Steel coil bundling state detection method and system, terminal and medium

A state detection and steel coil technology, applied in the field of image processing, can solve the problems of high risk, high cost, and high labor risk of workers, and achieve the effect of reducing cost, timely detection, and reducing labor risk of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

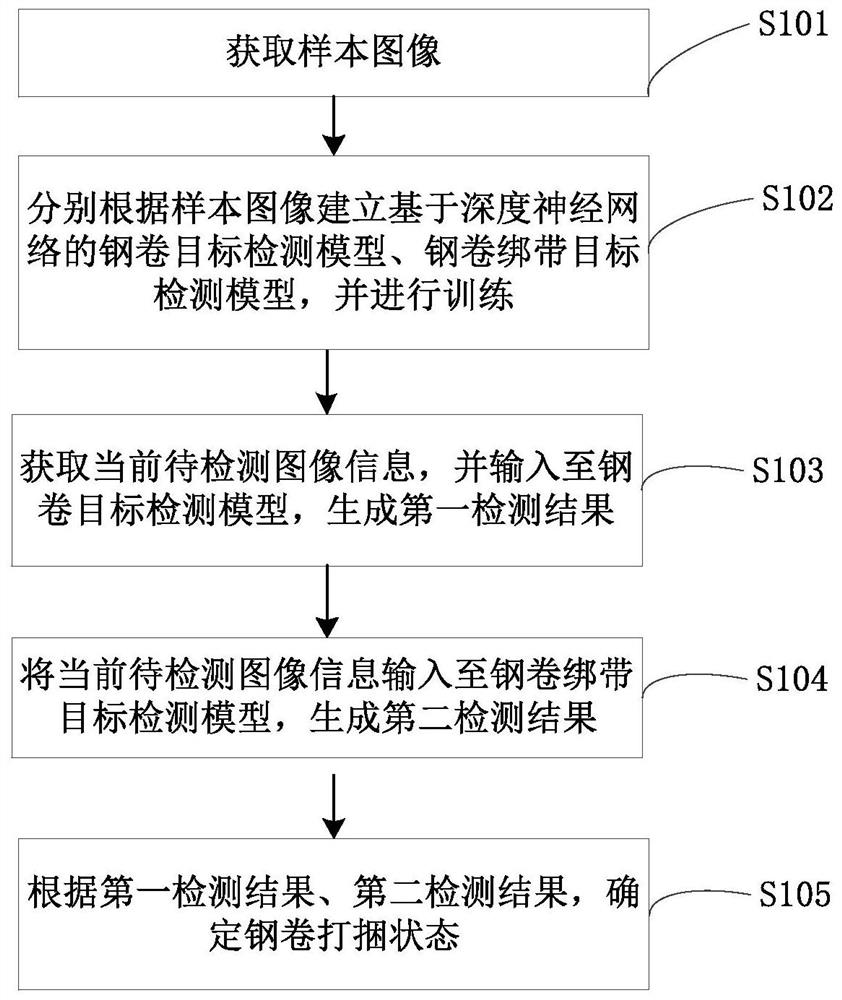

[0052] see figure 1 , the steel coil bundling state detection method that the embodiment of the present invention provides, comprises:

[0053] S101: Acquire a sample image.

[0054] Wherein, the sample image may be collected by a camera or an image collection device, or may be retrieved from images or videos stored in other databases, which is not limited here.

[0055] Optionally, the sample image includes at least one of the steel coil and the steel coil strap, that is, the sample image includes multiple sub-images, and the sub-image may include only the steel coil, or both the steel coil and the steel coil strap.

[0056] Optionally, the sample image includes an image of normally binding the strap on the steel coil.

[0057] Optionally, the steel coils include but are not limited to hot-rolled wire rod steel coils and the like.

[0058] S102: Establish a steel coil target detection model and a steel coil strap target detection model based on the deep neural network acco...

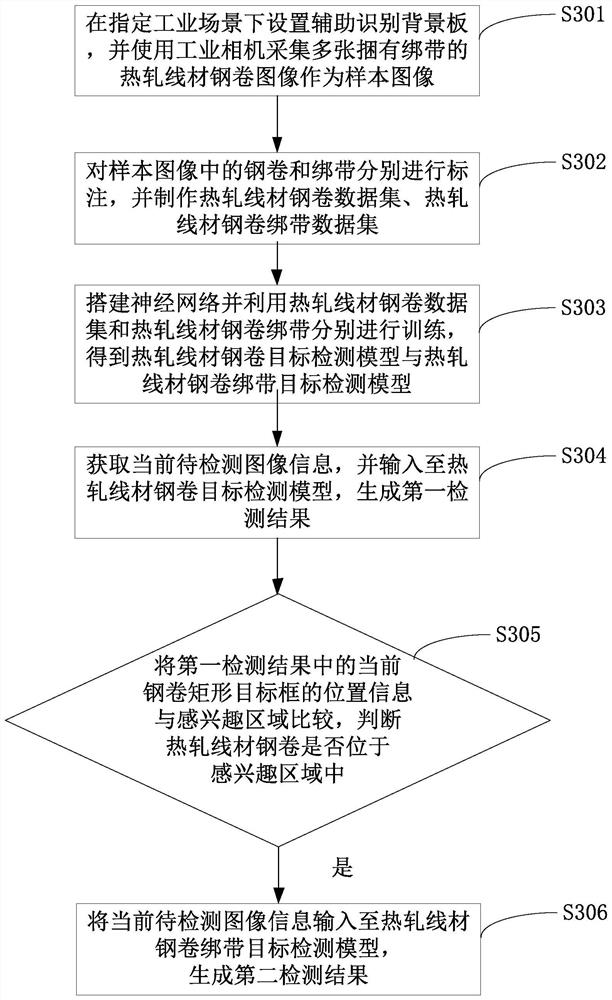

Embodiment 2

[0162] see Figure 5 , a steel coil bundling state detection system 500, comprising:

[0163] An image acquisition module 501, configured to acquire a sample image, the sample image including at least one of a steel coil and a steel coil strap;

[0164] Model building training module 502, used to set up a steel coil target detection model based on a deep neural network and a steel coil strap target detection model respectively according to the sample image, and perform training;

[0165] The first generation module 503 is used to obtain the current image information to be detected, and input it into the steel coil target detection model to generate the first detection result;

[0166] The second generation module 504 is used to input the current image information to be detected into the steel coil strap target detection model to generate a second detection result;

[0167] The determining module 505 is configured to determine the bundling state of the steel coil according to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com