Hole internal processing integrated cutter and processing technique thereof

A processing technology and internal processing technology, which is applied in the field of in-hole processing integrated tools and its processing technology, can solve problems such as low processing efficiency, low processing accuracy, and cumbersome processing operations, so as to improve processing efficiency, reduce positioning times, and improve processing. The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manner of the present invention will be described in further detail below by describing the embodiments with reference to the accompanying drawings.

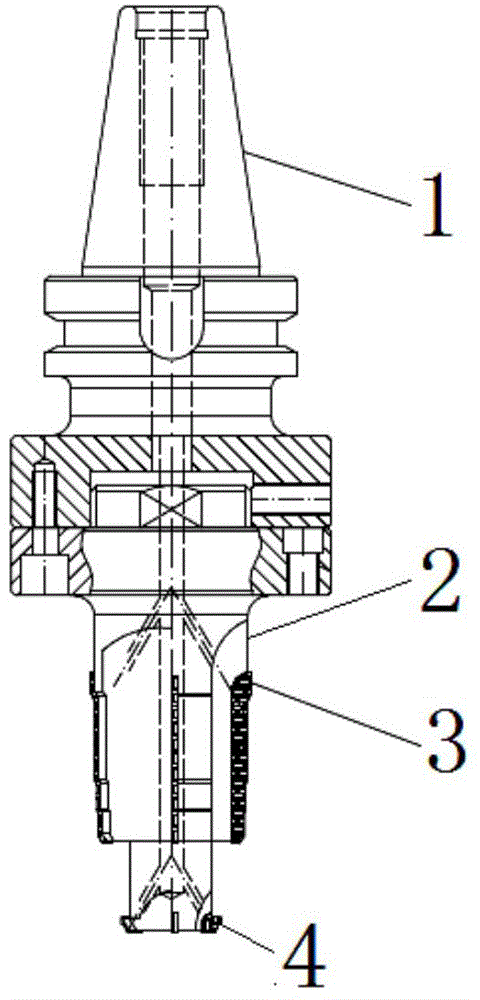

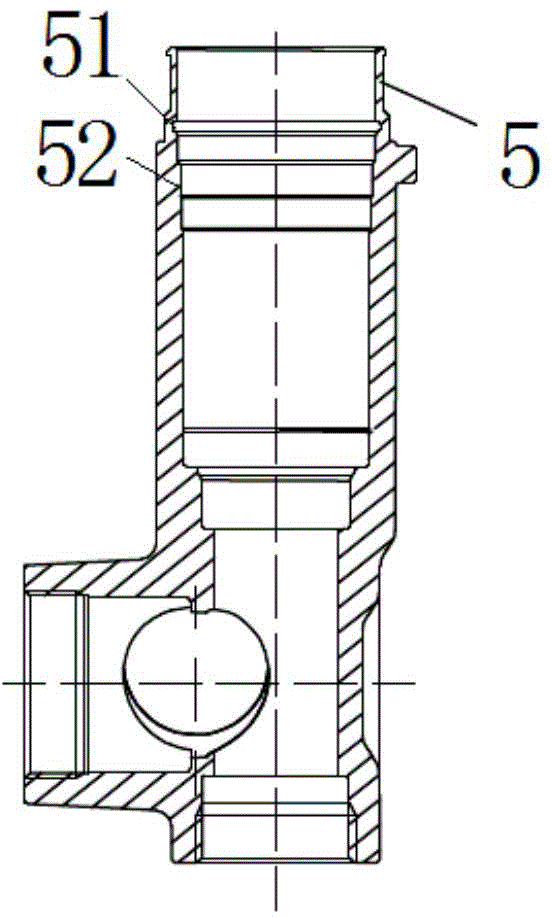

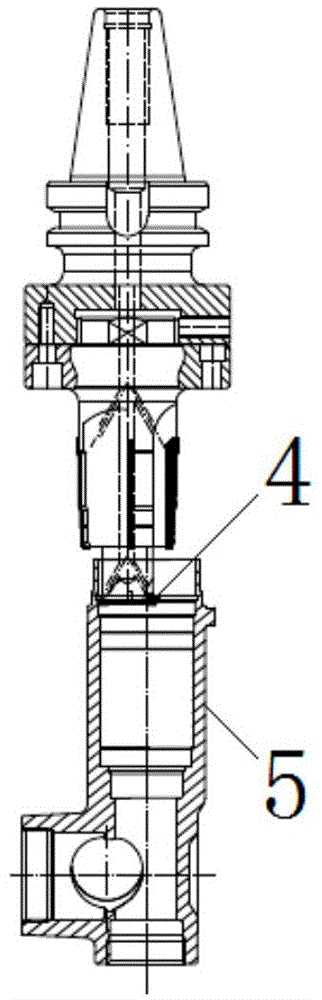

[0024] Such as Figure 1 to Figure 4 As shown, the integrated tool is processed in the hole, including a handle 1, a cutter body 2, and a forming blade, wherein the handle 1 is located at one end of the cutter body 2, and the forming blade is located at the other end of the cutter body 2, and the gap between the handle 1 and the cutter body 2 is The two are connected by a flange structure, which is convenient for disassembling and replacing the cutter body, and the cutter handle 1 is connected with the main shaft of the machine tool to fix the cutter on the processing machine tool.

[0025] The forming blade comprises a step hole forming reamer 3 and a groove forming knife 4, the groove forming knife 4 is fixed on the outermost end of the cutter body, and the step hole forming reamer 3 is fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com