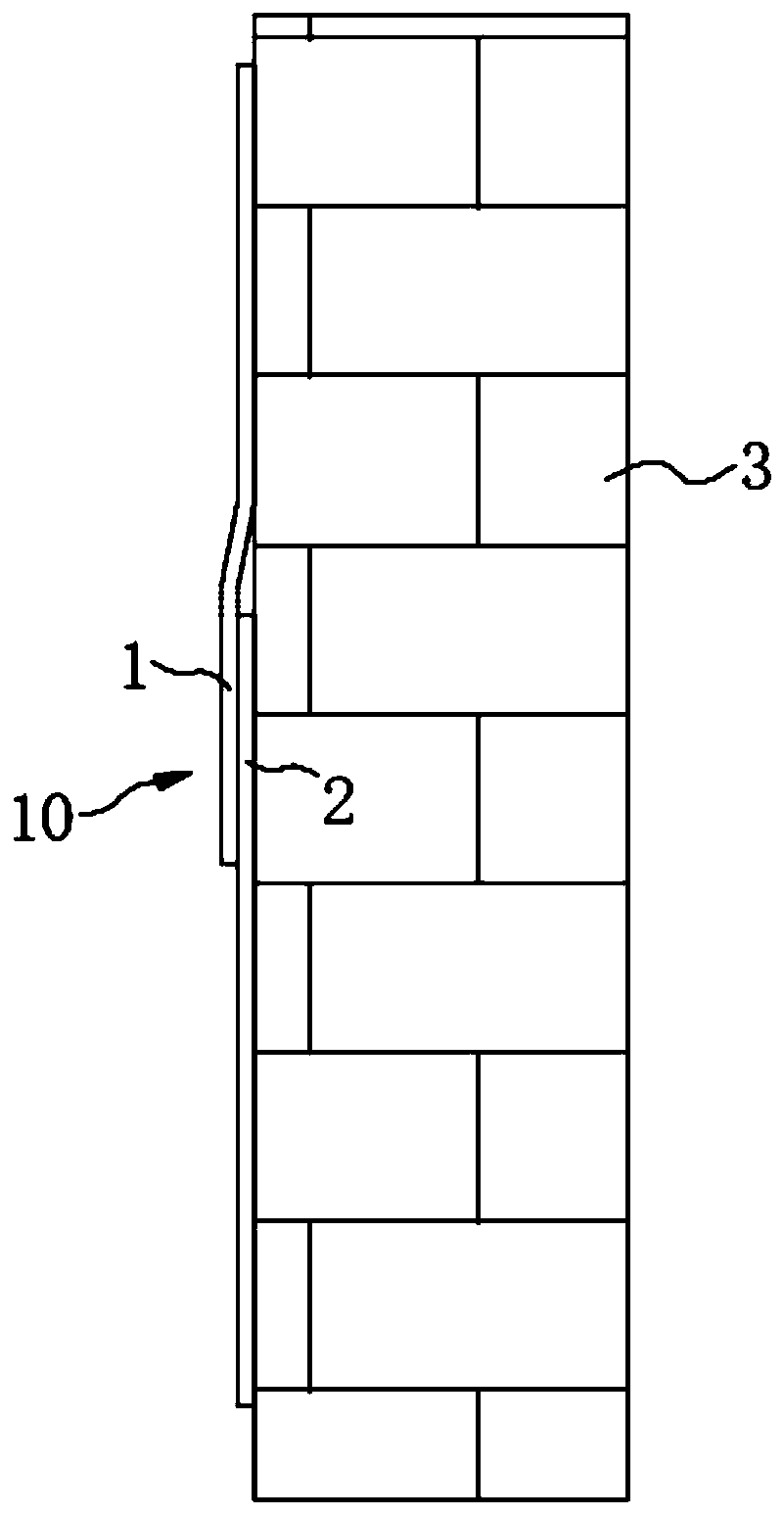

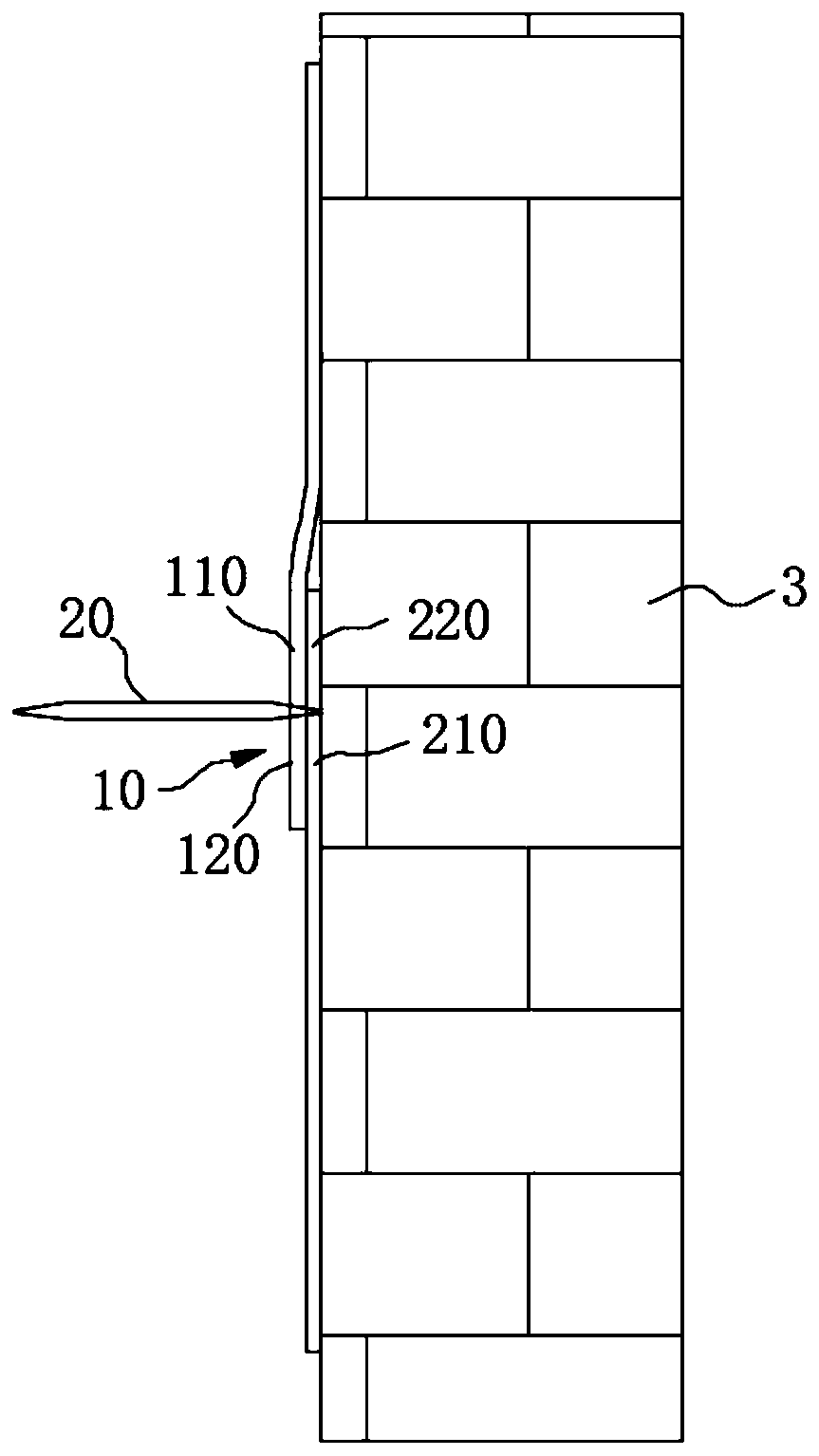

Method for processing a lining holder

ActiveCN101806329AFirmly connectedGood adhesionBraking elementsFriction liningHigh energyEngineering

The invention relates to a method for processing a lining holder (2) disposed to be used for making a brake block (10), the brake block has a friction liner (12) to be arranged on the lining holder (2), the method involves performing surface treatment of a processing area (4) of a lining support surface (2.1) by introducing a structure into the processing area by high-energy radiation. For the friction liner (12) is fixed on the lining holder (2) better, the structure differing from the rest of the processing area is processed in an edge (8) of the processing area (4).

Owner:TMD FRICTION SERVICES

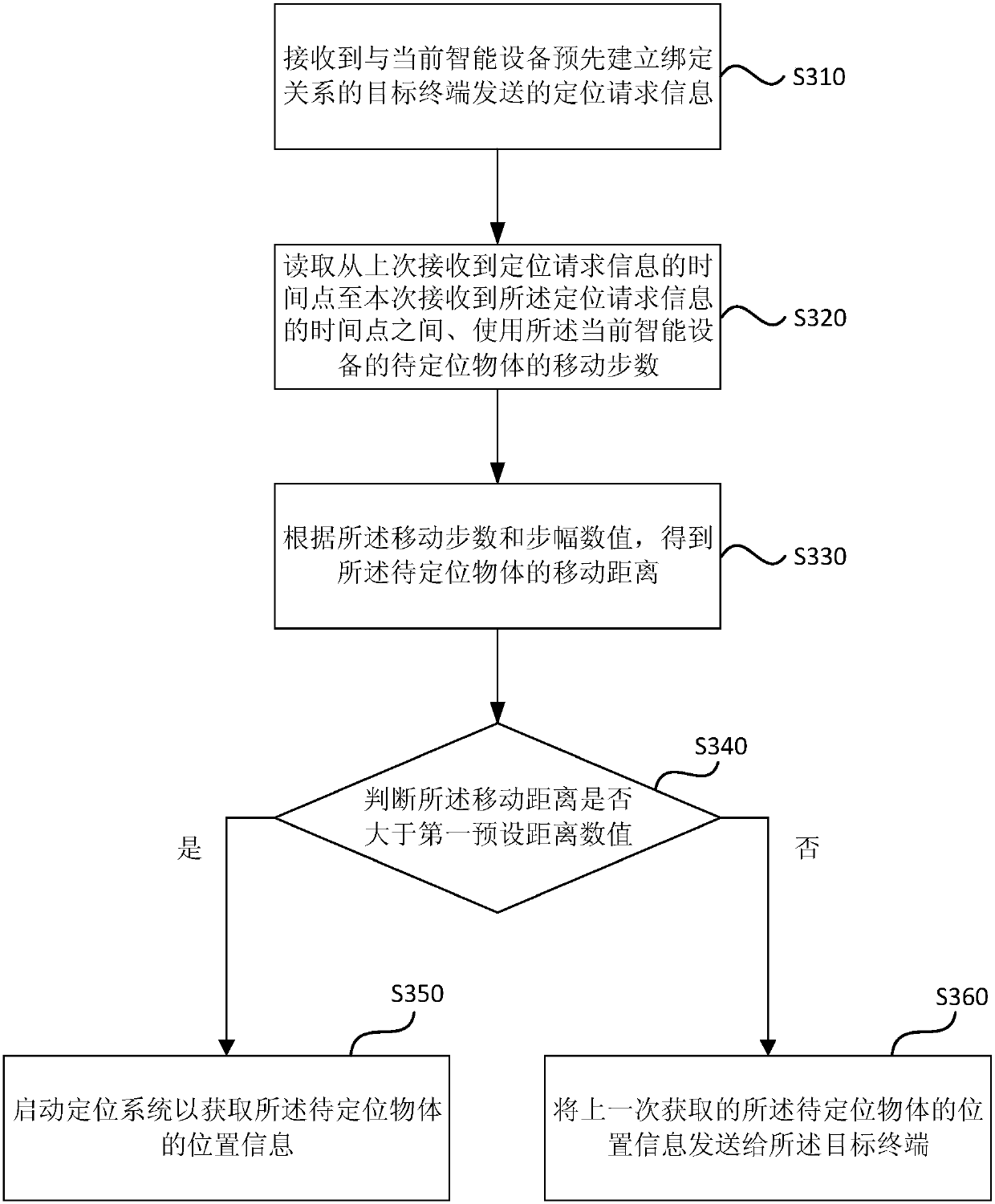

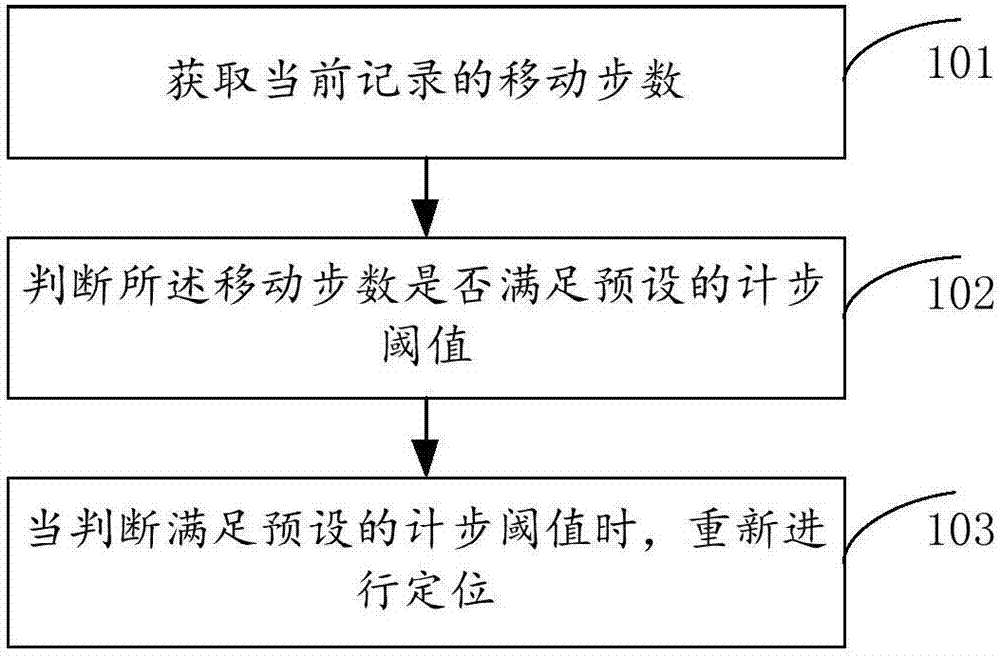

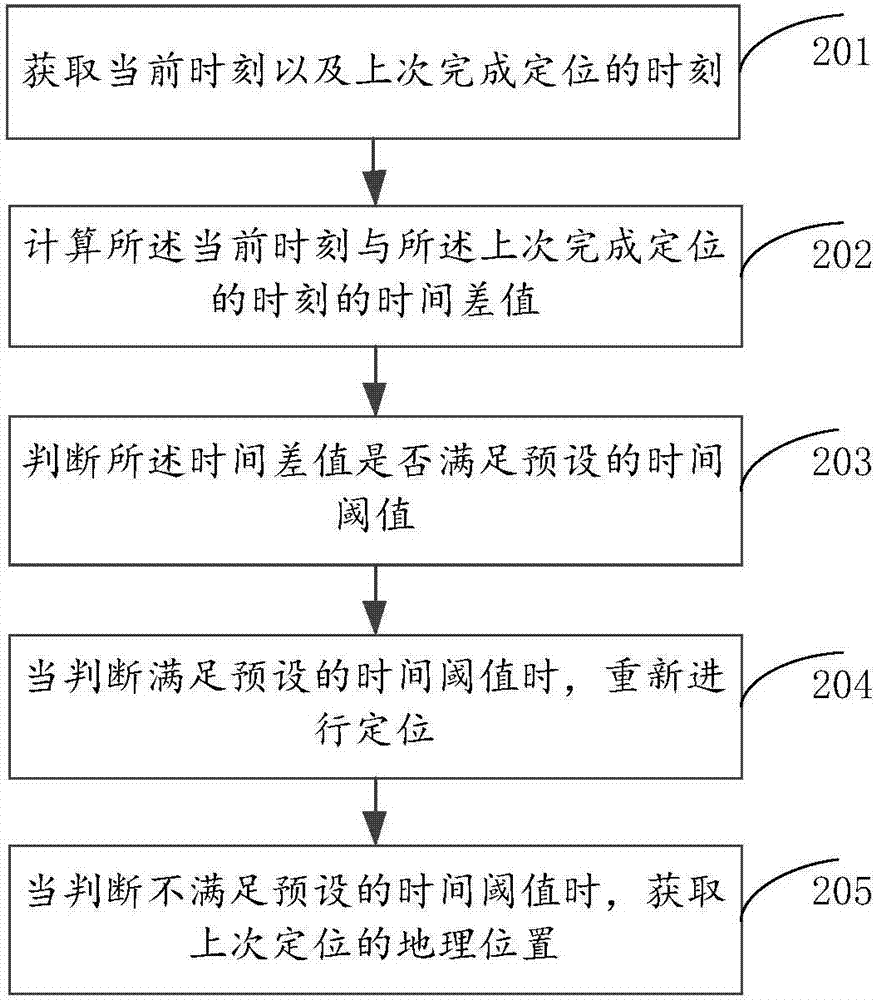

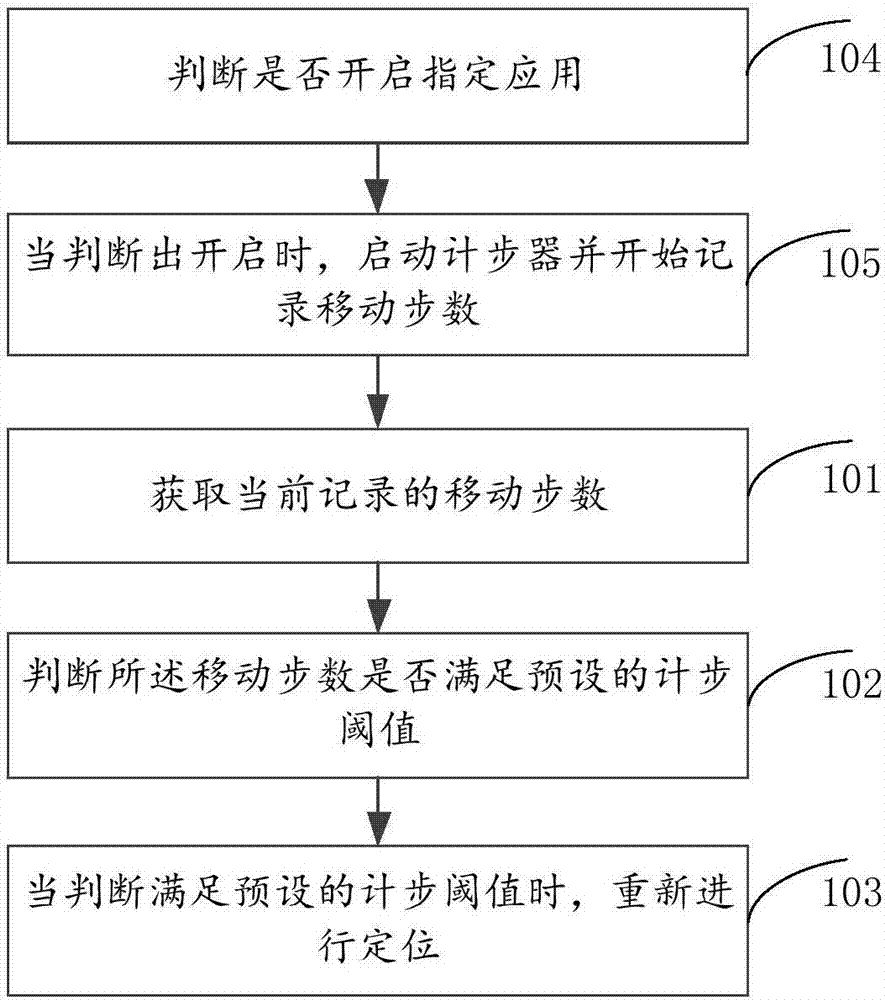

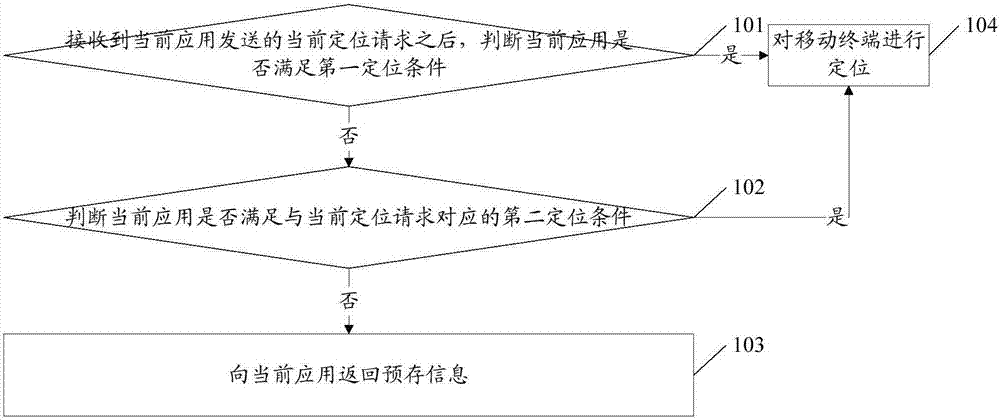

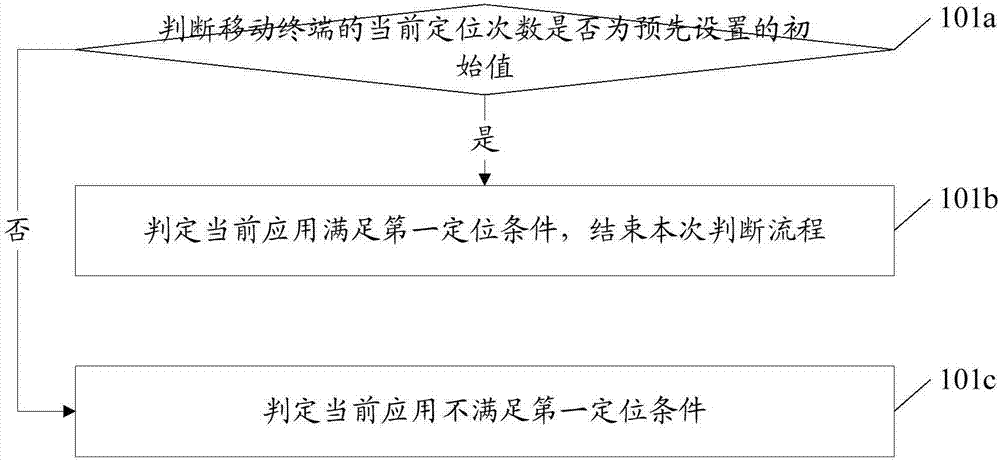

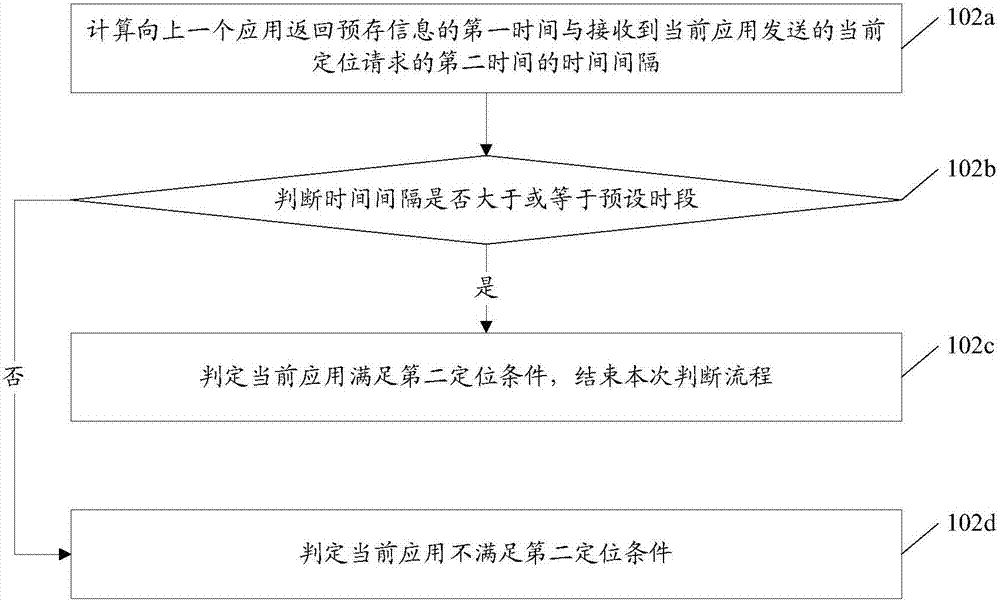

Positioning method and apparatus

InactiveCN107231678AReduce the number of targetingReduce power consumptionPower managementSubstation equipmentStep numberComputer terminal

The embodiment of the invention provides a positioning method and apparatus, and relates to the technical field of communication. Whether re-positioning is required can be determined by judging whether the position of a mobile terminal changes according to a recorded moving step number so as to reduce the positioning times of the mobile terminal within a short time, then the power consumption of the mobile terminal is reduced, and the electric energy of the mobile terminal is saved. The method comprises the following steps: firstly, obtaining the currently recorded moving step number; then, judging whether the moving step number satisfies a preset step counting threshold; and if the moving step number satisfies the preset step counting threshold, performing positioning again. The technical scheme provided by the embodiment of the invention is suitable for the positioning process of the mobile terminal.

Owner:SHENZHEN TINNO WIRELESS TECH +1

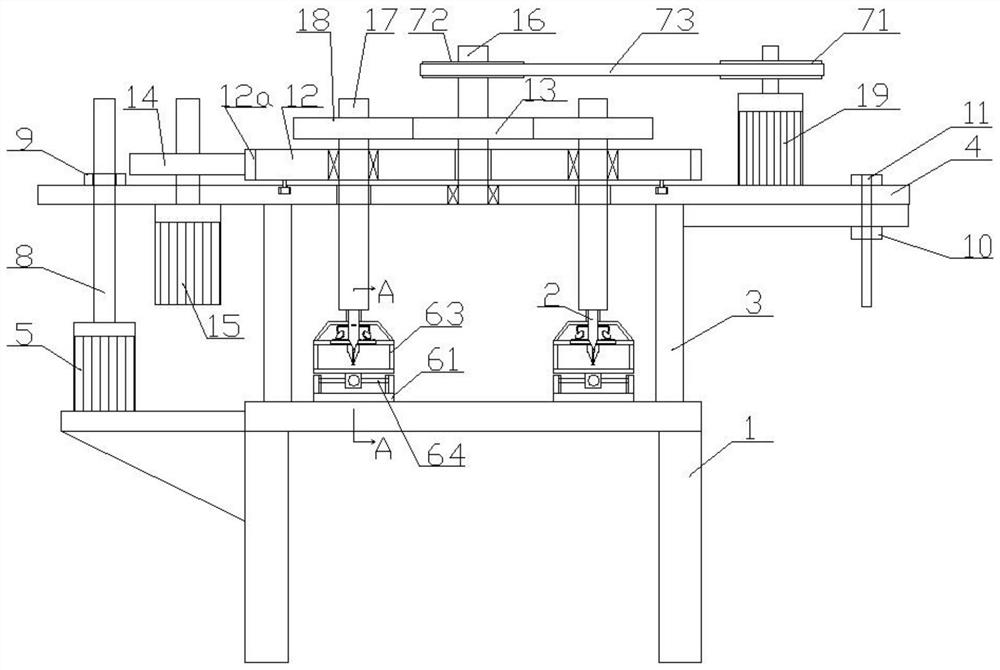

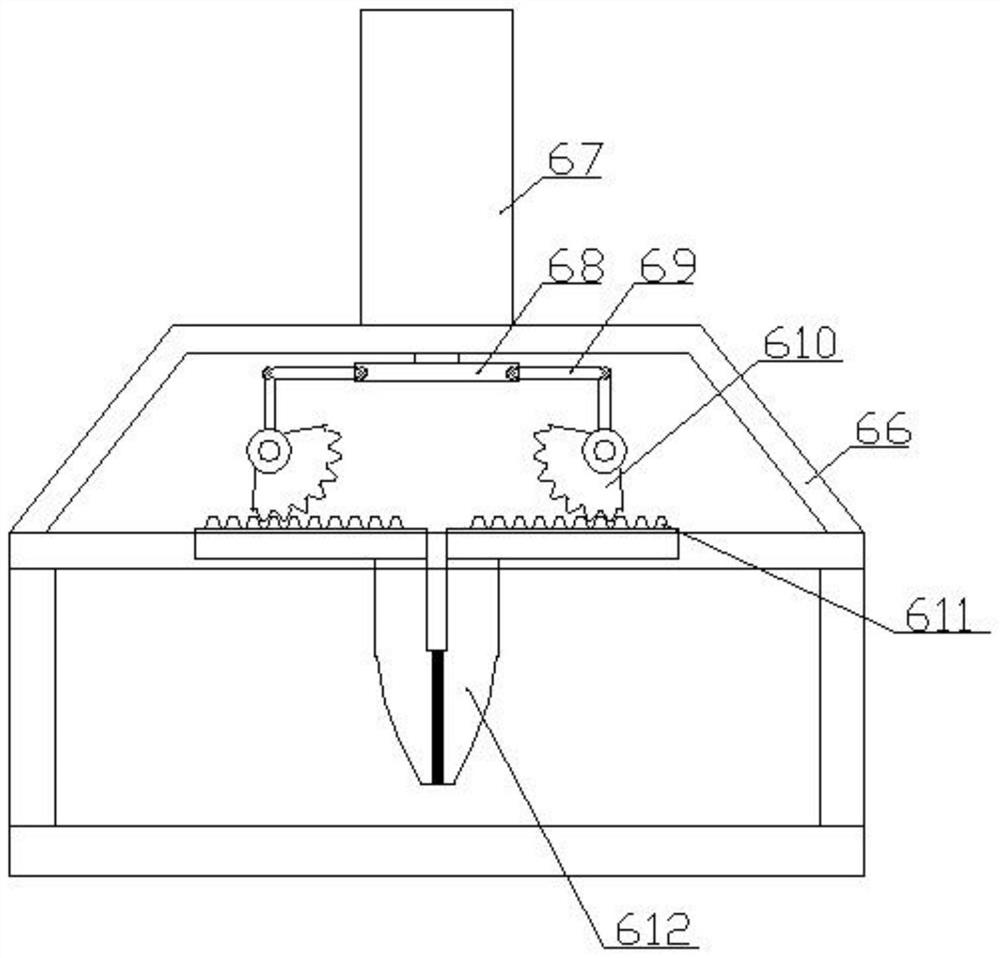

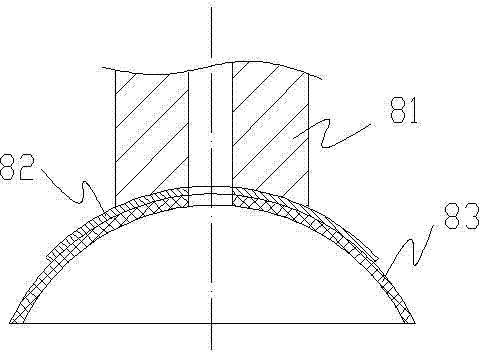

Automatic cementing machine for ultrahigh-voltage high-strength disc suspension porcelain insulator

The invention discloses an ultra-high-voltage, high-strength, disk-shaped suspension type porcelain insulator automatic gluing machine, which includes a workbench, on which an iron cap porcelain base is arranged, and a vibrating motor is arranged under the iron cap porcelain base. On the top of the workbench, there are glue mounting mechanism, steel foot funnel and steel foot pressing mechanism through the gantry frame, and on the side of the workbench, there are positioning and clamping cylinders and positioning and clamping roller devices. The invention has a compact structure, and can complete the glue-fitting process of steel feet, porcelain pieces, and iron caps at the same position through one process of moving the porcelain parts, which reduces the positioning times of each glue-mounted part in the glue-mounting process and improves the positioning The accuracy and the coaxiality of the glue are high, and the efficiency of the glue is high. At the same time, a vibrating motor with adjustable frequency and amplitude is installed under the gluing station, which can reduce the porosity of the adhesive, increase the density, and improve the gluing strength of the porcelain insulator.

Owner:GUIZHOU UNIV

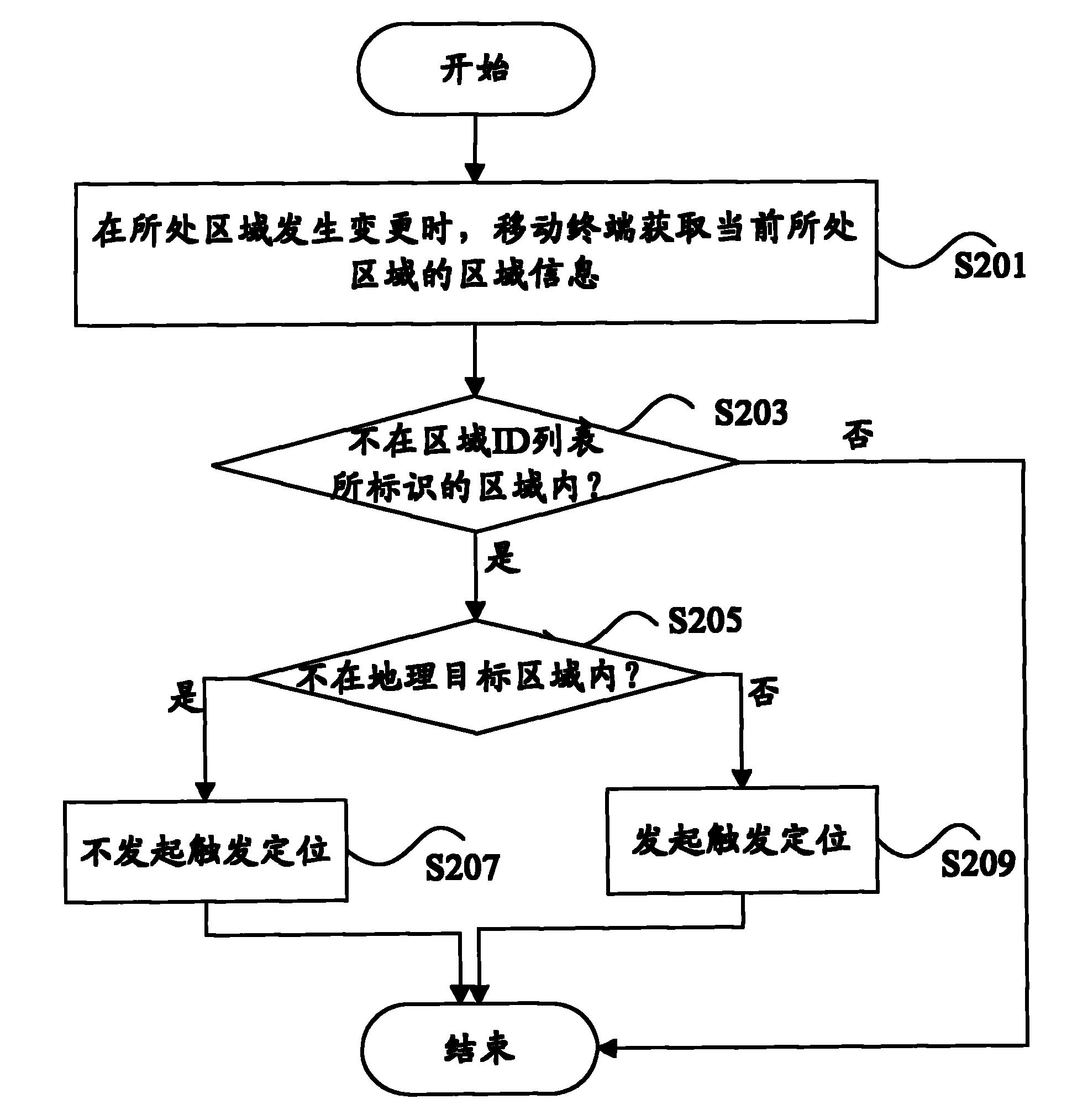

Triggered location method based on secure user plane location and mobile terminal

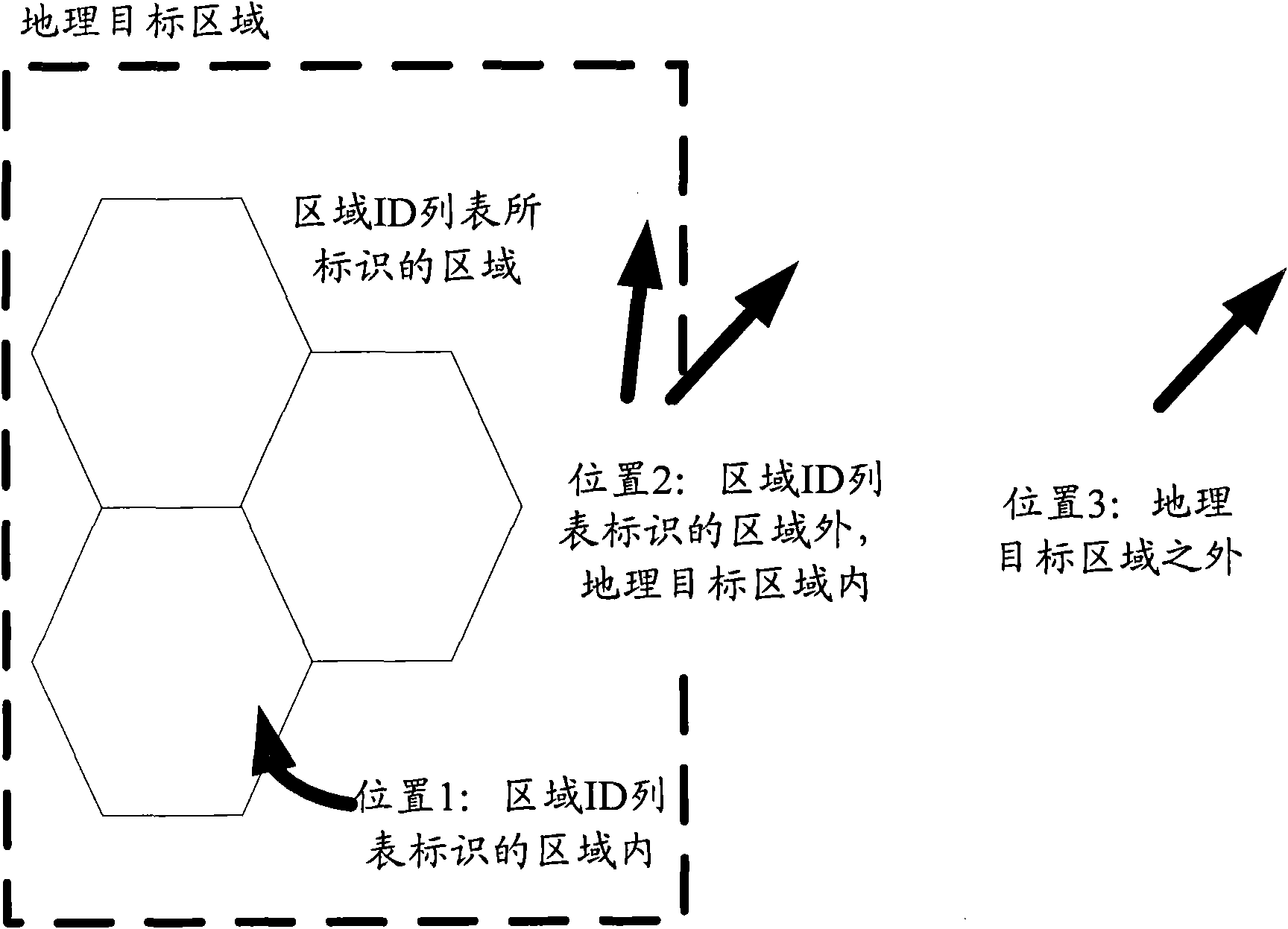

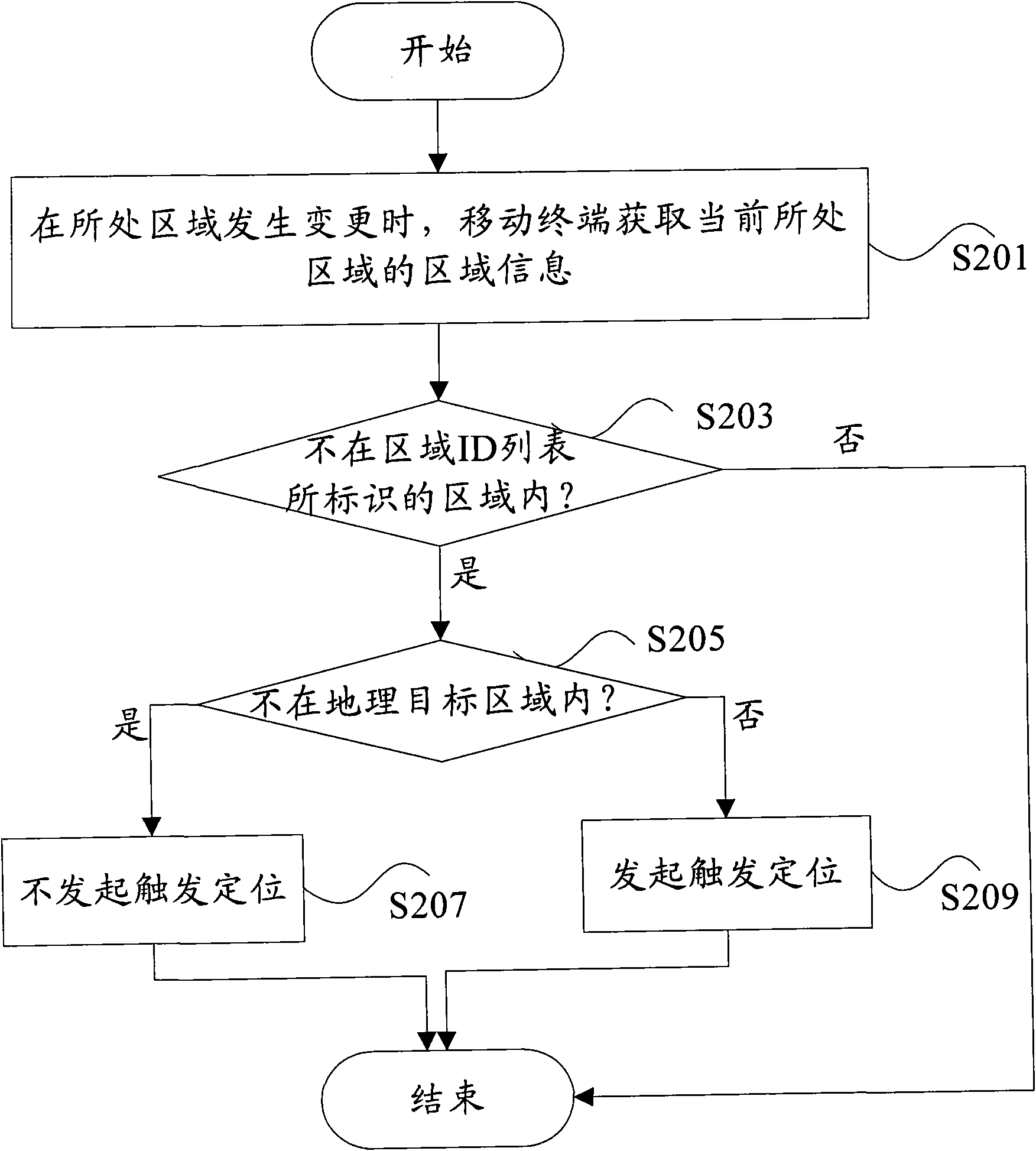

InactiveCN101815242AIncrease profitReduce the number of targetingLocation information based serviceSecure User Plane LocationArea change

The invention discloses a triggered location method based on secure user plane location and a mobile terminal, wherein the triggered location method comprises the steps of: when a located area changes, acquiring area information of a current located area by the mobile terminal; determining that the mobile terminal does not locate in an area identified by a preset area identification list by the mobile terminal, judging whether the mobile terminal does not locate in a geographical object area any more or not according to the area information and the preset geographical object area, if so, triggering no location, and or else, triggering the location. The invention can improve the efficiency of triggered location and the utilization ratio of system resources.

Owner:ZTE CORP

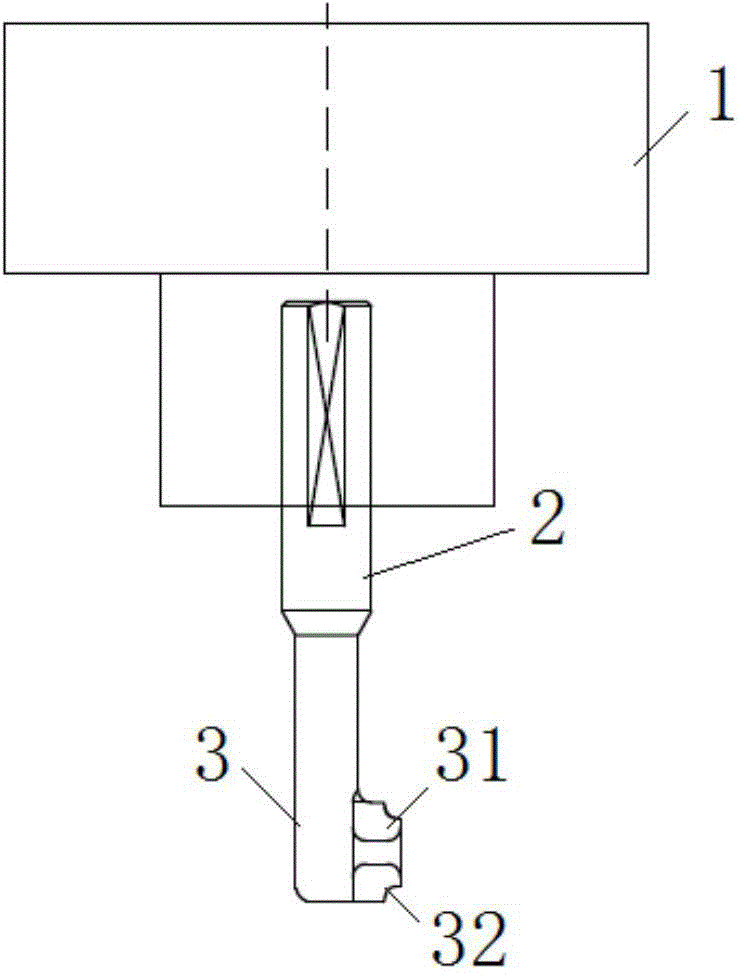

Chamfer forming tool and forming process thereof

InactiveCN104400036AReduce the number of targetingImprove machining accuracyCutting insertsTurning toolsEngineeringFront and back ends

The invention discloses a chamfer forming tool and a forming process thereof. The tool comprises a tool handle, a tool body and chamfer forming blades, wherein the tool handle is positioned at one end of the tool body; the chamfer forming blades are positioned at the other end of the tool body, protrude out of a side face of the tool body and comprise a first chamfer forming blade and a second chamfer forming blade; the edge of the first chamfer forming blade is arranged reverse to the edge of the second chamfer forming blade. Through the tool, rounding treatment can be directly performed on front and back end faces of a workpiece positioning hole, a workpiece is not required to be positioned secondarily, the positioning frequency is reduced, the machining accuracy is high, the operation is easy and convenient, and the machining efficiency is improved.

Owner:WUHU STERLING STEERING SYST

3D printing equipment

InactiveCN111169003AImprove printing efficiencyReduce the number of targetingAdditive manufacturing apparatusIncreasing energy efficiencyComputer printingIndustrial engineering

The invention relates to 3D printing equipment. The 3D printing equipment comprises a supporting frame, a printing assembly and a working box mechanism, wherein the printing assembly and the working box mechanism are integrally arranged on the supporting frame; the printing assembly comprises symmetrically-arranged discharging guide rails, a plurality of printing guide rails, a plurality of discharging mechanisms and a plurality of printing mechanisms, wherein the printing guide rails and the discharging mechanisms are arranged between the two discharging guide rails correspondingly, and one printing mechanism is arranged on at least one printing guide rail in a sliding mode; the two discharging guide rails are arranged on the two symmetrical sides of the supporting frame; and the workingbox mechanism comprises a working box and a jacking piece which are integrally arranged, wherein the jacking piece is used for jacking a bottom plate of the working box to ascend and descend in the vertical direction, and the working box and the jacking piece are movably arranged inside the supporting frame in a penetrating mode. The 3D printing equipment has the advantages of high printing efficiency and high product precision.

Owner:KOCEL INTELLIGENT FOUNDRY IND INNOVATION CENT CO LTD

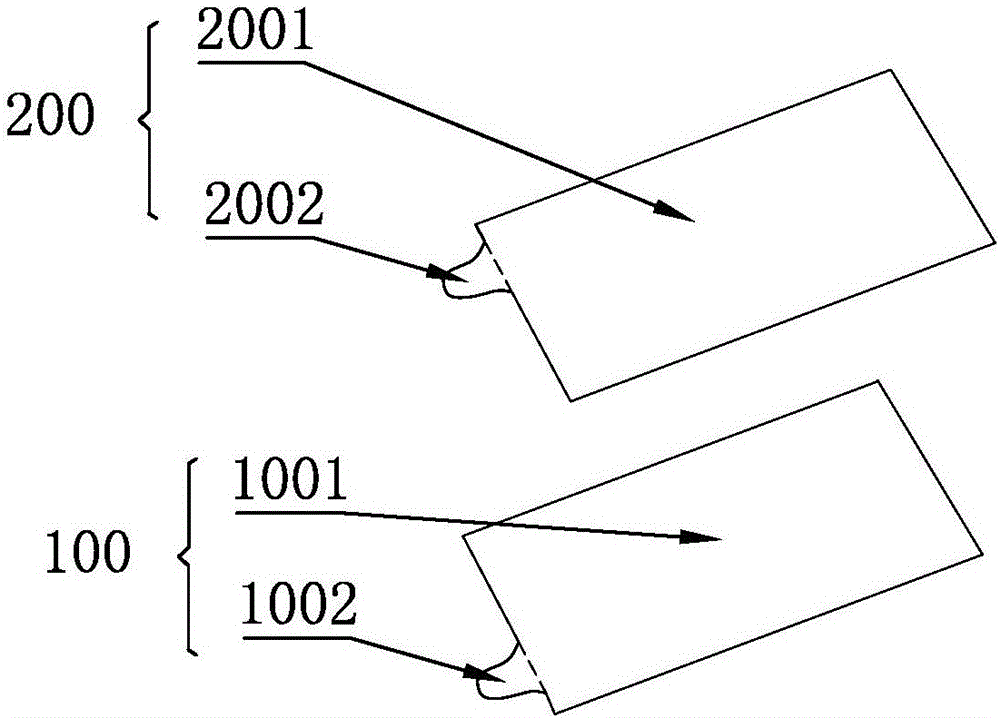

Novel double-sided processing device and technology

InactiveCN106363419AReduce the number of targetingReduce processing timeOther manufacturing equipments/toolsPrinted circuit manufactureNon symmetricFixed frame

The invention discloses a novel double-sided processing device comprising a lower supporting plate; the upper end of the lower supporting plate is provided with an upper supporting plate through an upright post; a fixed frame is mounted in the middle of the upright post, and a plate to be processed is spliced into the fixed frame; at least two asymmetric locating holes are formed in the plate to be processed; and a mounting frame is arranged on a position, located above the fixed frame, on the upright post. A novel double-sided processing technology realized by using the double-sided processing device comprises the following steps of S1, preparing; S2, locating; S3, processing; and S4, material changing. By using the novel double-sided processing device and technology, double sides of the plate can be simultaneously processed, so that the locating frequency and locating errors can be reduced, processing errors between the double sides are further reduced and are reduced within the range of + / -0.05mm, the processing time can be shortened by more than 30%, and the economic benefits of enterprises can be better increased in a specific plate processing field.

Owner:SUZHOU ANJIE TECH

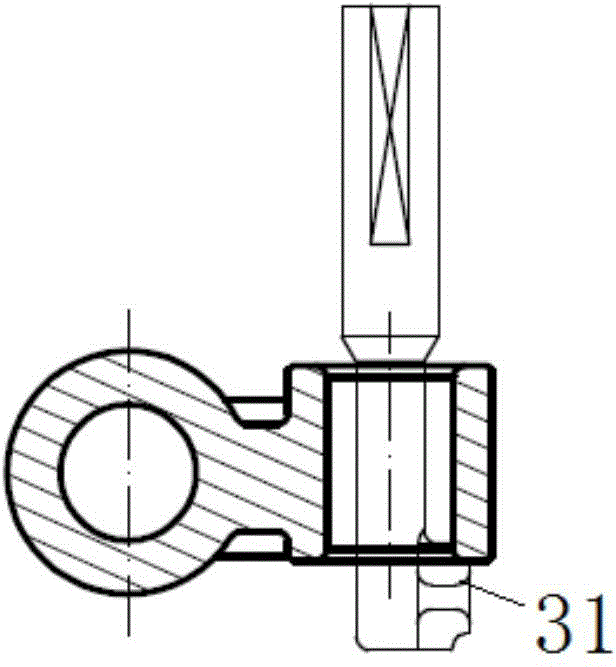

Tool device and production line for assembling mechanical arm joints

PendingCN113601550AGuaranteed assembly accuracyReduce the number of targetingManipulatorProduction lineEngineering

The invention relates to the technical field of automation equipment, in particular to a tool device and a production line for assembling mechanical arm joints. The tool device comprises a bearing part, a locking assembly, a sliding driving assembly and a rotating driving assembly, the bearing part is used for bearing a workpiece, and the bearing part is assembled in a sliding and rotating mode; the locking assembly comprises a locking disc and at least one locking part, the locking disc is assembled on the bearing part in a follow-up mode, locking parts are fixedly assembled, at least two locking holes are formed in the locking disc, the locking disc slides towards the locking parts along with the bearing part, the locking parts can stretch into the locking holes to achieve locking, and the locking disc slides away from the locking parts along with the bearing part. According to the tool device and the production line for assembling the mechanical arm joints, the locking part can be separated from a locking hole to achieve unlocking, the sliding driving assembly drives the bearing part to slide, the rotating driving assembly drives the sliding driving assembly and the bearing part to rotate, and the technical problem that in the prior art, the assembly precision of the two ends of the workpiece and other parts is poor is solved.

Owner:遨博(江苏)机器人有限公司

Perforating device for constructional engineering

PendingCN112916914AHigh automation intensityReduce the number of clampingFeeding apparatusPositioning apparatusElectric machineryRotational axis

The invention discloses a perforating device for constructional engineering. The perforating device comprises a rack and drill bits, wherein fixed plates are arranged at the two sides of the rack correspondingly; a lifting plate is arranged above the position between the two fixed plates; the rack is provided with a first gear motor; the first gear motor is provided with a lead screw; the lead screw is in threaded connection with a feed screw nut; the lifting plate is slidably connected to the fixed plates through a guide rod and a guide sleeve; the lifting plate is slidably connected to a disc; the disc is provided with an annular rack plate; a first driving gear is rotationally arranged at the left side of the lifting plate; the first driving gear sleeves an output shaft of a second gear motor; the lifting plate is rotationally connected to a rotary shaft; the rotary shaft is connected to a second driving gear; the lifting plate is provided with a third gear motor; the third gear motor is connected to the rotary shaft through a transmission device; the disc is rotationally connected to a plurality of rotating shafts; the rotating shafts are provided with driven gears; the driven gears are in meshed connection with the second driving gear; the tails of the rotating shafts are fixedly connected to the drill bits; and the perforating device further comprises a clamping and moving device.

Owner:南力建设集团有限公司

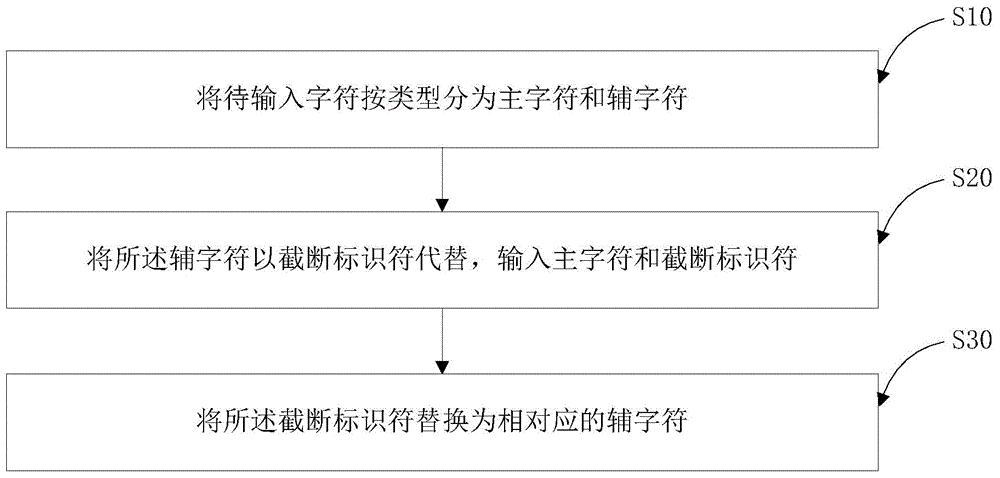

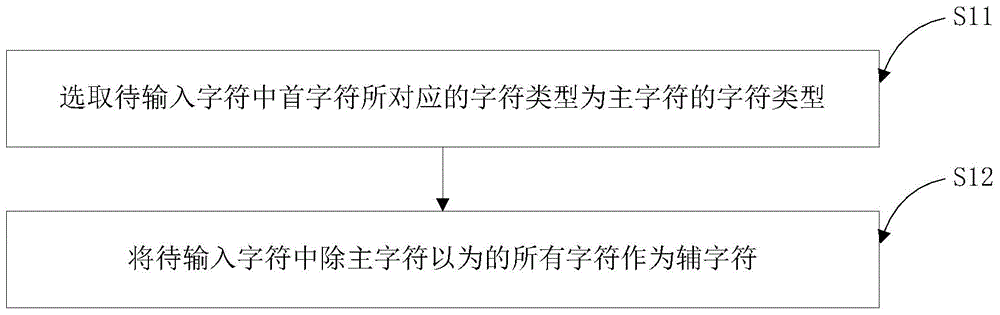

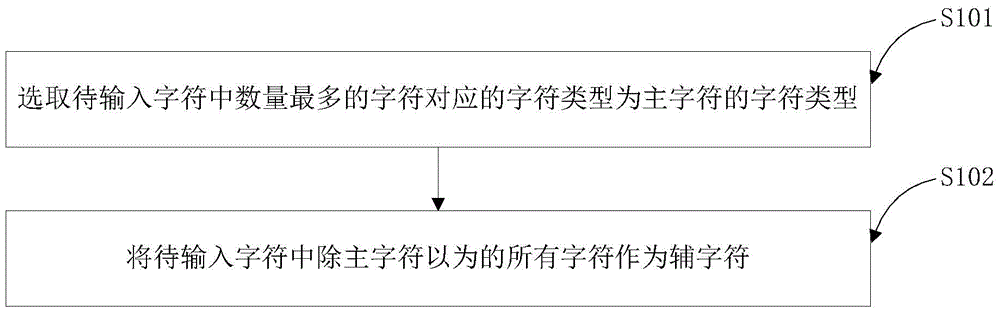

Character input method and device based on truncation identification

ActiveCN104898863AImprove input efficiencyReduce switchingInput/output processes for data processingTheoretical computer scienceAlgorithm

The invention discloses a character input method and device based on truncation identification, and belongs to the technical field of communication. The method comprises the following steps: dividing a character to be input into a main character and an auxiliary character according to types; replacing the auxiliary character with a truncation identifier, and inputting the main character and the truncation identifier; and replacing the truncation identifier with the corresponding auxiliary character. The truncation identification is added into a character mixed input process, and other characters to be input are successively input according to the truncation identification after the input of main content is finished so as to reduce the switching of input modes and the positioning frequencies of a cursor and improve character input efficiency.

Owner:NUBIA TECHNOLOGY CO LTD

Inclined multi-hole processing device for special-shaped die castings

ActiveCN104493487AReduce the number of targetingEffective targetingOther manufacturing equipments/toolsPunchingDie casting

The invention relates to an inclined multi-hole processing device for special-shaped die castings and aims to solve problems about processing of various holes of the special-shaped die castings. The processing device comprises a fixed base, an inclined bracket at one end of the fixed base and a main power cylinder and is characterized in that a propping device is arranged above the inclined bracket; the propping device comprises a push rod with an air hole; a rigid arc-shaped ladle is arranged at the end part of the push rod; a protective air cushion, of which the area is greater than that of the rigid arc-shaped ladle, is arranged on the surface of the rigid arc-shaped ladle; the fixed base comprises a tool rest guiding device; a multi-purpose tool is arranged in the tool rest guiding device; and the multi-purpose tool comprises a punching die and a multi-angle drilling tool. The processing device provided by the invention provides an effective positioning way for irregular products, and can reduce the positioning times or achieve one-step processing forming for components with a multi-angle hole processing requirement; the punching die and the multi-angle drilling tool are arranged in the processing device so as to satisfy selective use; the universal propping device is better adapted to special-shaped parts such as parts with curved surfaces.

Owner:宁波环亚机械制造有限公司

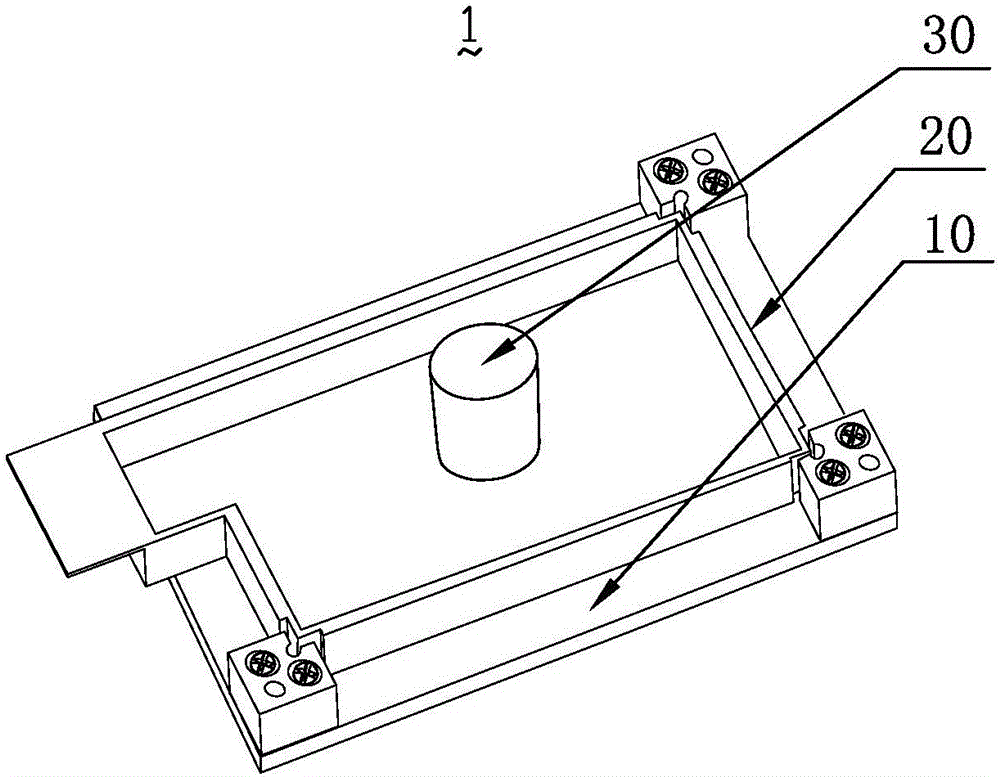

Lithium battery stacking equipment and method

ActiveCN106785062AAvoid the risk of contact short circuitImprove yieldFinal product manufactureElectrolyte accumulators manufactureEngineeringPole piece

The invention aims to provide lithium battery stacking equipment. The lithium battery stacking equipment comprises a positioning device and a stacking device, wherein the positioning device comprises a main body and a positioning piece fixed on the main body; the positioning piece defines a positioning region on the main body and is used for positioning a pole piece body in the positioning region; the stacking device is a hollow frame structure, defines a body region and a limiting region which extends from the body region and communicates with the body region; and the body region and the limiting region jointly form a penetration region and are respectively matched with a main body and a pole lug of a pole piece. When the lithium battery stacking equipment is used, the stacking device is stacked on the positioning device, corners of the stacking device is combined to positioning pieces of the positioning device in a clamped manner, and the limiting region of the stacking device is staggered from the pole lug of the pole piece positioned on the positioning device in the stacking direction of the stacking device and the positioning device. The invention further provides a stacking method using the lithium battery stacking equipment. The lithium battery stacking equipment has the advantages of simplicity and convenience in operation, accurate positioning, high efficiency and improvement of yield of products.

Owner:衡电科技(成都)有限公司

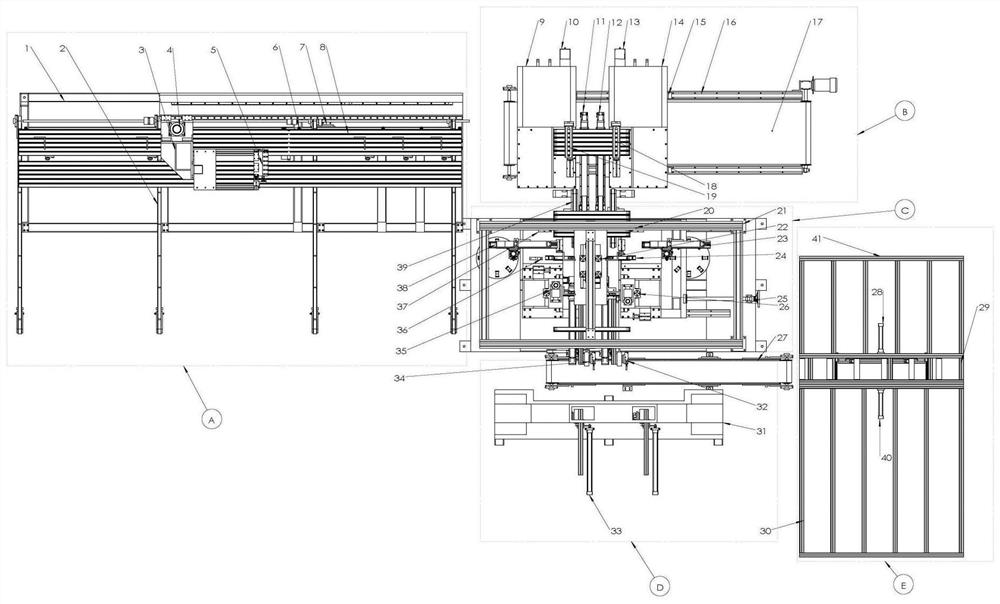

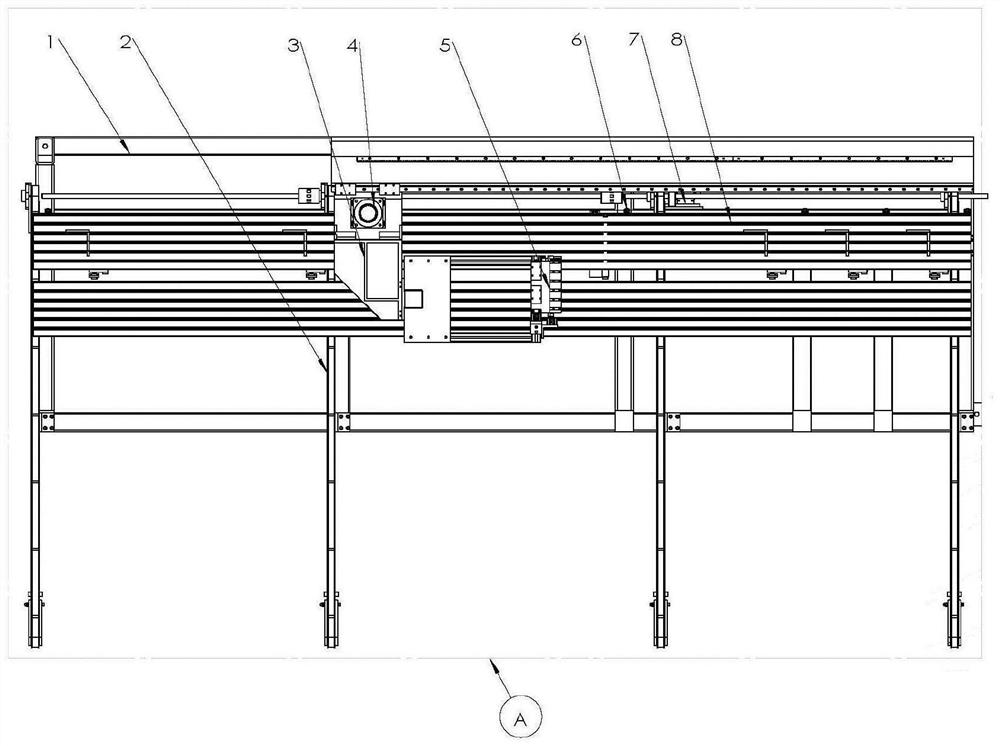

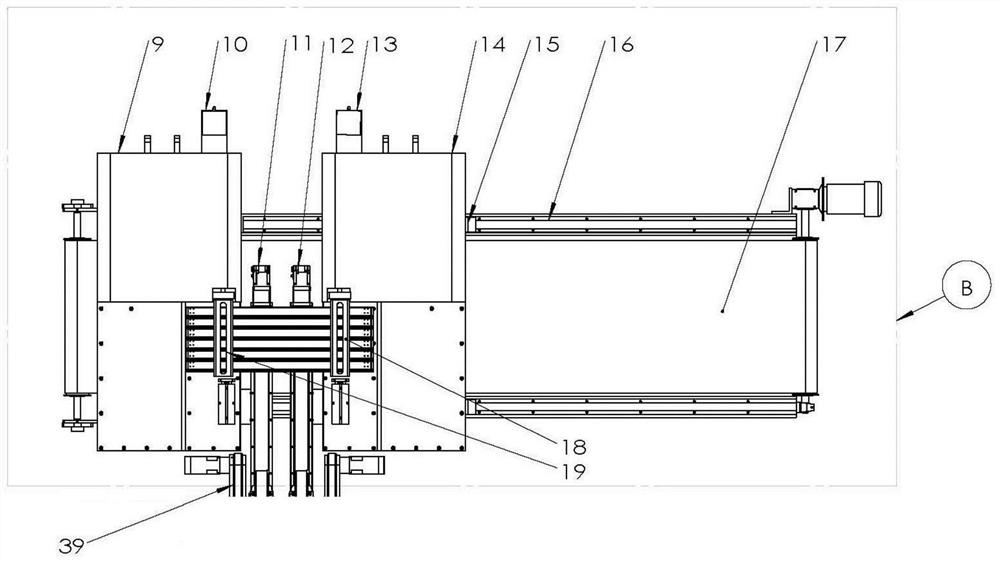

Processing method and production line of photovoltaic frame

ActiveCN112917105AReduce the number of flipsReduce the number of targetingOther manufacturing equipments/toolsMetal working apparatusProduction linePunching

The invention discloses a processing method and a production line of a photovoltaic frame. The processing method comprises the following steps of automatic feeding, automatic sawing, detection of the length of a work material, corner connector and riveting point punching, one-time work material overturning, punching and automatic sorting of qualified products. The full-automatic production line needed for achieving the method comprises an automatic sawing section on the right side of an automatic feeding section, one side of the automatic sawing section is connected with one side of a corner connector and riveting point punching section, the other side of the corner connector and riveting point punching section is connected with a punching section, a finished product section is arranged on the right side of the punching section, the work material can be automatically overturned one time after automatic feeding, sawing, detection of the length of the work material, corner connector and riveting point punching are achieved, then the work material is conveyed to a punching device to be punched, and the finished products are obtained after the qualified products are sorted through the finished product section. The processing method and the production line have the beneficial effects that the length of the work material is automatically detected, the qualified products can be sorted conveniently, the overturning frequency of the work material is small, the production efficiency and the processing precision are improved, full-automatic processing is achieved, and the production cost is reduced.

Owner:山东迈高智能科技有限公司

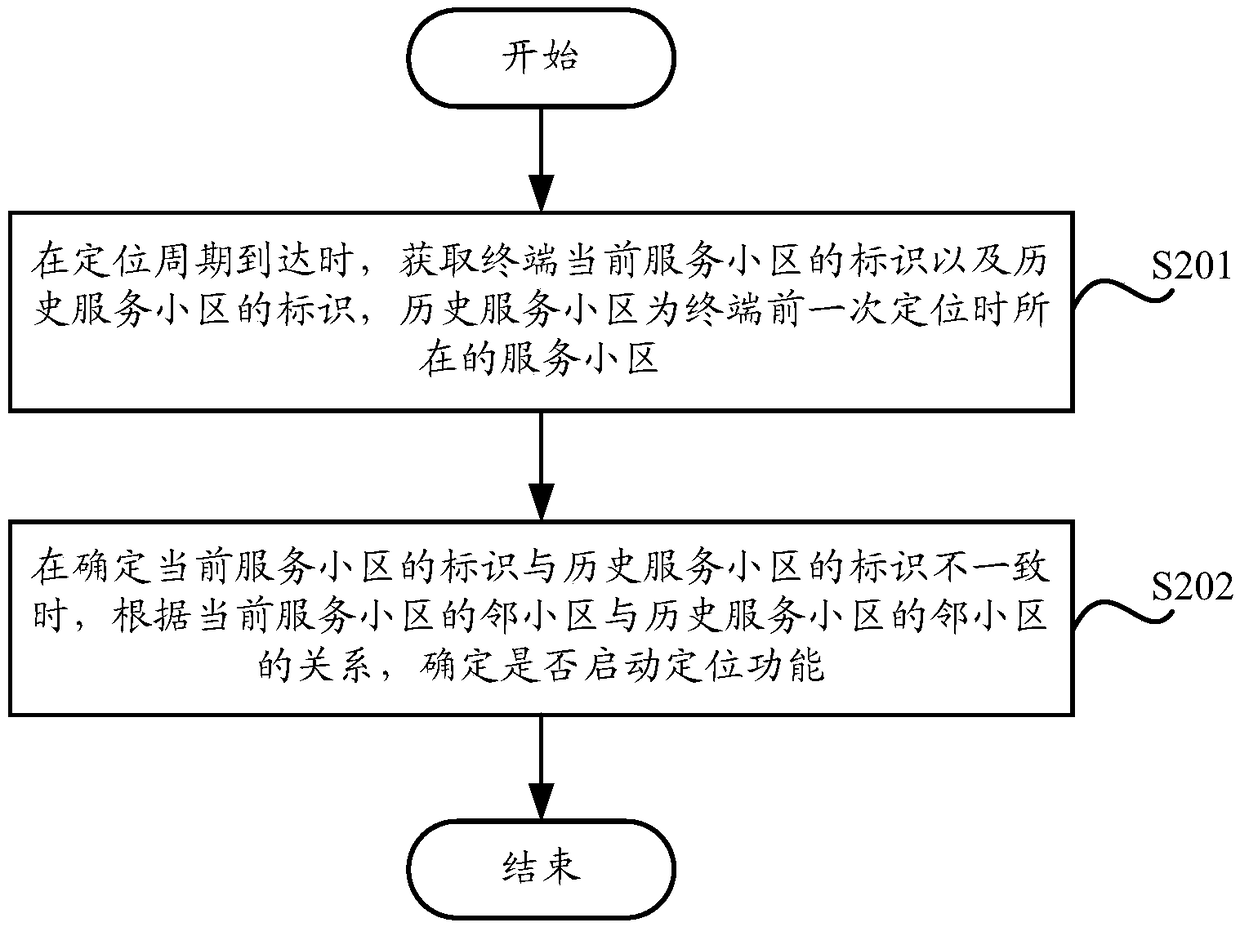

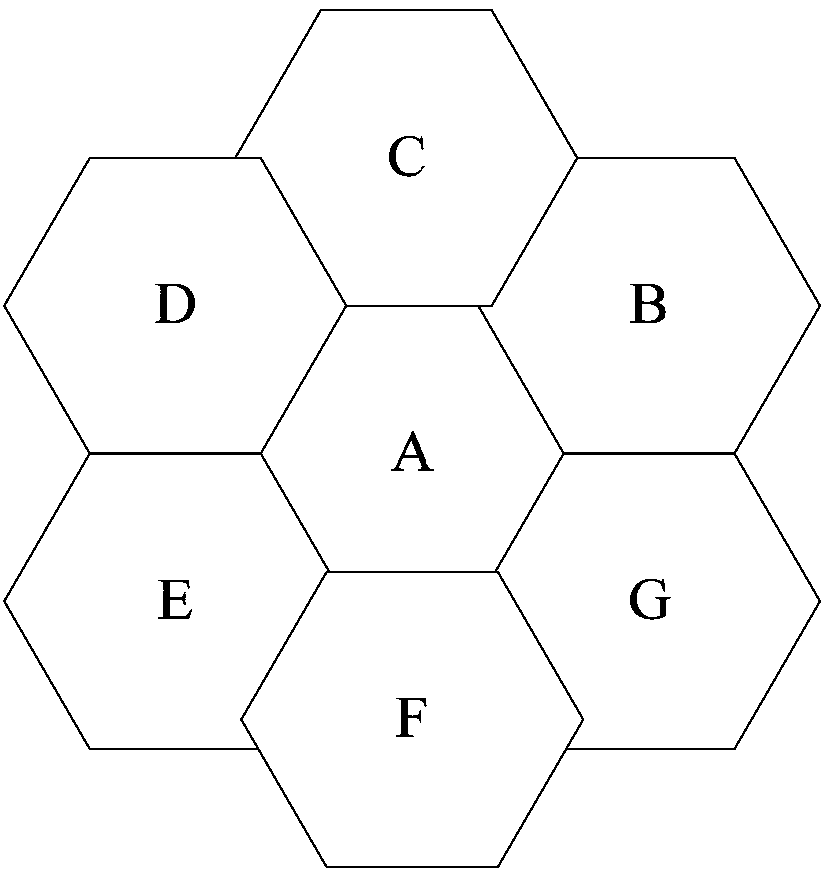

Positioning method and terminal

InactiveCN108513263AReduce the number of targetingReduce power consumptionLocation information based serviceHigh level techniquesTelecommunicationsPower consumption

The embodiment of the invention provides a positioning method and a terminal, and relates to the technical field of computers. The method comprises the following steps: at the arrival of a positioningperiod, obtaining an identifier of a current serving cell and the identifier of a historical serving cell of of the terminal, wherein the historical serving cell is a serving cell where the previouspositioning of the terminal is located; and when it is determined that the identifier of the current serving cell is inconsistent with the identifier of the historical serving cell, determining whether to start a positioning function according to the relationship between a neighboring cell of the current serving cell and the neighboring cell of the historical serving cell. At the arrival of the positioning period, whether to start the positioning function is judged according to the relationship between the current serving cell and the historical serving cell of the terminal and the relationship between the neighboring cell of the current serving cell and the neighboring cell of the historical serving cell, instead of starting the positioning function at the arrival of the positioning period, therefore the positioning times are reduced, the power consumption is reduced, and the endurance time is prolonged.

Owner:SHANGHAI CHUANGGONG COMM TECH

Multi-function indoor construction hanging machine

InactiveCN108442654AAvoid displacement deviationMeet construction needsBuilding material handlingSupporting systemAngle grinder

The invention relates to a multi-function indoor construction hanging machine, comprising a main machine, hanging pieces, a railway and the like. The multi-function indoor construction hanging machineis characterized in that the main machine has a walking levelling function, a stand bar supporting system of the main machine can be lengthened and stretched so that the main machine can be supportedbetween the ground and a ceiling, and can move along the railway; under the driving control of a power distribution system, a lifting rack system moves up and down with the stand bar as a guiding rail and the lifting rack system can also move forward and backward horizontally; by hanging a hopper, a plastering machine head, a feeding groove, a hanging machine head, a counterweight and other hanging pieces and hanging a spraying head, a grooving machine, a polishing machine, an angle grinder and other small equipment on the lifting rack, lifting of concrete, building blocks, mortar and other materials in secondary structure construction is finished, and inner wall plastering, putty spraying, paint spraying, grooving, polishing, cleaning and other decoration construction are finished. The multi-function indoor construction hanging machine has the advantages that adaptation is high, operation is convenient, the main machine is regarded as the basic equipment, different equipment can be hung, function extension can be achieved, and multi-usage of one machine is achieved.

Owner:刘满仓

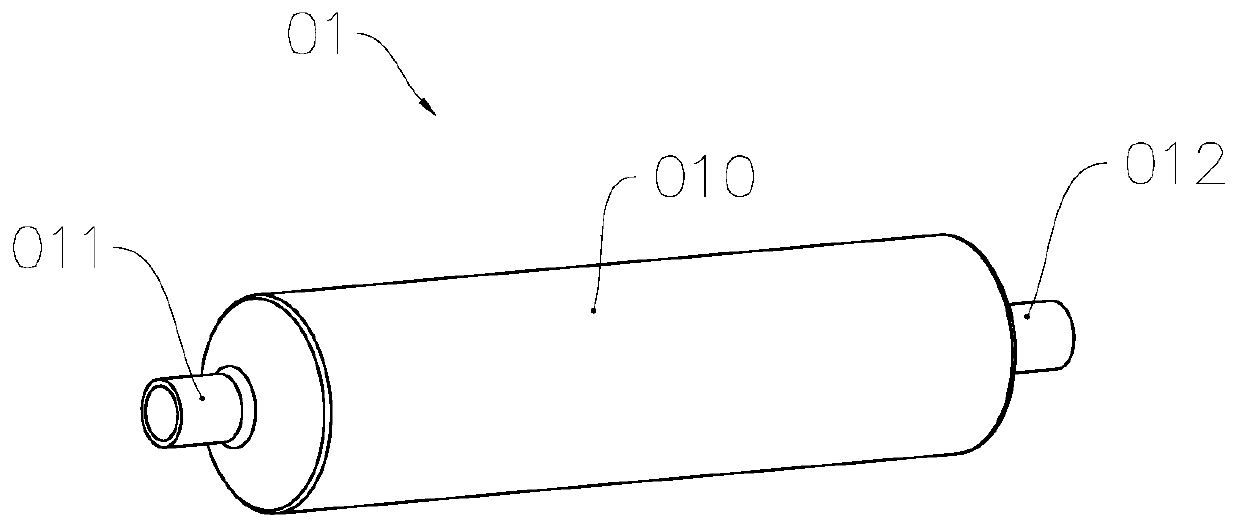

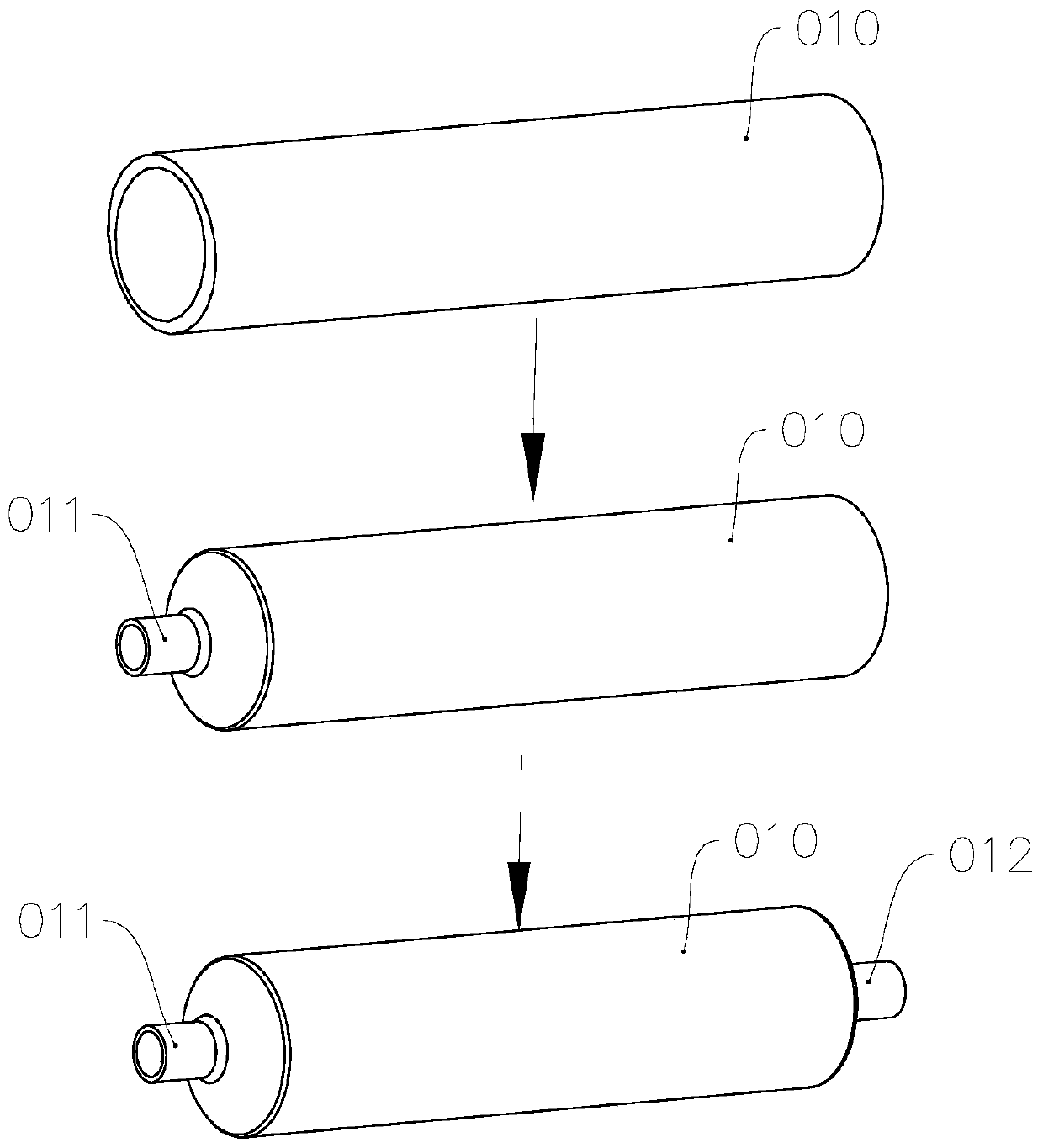

Double-headed spinning system and double-headed spinning method

ActiveCN110252844AImprove processing efficiencyQuality assuranceMetal-working feeding devicesOther manufacturing equipments/toolsHEAD SPINNINGAviation

The invention relates to a double-headed spinning system and a double-headed spinning method, and belongs to the technical field of pipe processing. The double-headed spinning system comprises a double-headed spinning device, a pipe end trimming device and a pipe transferring system, wherein the pipe transferring system comprises a pipe transferring clamp jaw; the double-headed spinning device comprises a pipe spinning clamp die and two spinning machine heads; and in the process that the pipe transferring system transfers a pipe processed through the double-headed spinning device to the pipe end trimming device, the pipe transferring clamp jaw is controlled to clamp a pipe clamped on the pipe spinning clamp die before the pipe spinning clamp die releases the clamping on the pipe, and a pipe end trimming clamp die is controlled to clamp the pipe conveyed by the pipe transferring clamp jaw before the pipe transferring clamp jaw releases the clamping on the pipe. According to the spinning system, the processing efficiency on spinning the pipe at two ends is ensured, the follow-up processing quality of the pipe is effectively ensured, and the double-headed spinning system and the double-headed spinning method can be widely applied to the manufacturing fields such as refrigeration, automobiles and aviation.

Owner:浙江长兴和良智能装备有限公司

Wall paper cutting device

ActiveCN111590678AGuaranteed cutting accuracyIncrease cutting powerMetal working apparatusStructural engineeringElasterell

The invention provides a wall paper cutting device, and relates to the technical field of building machines. The wall paper cutting device comprises a guide rail, a sliding base, a cutter assembly, and a pressure adjusting assembly, the sliding base is mounted on the guide rail and in sliding connection with the guide rail, the cutter assembly is used for cutting wall paper, the pressure adjustingassembly comprises a first sliding frame, a pressing plate and an elastic part, the first sliding frame is mounted on the sliding base, the cutter assembly is slidingly mounted on the first sliding frame, the elastic part is mounted between the pressing plate and the cutter assembly, during wall paper cutting, external force acts on the pressing plate, the pressing plate is in abut joint with thesliding base and is spaced from a target cutting face by the preset distance, the pressing plate acts on the cutter assembly through the elastic part, the cutter assembly is in abut joint with the target cutting face and enables the elastic part to be compressed, according to the all paper cutting device, the strength for wall paper cutting is constant in magnitude, the cutting efficiency and precision are improved, and the wall paper damage is prevented.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

Positioning method and apparatus

ActiveCN107580361AReduce the number of targetingReduce power consumptionPower managementHigh level techniquesComputer scienceReal-time computing

Owner:ZTE CORP

Hole internal processing integrated cutter and processing technique thereof

ActiveCN104526037AReduce the number of targetingImprove machining accuracyTurning machine accessoriesMilling cuttersReamerEngineering

The invention discloses a hole internal processing integrated cutter and a processing technique thereof. The cutter comprises a cutter handle, a cutter body and a forming cutter blade; the cutter handle is positioned at one end of the cutter body; the forming cutter blade is positioned at the other end of the cutter body; the forming cutter blade comprises a step hole forming reamer and a groove forming knife; the groove forming knife is arranged at the outer end of the cutter body; the step hole forming reamer is positioned at the inner side of the groove forming knife; the outer diameter of the step hole forming reamer is greater than the outer diameter of the groove forming knife. The processing technique comprises the following steps of positioning a to-be-processed workpiece, enabling a to-be-processed hole to be straight up, and fixing the cutter on a machine tool spindle; processing an annular groove in a manner that the cutter moves by virtue of circular interpolation; enabling the centers of the machine tool spindle and the cutter to return to the center of the to-be-processed hole, and processing a step hole in a manner that the cutter downwards performs cutting by virtue of linear interpolation; retracting the cutter. Replacement of different cutters is not needed, the positioning times of the cutter are reduced, the processing precision is improved, the processing process is simplified, and the processing efficiency is improved.

Owner:WUHU STERLING STEERING SYST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com