Automatic cementing machine for ultrahigh-voltage high-strength disc suspension porcelain insulator

A porcelain insulator and form suspension technology, which is applied in the field of automatic glue-mounting machines for ultra-high-voltage and high-strength disc-shaped suspension porcelain insulators, can solve the problems of the coaxiality of glue-installation, the difficulty of ensuring the porosity and filling degree of the glue, steel feet, Adverse effects of coaxiality and unstable product quality of porcelain parts and iron caps, achieving the effects of compact structure, high glue-packing efficiency, and increased density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

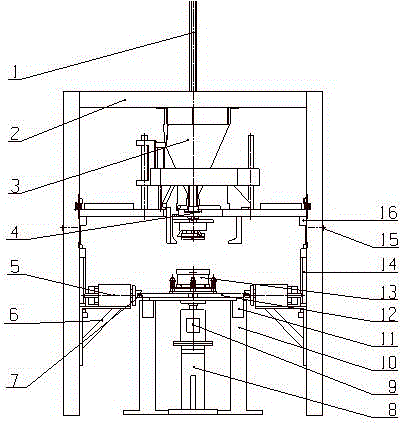

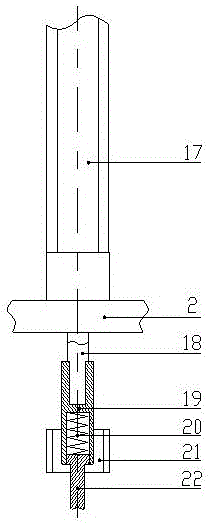

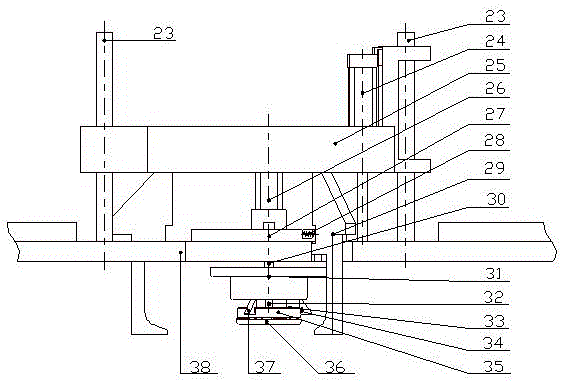

[0015] The embodiment of the present invention: ultra-high-voltage high-strength disk-shaped suspension porcelain insulator automatic bonding machine, such as figure 1 As shown, the workbench 12 is made, the iron cap porcelain base 13 is installed on the workbench 12, the vibration motor 9 is installed under the iron cap porcelain base 13, and the vibration motor 9 is installed on the vibration motor mounting frame 8. Connect the glue assembly 4, the steel foot funnel 3 and the steel foot pressing mechanism 1 through the gantry 2 above the worktable 12, and install the positioning and clamping cylinder 5 and the positioning and clamping roller device 7 on the side of the worktable 12 to position and clamp The cylinder 5 is installed on the positioning and clamping cylinder bracket 6. The workbench 12 is installed on the workbench slide support column 10 and the workbench slide 11. The steel foot pressing mechanism 1, the steel foot funnel 3, the glue mounting mechanism 4, the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com