A pressing system with mold automatic transfer function and its application method

An automatic transfer and mold technology, applied in the field of powder metallurgy equipment, to achieve the effects of easy operation, reduced labor risks, and reduced footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

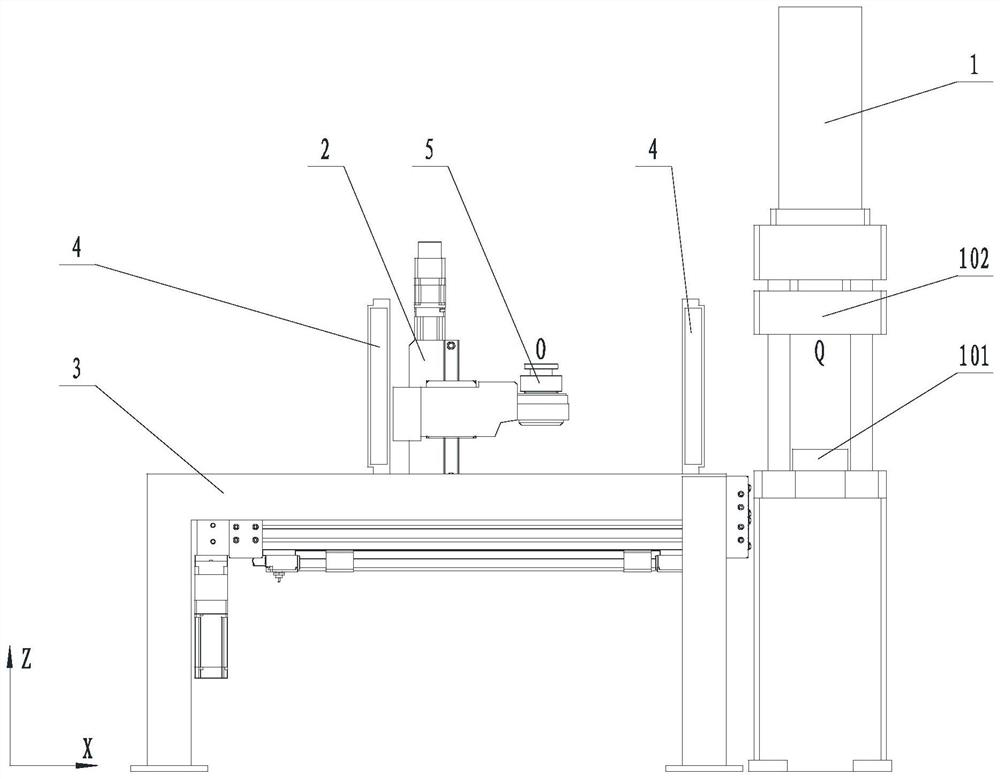

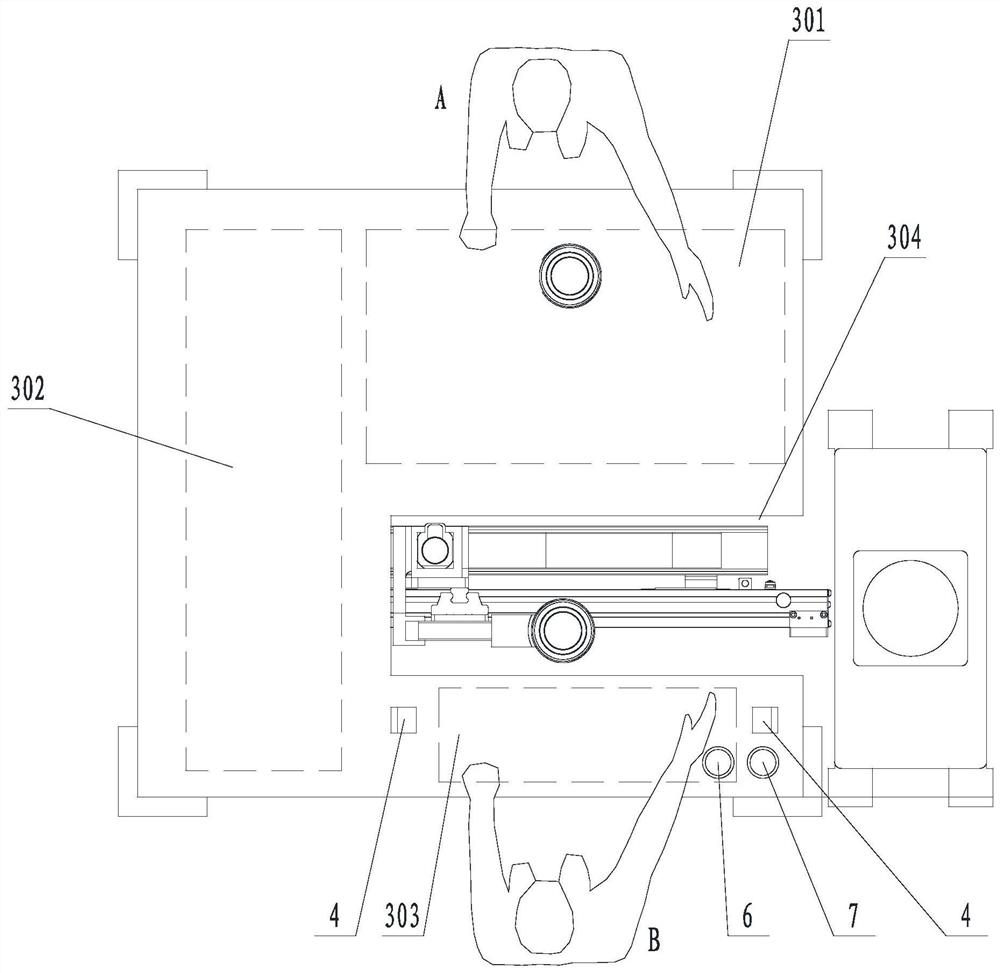

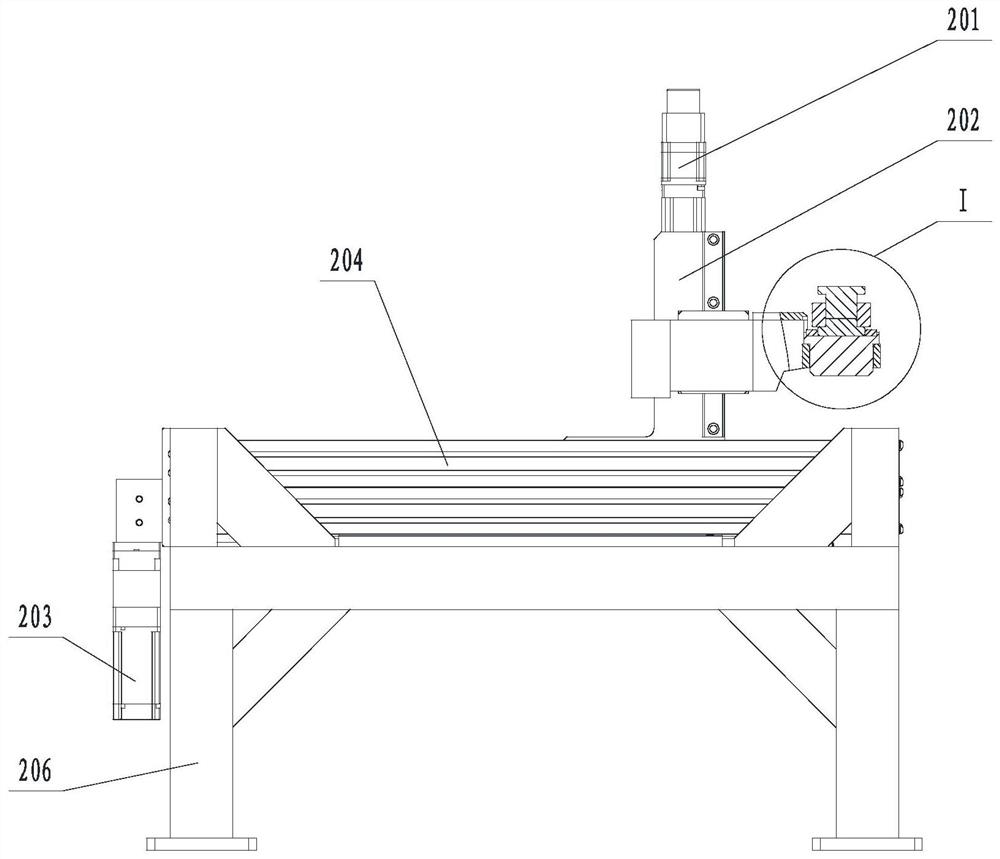

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0031] Such as Figure 1~5 As shown, the pressing system of the present invention includes a press 1, a mold transfer manipulator 2, an operating table 3, a safety grating 4, a mold 5 and an electric control system, wherein the actuator of the press 1 includes a press head 102 and a press for carrying The platform 101 and the indenters 1-2 can be driven in various ways such as hydraulic drive or electric servo drive, and can be selected according to actual working conditions. The console 3 includes an operation pretreatment area 301 , a transfer channel 302 , a mold pick-and-place position 303 , and a notch 304 provided in conjunction with the mold transfer manipulator 2 to avoid interference with the Z-axis module 202 during movement. The transfer channel 302 is located between the operation pretreatment area 301 and the mold pick-and-place position 303 , a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com