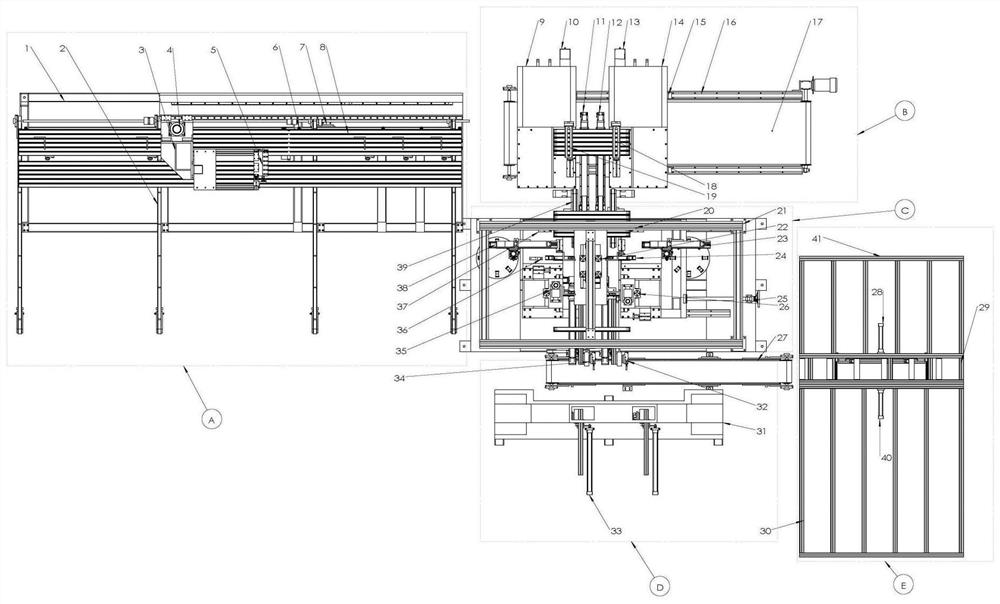

Processing method and production line of photovoltaic frame

A processing method and production line technology, applied in metal processing, manufacturing tools, other manufacturing equipment/tools, etc., can solve the problem that the production line cannot automatically detect product length and separate non-qualified products, affect processing accuracy and production efficiency, and low degree of automation, etc. problems, to achieve the effect of reducing the number of material positioning times, improving production efficiency, and improving processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

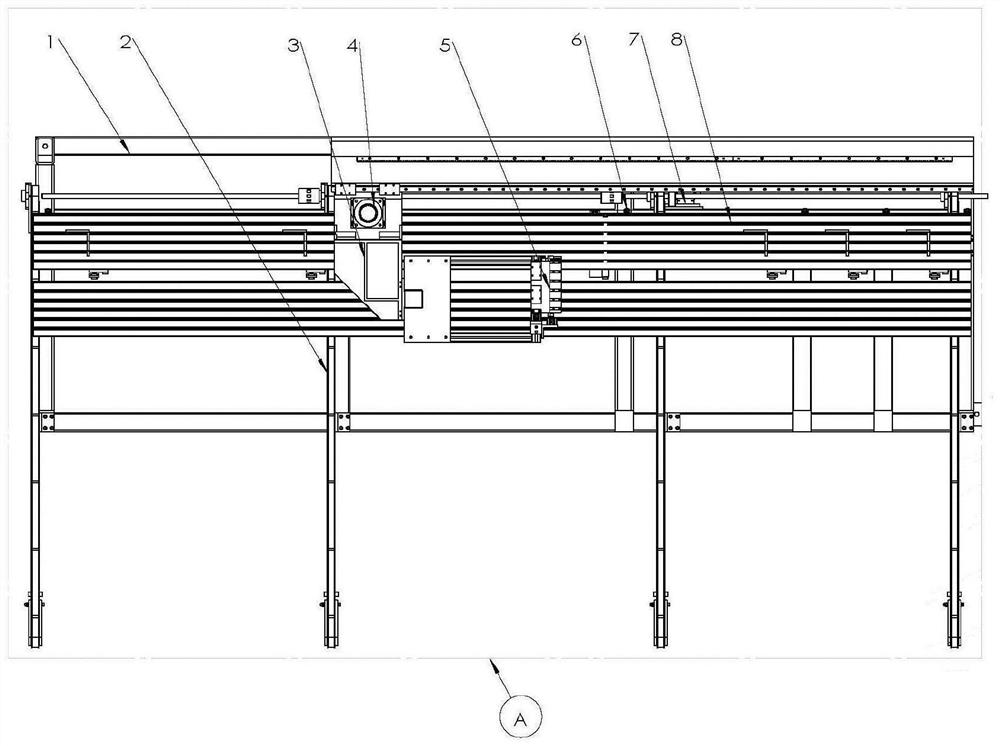

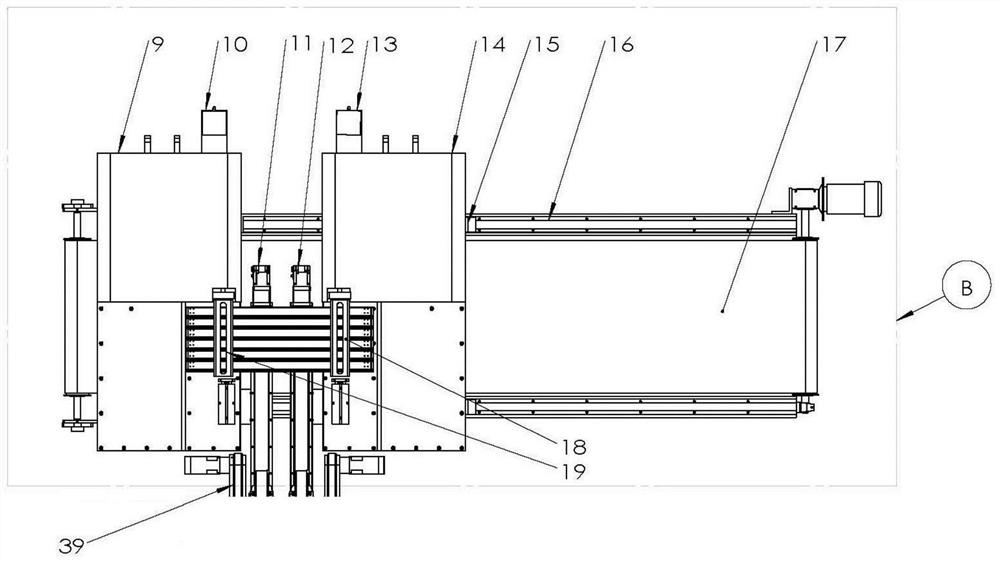

[0046] Put a group of six working materials on the coil material synchronization device 2, and the coil material synchronization device 2 sends the materials to the position detection switch 6, further, the feeding clamping device 5 on the feeding device 3 clamps the materials, and then, automatically Servo motor 4 starts, and feeding device 3 automatically sends the work material to the designated position on the right side of the automatic feeding section, and the left pressing device 19 and right pressing device 18 of the sawing section start to move, and the left saw on the sawing frame body 16 The cutting machine device 9 and the right sawing machine device 14 automatically complete the sawing action at the same time, and the cut tailings are sent to the designated position through the tailings conveying device 17, and the left sawing and discharging device 11 and the right sawing and discharging device 12 transfer the materials After being picked up, the work material is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com